Modified PA11 material, pipe and preparation method thereof

A modification and pipe technology, applied in the field of pipes, pipe preparation, and modified PA11 materials, can solve the problems of general 65# coolant resistance, poor high and low temperature blasting resistance, and poor blasting resistance of pipes, and achieve excellent Chemical resistance, excellent coolant corrosion resistance, low temperature and high temperature resistance to the effect of increased burst pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

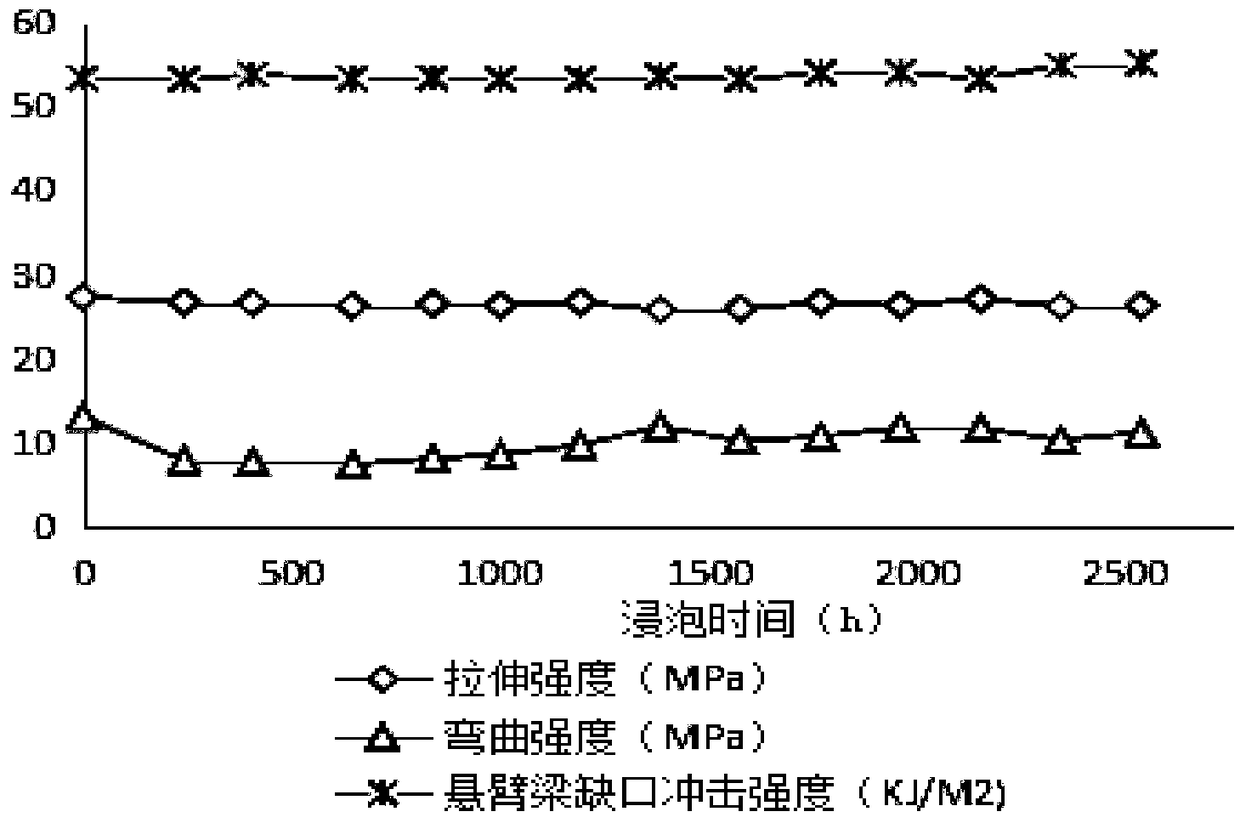

Embodiment 1

[0029] The pipe in this embodiment is made of modified PA11 material, and the modified PA11 material is composed of the following components by weight:

[0030]

[0031] The specific preparation steps of the pipe in the present embodiment are as follows:

[0032] Step 1: Mix PA11 resin, nano-montmorillonite, antioxidant 1098 and N, N-hexylene bishard amide evenly according to the proportion, then add it into a twin-screw extruder, extrude after melting, and cool. Air-dried and pelletized to obtain PA11 modified material; among them, the working temperature of each zone of the twin-screw extruder is 200 °C in the first area, 220 °C in the second area, 230 °C in the third area to the fifth area, and 220 °C in the sixth area to the ninth area. 230°C, the screw speed is 380rpm.

[0033] Step 2: Put the PA11 modified material into the pipe extruder, adjust the extrusion temperature, feed the material, form the die, cool through water, mechanically pull, and cut to obtain pipes ...

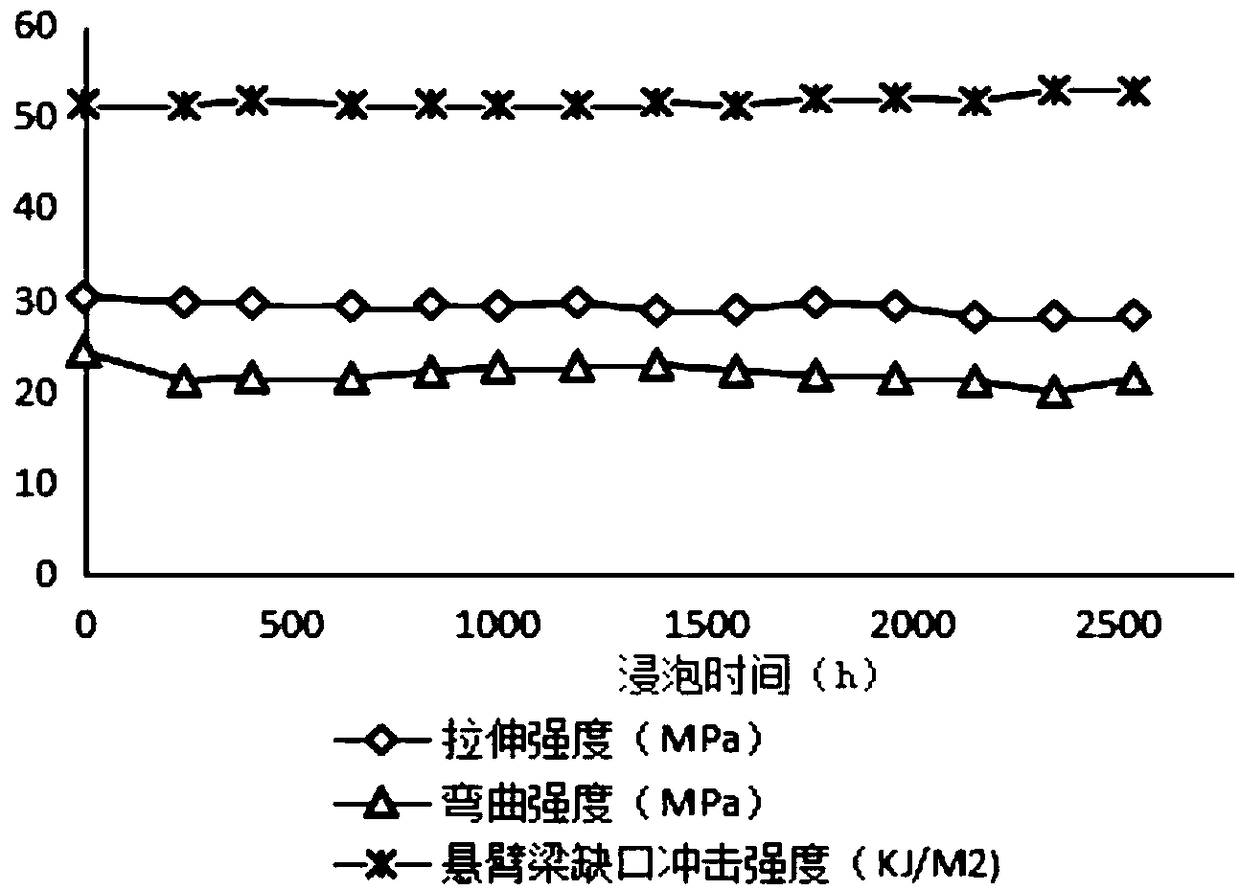

Embodiment 2

[0035] The pipe in this embodiment is made of modified PA11 material, and the modified PA11 material is composed of the following components by weight:

[0036]

[0037]

[0038] The specific preparation steps of the pipe in the present embodiment are as follows:

[0039] Step 1: Mix PA11 resin, nano-calcium carbonate, antioxidant 1010, antioxidant 168, pentaerythritol stearate and glyceryl monostearate evenly according to the proportioning ratio, and then add them to a twin-screw extruder, melt Extruded, cooled, air-dried, and pelletized to obtain PA11 modified material; the working temperature of each zone of the twin-screw extruder is 210°C in the first zone, 225°C in the second zone, 240°C from the third zone to the fifth zone, and 240°C from the sixth zone to the ninth zone 225°C, head temperature 240°C, screw speed 400rpm.

[0040] Step 2: Put the PA11 modified material into the pipe extruder, adjust the extrusion temperature, feed the material, form the die, cool...

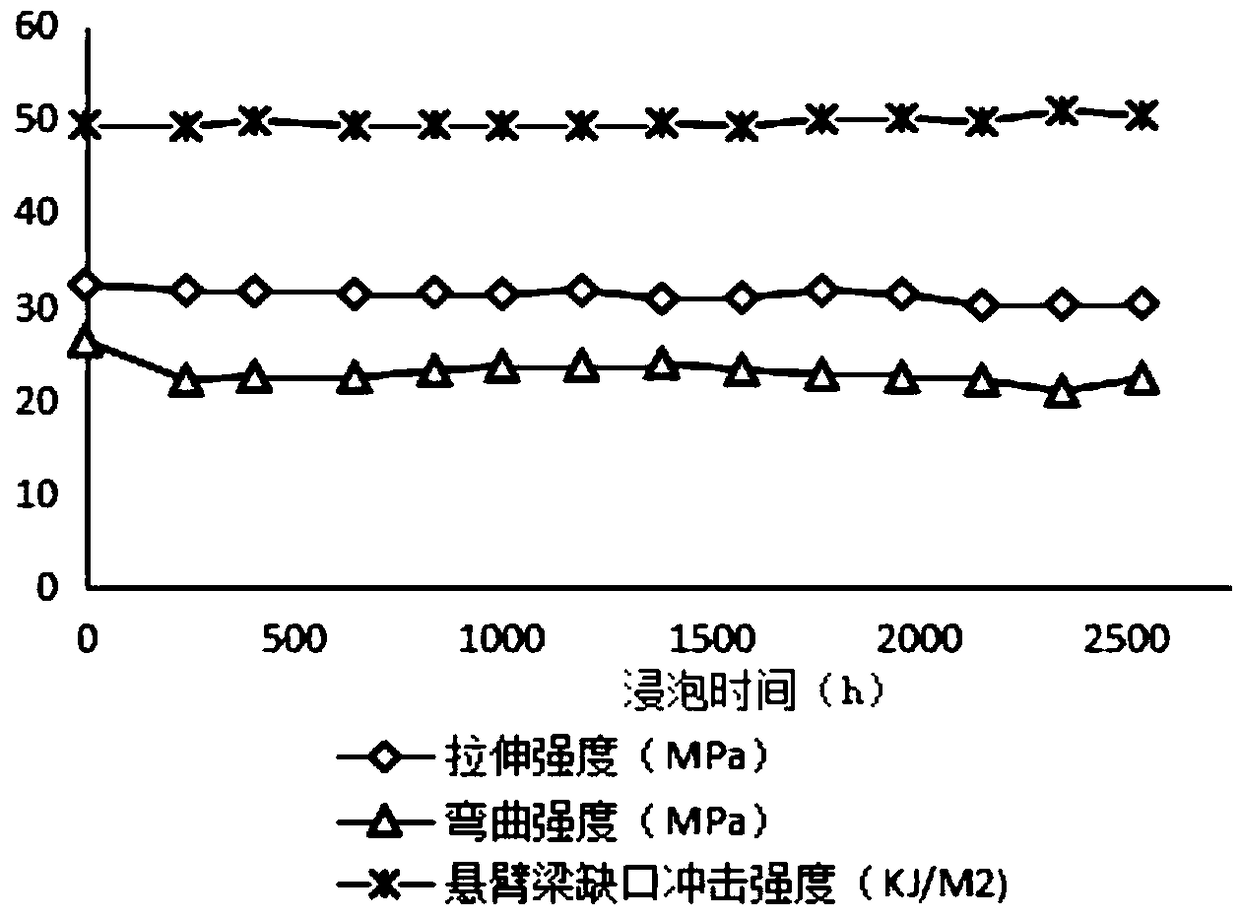

Embodiment 3

[0042] The pipe in this embodiment is made of modified PA11 material, and the modified PA11 material is composed of the following components by weight:

[0043]

[0044] The specific preparation steps of the pipe in the present embodiment are as follows:

[0045] Step 1: Mix PA11 resin, nano-calcium carbonate, antioxidant 1010, antioxidant 168, and N-N-hexylene bishard amide evenly according to the proportion, then add them to a twin-screw extruder, melt and extrude, and Cool, air-dry, and pelletize to obtain PA11 modified materials; the working temperature of each zone of the twin-screw extruder is 220 °C in the first area, 230 °C in the second area, 250 °C in the third area to the fifth area, and 230 °C in the sixth area to the ninth area. The head temperature was 250°C and the screw speed was 420 rpm.

[0046] Step 2: Put the PA11 modified material into the pipe extruder, adjust the extrusion temperature, feed the material, form the die, cool through water, mechanically...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com