Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about How to "Reduced manufacturing method" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

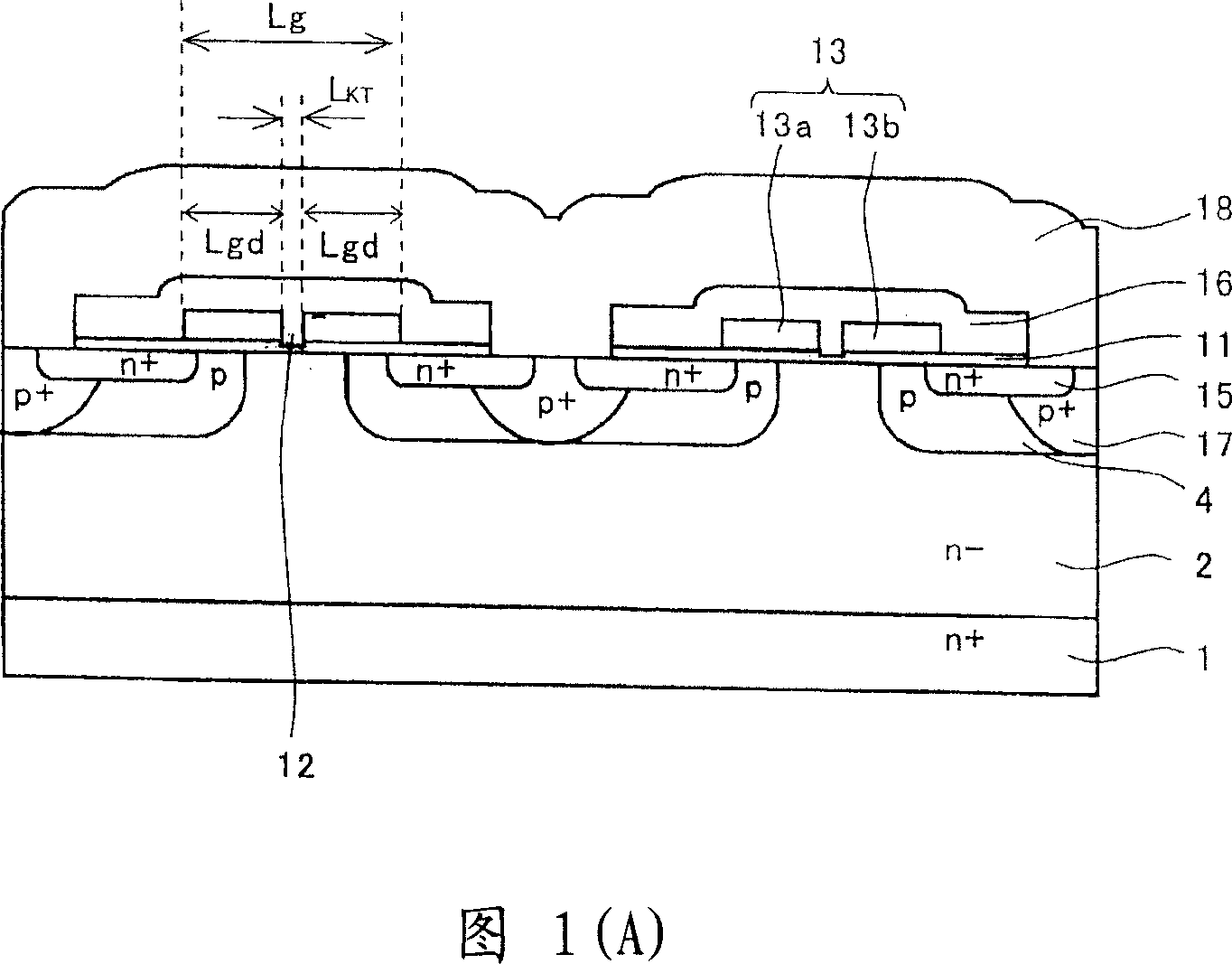

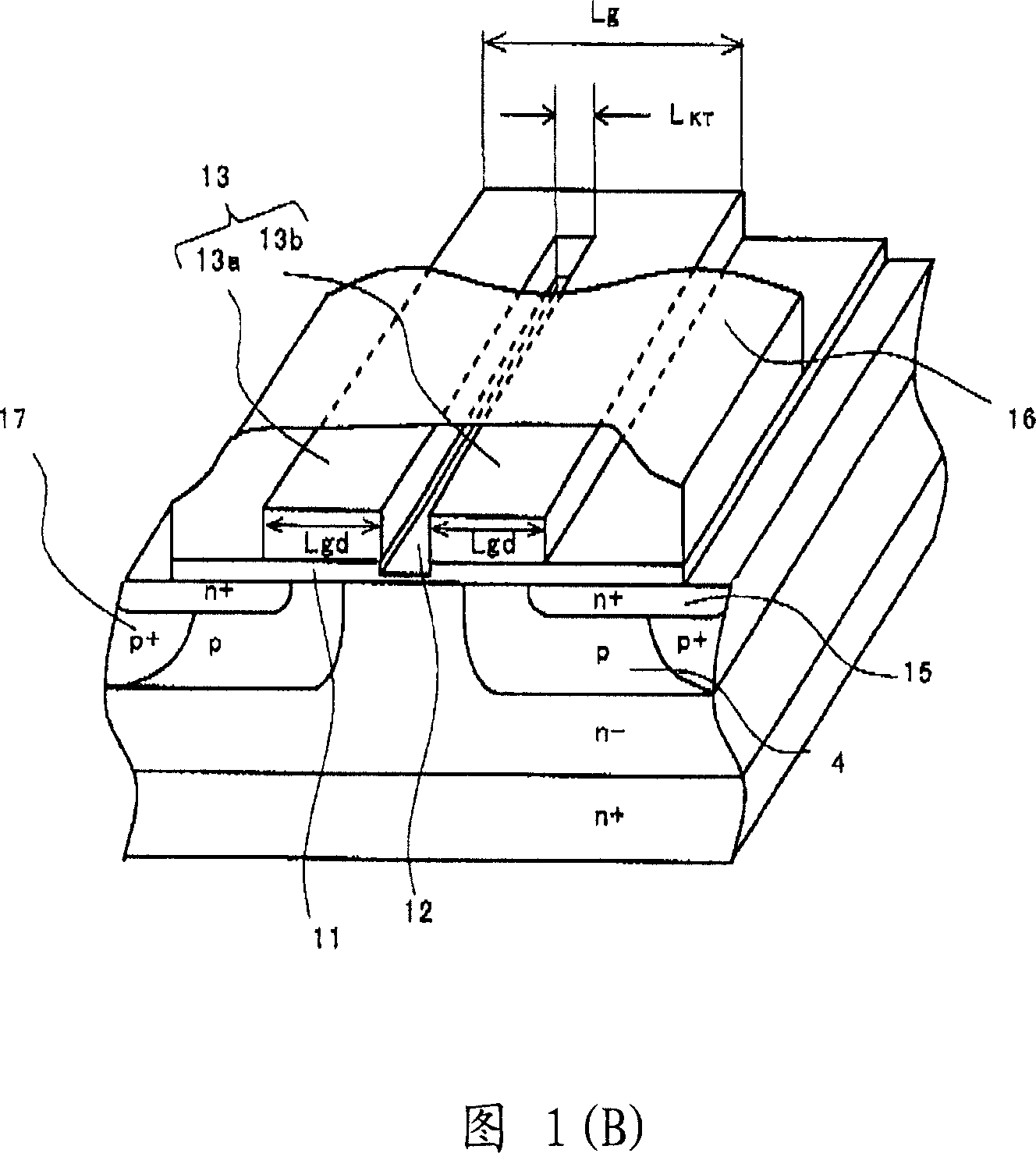

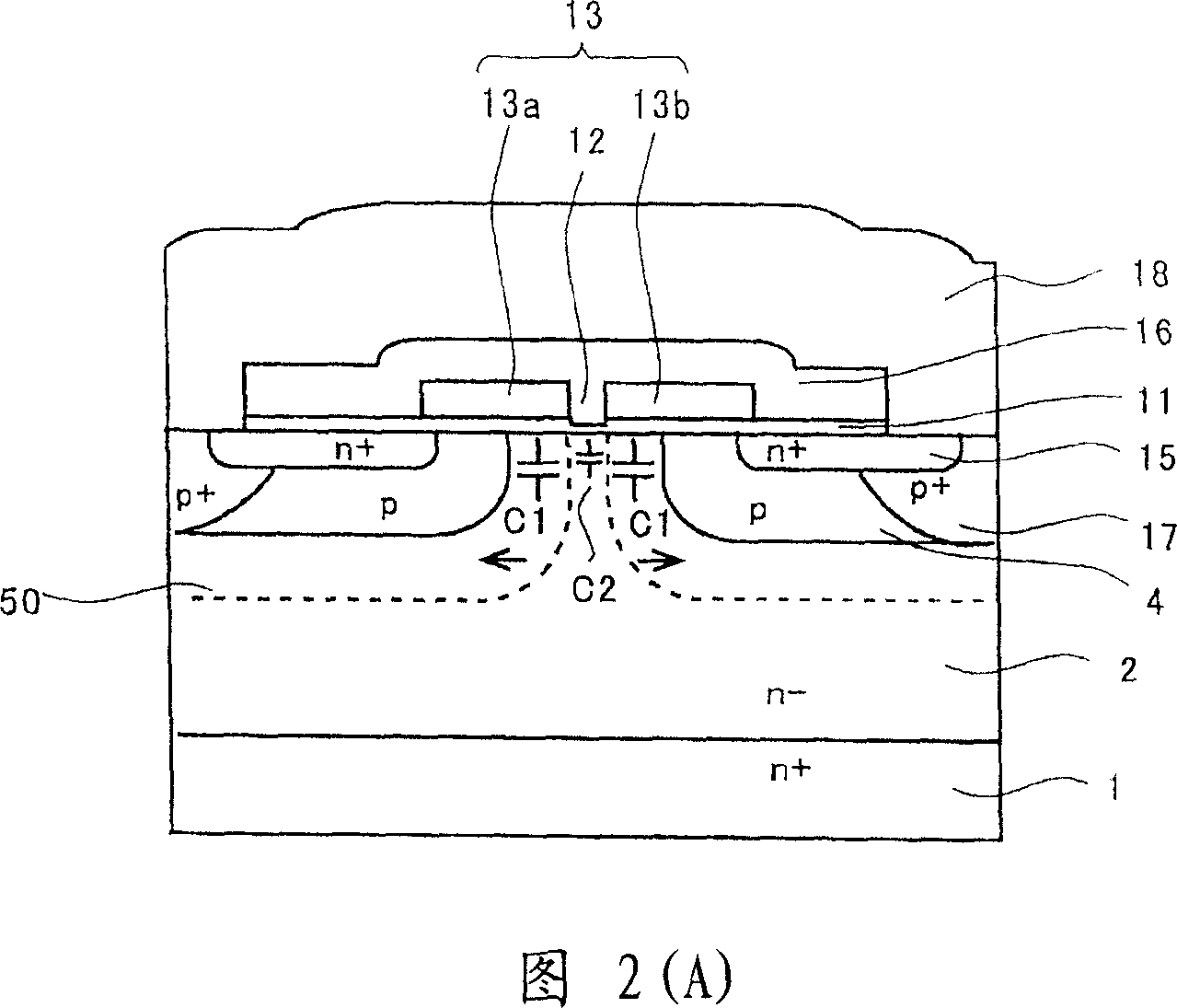

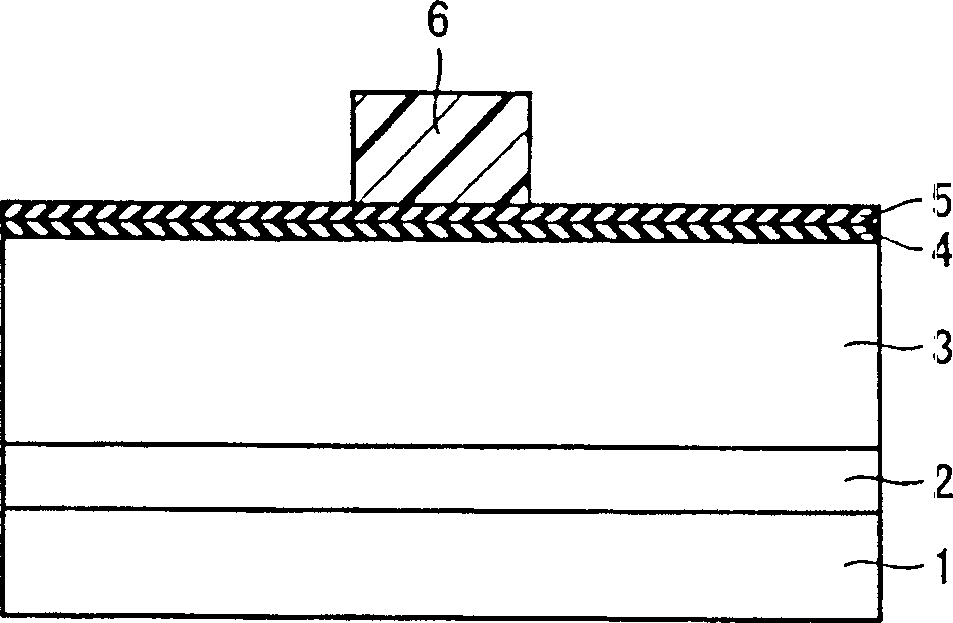

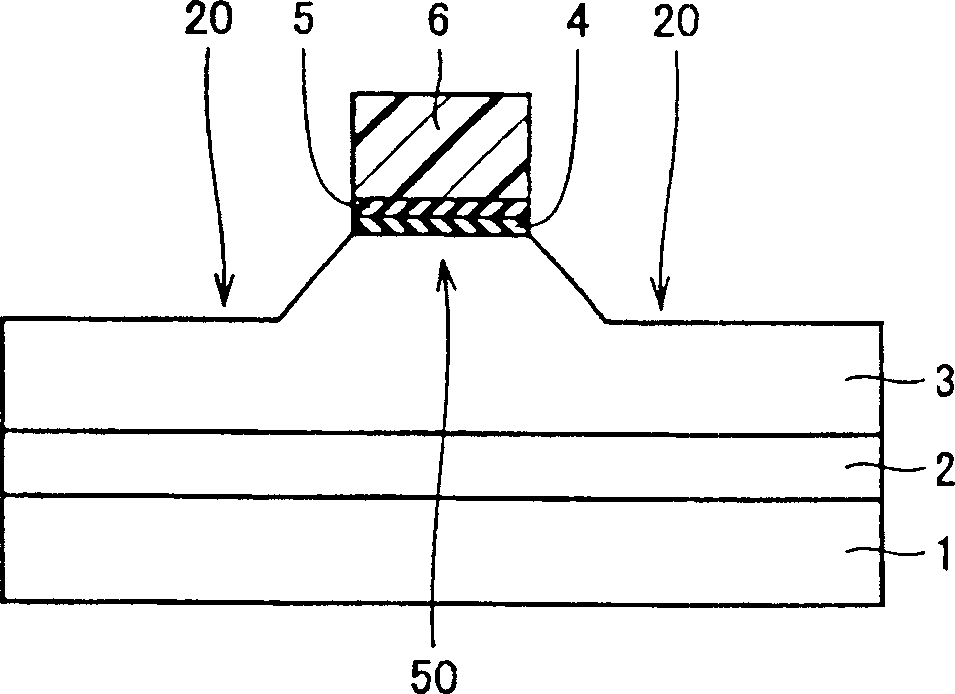

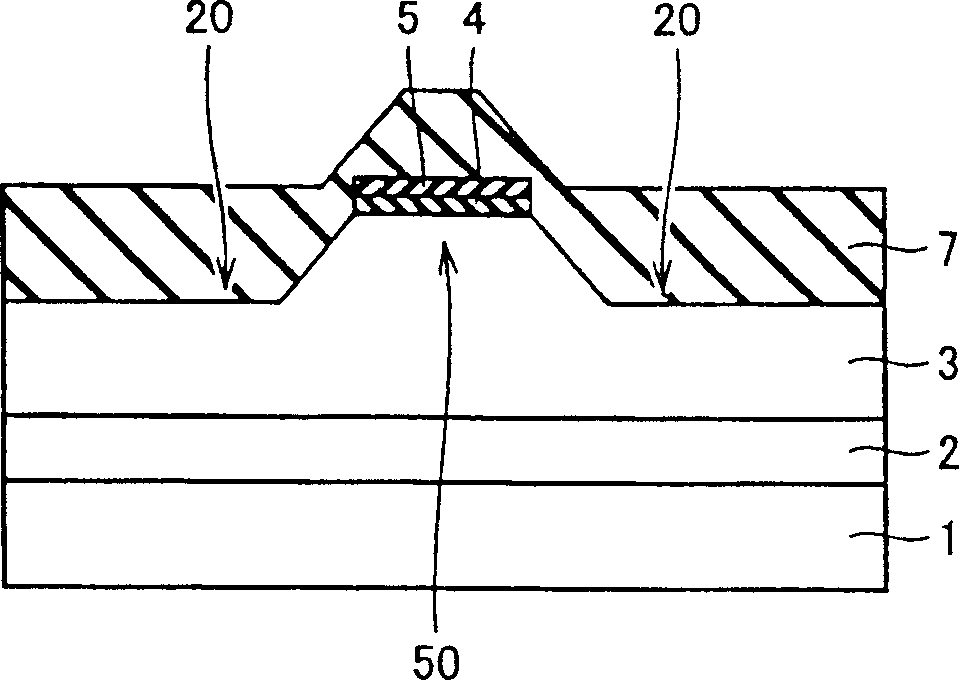

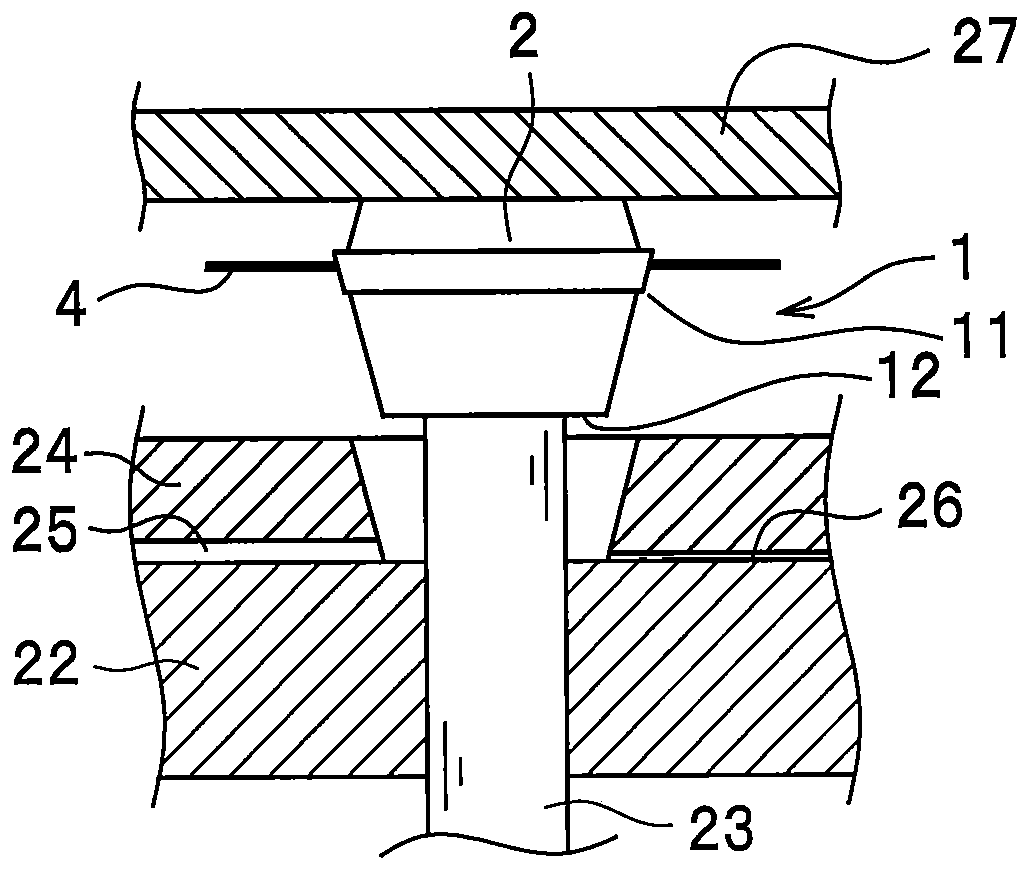

Insulated gate field effect transistor and manufacturing method thereof

InactiveCN1941413ALower resistanceLower on-resistanceSemiconductor/solid-state device manufacturingSemiconductor devicesElectrical resistance and conductanceCapacitance

A separation hole is provided in the center of the gate electrode. Accordingly, it is possible to suppress a drastic increase in feedback capacitance Crss in the case where drain-source voltage VDS is decreased and the width of the depletion layer is narrowed. Thus, high-frequency switching characteristics are improved. Moreover, n type impurities are implanted from the separation hole to form an n type impurity region between channel regions. Since a resistance in a portion below the gate electrode can be reduced, an on-resistance can be reduced. The n type impurity region can be formed in a self-aligning manner.

Owner:SANYO ELECTRIC CO LTD

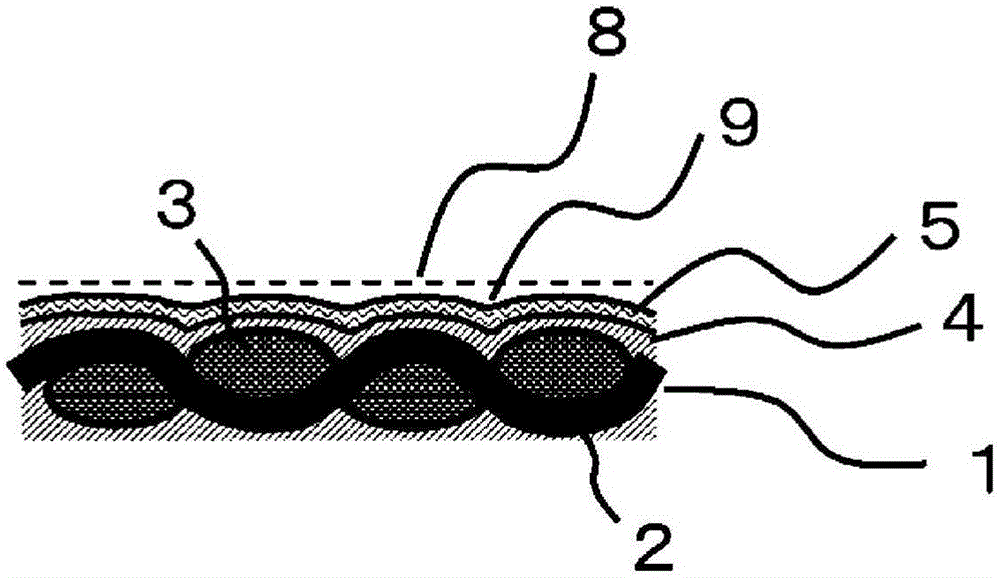

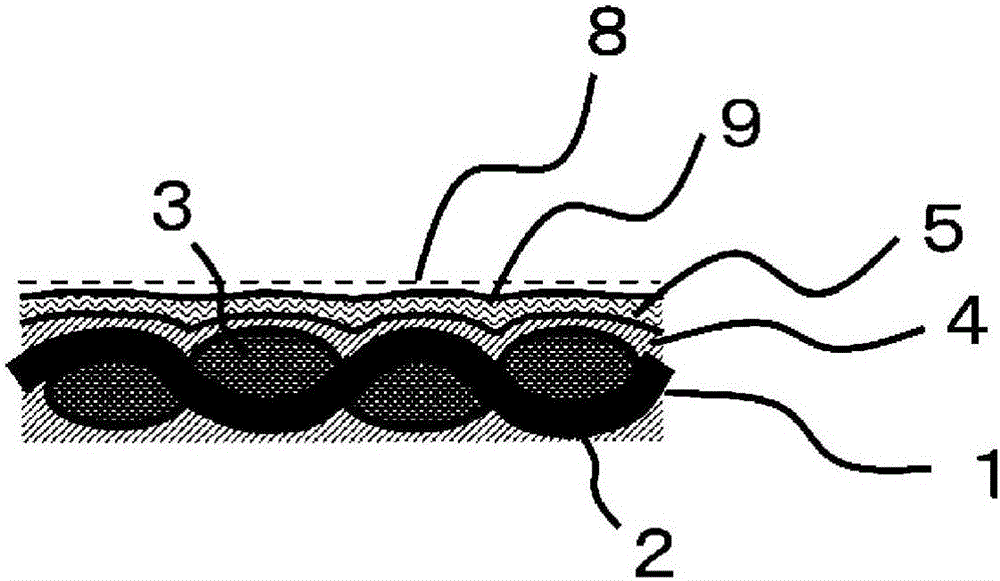

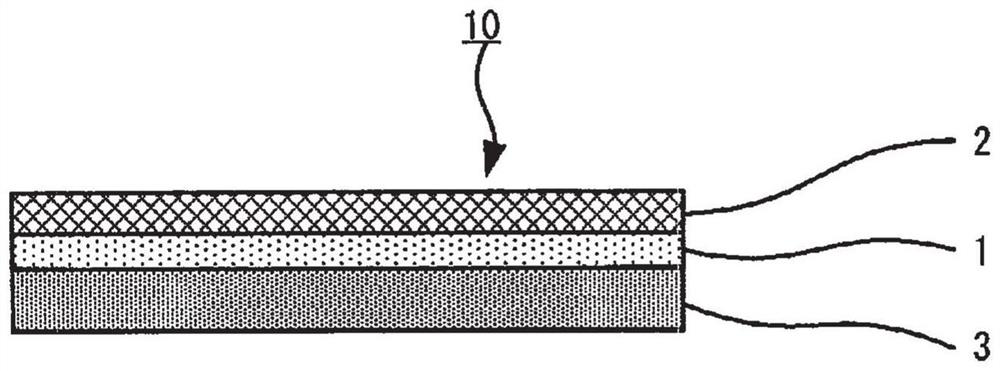

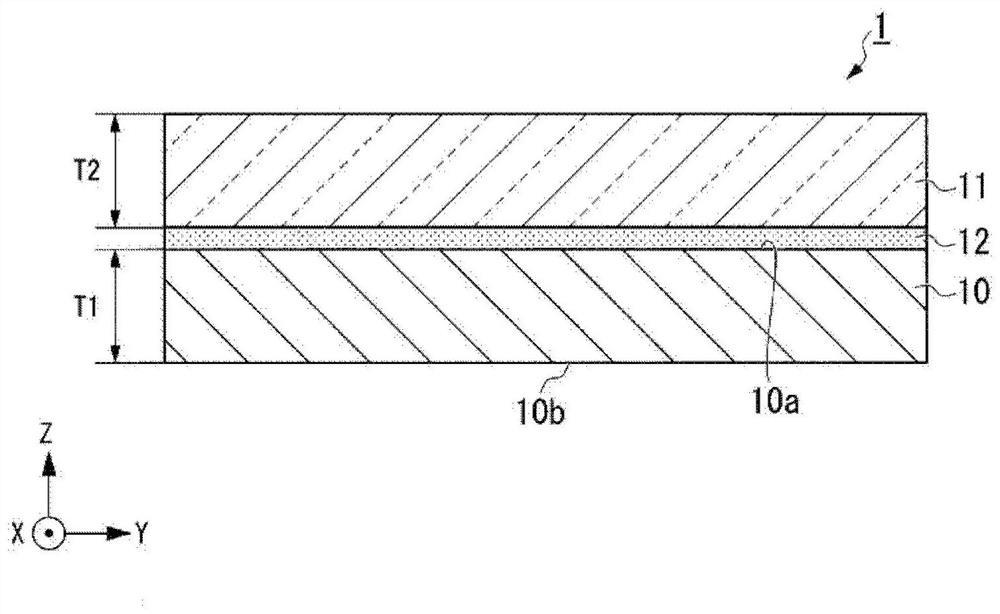

Coated fiber-reinforced resin molding and process for producing same

InactiveCN105829046AReduce surface bumpsReduced manufacturing methodCoatingsLiquid stateSurface roughness

Provided are: a process for producing a fiber-reinforced resin, said process being capable of remarkably reducing, in molding a fiber-reinforced resin, the occurrence of feeding defects or faults on the surface and the surface roughness due to the temperature difference between molding temperature (curing temperature) and ordinary temperature; and a product obtained thereby. A process for producing a coated fiber-reinforced resin molding, comprising: a first molding step for subjecting a matrix resin which has been impregnated into a reinforcing fiber to curing at a temperature (T1) (DEG C), and thus forming a fiber-reinforced resin molding; and a second molding step for disposing the fiber-reinforced resin molding in a mold cavity which is configured by at least two molds and which has nearly the same shape as that of the fiber-reinforced resin molding, adjusting the internal temperature of the mold cavity to a temperature (T2) (DEG C) lower than the temperature (T1) (DEG C), pouring a liquid resin material for forming a coating layer into the mold cavity in such a way that the liquid resin covers at least a part of the fiber-reinforced resin molding, and curing the liquid resin material at the temperature (T2) (DEG C) to form a coated fiber-reinforced resin molding. A product obtained by the process.

Owner:TORAY IND INC

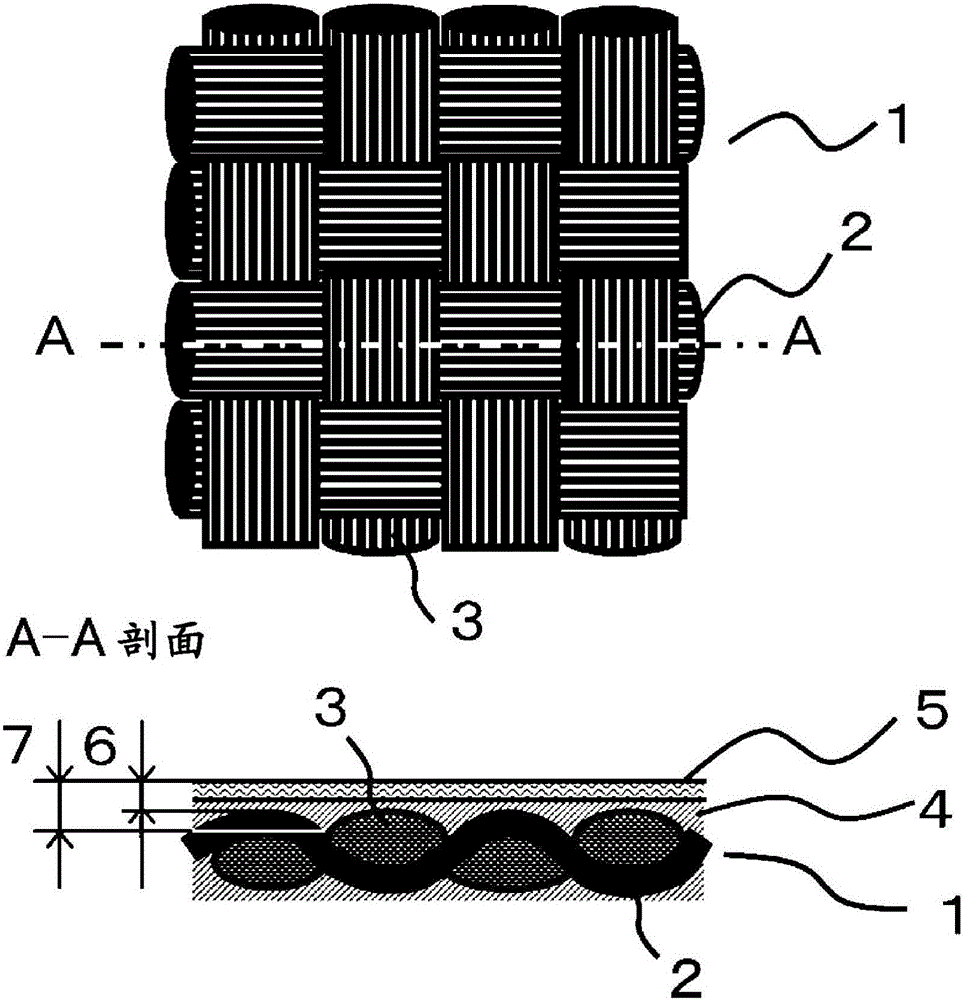

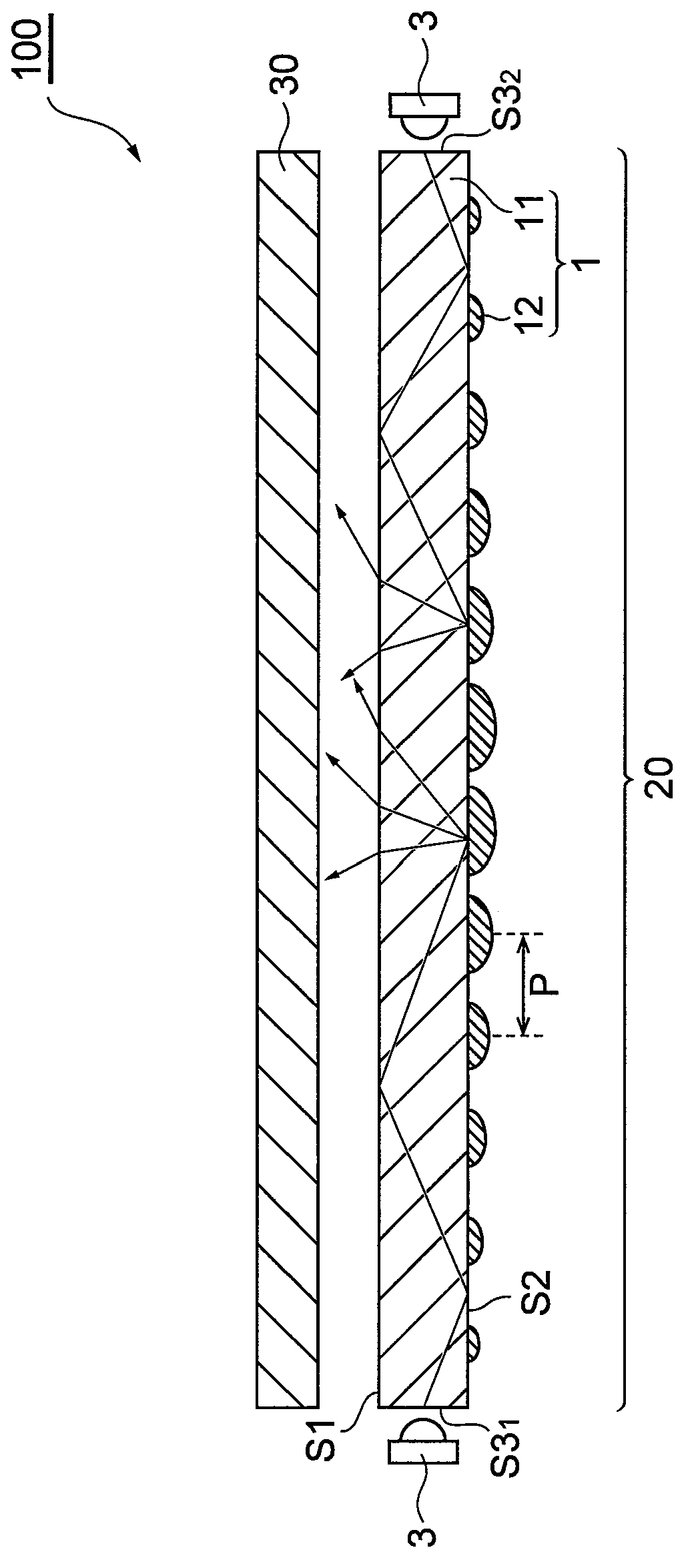

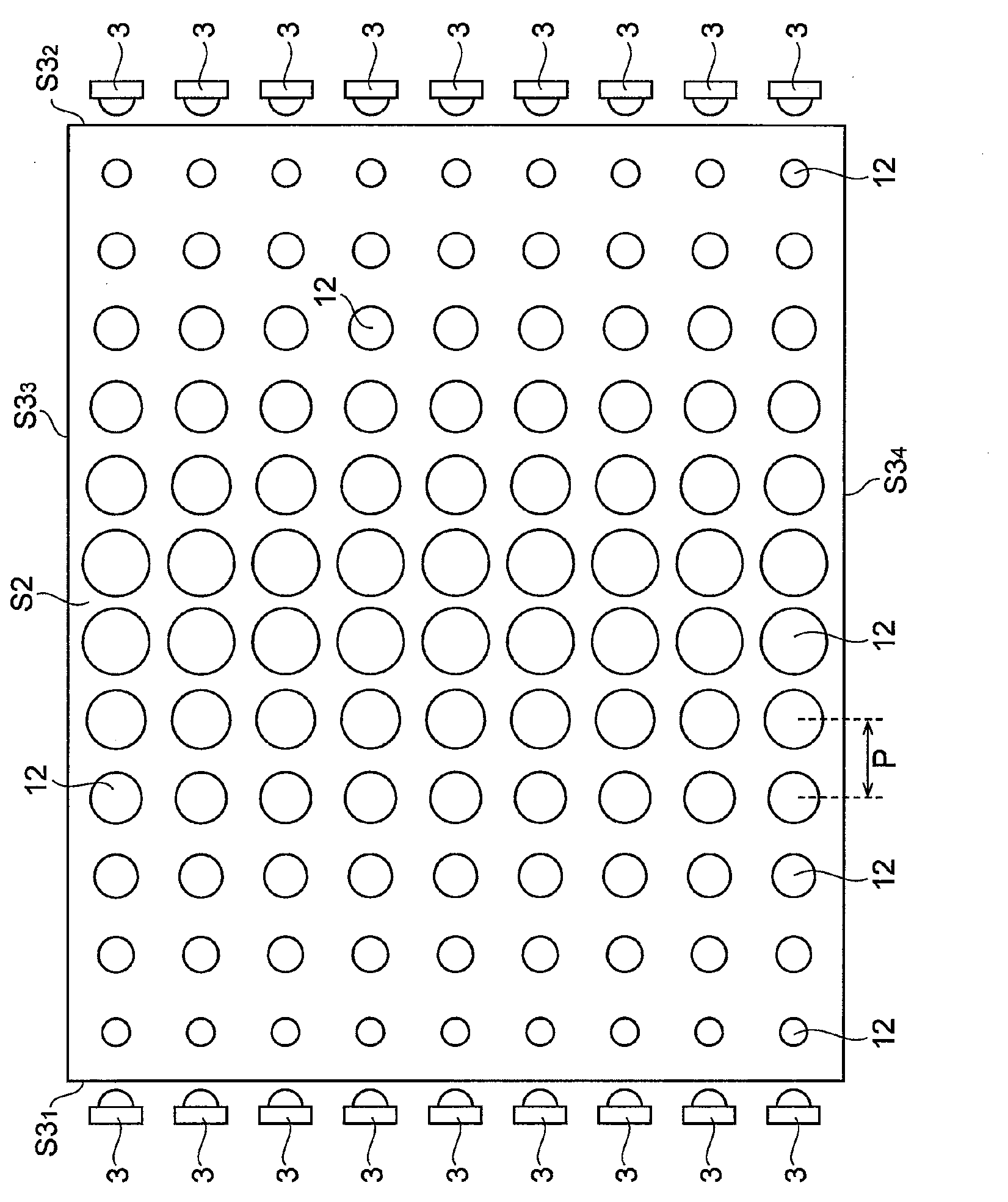

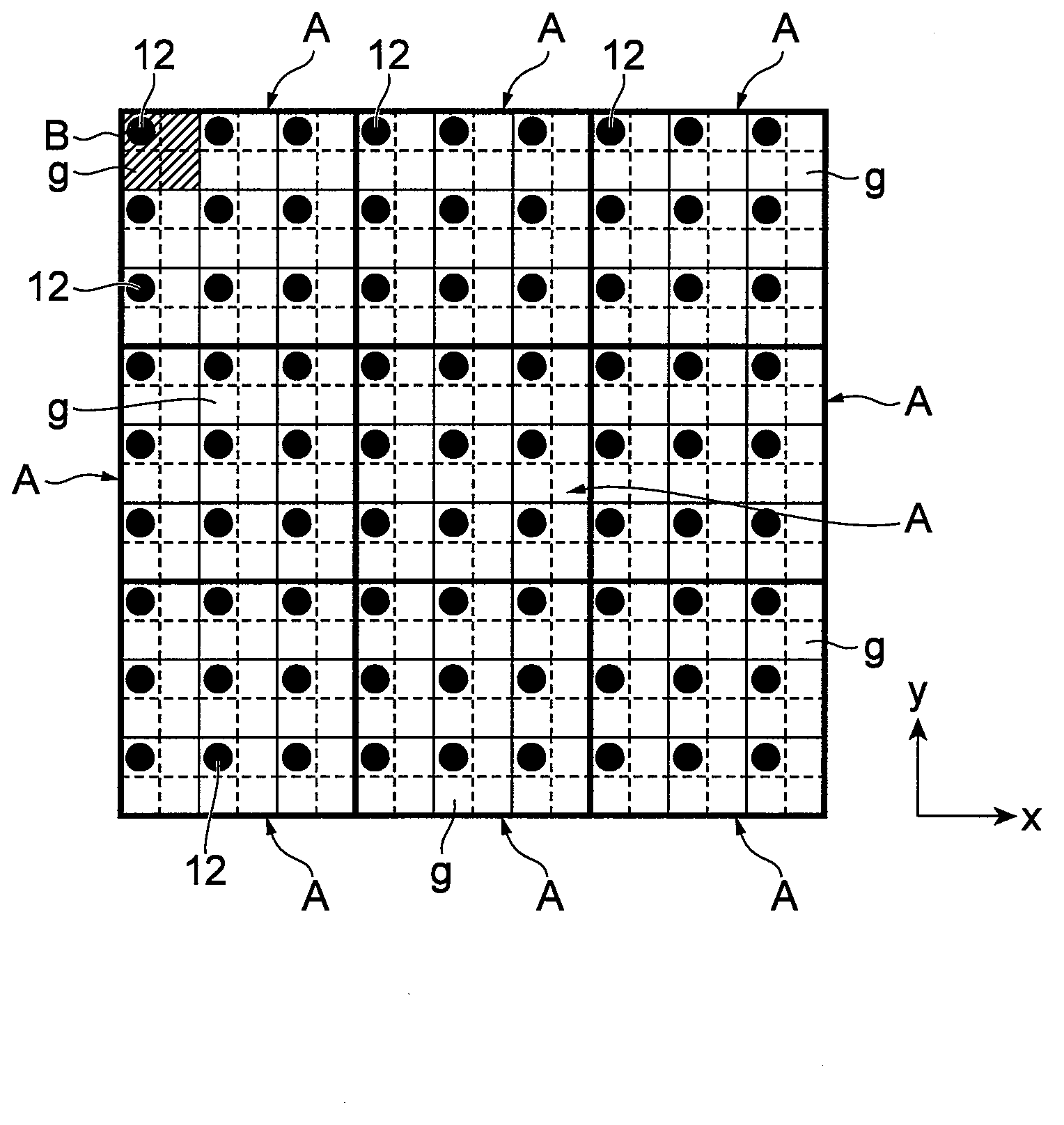

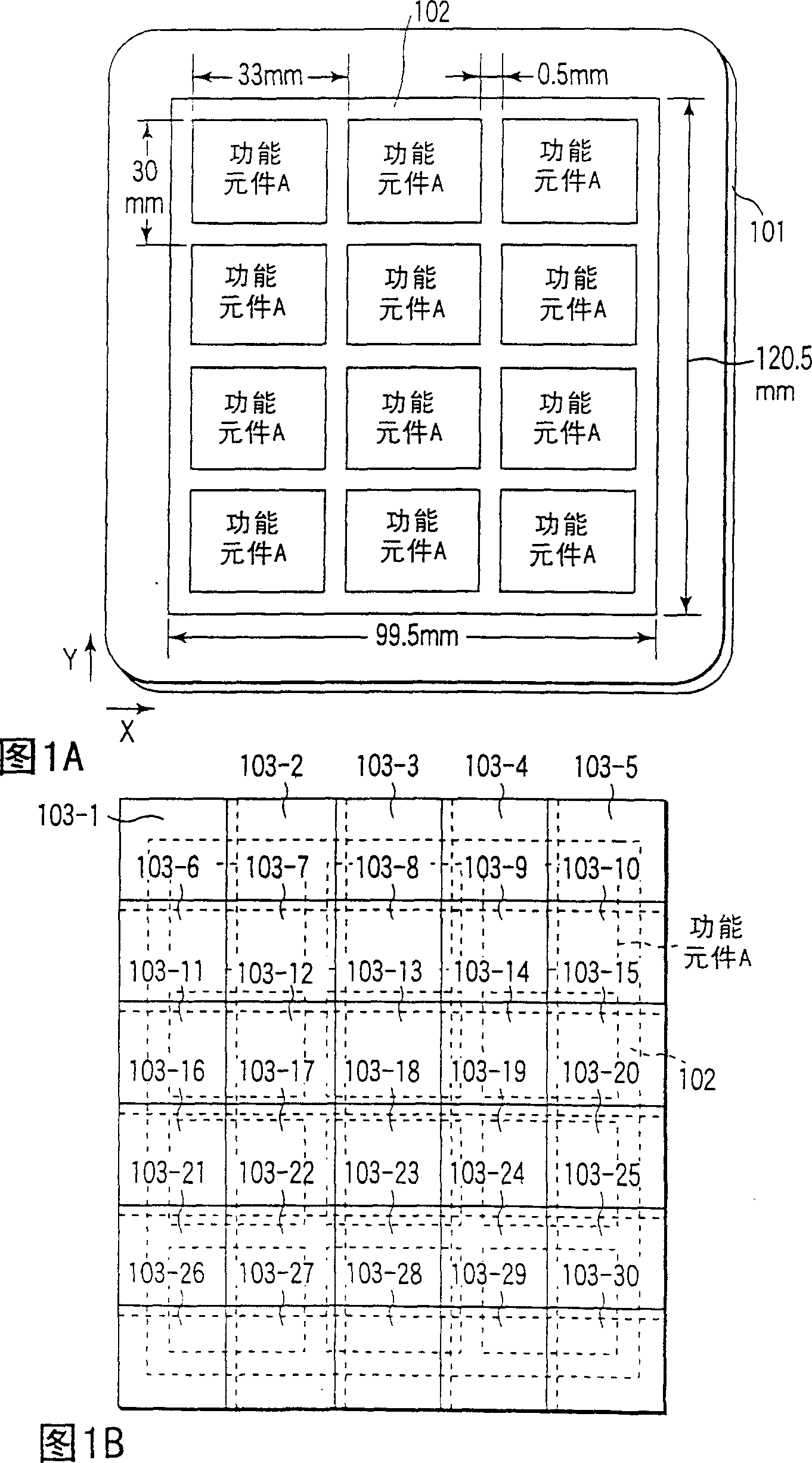

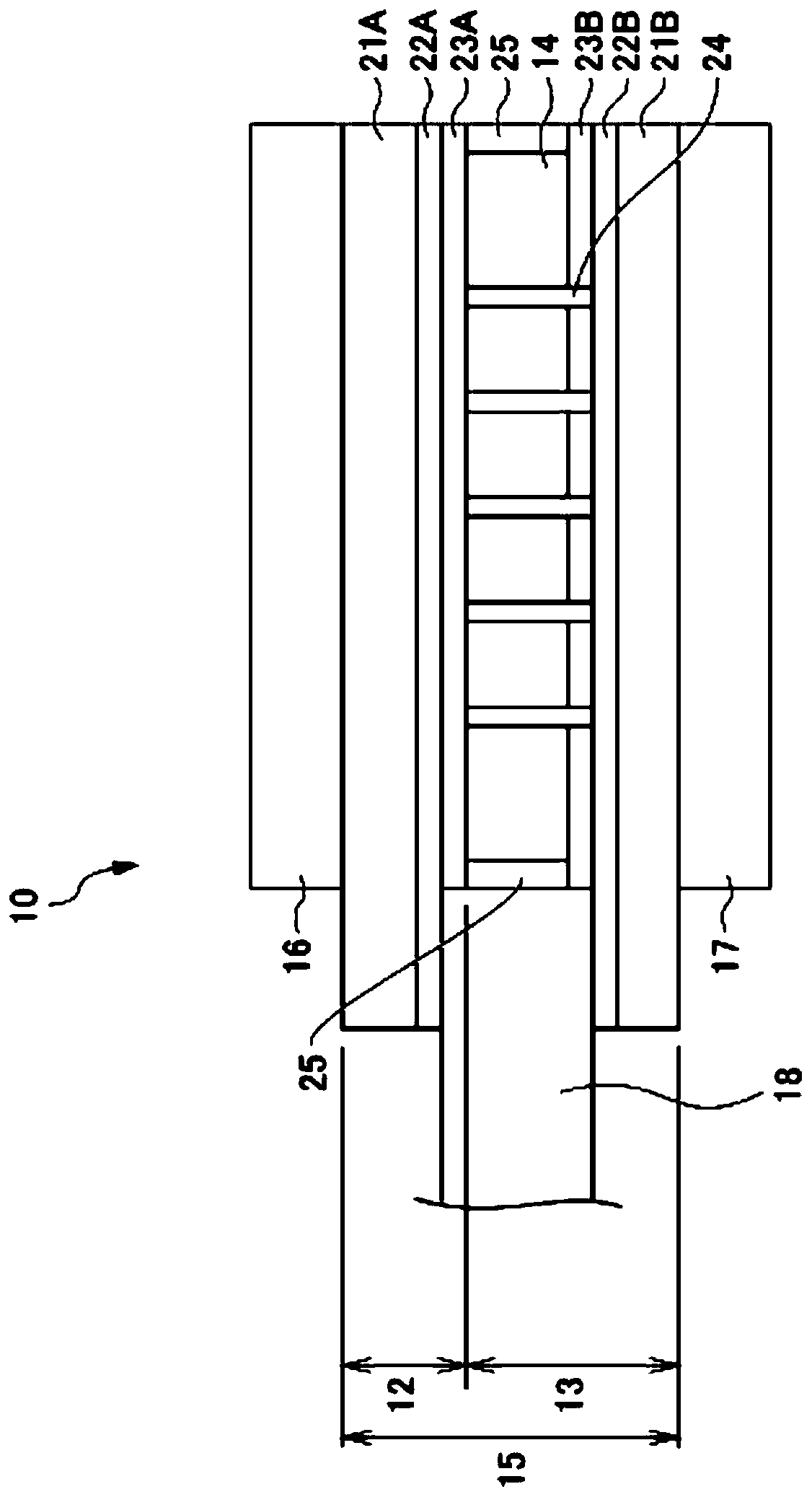

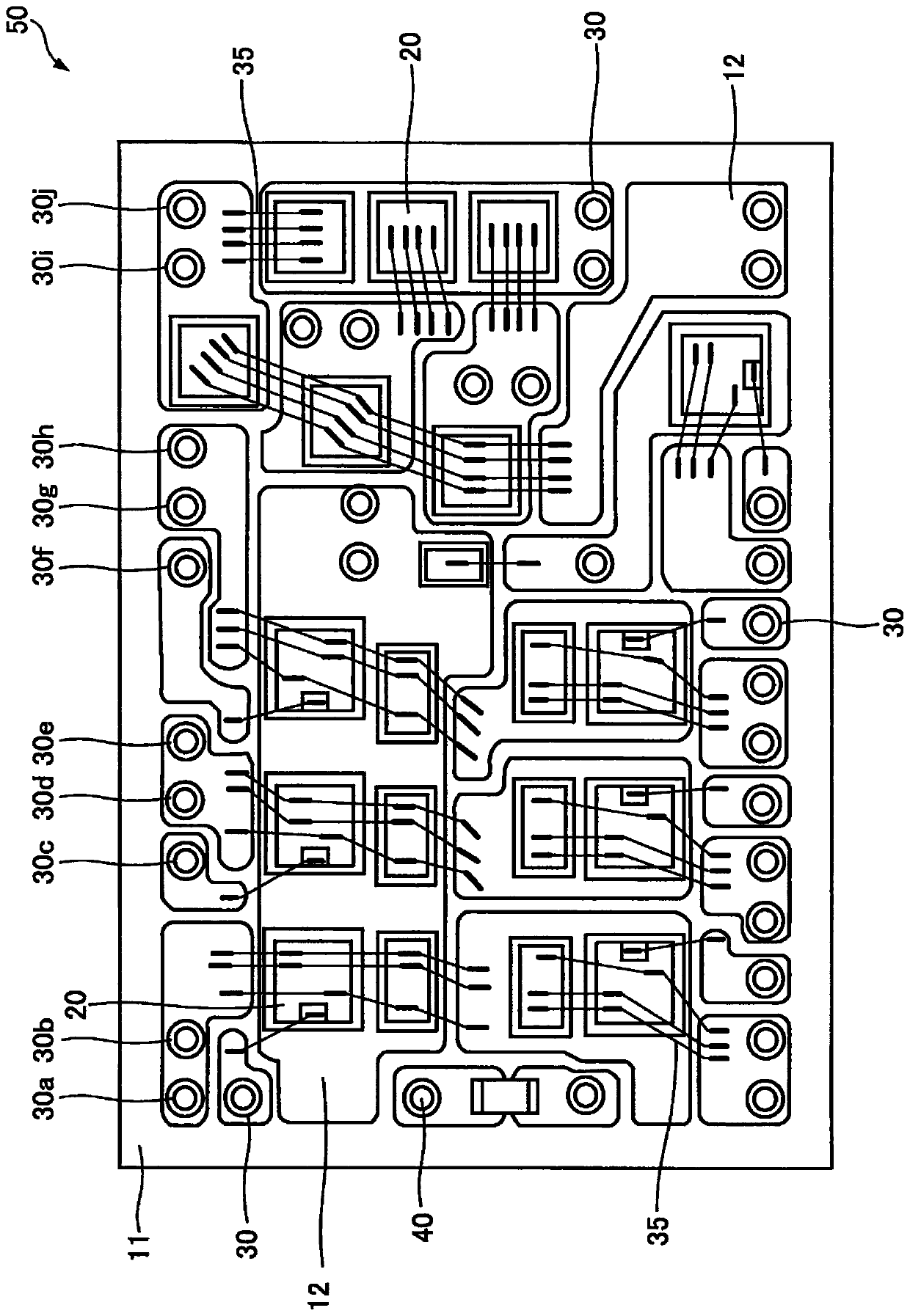

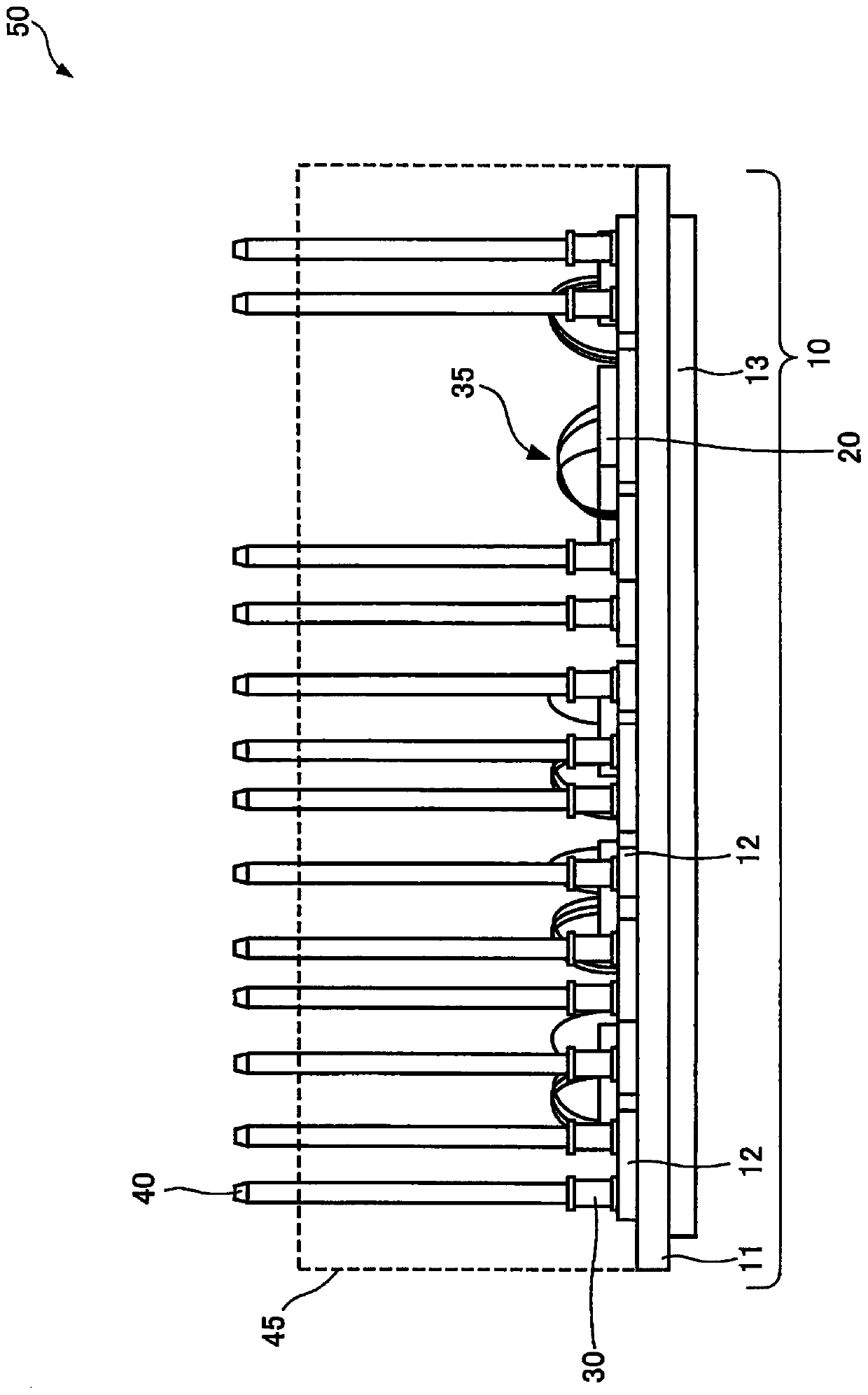

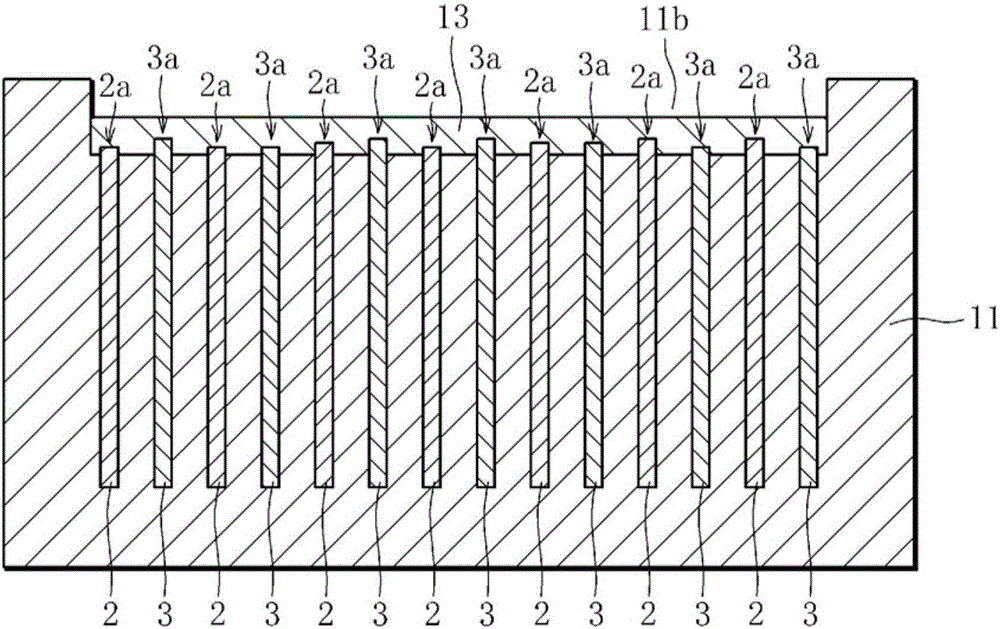

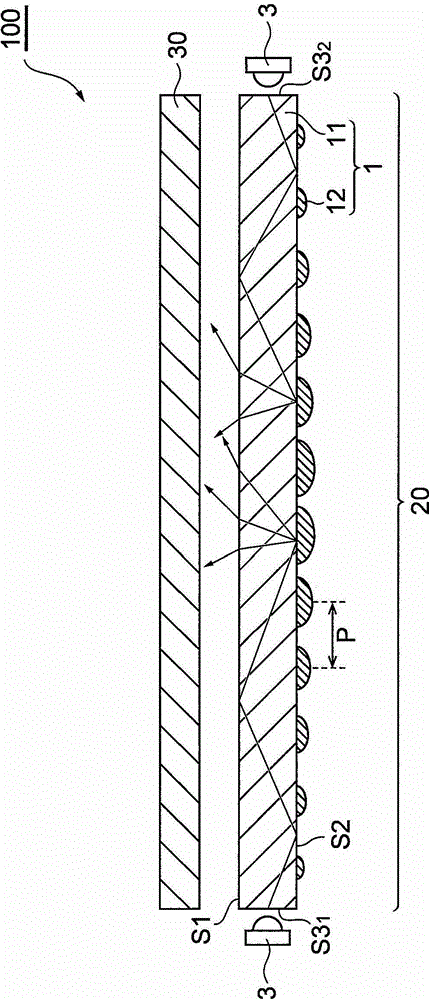

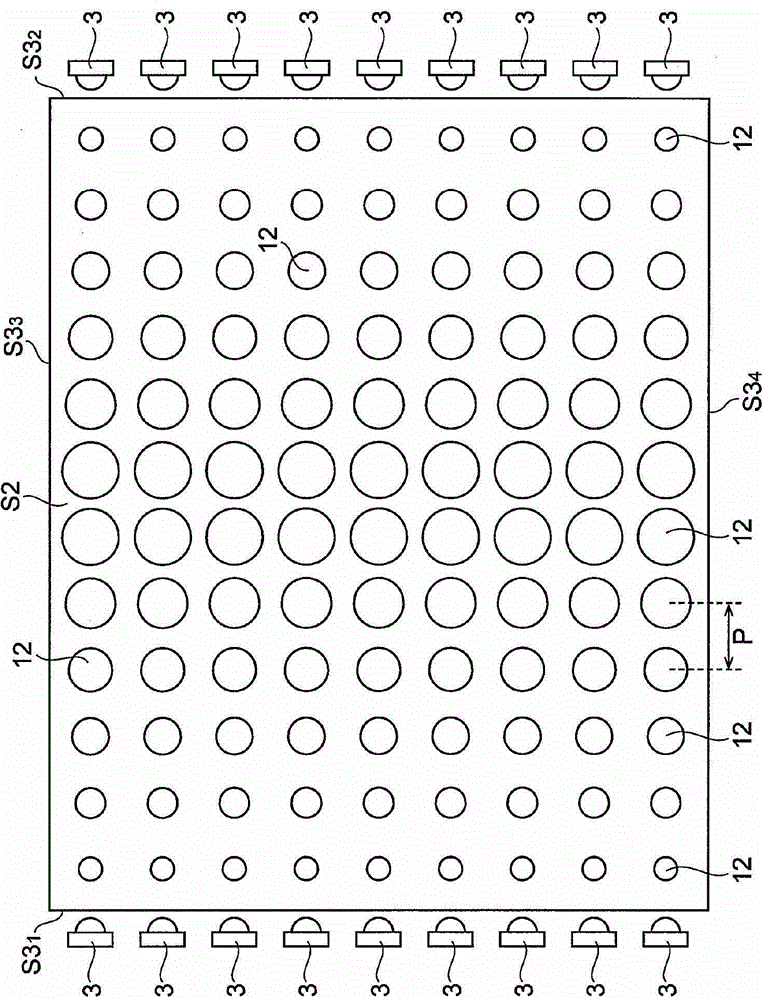

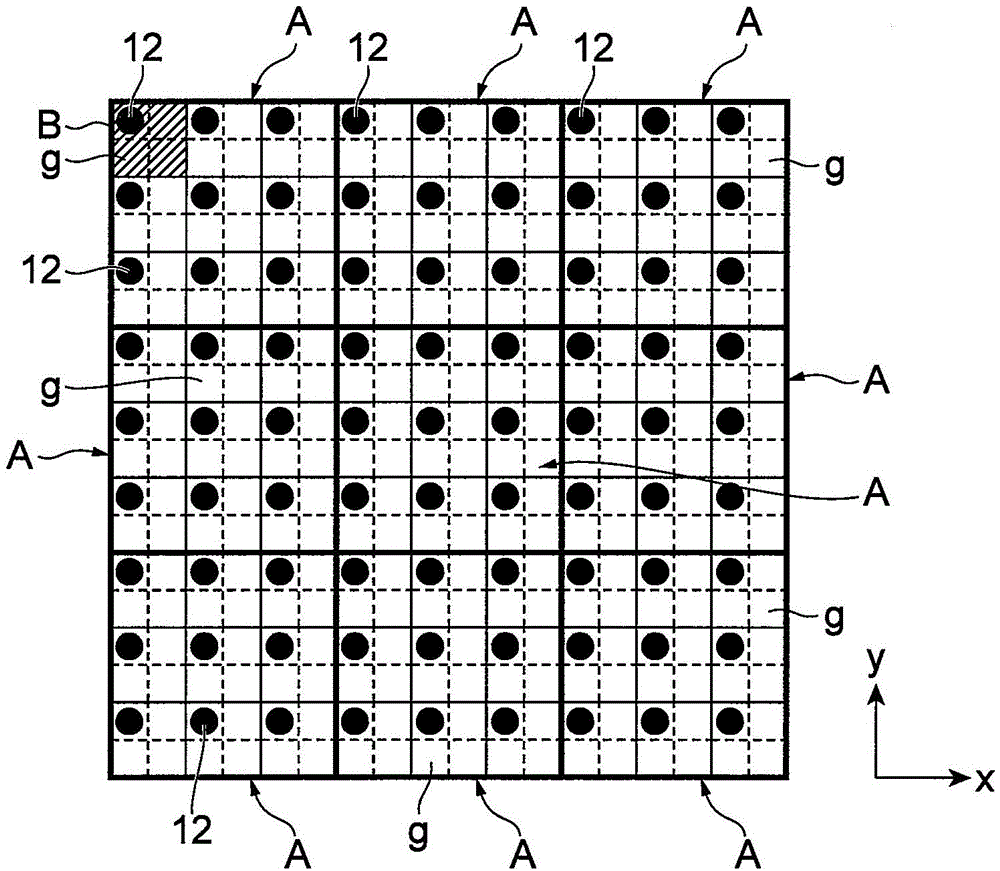

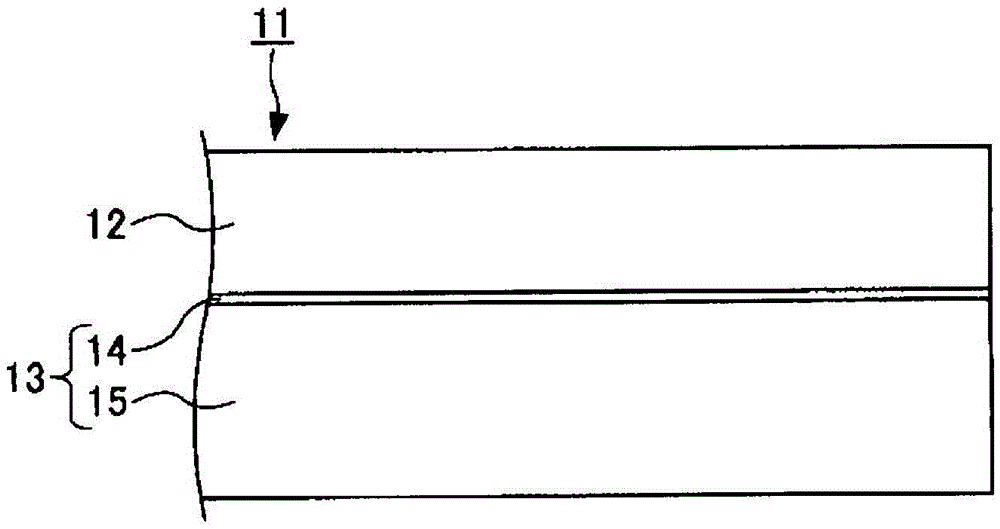

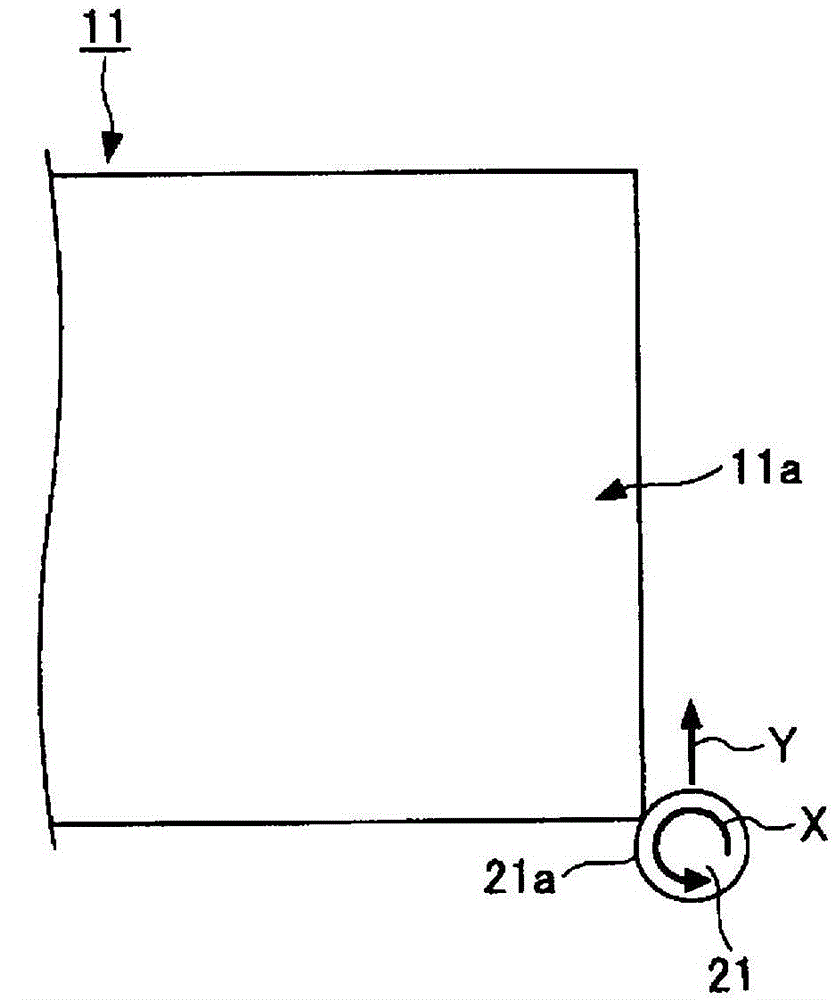

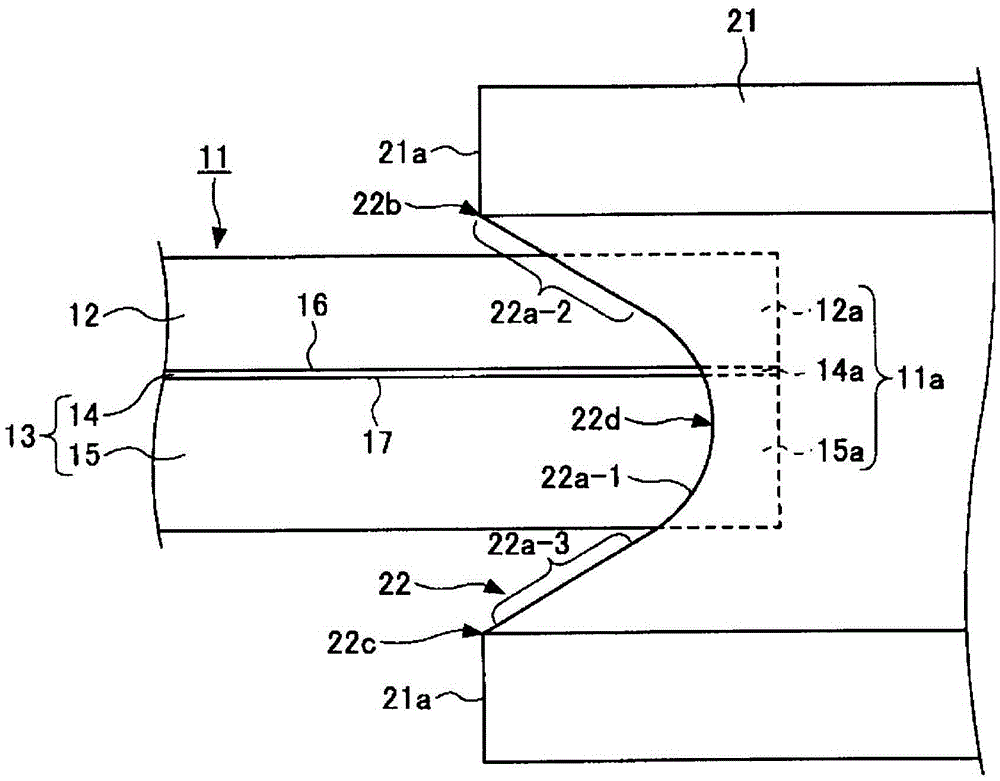

Light guide plate and method of manufacturing light guide plate, surface light source apparatus and transmission type image display apparatus

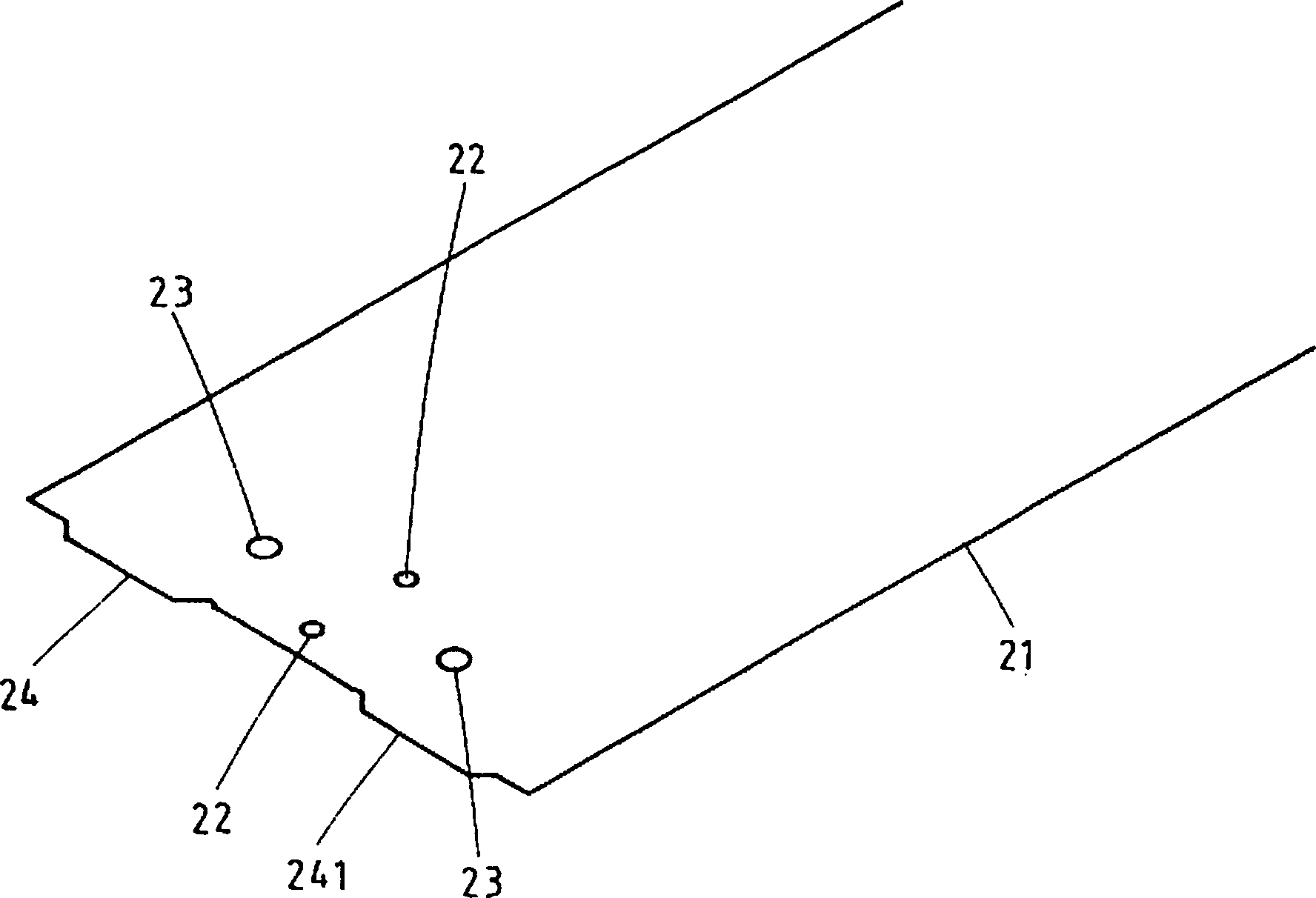

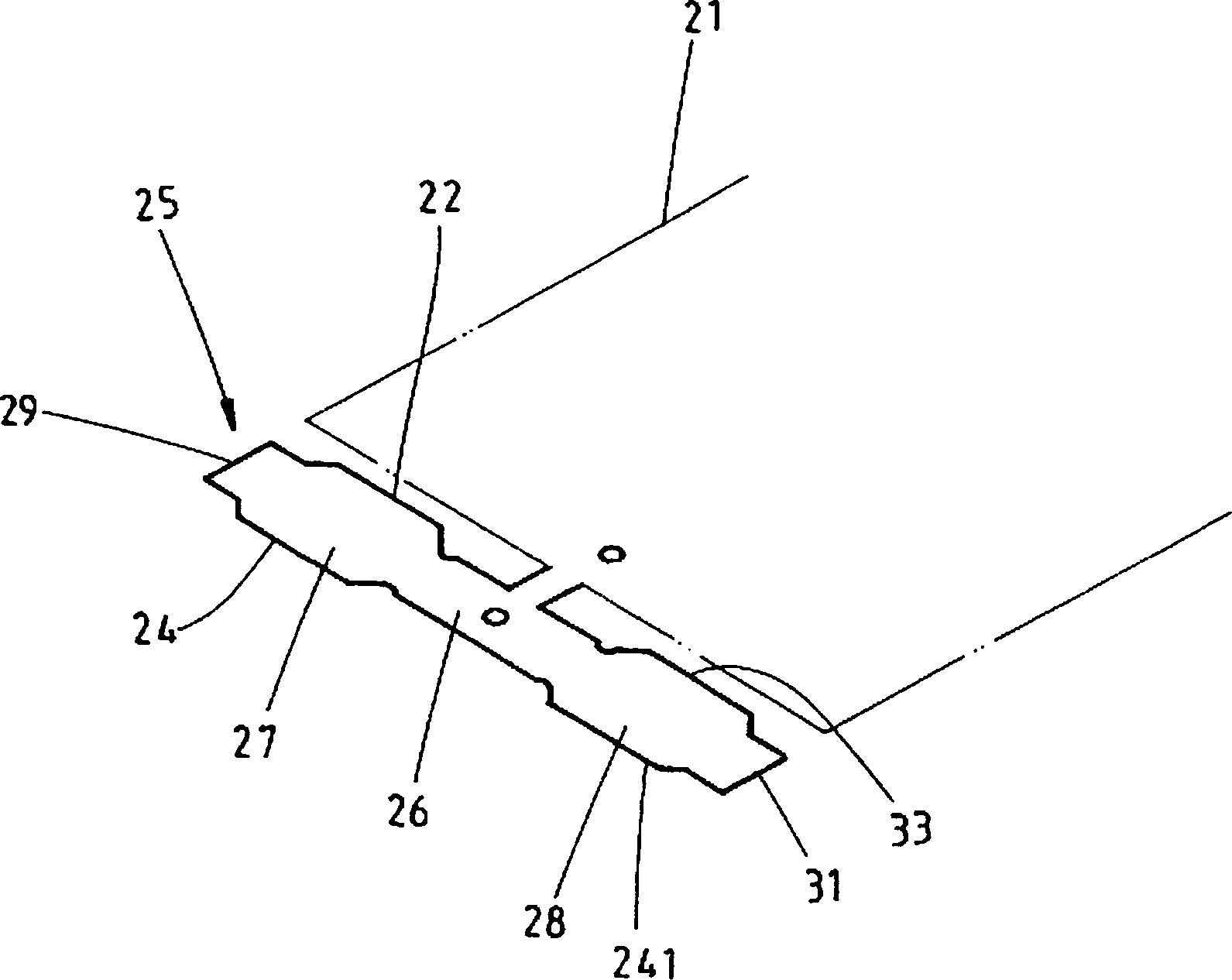

InactiveCN103091764AReduced design methodReduced manufacturing methodMechanical apparatusPoint-like light sourceLight guideDistribution pattern

Provided are designed methods of a light guide plate, a surface light source apparatus and a transmission type display apparatus and a method of manufacturing the light guide plate, which can recues grey unevenness generated nearby a light incoming portion of an incoming light. The light guide plate includes a light guide plate substrate (11) which transmits light, and multiple light reflection points (12) which formed on at least one surface of the light guide plate substrate. In multiple virtual areas formed by virtually segmenting a surface where the light reflection points, that is the point formation surface (S2) at equal intervals, multiple virtual grids (g) are regularly and two-dimensionally arranged, wherein light reflection points are formed in specific virtual grids in the multiple virtual grids; light distribution patterns that are symmetrically translated are formed according to configuration of the light reflection points in one virtual area of the multiple virtual areas and the configuration of the light refection points in at least one virtual area of the remaining multiple virtual areas, and multiple light reflection points are formed on the point formation surface.

Owner:SUMITOMO CHEM CO LTD +1

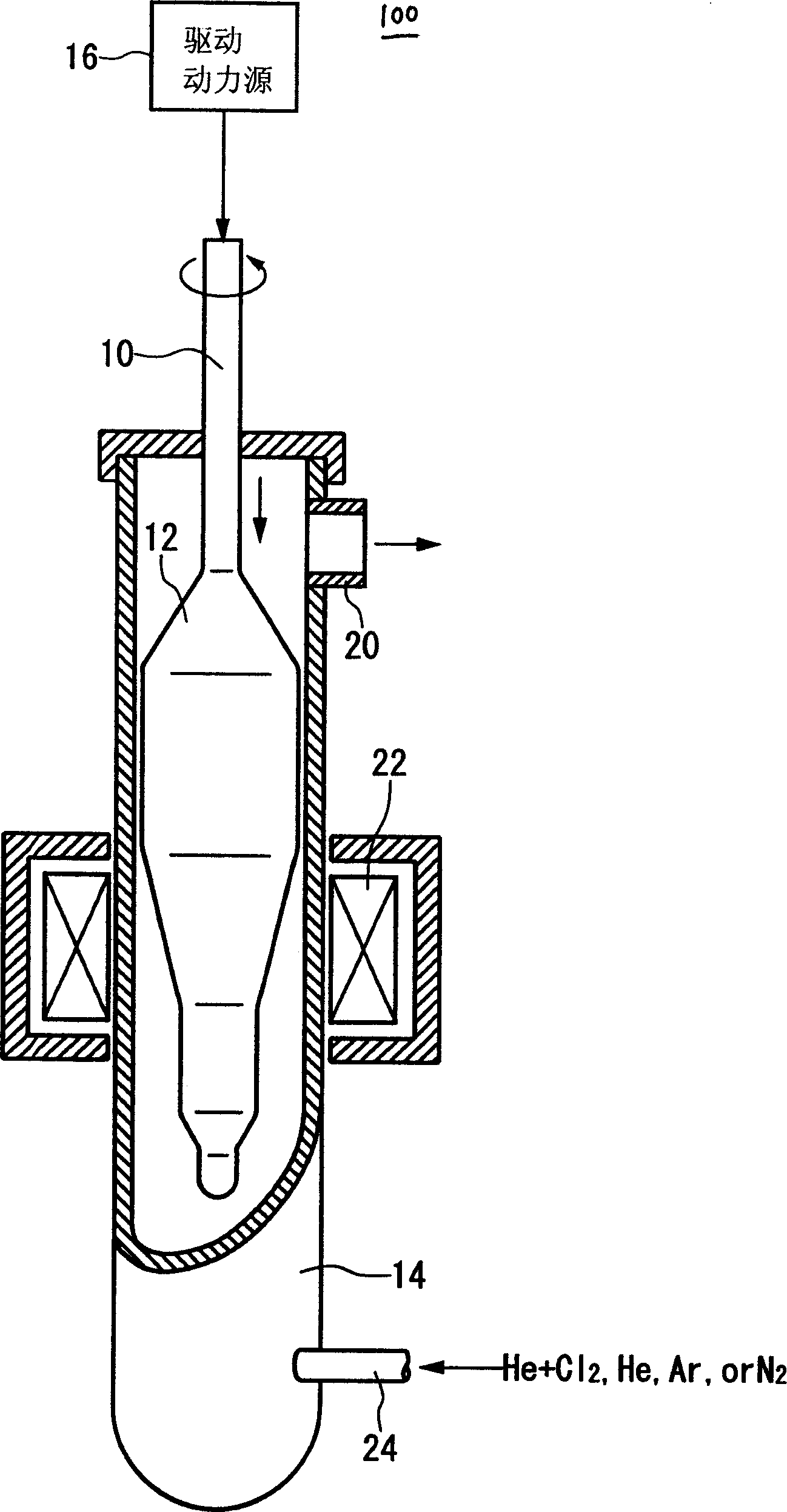

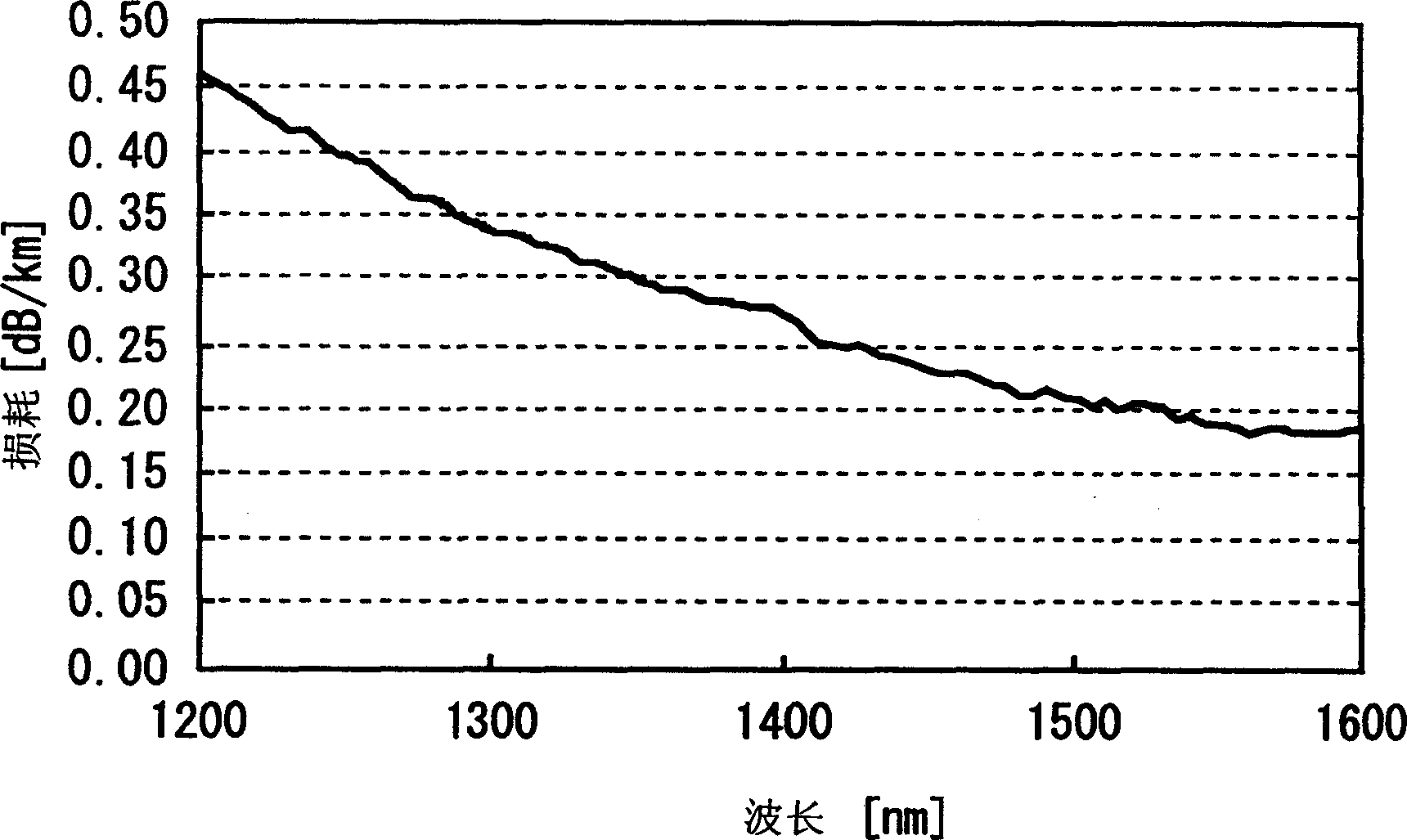

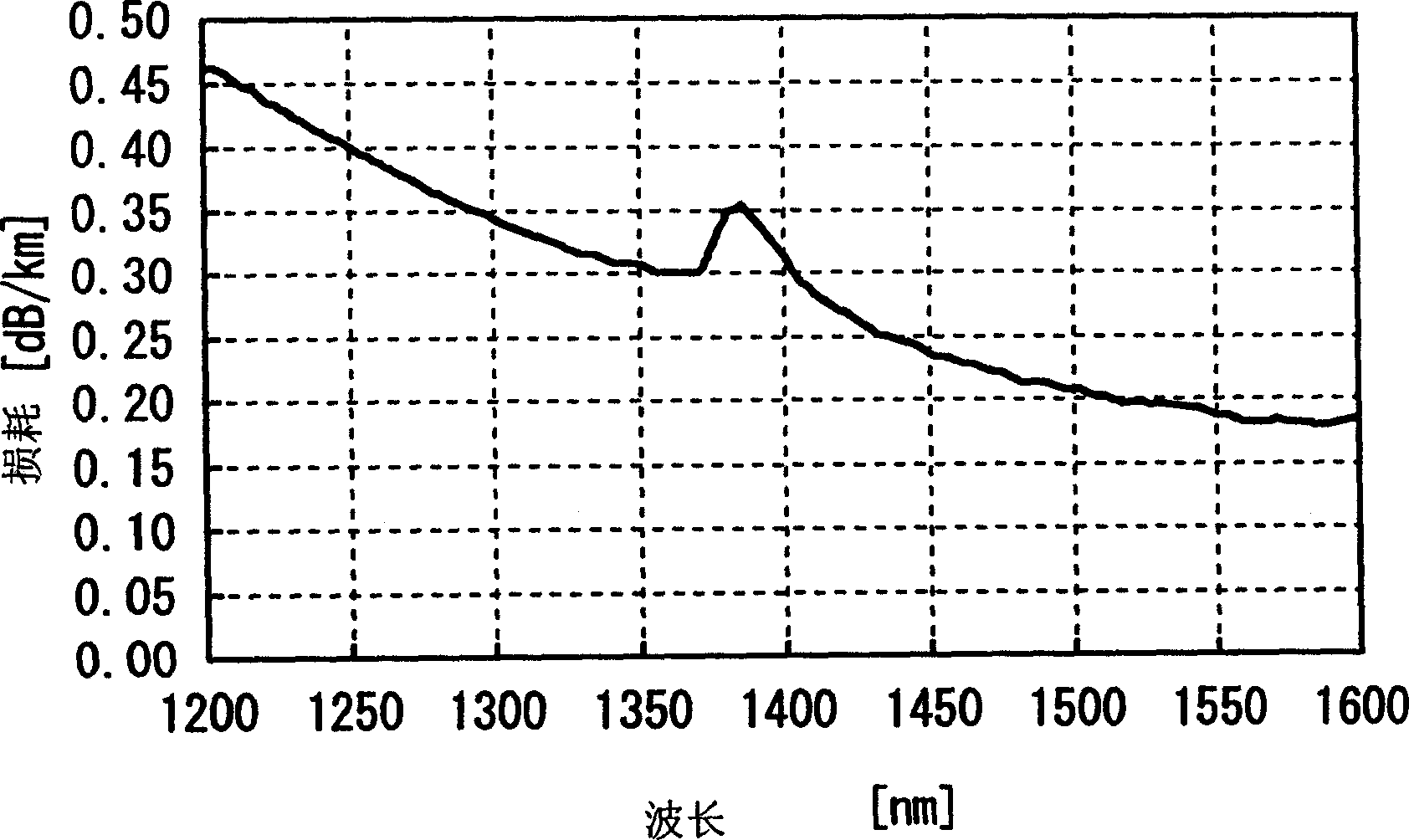

Low light loss matrix material for fibre-optical and its manufacturing method

InactiveCN1461737AReduce light lossReduced manufacturing methodGlass making apparatusOptical light guidesVitrificationGlass particle

A method for manufacturing a base material of optical fibres having a desired ratio of core to clad, including forming a porous base material upon depositing glass particles, producing a core member upon dehydrating and vitrifying the porous base material, adding a clad member onto the core member, is characterized in that the method includes, a step of dehydrating the porous base material in an atmosphere of gas including helium and chlorine within an electric furnace; a step of vitrifying the porous base material in an atmosphere of inert gas including helium; and a step of providing a purging step of heating the porous base material in an atmosphere of inert gas mainly including helium between the dehydrating step and the vitrifying step.

Owner:SHIN ETSU CHEM IND CO LTD

Piezoelectric ceramic, piezoelectric element, and manufacturing method thereof

ActiveCN1702882ALower firing temperatureReduced manufacturing methodPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostrictive devicesCeramicBurns temperature

The objective of the invention is to provide a method for producing a piezoelectric ceramic and a piezoelectric element where their burning temperatures can be sufficiently lowered without adding an additive or the like, a method for lowering burning temperature at a burning step in piezoelectric ceramic production and the piezoelectric element which can be obtained by the methods. The method for producing the piezoelectric ceramic comprises a mixing step to prepare a powdery raw material mixture being mixed with a raw material containing Pb, Zr and Ti and a burning step to burn the raw material mixture. The raw material mixture being satisfied with the following equations denoted as D50<=0.6 [mu]m (1) and D90-D10<=0.4 [mu]m (2) (wherein, D50 is a mean particle diameter; D90 is a 90% cumulation particle diameter; D10 is a 10% cumulation particle diameter) is prepared at the mixing step.

Owner:TDK CORPARATION

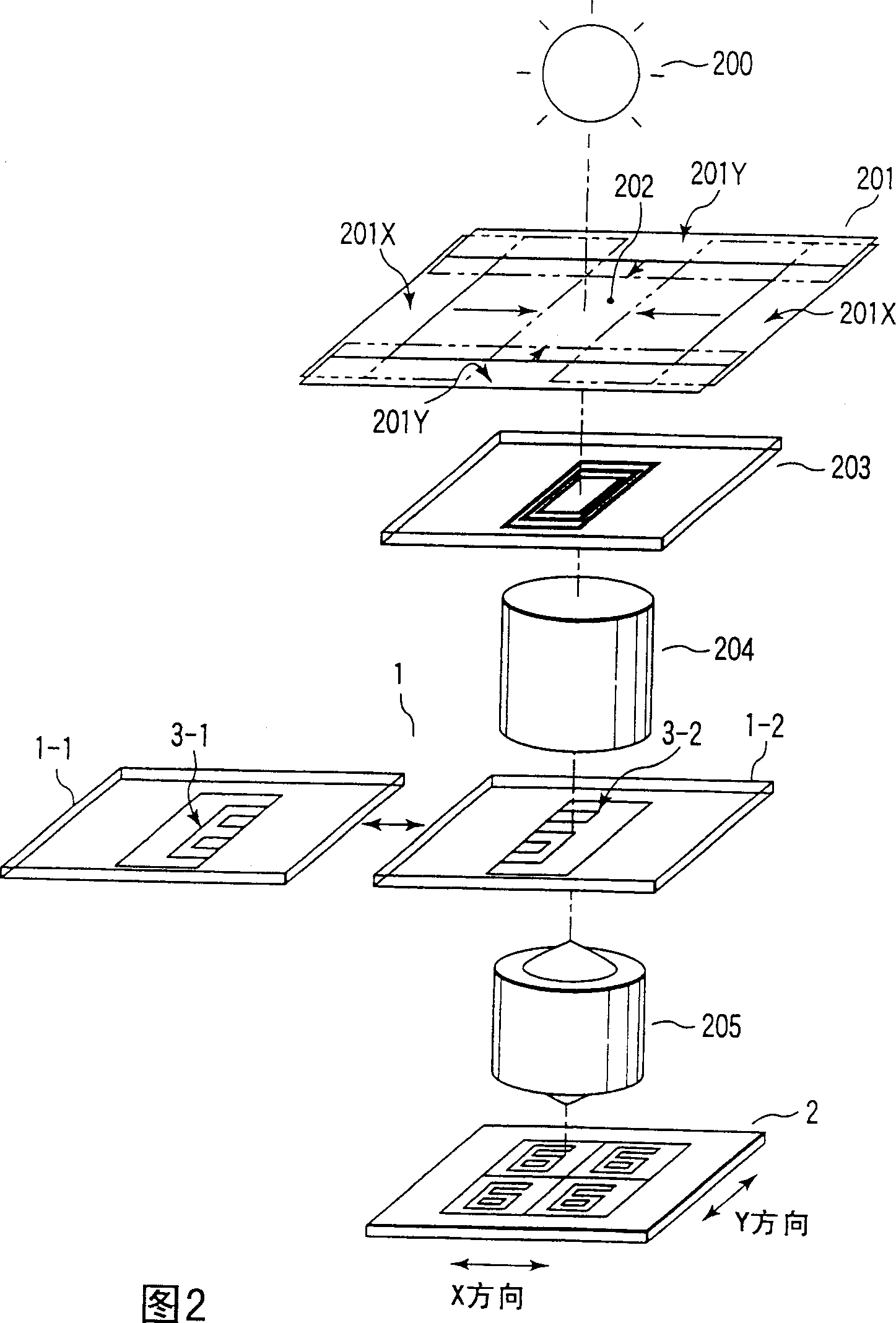

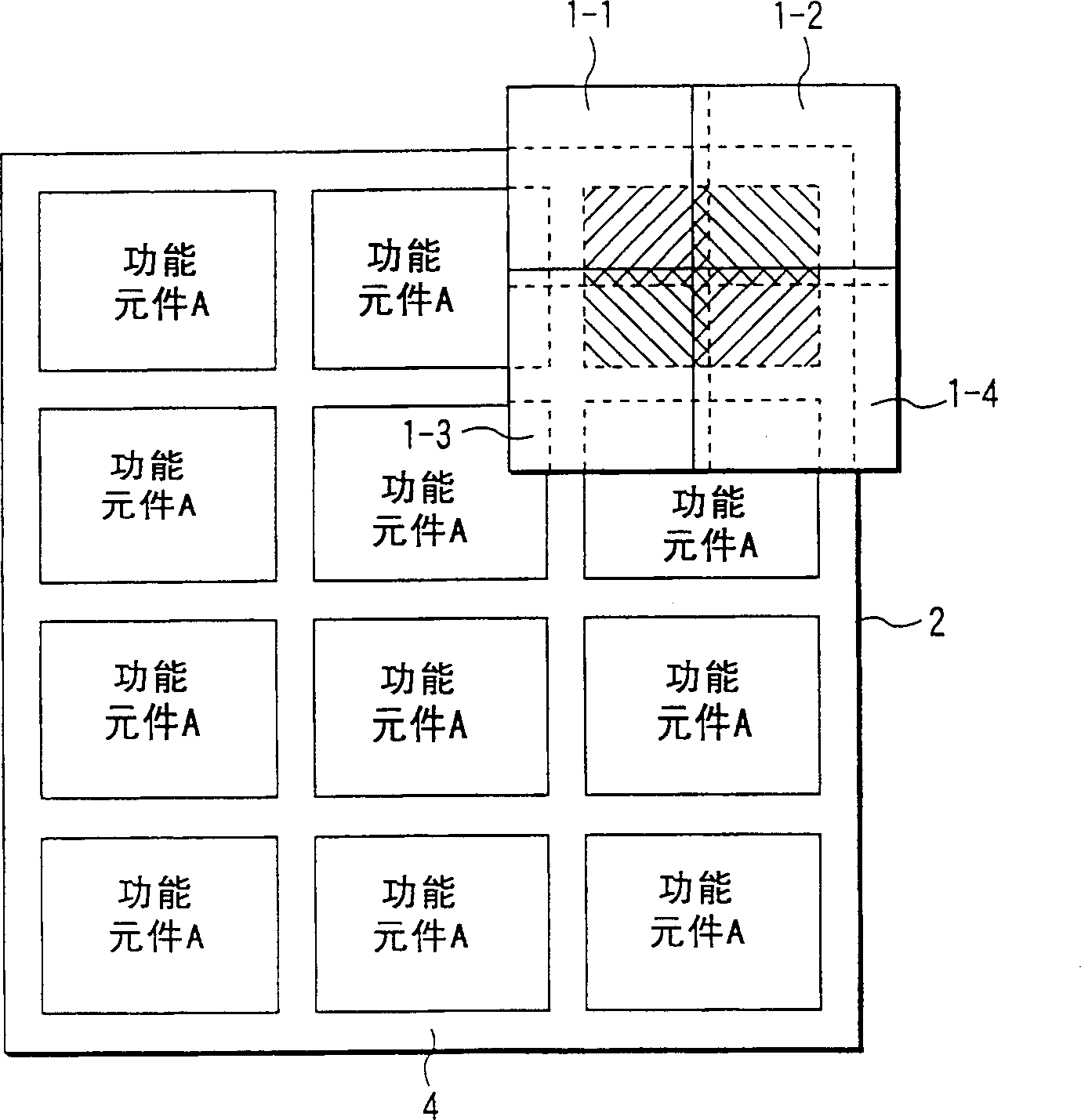

Exposure method for forming IC chip image in intermeidate mask using main mask

InactiveCN1380584AReduced manufacturing methodReduce manufacturing costSemiconductor/solid-state device manufacturingPhotomechanical coating apparatusGraphicsSingle exposure

A method for manufacturing a master mask, which is used for exposing, on an object to be exposed (2), a pattern having a size larger than an area that can be exposed at one time. A pattern having a size larger than an area that can be exposed at one time is divided into an area (4) with low repeatability and an area (A) with high repeatability. Secondly, the pattern of the aforementioned low-repeatability region (4) is drawn on at least one first master mask (1-5, 1-6). The pattern of the above-mentioned highly repeatable region (A) is drawn on at least one second master mask (1-1 to 1-4).

Owner:KK TOSHIBA +1

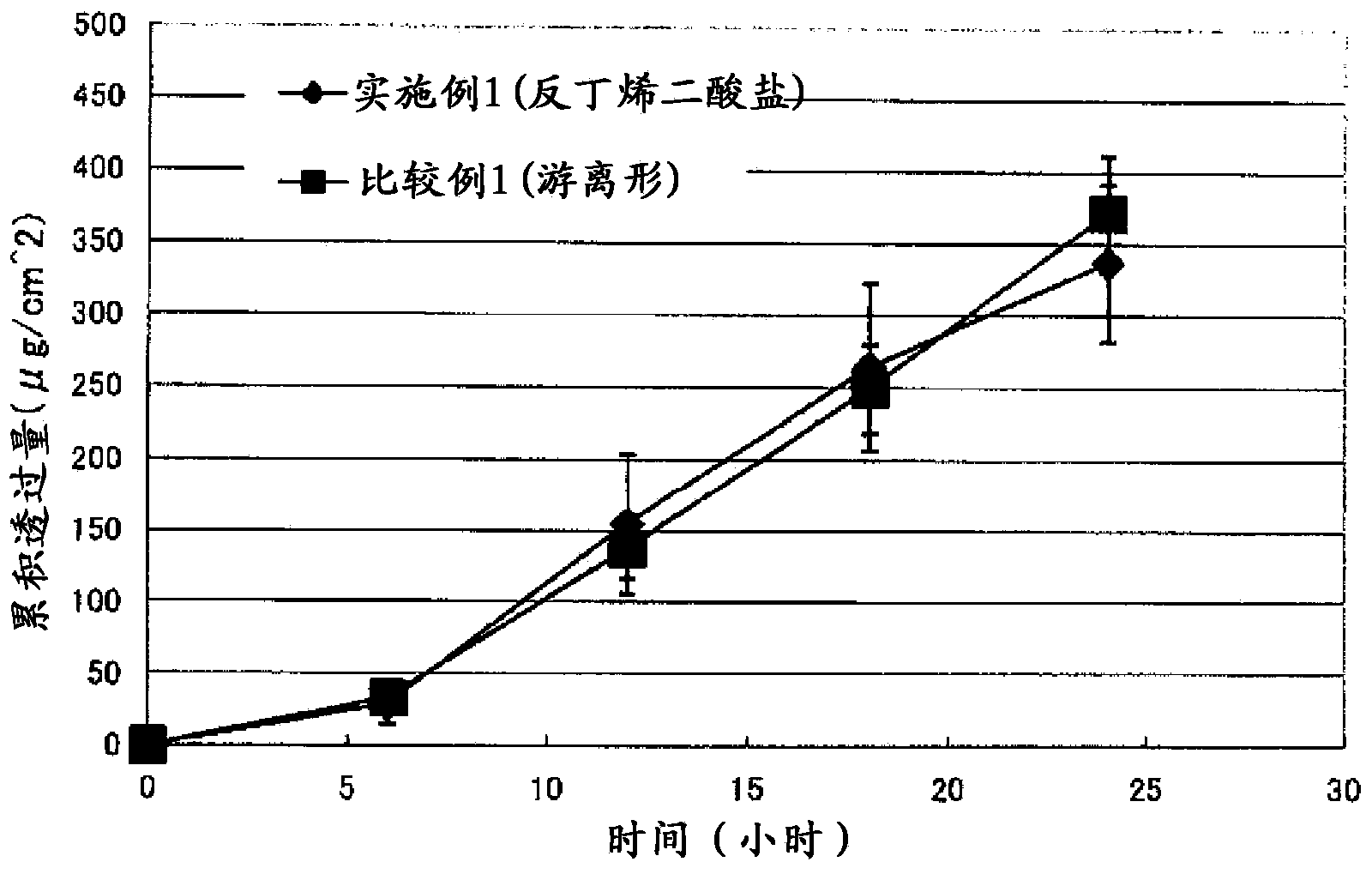

Method for producing patch, and patch

ActiveCN103501770AReduced manufacturing methodOrganic active ingredientsNervous disorderMetalAlkali metal

A method for producing a patch including a support layer and an adhesive layer, comprising the step of forming the adhesive layer with use of an adhesive layer composition obtained by mixing an alkali metal diacetate, a drug, and a nonaqueous adhesive base such that the molar ratio between the drug and the alkali metal diacetate (the number of moles of the drug: the number of moles of the alkali metal diacetate) is from 1:0.5 to 1:15.

Owner:HISAMITSU PHARM CO INC

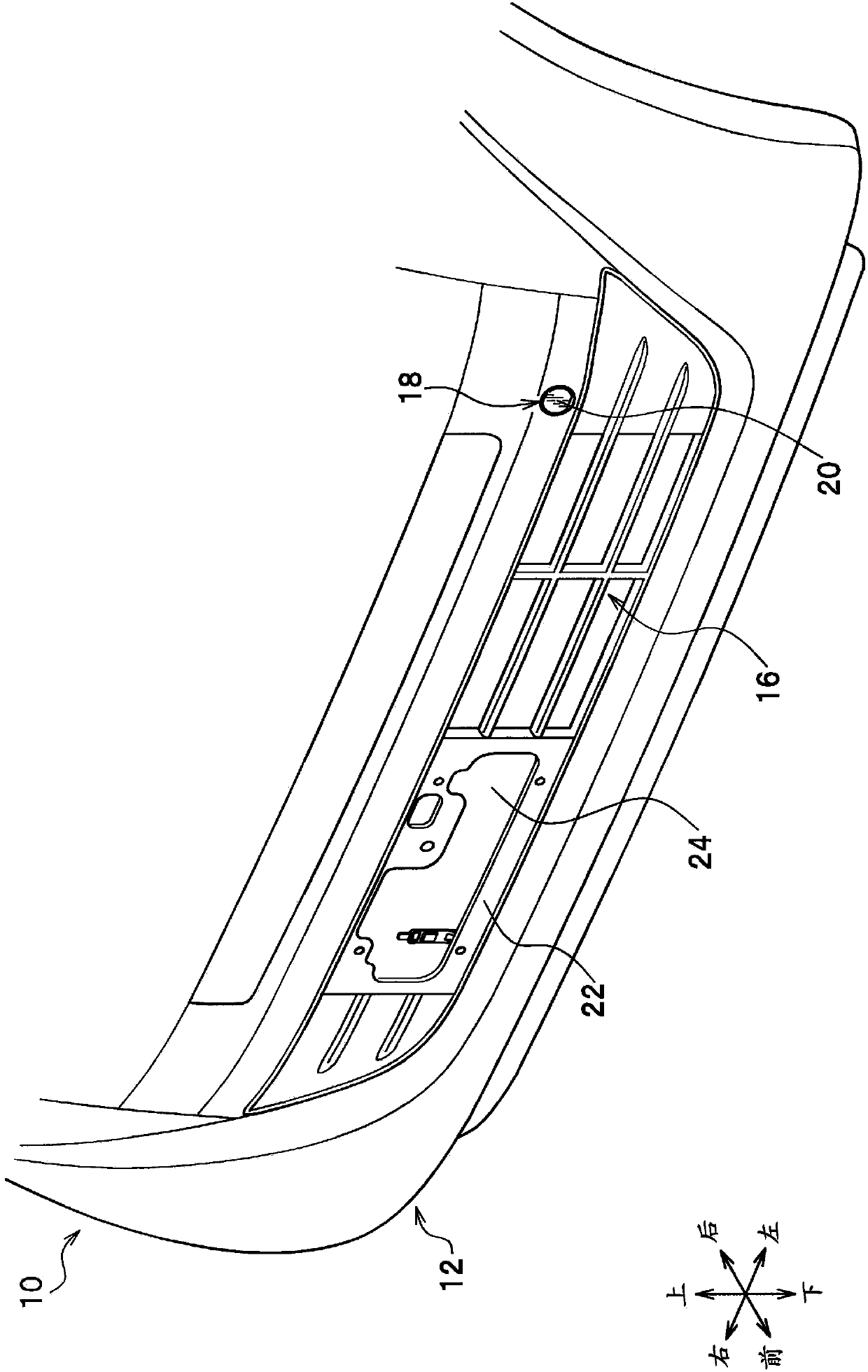

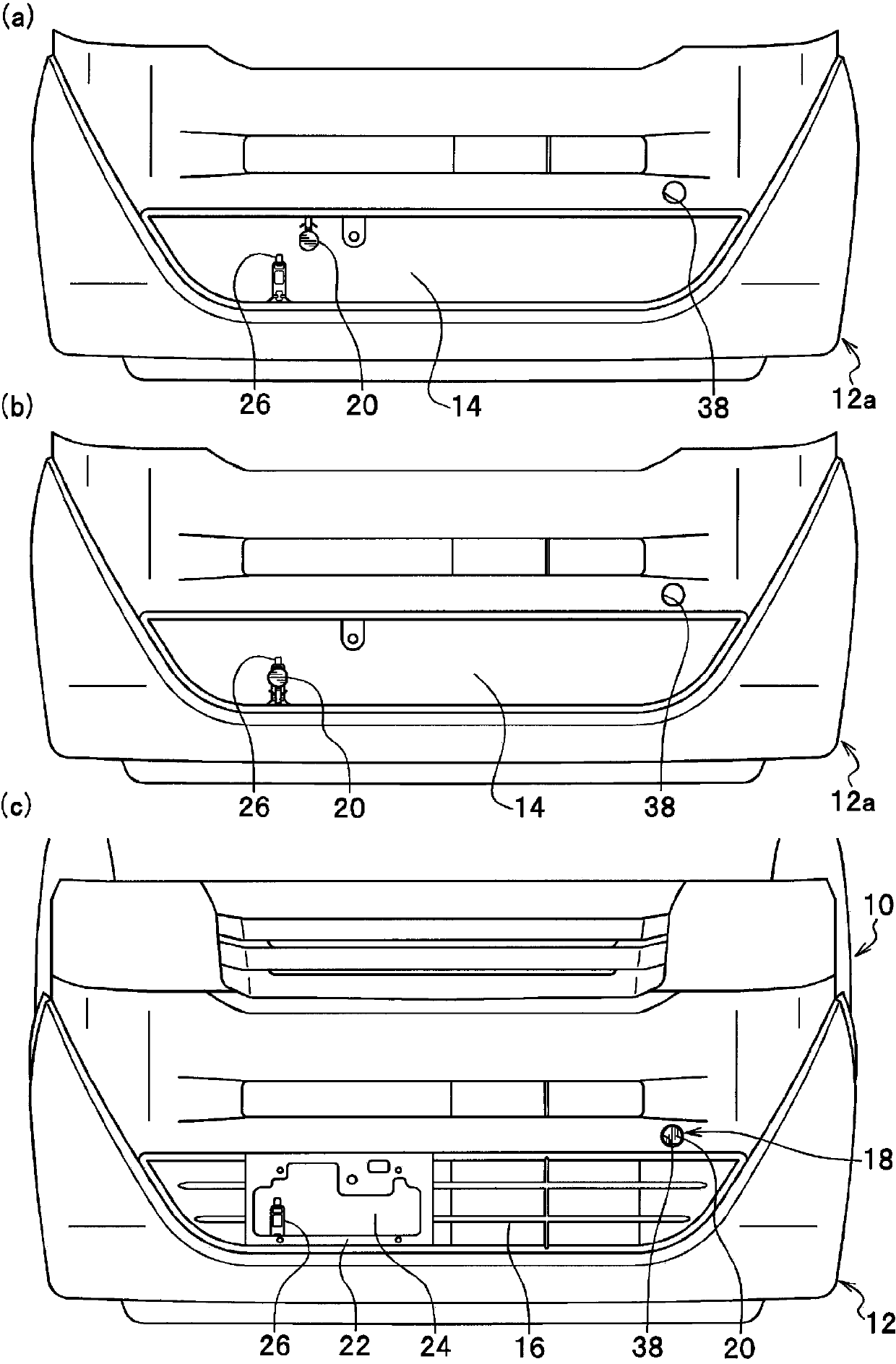

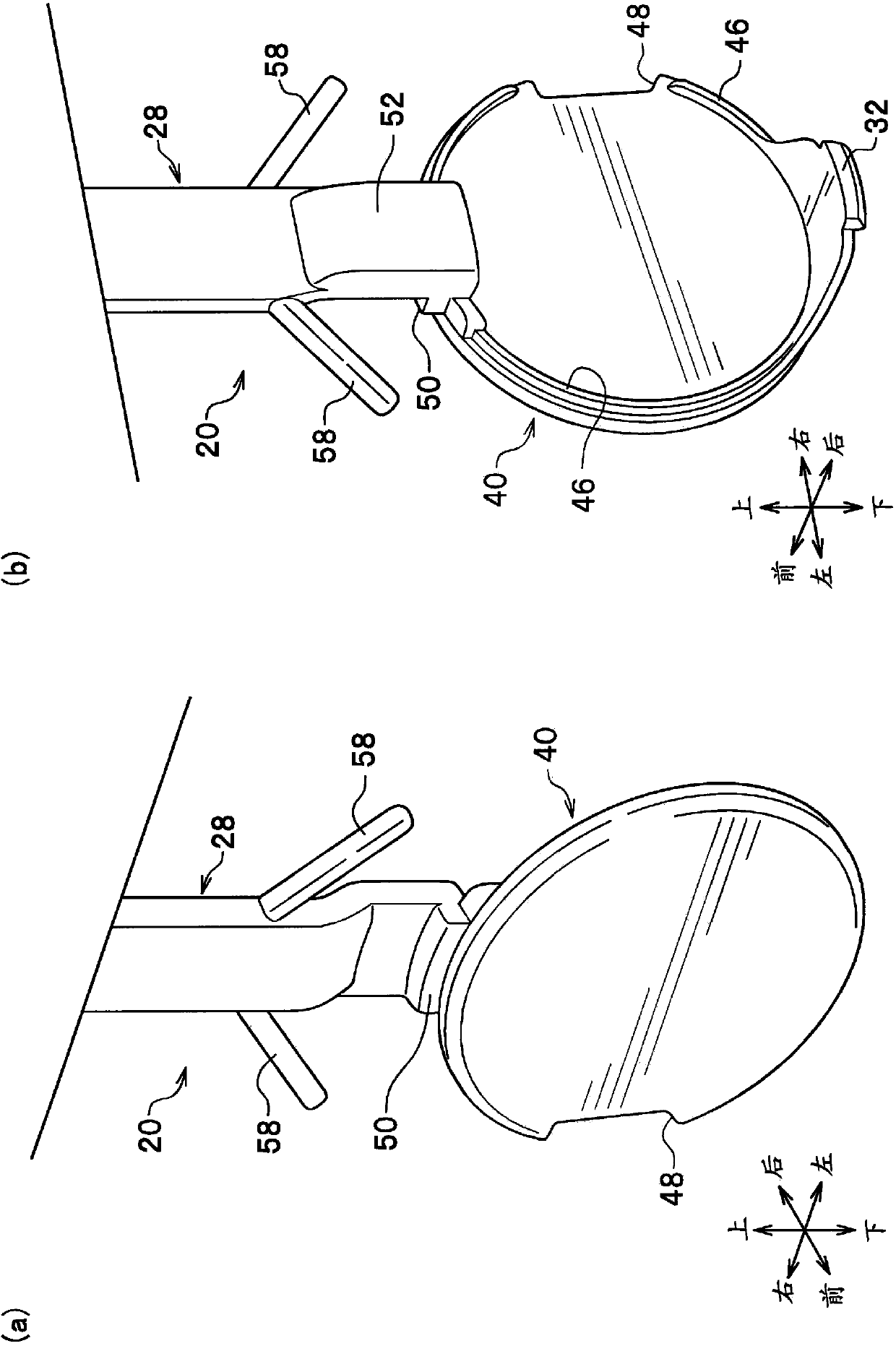

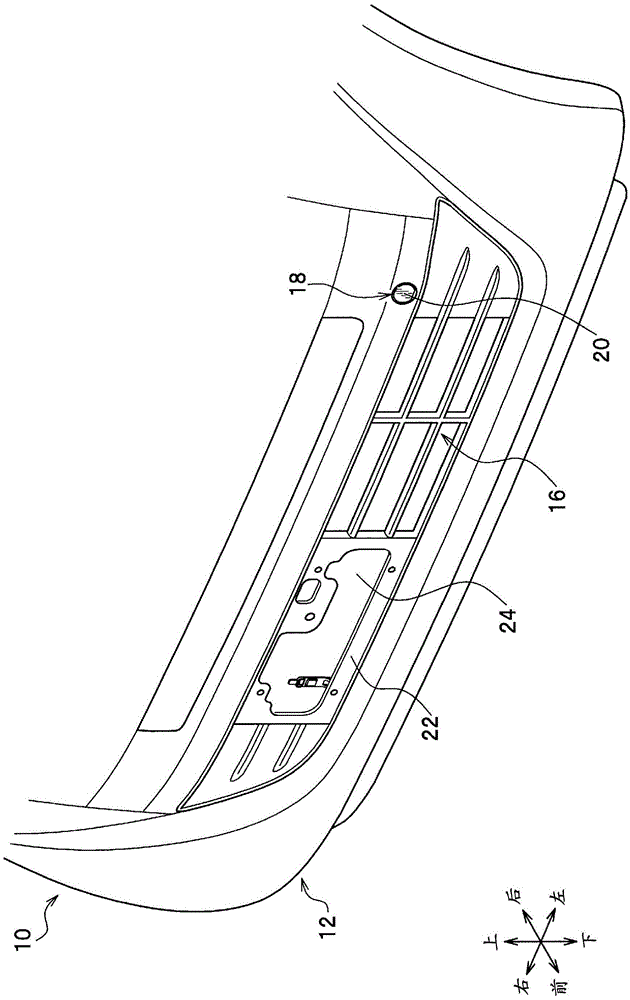

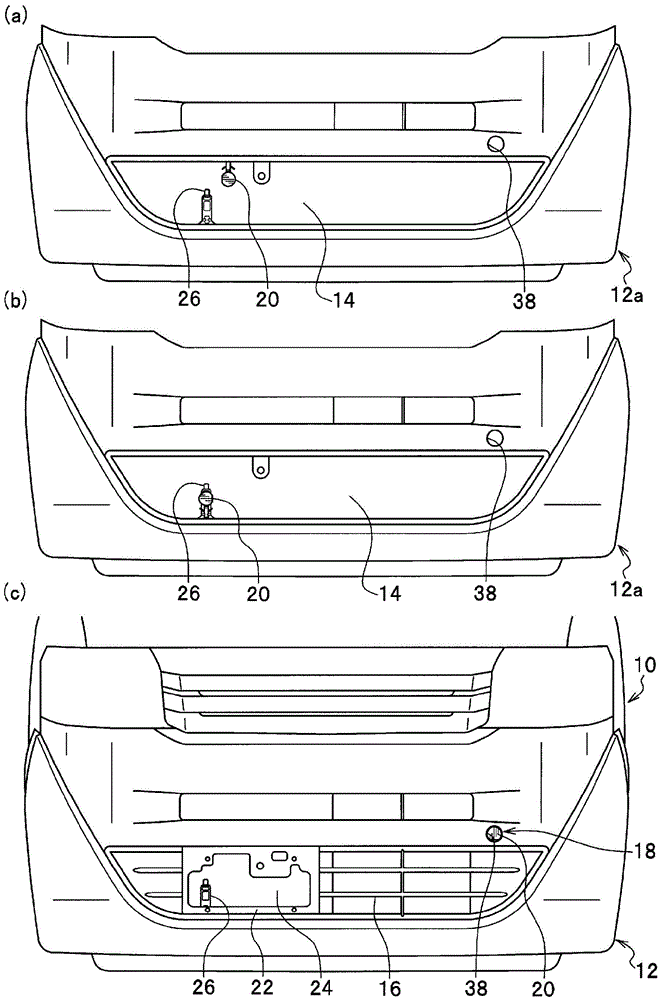

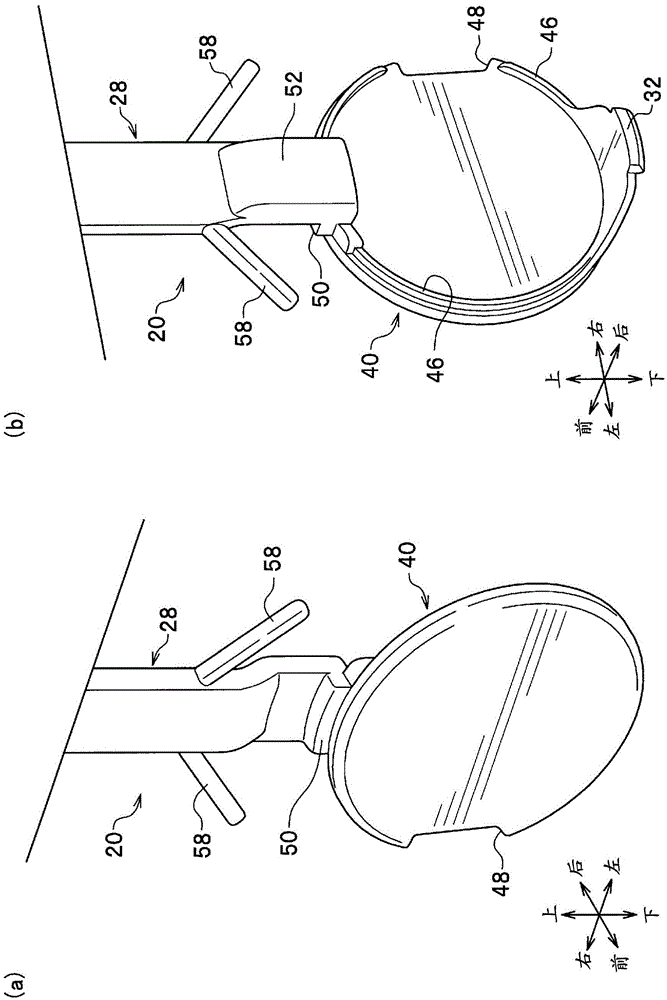

Structure for front portion of vehicle and method for manufacturing vehicle

ActiveCN103732453AStop vibrationAvoid displacementTowing devicesBumpersEngineeringMechanical engineering

Owner:HONDA MOTOR CO LTD

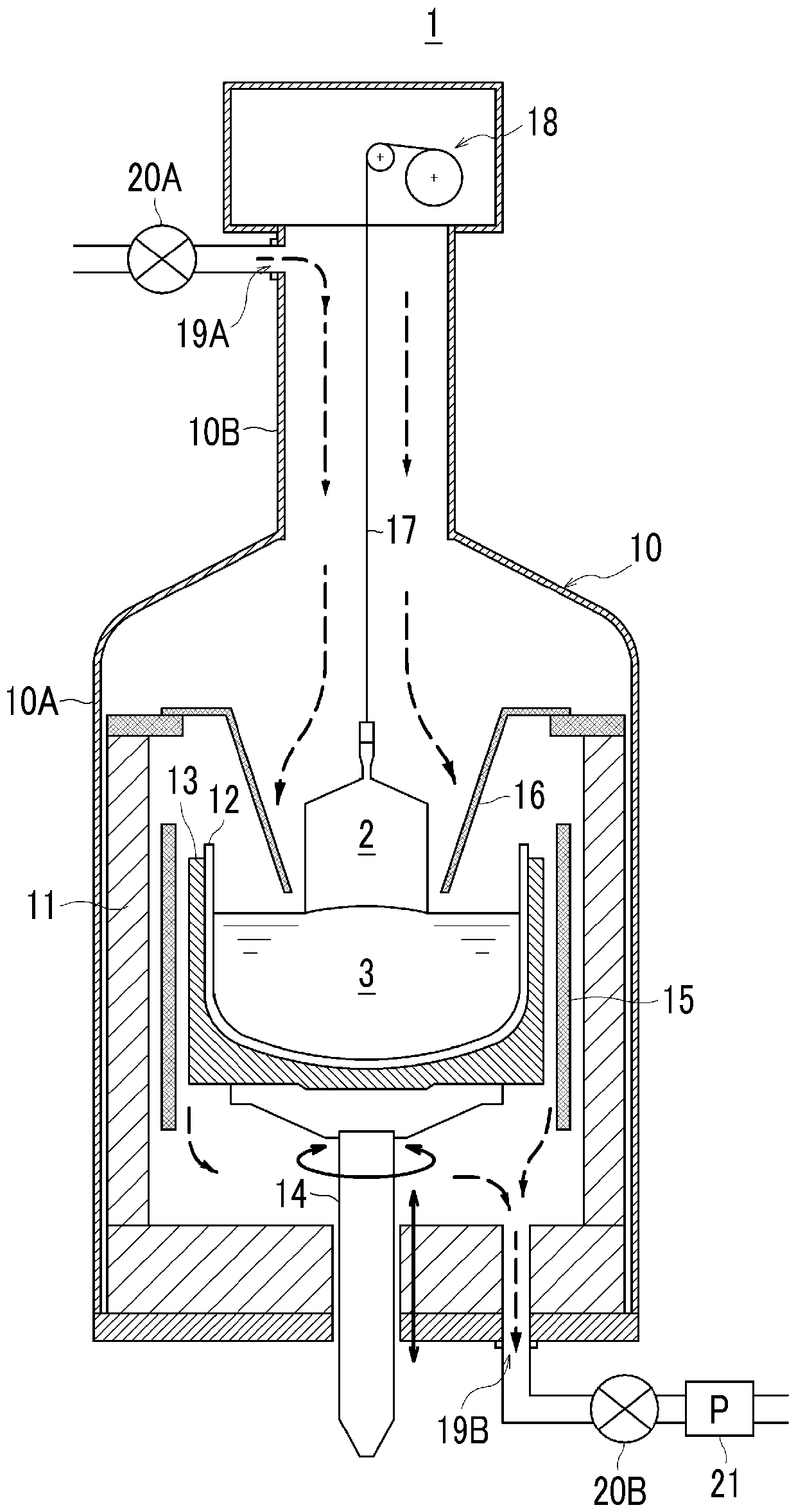

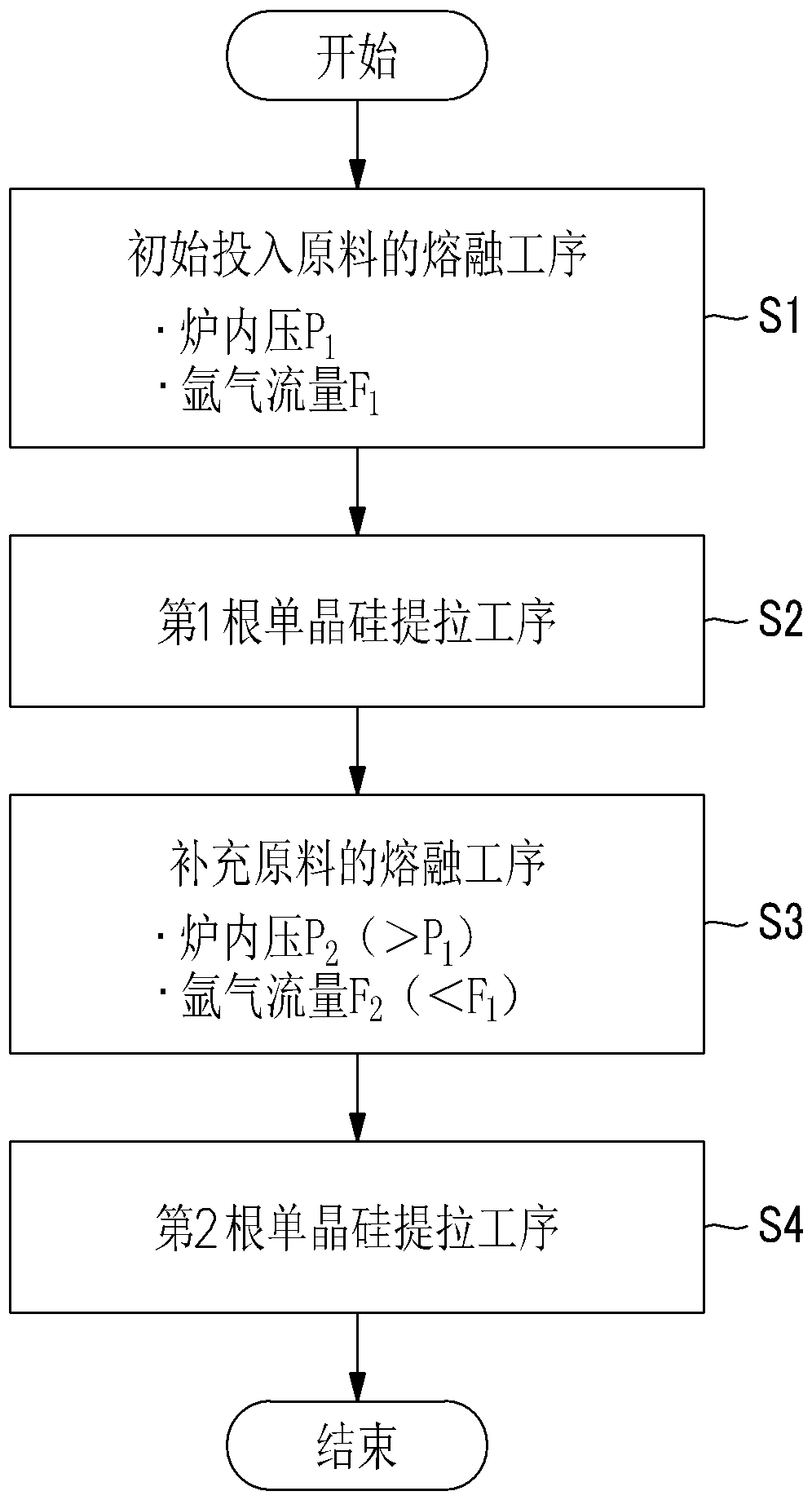

Method for producing silicon monocrystal

ActiveCN107709634APoor pinholeReduced manufacturing methodPolycrystalline material growthBy pulling from meltCrystalline siliconQuartz

Owner:SUMCO CORP

Method of mfg. semiconductor device

InactiveCN1519910AReduce manufacturing costReduced manufacturing methodSemiconductor/solid-state device manufacturingEngineeringSemiconductor

A method of fabricating a semiconductor device capable of suppressing defective etching in formation of a deep trench also when the number of polishing steps is reduced is obtained. This method of fabricating a semiconductor device comprises steps of forming a first trench on an element isolation region of a semiconductor substrate, forming a first film consisting of an insulator film to fill up the first trench, forming a second trench larger in depth than the first trench in the first trench, forming an embedded film in the second trench and substantially simultaneously polishing an excess depositional portion of the first film and an excess depositional portion of the embedded film.

Owner:SANYO ELECTRIC CO LTD

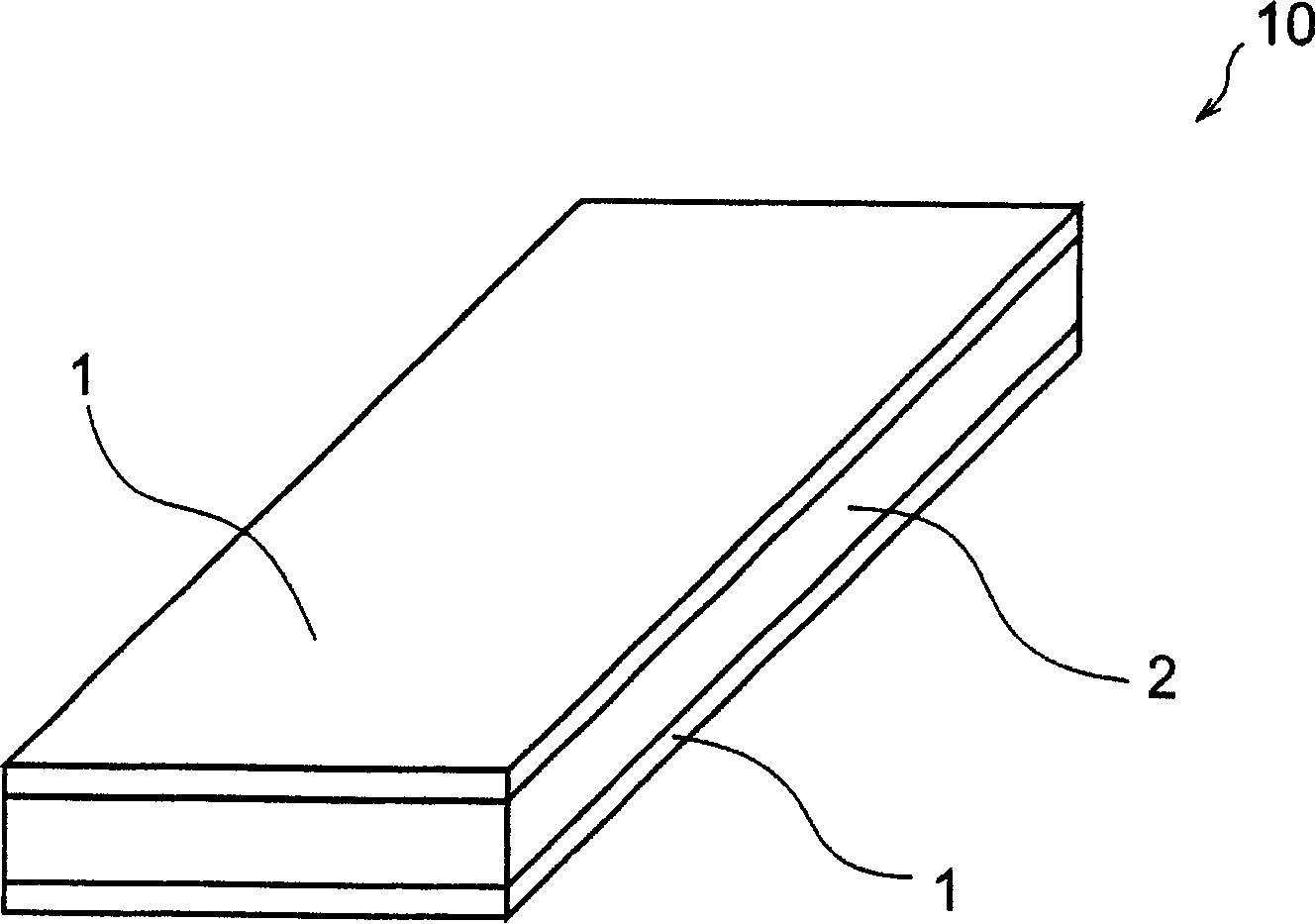

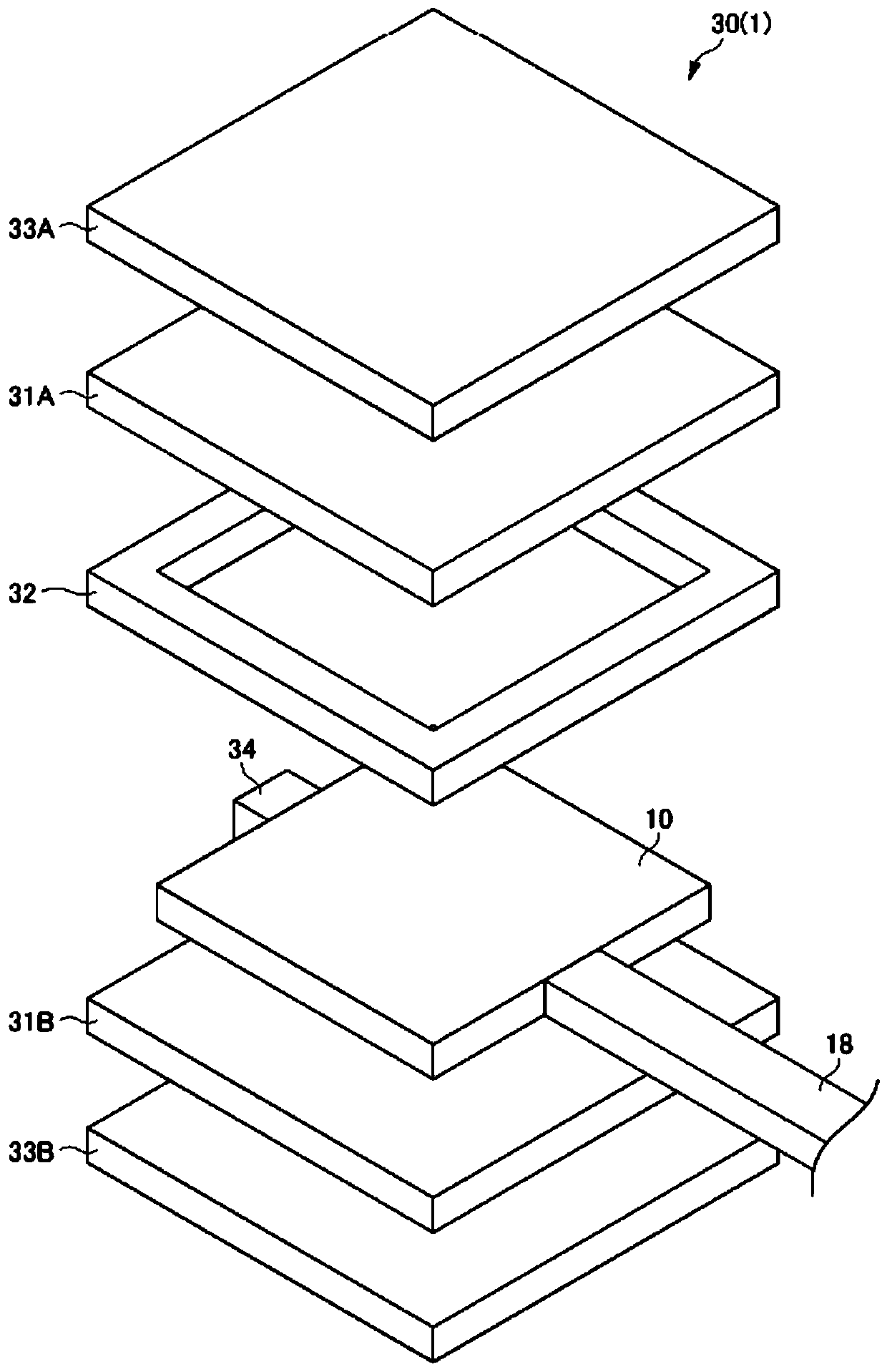

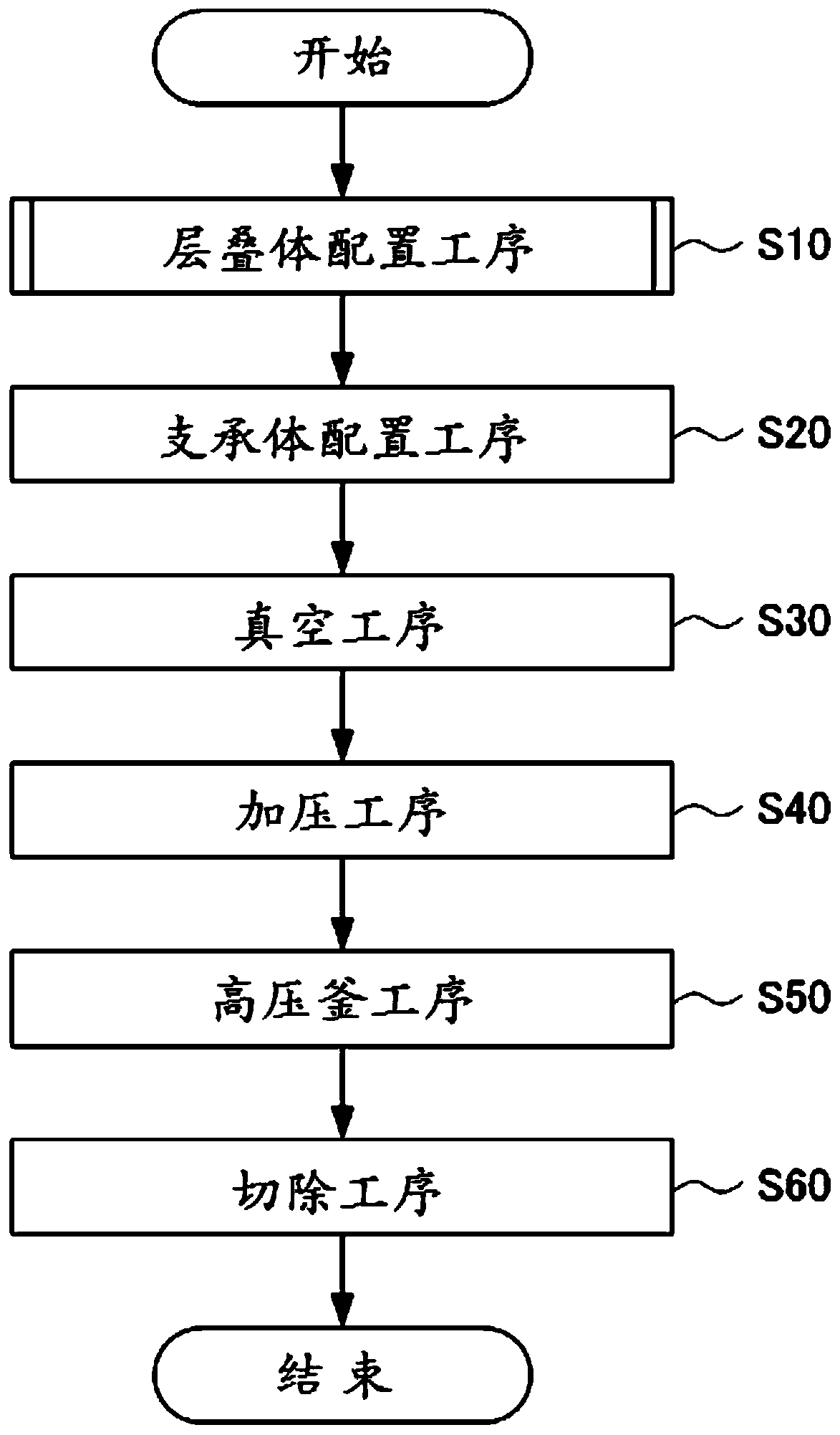

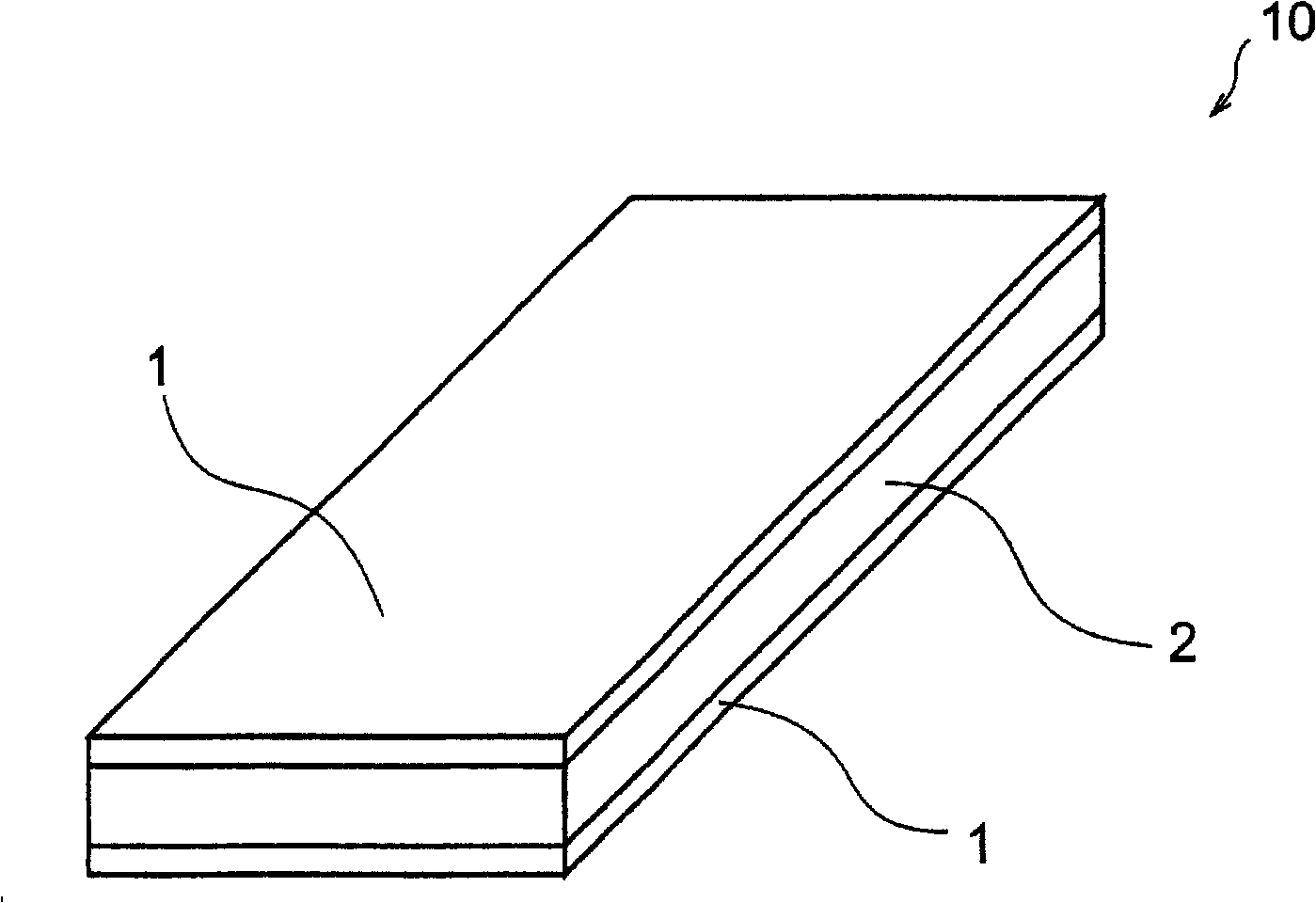

Laminated glass and production method for laminated glass

PendingCN111051264AReduced manufacturing methodPrevent agingGlass/slag layered productsNon-linear opticsPolymer scienceGlass sheet

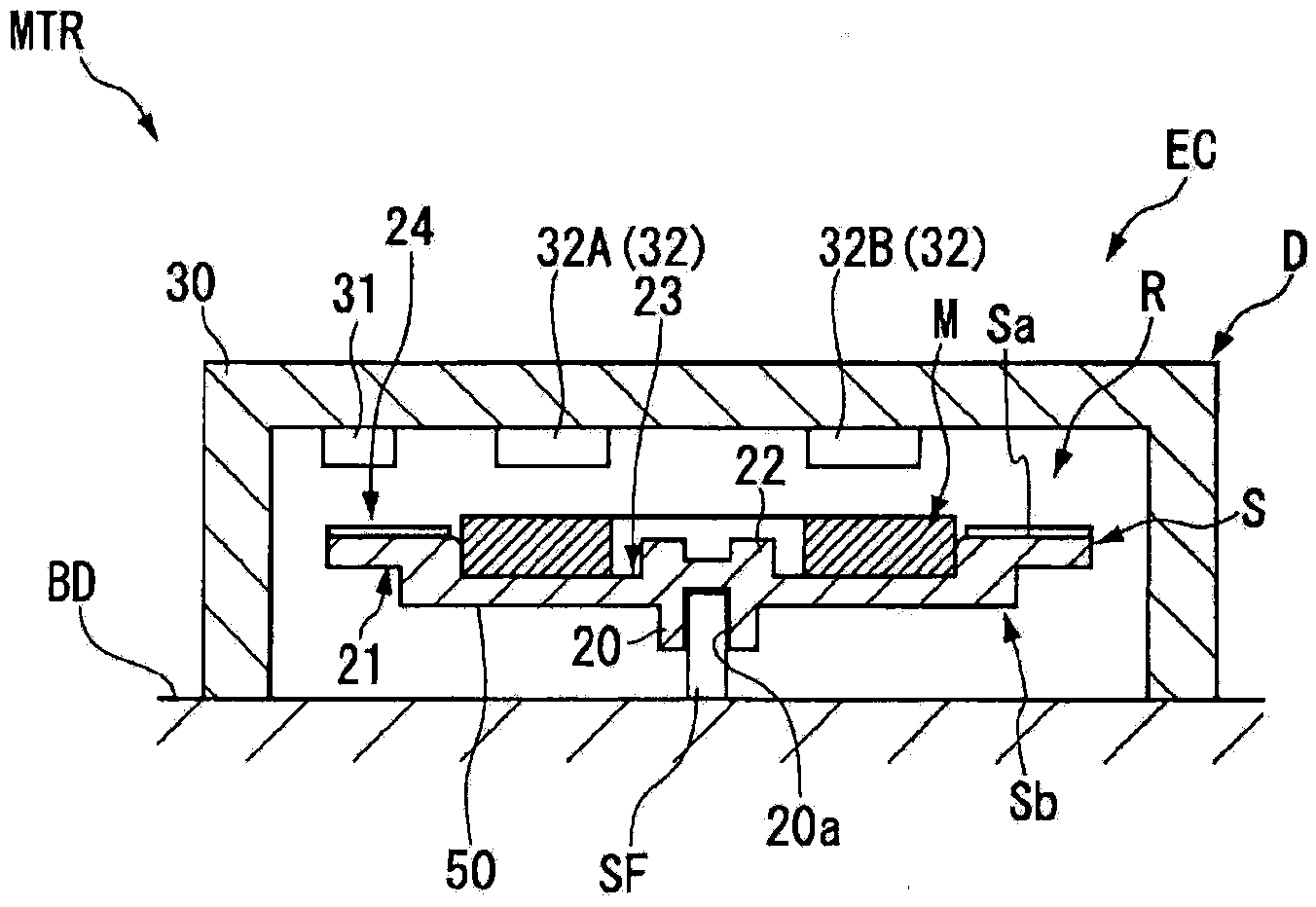

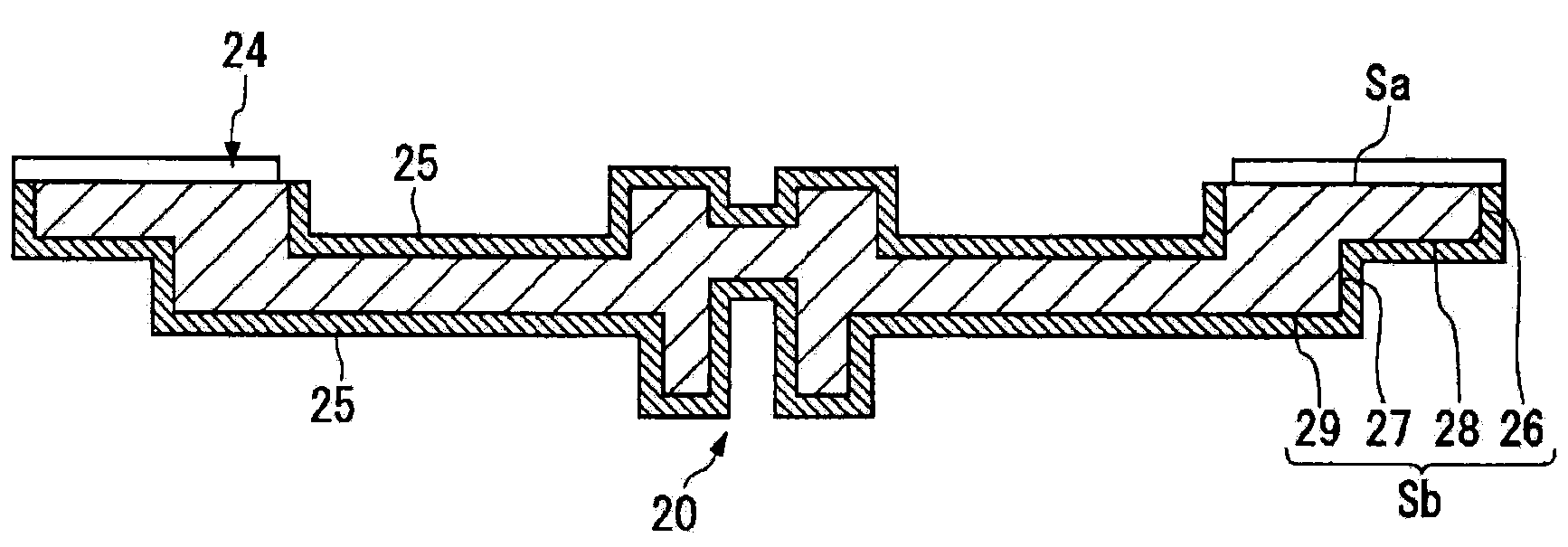

Provided are a laminated glass which has a reduced occurrence of voids and accumulation of liquid crystal, and a production method for the laminated glass. Also provided is a laminated glass which canprevent deterioration of a sealing material. This laminated glass 1 comprises a first glass plate 33A, a first intermediate film 31A, a liquid crystal film 10, a second intermediate film 31B, and a second glass plate, which are layered and disposed in this order, wherein the first glass plate 33A and the second glass plate 33B have a larger outer shape than that of the liquid crystal film 10, anda spacer 32 is provided in at least a portion of a region which is interposed between the first glass plate 33A and the second glass plate 33B and in which the liquid crystal film 10 is not disposed.

Owner:DAI NIPPON PRINTING CO LTD

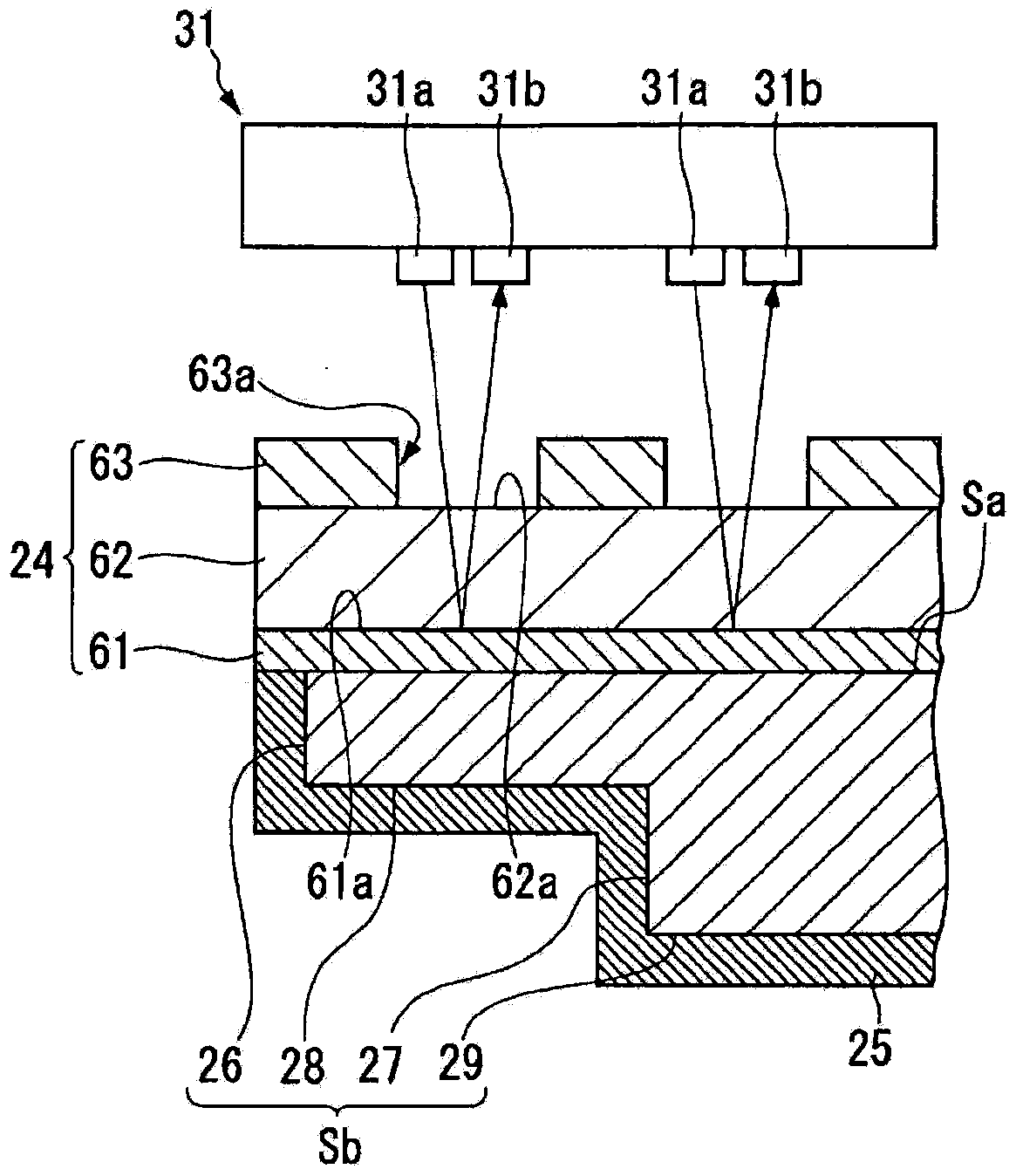

Encoder, production method for encoder scale, production method for encoder, and drive device

ActiveCN104094087ALow yieldReduced manufacturing methodManufacturing dynamo-electric machinesConverting sensor output electrically/magneticallyMetallic materialsEngineering

An encoder, comprising: a scale section having a base material comprising a metal material, having a pattern formed on a first surface of the base material, and having a passivation section formed on a second surface of the base material differing from the first surface; and a detection unit that moves relative to the scale section, and detects the pattern.

Owner:NIKON CORP

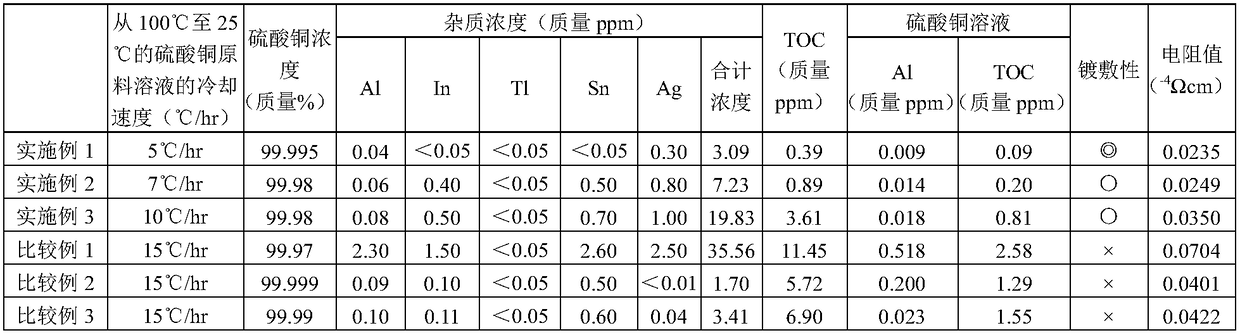

Copper sulfate, copper sulfate solution, plating solution, method for producing copper sulfate, method for producing semiconductor circuit board, and method for producing electronic apparatus

The invention discloses copper sulfate, a copper sulfate solution, a plating solution, a method for producing copper sulfate, a method for producing a semiconductor circuit board, and a method for producing an electronic apparatus, and particularly provides copper sulfate which reduce an aluminum concentration, a copper sulfate solution, a plating solution, a manufacturing method of copper sulfate, a manufacturing method of a semiconductor circuit board and a manufacturing method of an electronic device. The copper sulfate has the Al concentration of 0.08 mass ppm or less.

Owner:JX NIPPON MINING & METALS CO LTD

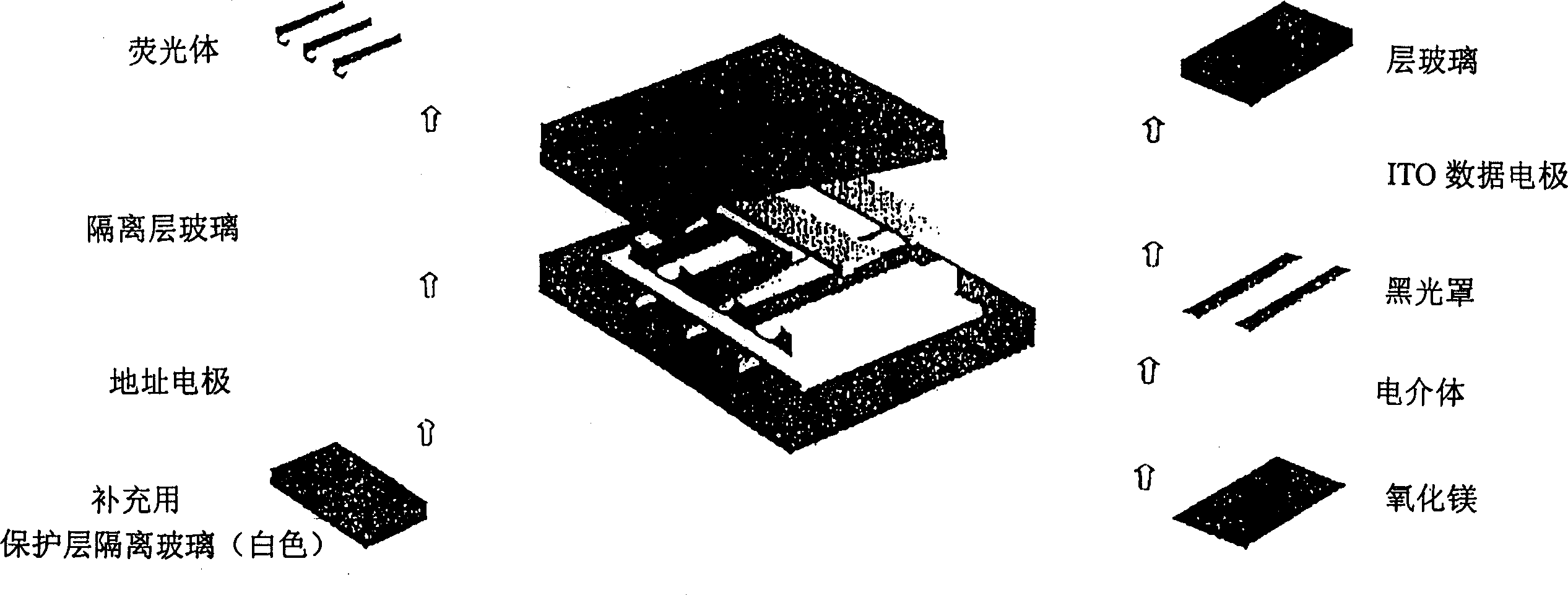

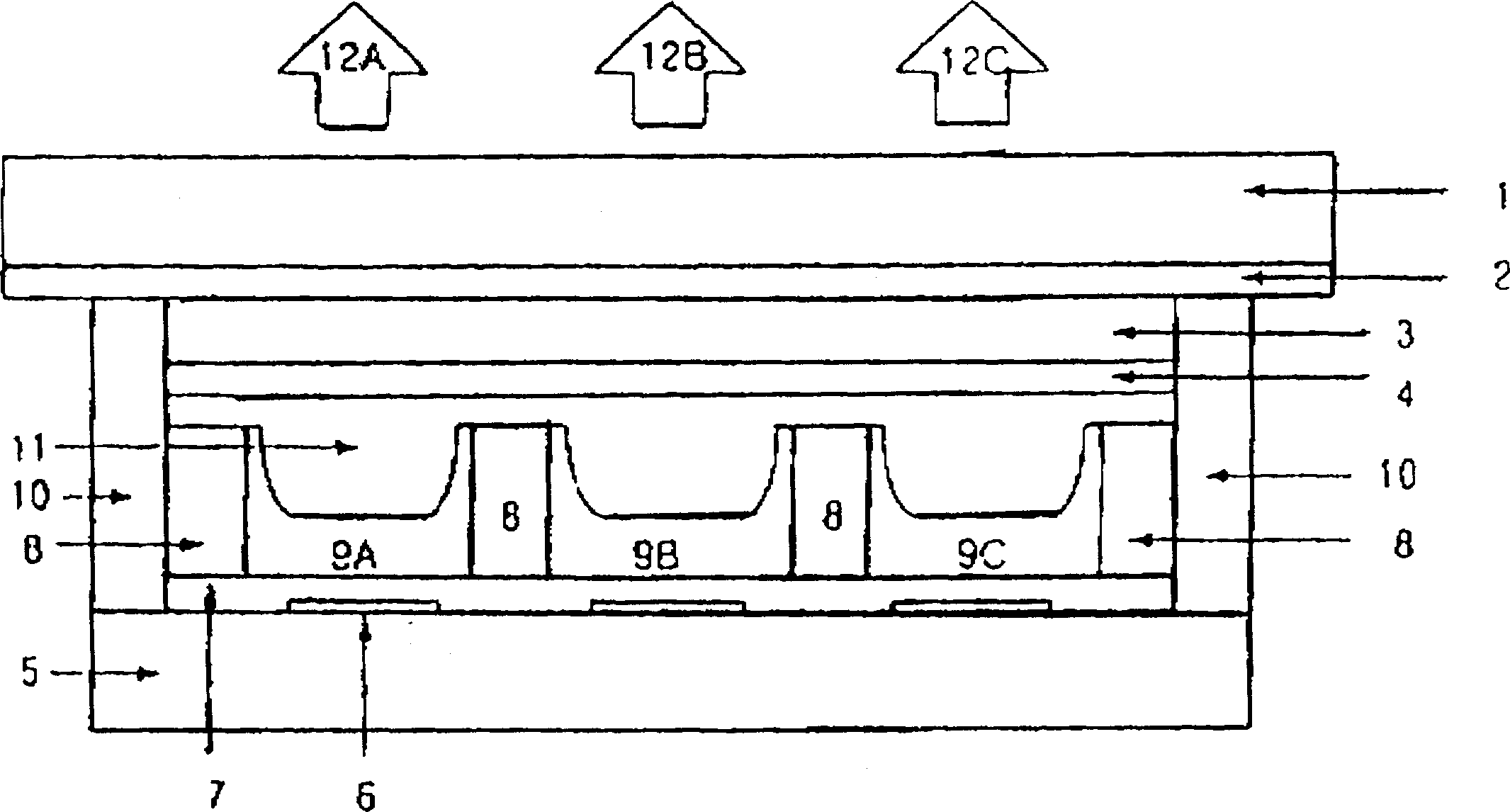

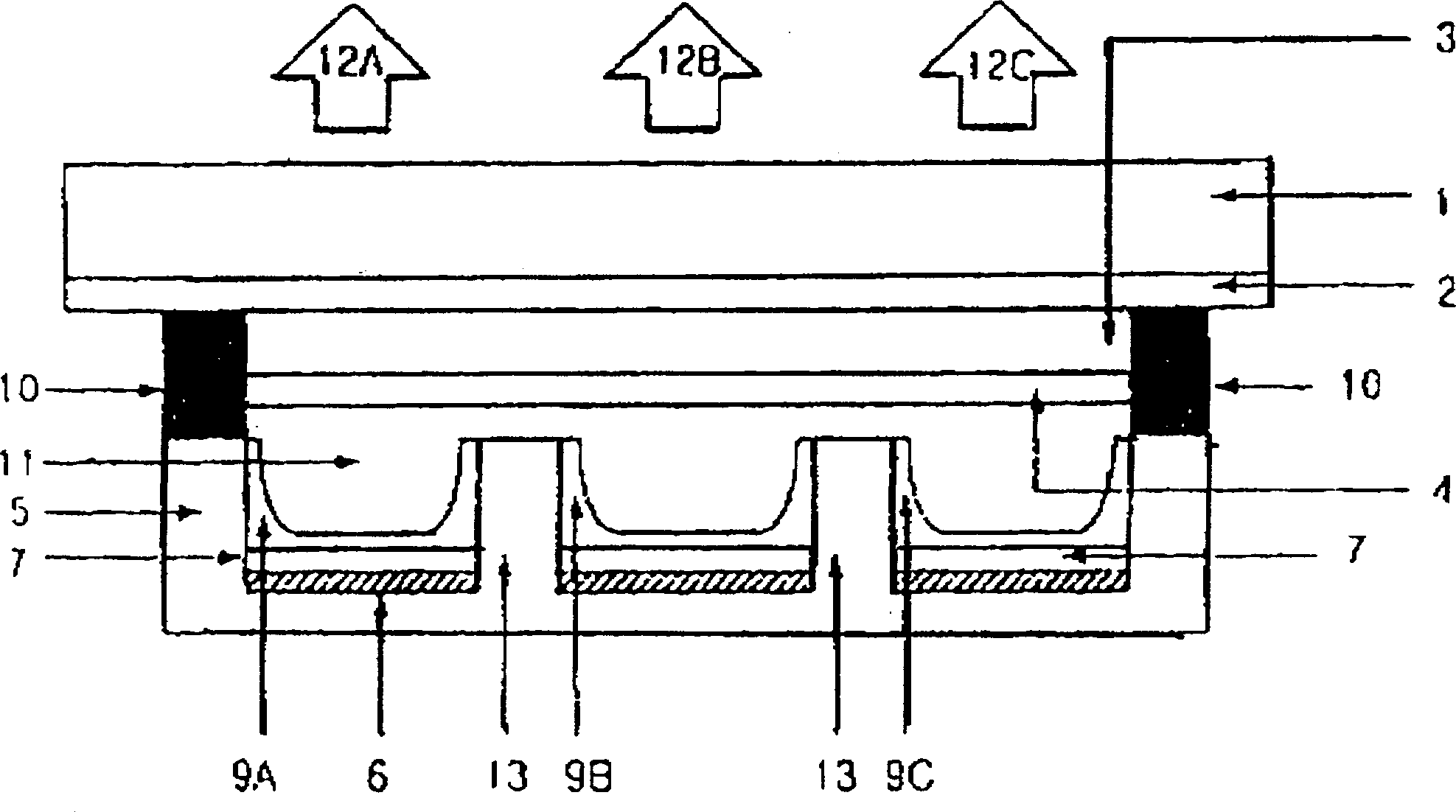

AC drive type plasma display device for electro-optical plate and its manufacturing method

InactiveCN1430237AEasy to prepareReduce manufacturing costAddress electrodesSustain/scan electrodesDielectricElectricity

An AC driven plasma display device for electroluminescent board features that its external surface has transparent electrode and metal electrode, the back of the glass plate parallel to said electrodes is machined to form slots, which are joined to form discharge cell, and the upper and lower substrates instead of partition, transparent dielectric and white dielectric constitute a dielectric bandlayer which is machined to form discharge cell to expose the electrodes to the outside of discharge cell. Its advantages are simple making method, low cost and low drive voltage. It is suitable for outdoor signboard, railway timetable, etc.

Owner:SCI ADVENTURE TECH C KR

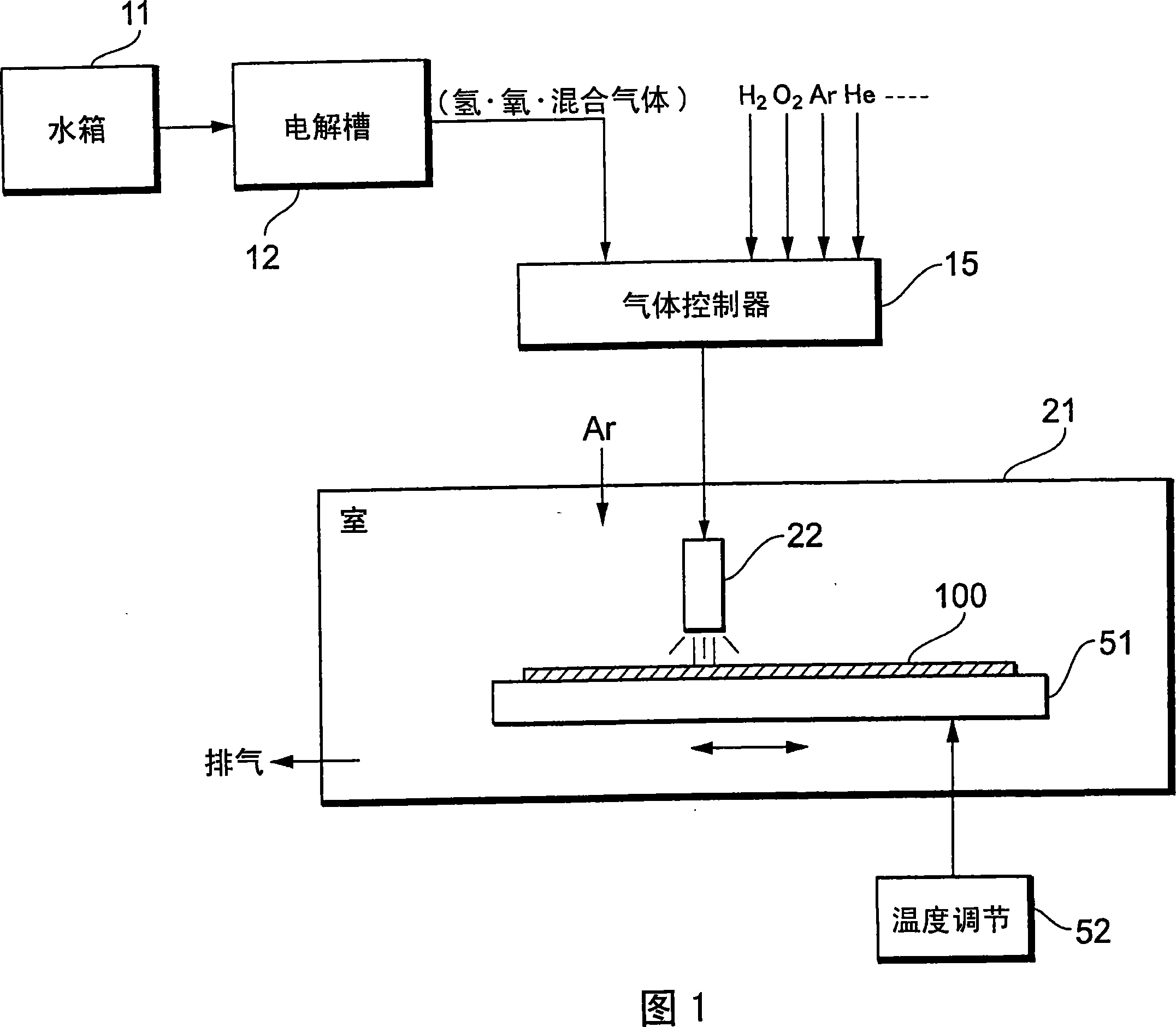

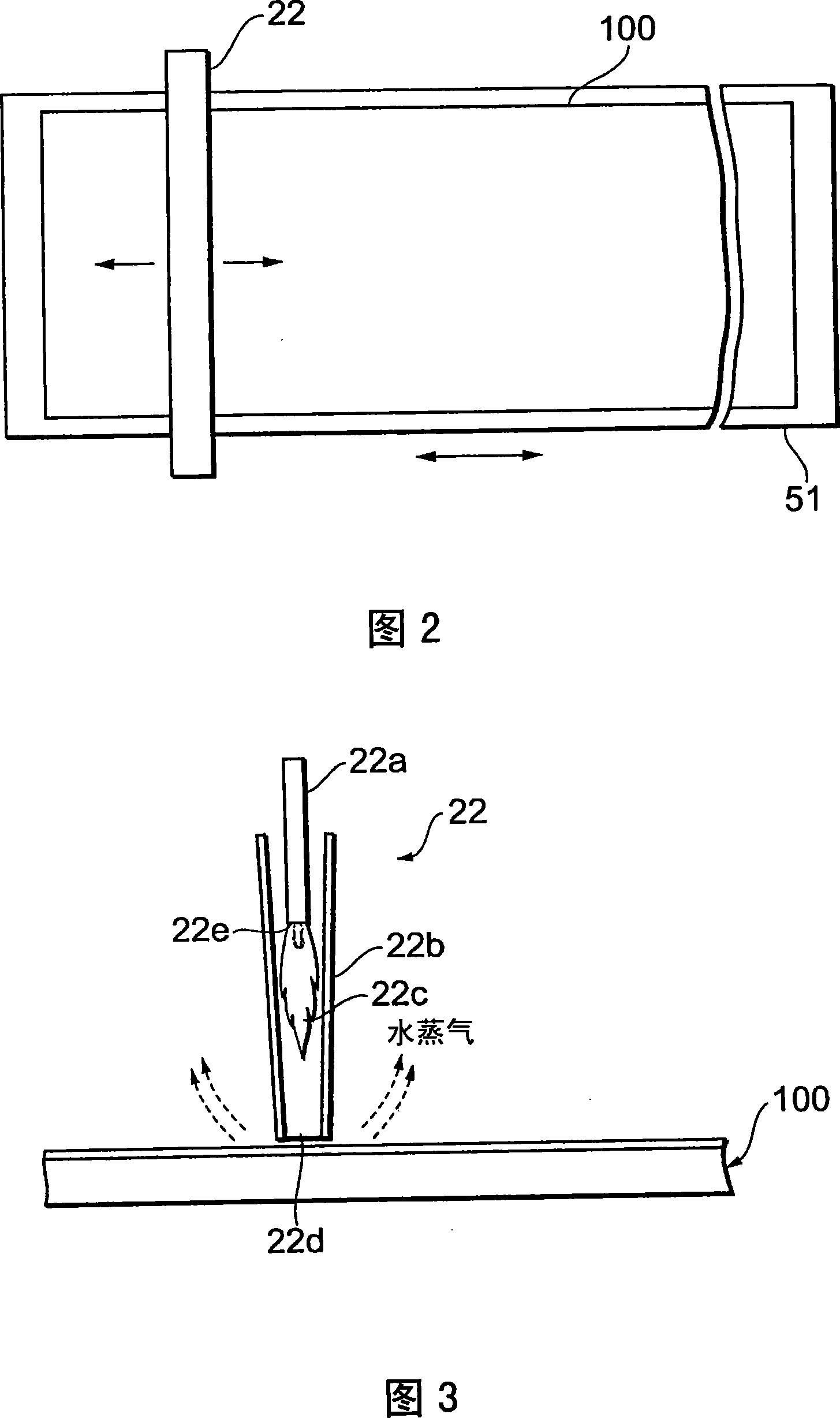

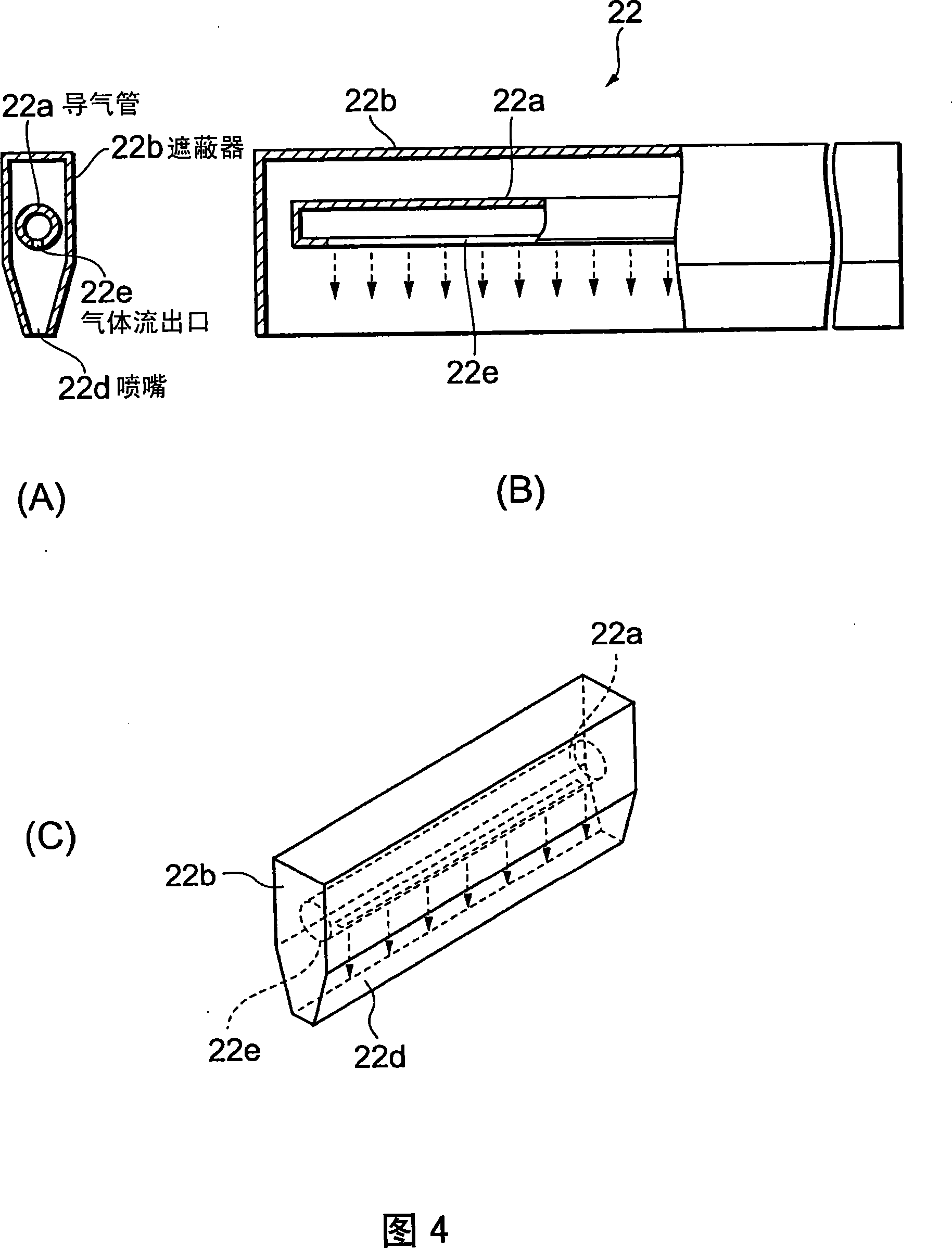

Method of fabricating semiconductor device and method for fabricating electronic device

InactiveCN101221906AReduced manufacturing methodReduce manufacturing costAfter-treatment detailsSolid-state devicesEngineeringElectron

The invention provides a method for producing a semiconductor device of heat load of a substrate, further providing a method for producing a semiconductor device capable of improving the characteristic of the semiconductor element and a method for producing an electronic apparatus. The method for producing the semiconductor device comprises steps as follows: forming a silicon film on a substrate (100); and recrystallizing the semiconductor film using as a heat source flame of a gas burner that uses hydrogen and oxygen gas mixture as a fuel. The treatment of the flame can reduce the heat load to the substrate by increasing the scanning speed of the gas burner corresponding to the substrate, ensuring the solid phase crystal with little deviation of the crystal grain diameter in recrystallization of the silicon film to grow, and improving the characteristic of the semiconductor element.

Owner:SEIKO EPSON CORP

Transistor, display device, electronic device and fabrication method of transistor

InactiveCN102110715BSmall characteristic deviationReduced manufacturing methodSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

An electric-field blocking film is provided between a BL insulation film and BL insulation film of a transistor, and a blocking film includes those three layers. The electric-field blocking film blocks an electric field produced by a drain electrode, a source electrode, and an n+-Si film. Even if misalignment of the drain electrode, the source electrode, and the n+-Si film in each drive transistor varies to make a portion overlying an i-Si film larger, therefore, the electric field at this portion is blocked by the electric-field blocking film, thereby making a variation in characteristic smaller.

Owner:SOLAS OLED LTD

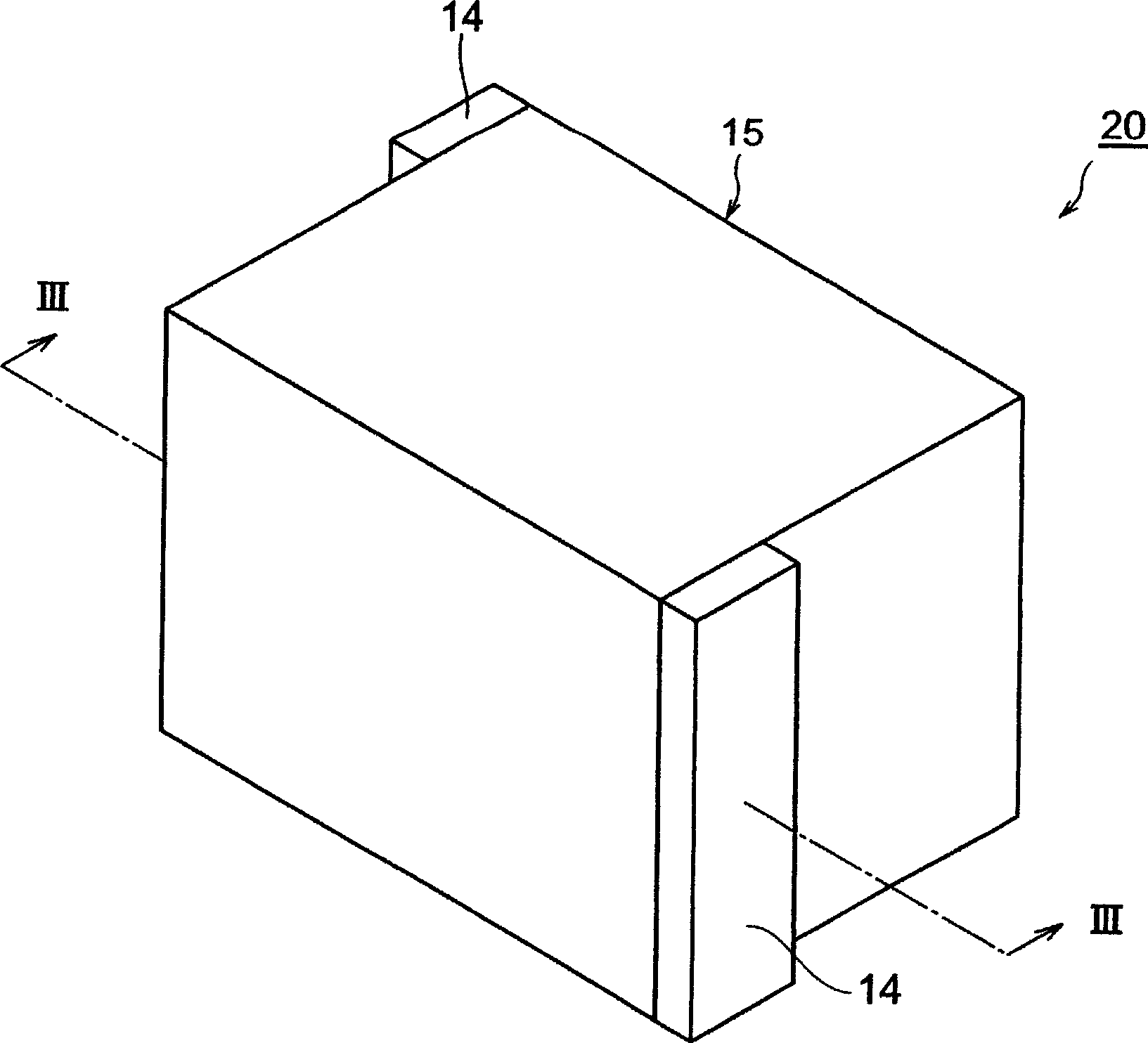

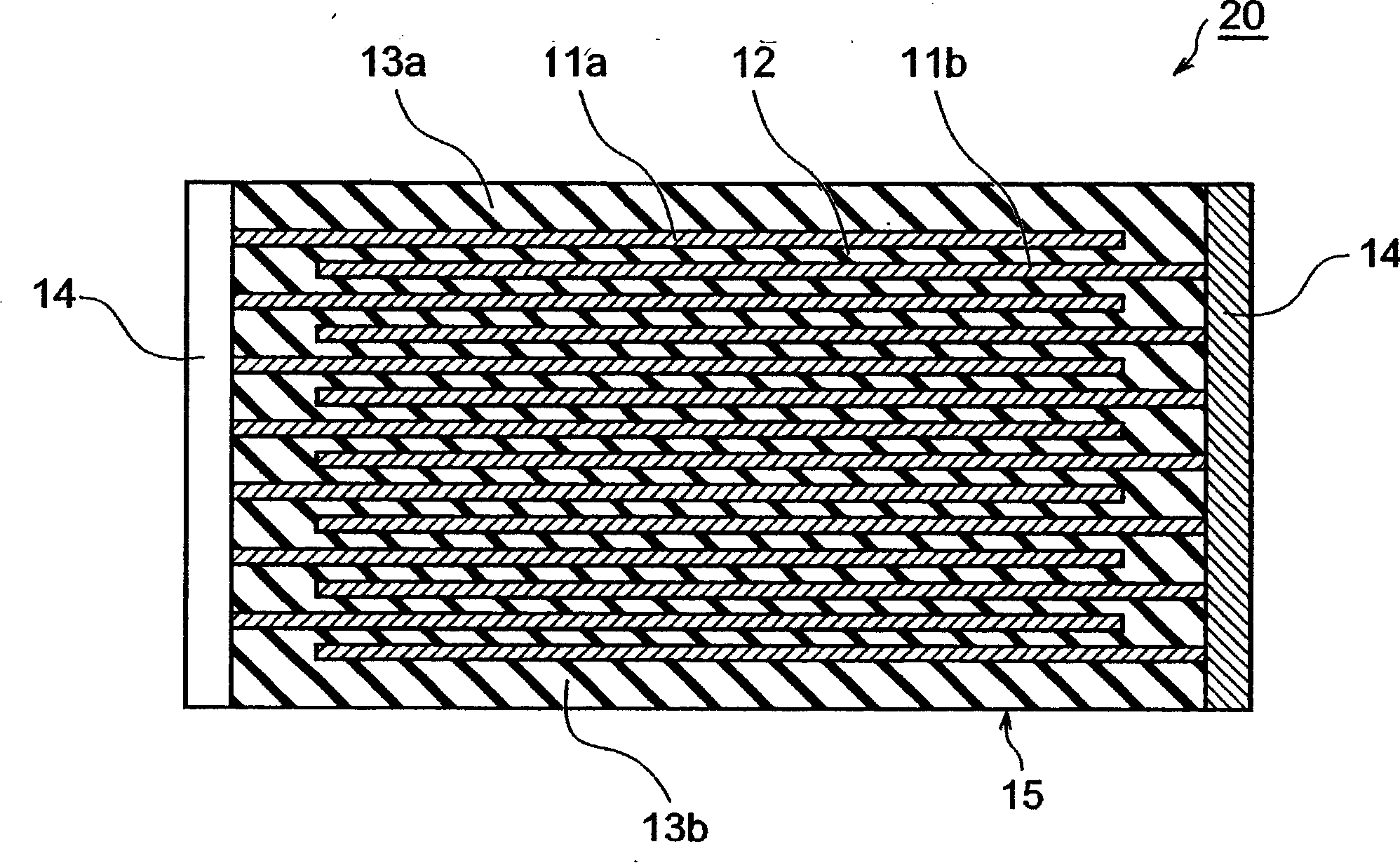

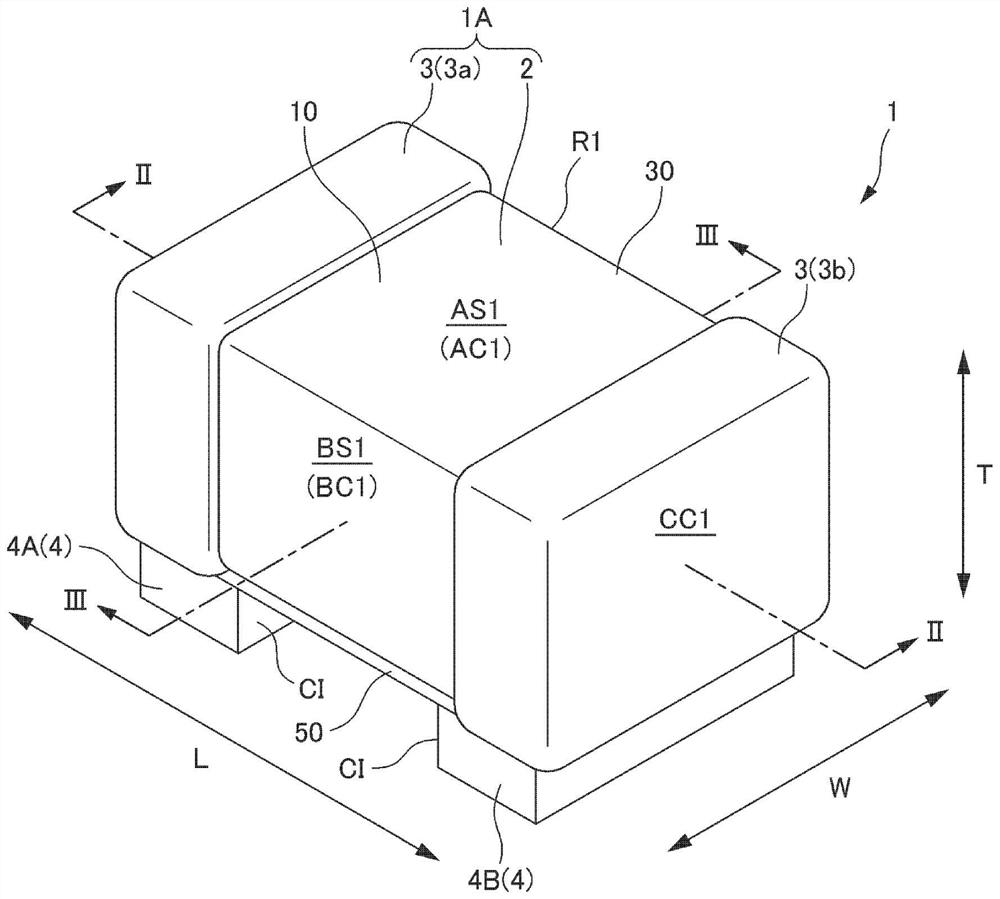

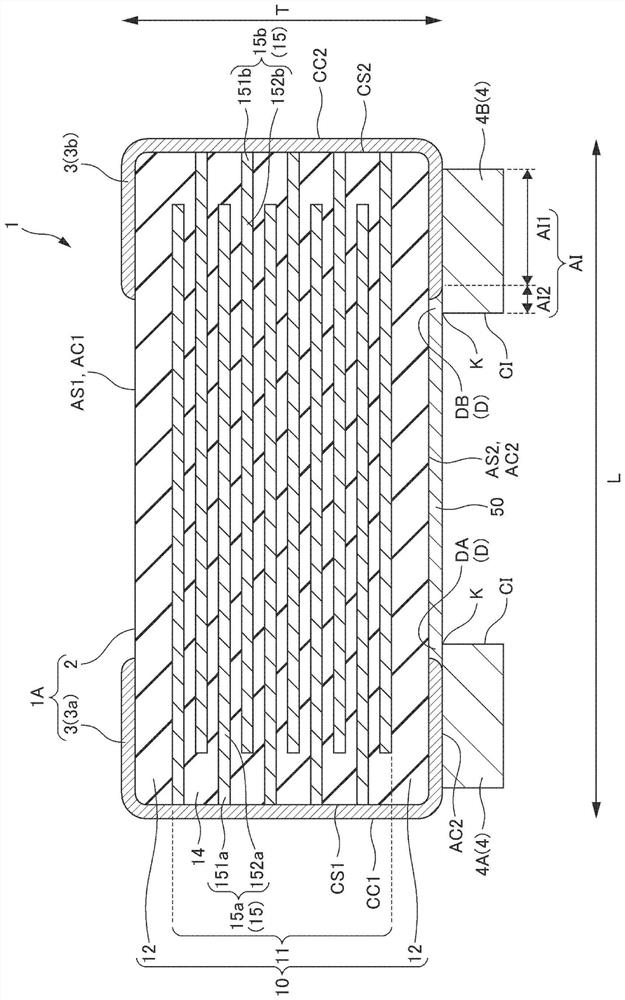

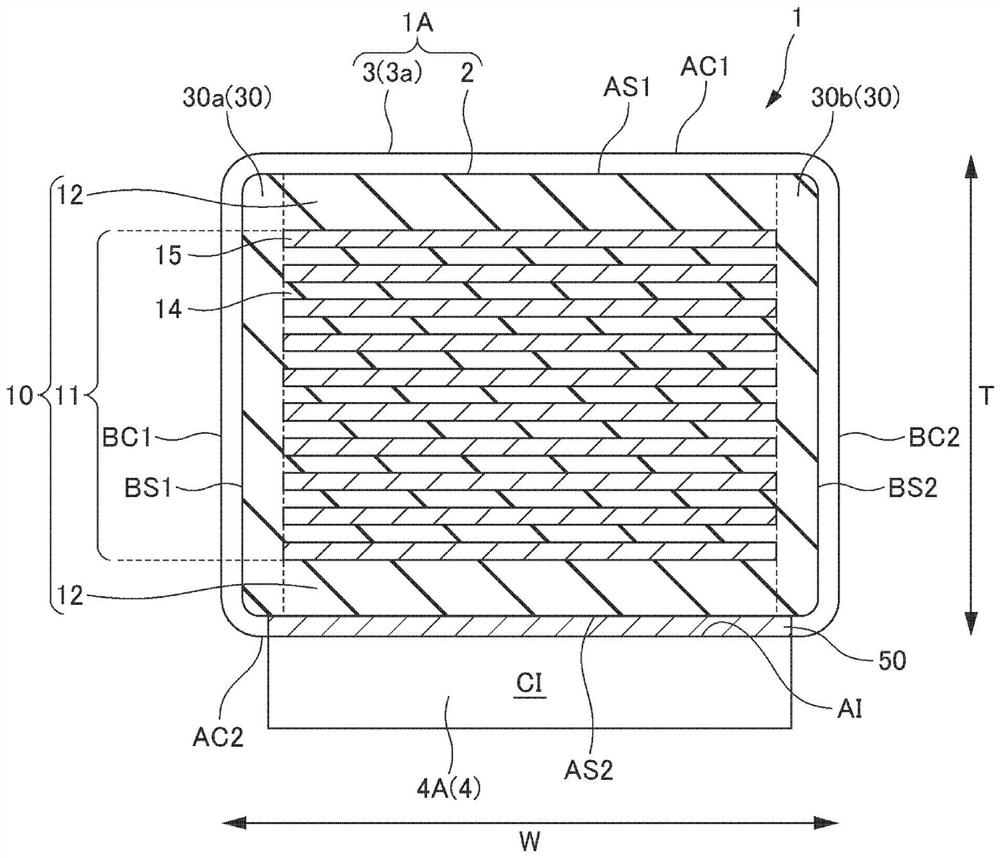

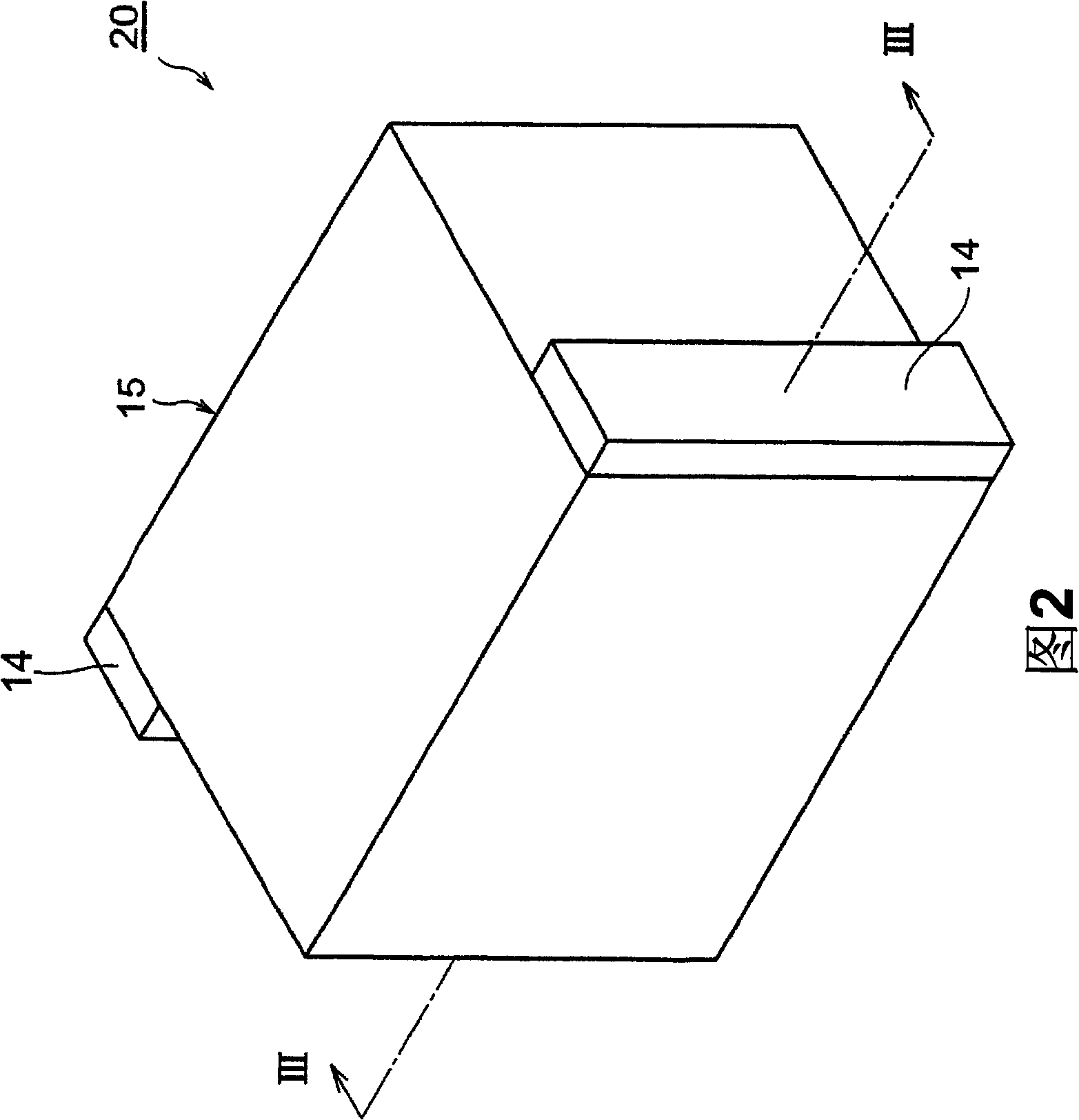

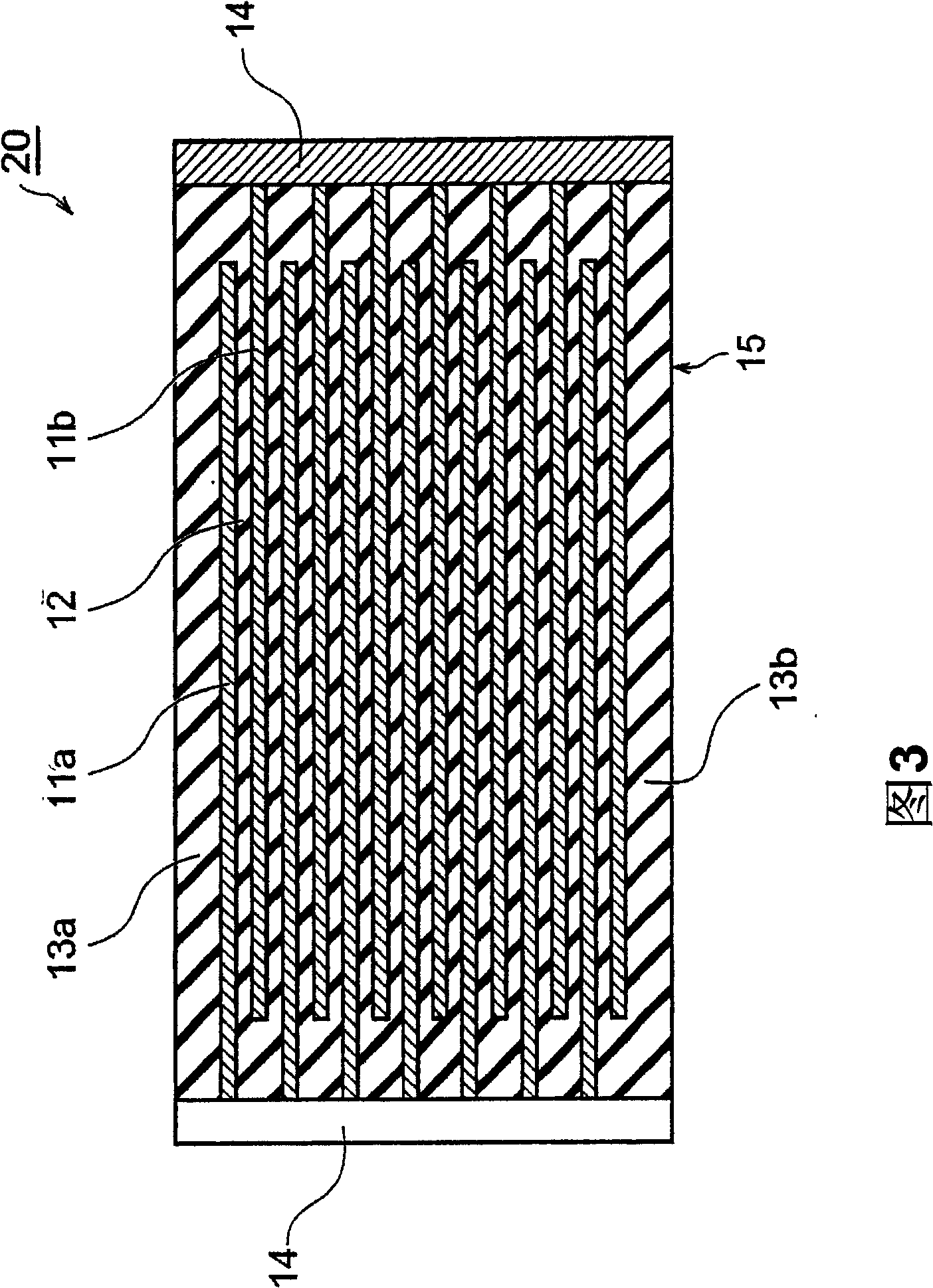

Multilayer ceramic capacitor and method for manufacturing multilayer ceramic capacitor

PendingCN114664566AReduced manufacturing methodFixed capacitor electrodesFixed capacitor dielectricCeramic capacitorInterposer

The invention provides a laminated ceramic capacitor and a method for manufacturing the laminated ceramic capacitor, which can reduce stress concentration on a capacitor main body caused by contact with an interposer. A multilayer ceramic capacitor (1) according to the present invention is provided with: a capacitor body (1A) having a multilayer body (2) in which dielectric layers (14) and internal electrode layers (15) are alternately laminated, and external electrodes (3) that are respectively arranged on both end surfaces of the multilayer body (2) and are connected to the internal electrode layers (15); an interposer (4) disposed on a substrate mounting side surface (AC2) of the capacitor body (1A); and an insulating resin film (50) disposed in a gap between the substrate mounting side surface (AC2) and a capacitor facing surface (AI) of the interposer (4), the capacitor facing surface (AI) facing the substrate mounting side surface (AC2).

Owner:MURATA MFG CO LTD

Manufacture method of simple metal clips

The present invention relates to a production method of simple metal clip, and is characterized by using a base plate and adopting the following steps: defining hole, cutting edge, forming unit sheet, folding lip, warping, forming elastic portion, bending, closing-in and cutting so as to obtain the invented integrally-formed simple clip. It can reduce working time, and can raise production efficiency.

Owner:陈许丽娜

Manufacturing method of electrode for solid state battery

ActiveCN110783518BReduced manufacturing methodElectrode rolling/calenderingElectrode collector coatingPhysical chemistryEngineering

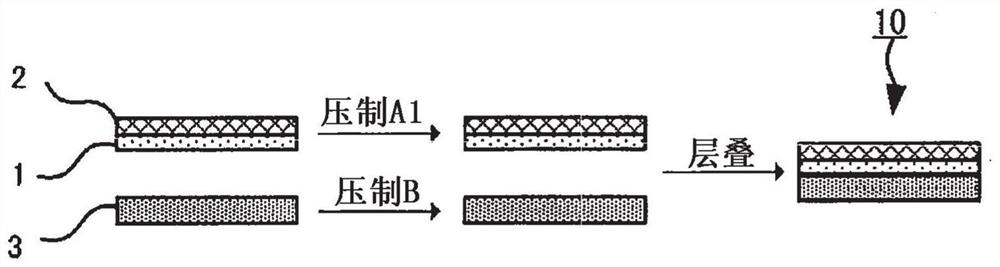

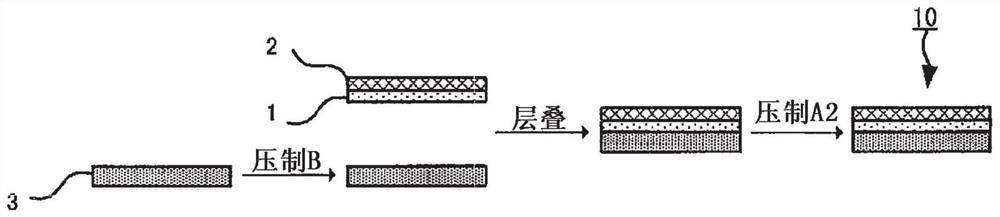

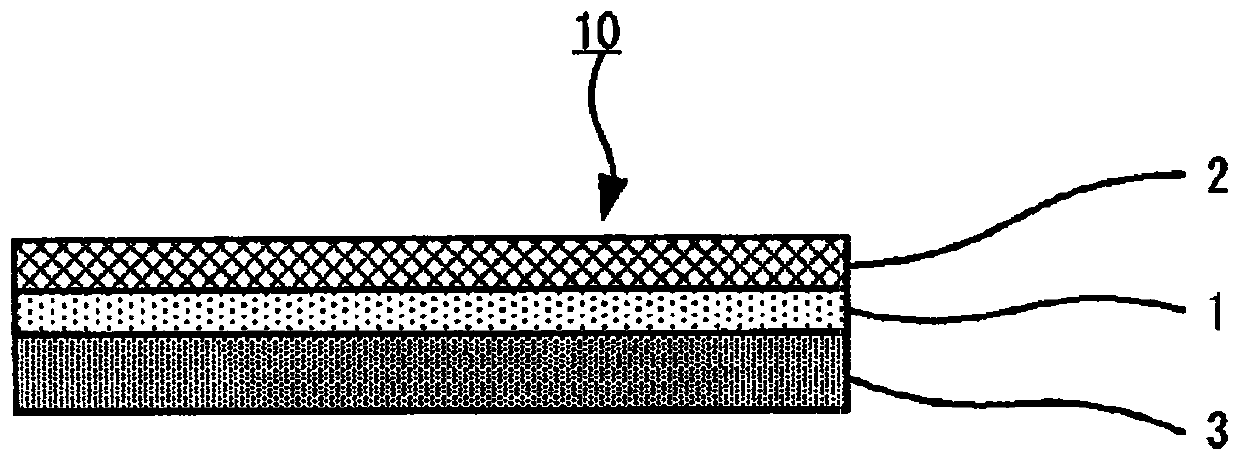

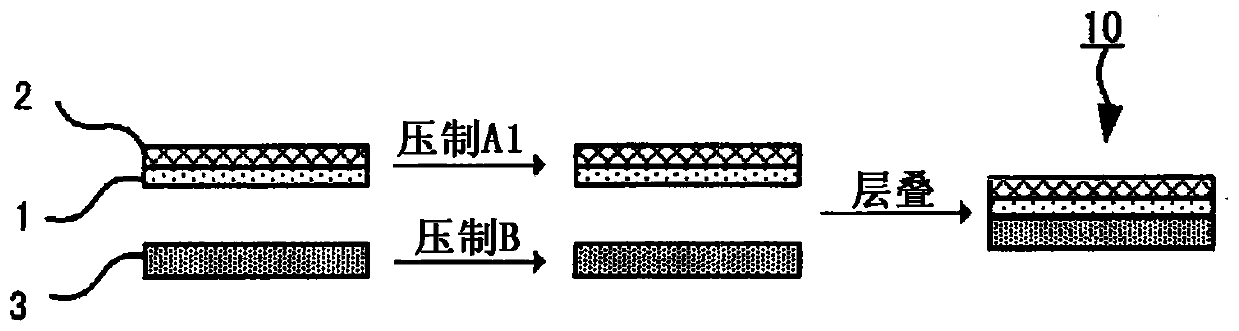

The present invention relates to a method for producing an electrode for a solid state battery. The manufacturing method includes: coating a slurry containing a conductive material and a polymer on at least one surface of the current collector, followed by drying to form a PTC resistor layer; Pressing process A1 in which the current collector is pressed with a maximum pressure of a1; pressing process B in which the electrode active material member having at least the electrode active material layer but not the PTC resistor layer is pressed with a maximum pressure of b and the current collector formed with the PTC resistor body layer and the electrode active material member are stacked so that the PTC resistor body layer is in contact with the electrode active material layer, thereby obtaining a solid-state battery electrode process, in Each maximum pressure applied in the pressing process B and the pressing process A1 satisfies the following relationship: b>a1.

Owner:TOYOTA JIDOSHA KK

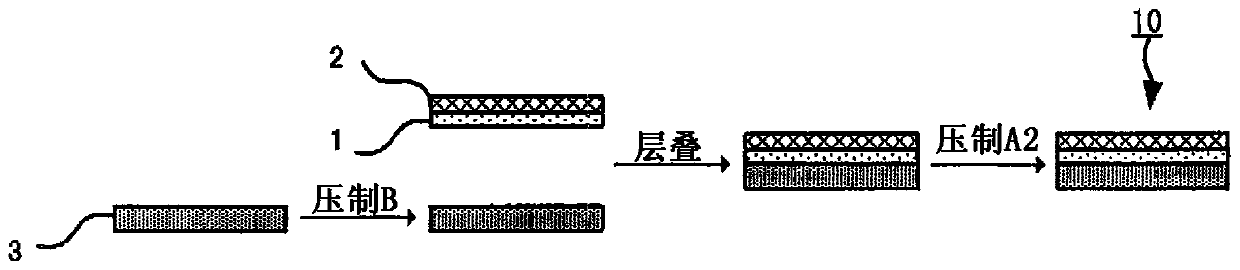

Method for producing electrode for solid-state batteries

ActiveCN110783518AReduced manufacturing methodElectrode rolling/calenderingElectrode collector coatingElectrical batteryPhysical chemistry

The invention relates to a method for producing an electrode for solid-state batteries, which comprises a step of forming a PTC resistor layer by applying a slurry containing an electroconductive material and a polymer to at least one of both surfaces of a current collector and drying the applied slurry; a step of pressing the current collector on which the PTC resistor layer is formed, at a maximum pressure a1 (pressing A1); a step of pressing an electrode active material member comprising at least the electrode active material layer and excluding the PTC resistor layer, at a maximum pressureb (pressing B); and a step of obtaining the electrode for solid-state batteries by laminating the current collector on which the PTC resistor layer is formed and the electrode active material memberso that the PTC resistor layer and the electrode active material layer are in contact with each other, wherein the maximum pressure applied in the pressing B and the maximum pressure applied in the pressing A1 satisfy the following relation: b>a1.

Owner:TOYOTA JIDOSHA KK

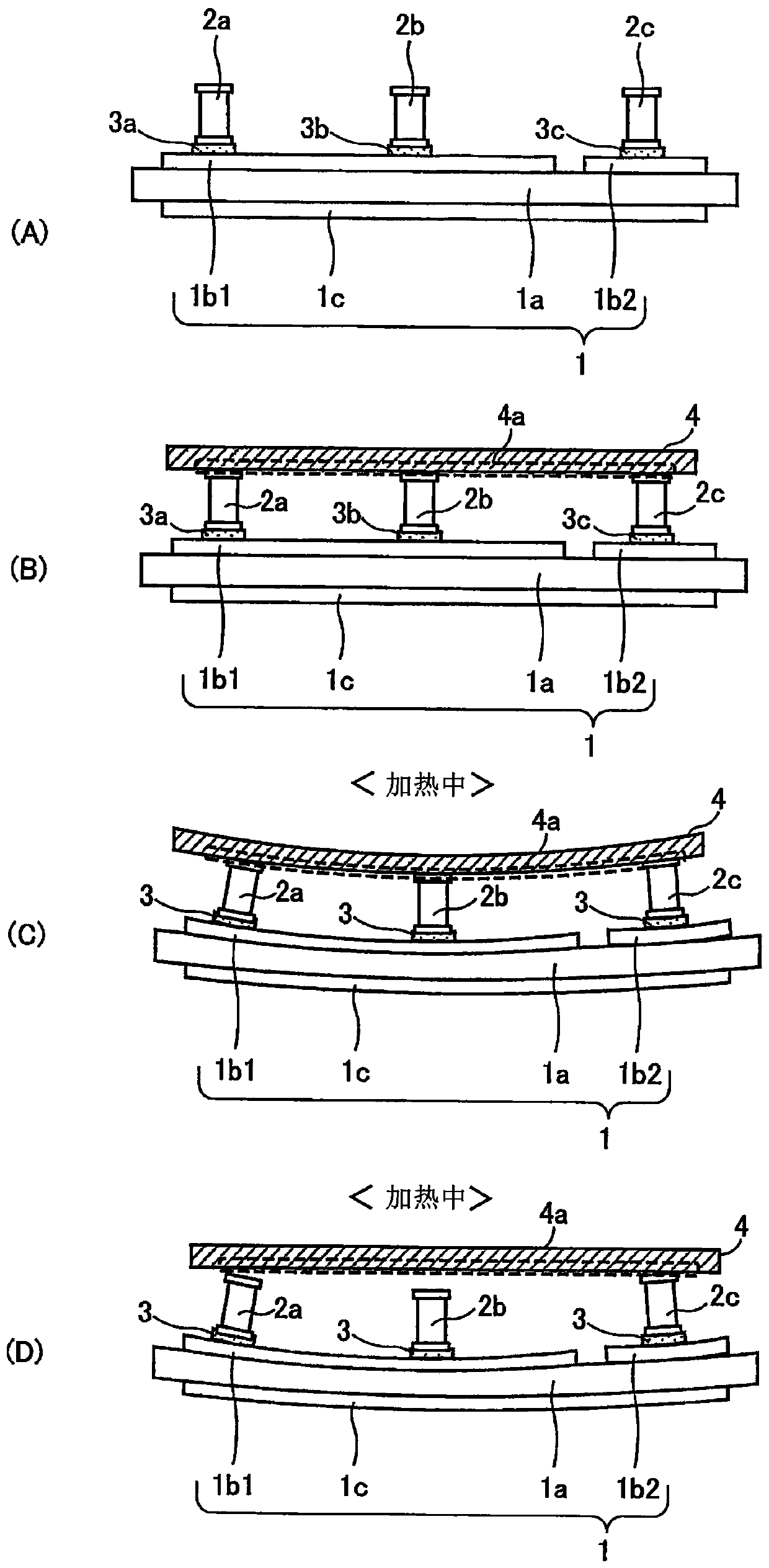

Semiconductor device manufacturing method

PendingCN111584474AReliable jointReduce qualityFinal product manufactureSemiconductor/solid-state device detailsDevice materialMechanical engineering

The invention provides a method of manufacturing a semiconductor device. A contact member can be reliably joined. A pressing region (4a) set on the main surface of a flat-plate-shaped pressing tool (4) is disposed on contact members (2a-2c). Then, while heating, the pressing region (4a) of the pressing tool (4) is tilted in accordance with warpage occurring in a laminated substrate (1), and the contact members (2a-2c) are pressed toward the laminated substrate (1). As a result, when pressing is performed for bonding the contact members (2a-2c), the contact members (2a-2c) can be reliably pressed against the laminated substrate (1) even if warpage occurs in the laminated substrate (1) due to heating and the positions of the contact members (2a-2c) are shifted.

Owner:FUJI ELECTRIC CO LTD

Transistor, display device, electronic device and fabrication method of transistor

InactiveCN102110715ASmall characteristic deviationReduced manufacturing methodSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

The invention provides a transistor with a reduced characteristic deviation. An electric field shielding electrode (54) is disposed between a BL insulating film (53) of a transistor and a BL insulating film (55), and a barrier film (58) is composed of the three layers. The electric field shielding electrode (54) shields the electric field of a drain electrode (T1d), a source electrode (T1s) and a n+-Si film (56). Therefore, in various driven transistors, even if the alignment dislocation of the drain electrode (T1d), the source electrode (T1s) and the n+-Si film (56) is deviated and the overlapping part with an i-Si film (52) is enlarged, the electric field of the part is shielded by the electric field shielding electrode (54), and the characteristic deviation is reduced.

Owner:SOLAS OLED LTD

Method for manufacturing thermoelectric conversion element, and thermoelectric conversion element

ActiveCN105960716AAvoid preparation methodReduced thermoelectric propertiesThermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentMetallurgyMetal powder

A method for manufacturing a thermoelectric conversion element includes: a holding step of holding at least one thermoelectric conversion member (2, 3) while at least one end of the thermoelectric conversion member is exposed; a coating step of coating the exposed end of the thermoelectric conversion member with metal powder (13); and an electrode forming step of forming an electrode (4a) at the end of the thermoelectric conversion member by sintering the metal powder.

Owner:ATSUMITEC CO LTD

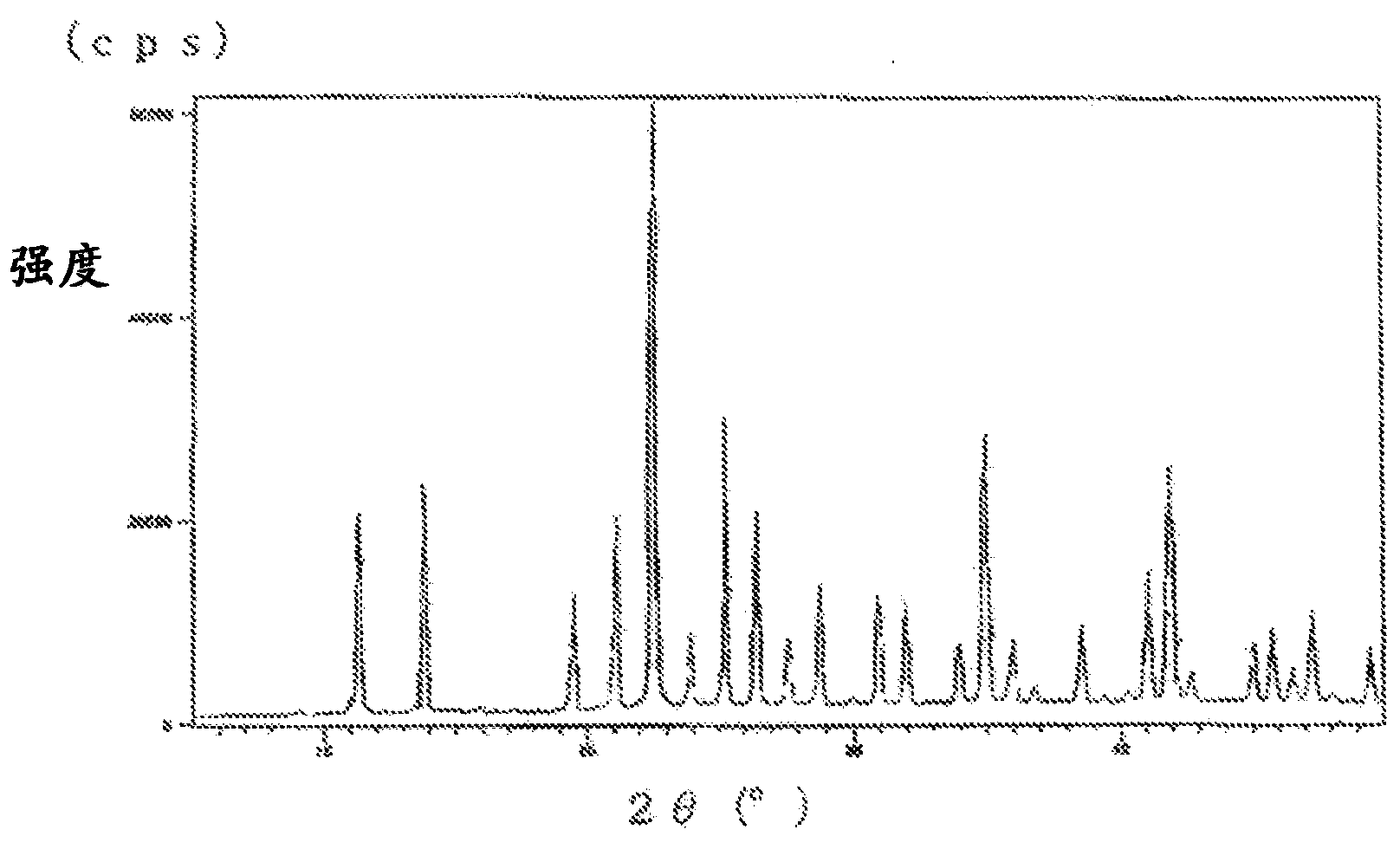

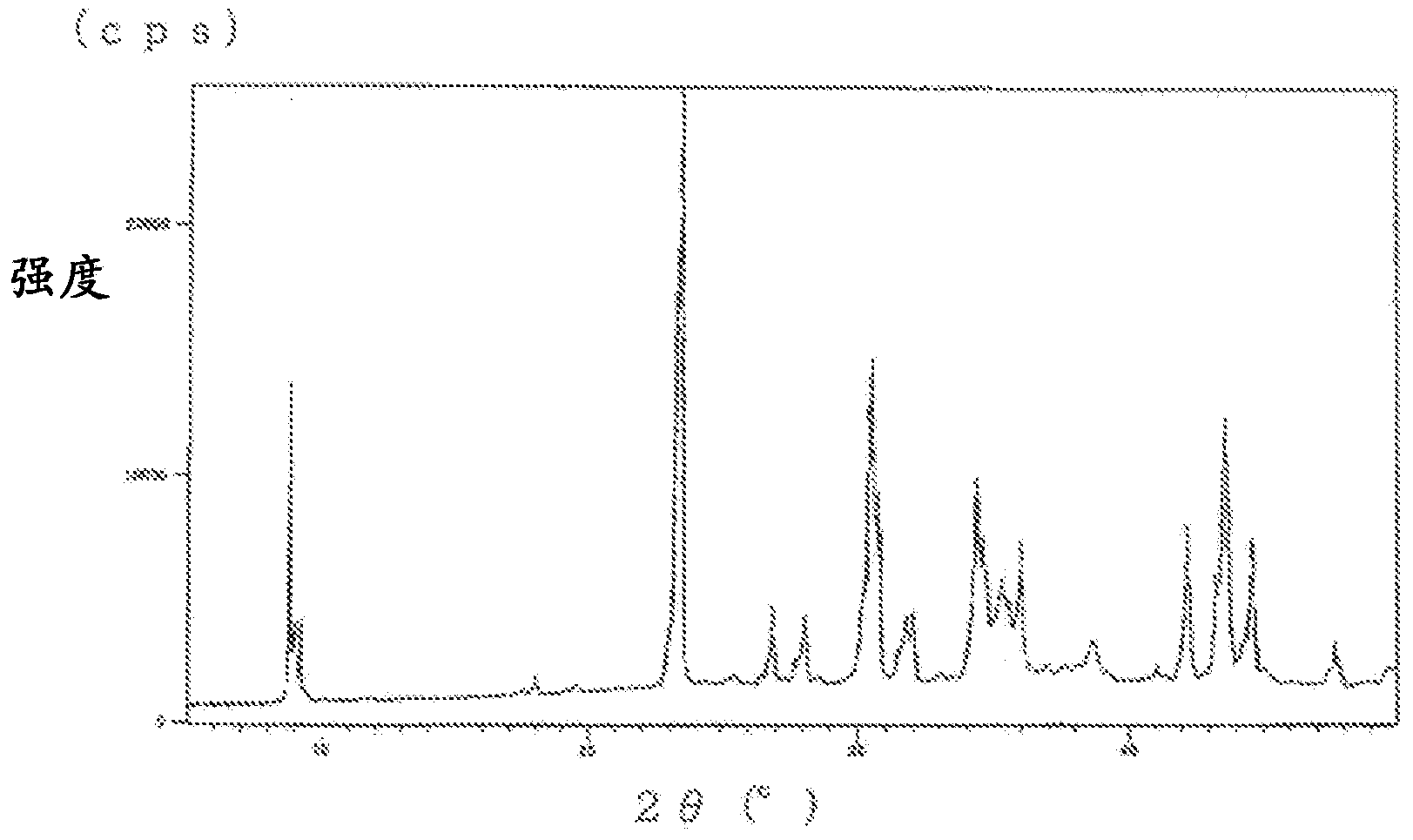

Piezoelectric ceramic, piezoelectric element, and manufacturing method thereof

ActiveCN100440563CLower firing temperatureReduced manufacturing methodPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostrictive devicesCeramicBurns temperature

The objective of the invention is to provide a method for producing a piezoelectric ceramic and a piezoelectric element where their burning temperatures can be sufficiently lowered without adding an additive or the like, a method for lowering burning temperature at a burning step in piezoelectric ceramic production and the piezoelectric element which can be obtained by the methods. The method for producing the piezoelectric ceramic comprises a mixing step to prepare a powdery raw material mixture being mixed with a raw material containing Pb, Zr and Ti and a burning step to burn the raw material mixture. The raw material mixture being satisfied with the following equations denoted as D50<=0.6 [mu]m (1) and D90-D10<=0.4 [mu]m (2) (wherein, D50 is a mean particle diameter; D90 is a 90% cumulation particle diameter; D10 is a 10% cumulation particle diameter) is prepared at the mixing step.

Owner:TDK CORPARATION

Vehicle front structure and method of manufacturing the vehicle

ActiveCN103732453BReduced manufacturing methodAvoid stainsTowing devicesBumpersEngineeringMechanical engineering

Owner:HONDA MOTOR CO LTD

Light guide plate, manufacturing method thereof, surface light source device, and transmissive image display device

InactiveCN103091764BReduced design methodReduced manufacturing methodMechanical apparatusPoint-like light sourceEngineeringBrightness perception

PURPOSE: A manufacturing method of light guide plates is provided to reduce the brightness smudge placing around a light incoming unit in which the light is incoming. CONSTITUTION: A light guide plate member(11) has four sides(S31-S34) intersecting in an exit side(S1), a rear side(S2) of an opposite side of the exit side, and the exit side and the rear side. The four sides S31~S34 are figured by orthogonally crossing the exit side and the rear side. In the rear side of the light guide plate member a plurality of light reflection dot(12) is formed. In order to exit the light of a uniform plane shape from the exit side efficiently, the light reflection dot is small in an incoming light unit side close to a light source(3) and gets bigger as the light reflection dot goes further from the light source. The light reflection dot is formed in a virtual grid regularly arranged in two dimension through a front side of the rear side.

Owner:SUMITOMO CHEM CO LTD +1

Manufacturing method of laminated body

The present invention relates to a method for producing a laminate obtained by chamfering side edge portions of a laminate block having a base plate and a reinforcement plate having a resin layer and a support plate. , the manufacturing method includes a grinding step of grinding the side edge portion of the above-mentioned laminate block with a disc-shaped or cylindrical rotating grindstone, and in the grinding step, the grinding surface of the grindstone is obliquely abutted against At the interface between the aforementioned resin layer and the aforementioned substrate, and at the interface between the aforementioned resin layer and the aforementioned support plate.

Owner:ASAHI GLASS CO LTD

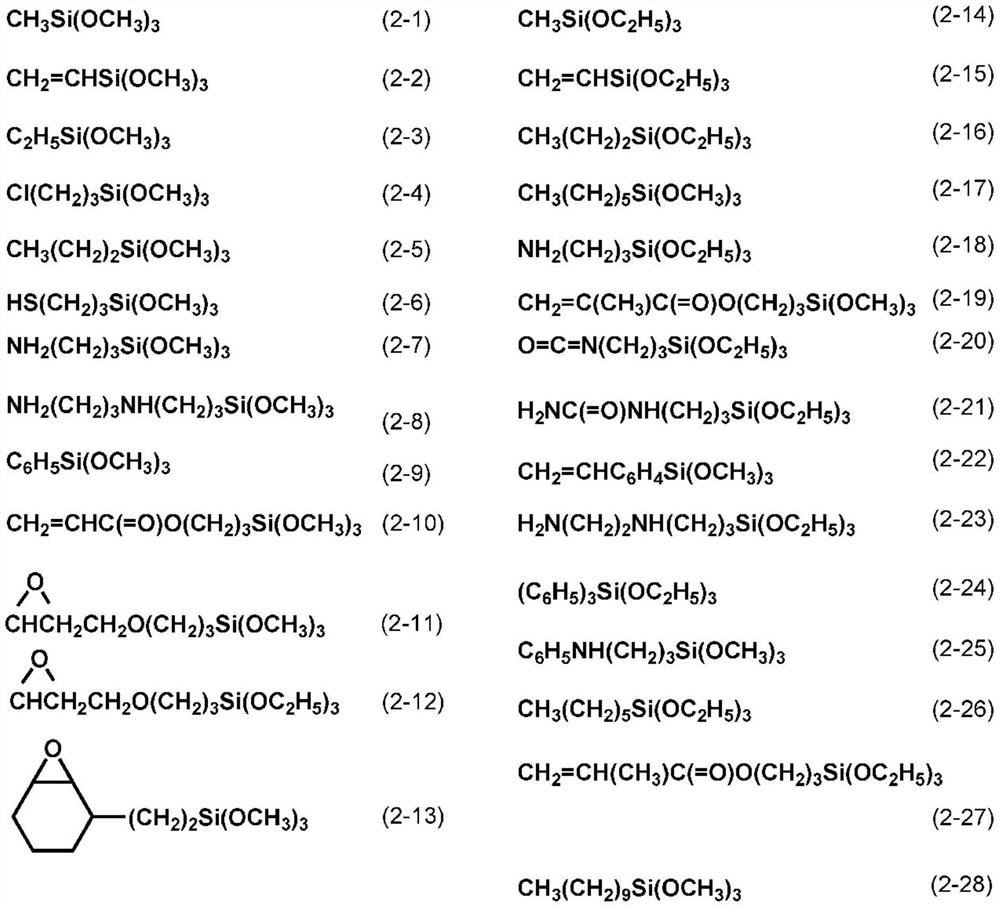

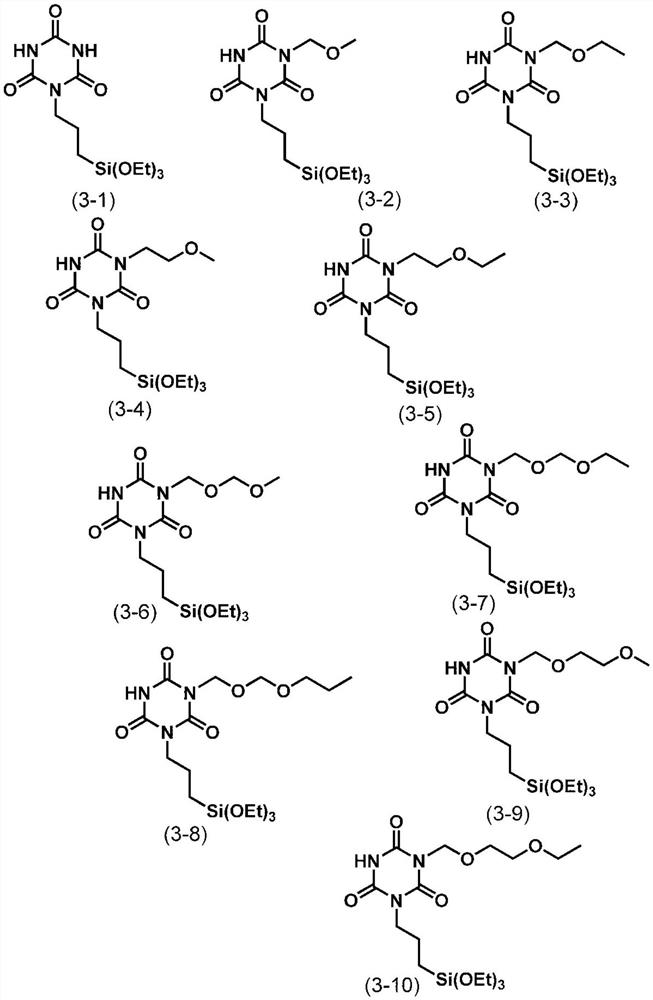

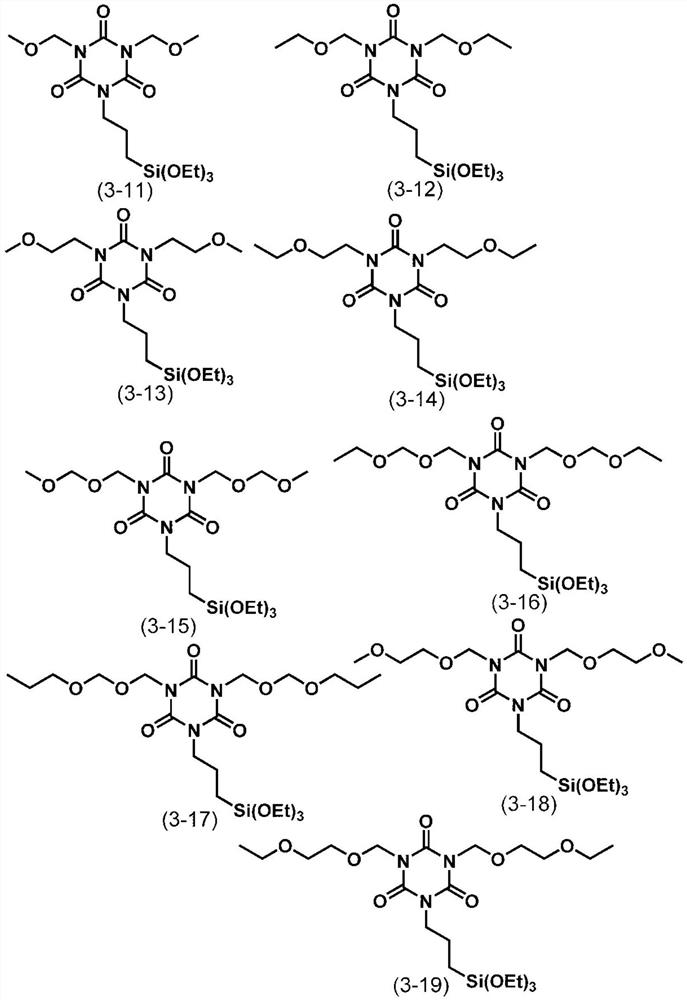

Method for producing silicon-containing polymer composition

PendingCN114341232ALess metal impuritiesAvoid modificationIon-exchange column/bed processesCation exchanger materialsPolymer scienceOrganic solvent

Owner:NISSAN CHEM IND LTD

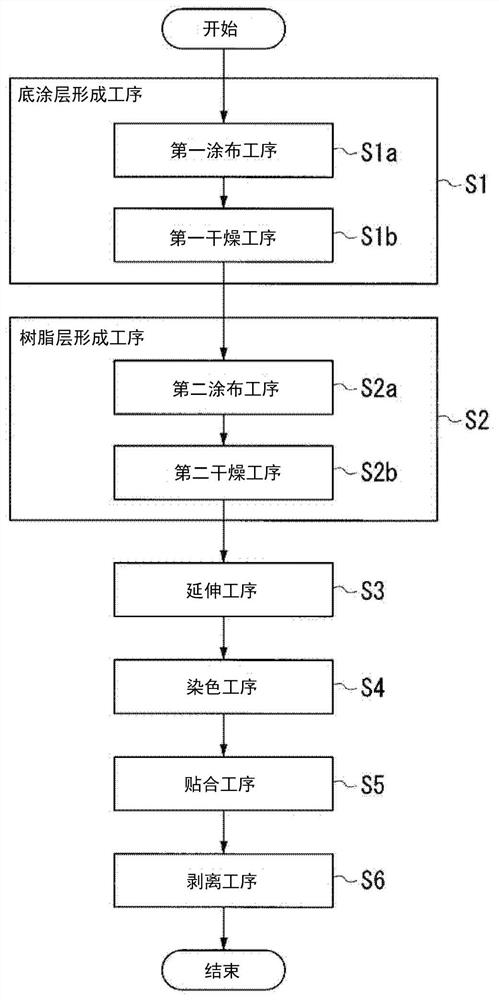

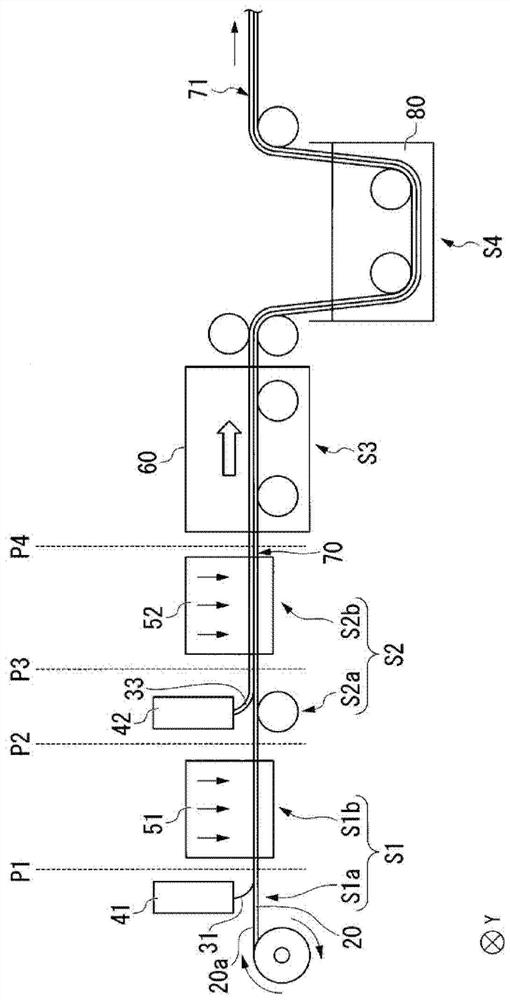

Polarizing plate, polarizing film, and method for manufacturing polarizing plate

The present invention provides a thin polarizing plate having a small thickness distribution, a polarizing film including such a polarizing plate, and a method for producing a polarizing plate. A polarizing plate related to a technical solution of the present invention is a polarizing plate in which a dichroic dye is oriented in a polyvinyl alcohol-based resin, and the polarizing plate is characterized in that the thickness of the polarizing plate is 10 μm or less, and the polarizing plate has a thickness of 10 μm or less. direction, the maximum amplitude of the thickness distribution is 0.4 μm or less.

Owner:SUMITOMO CHEM CO LTD

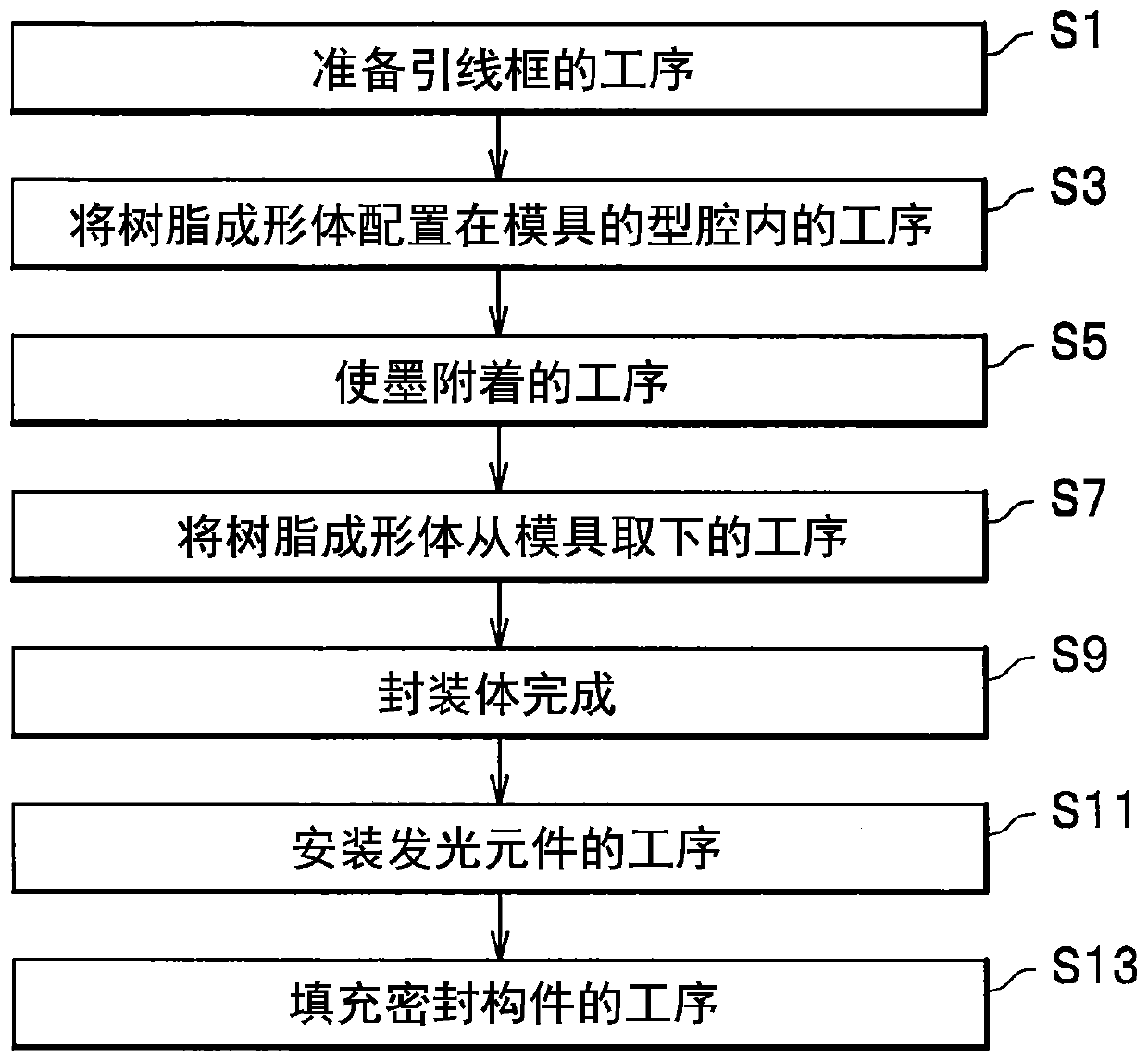

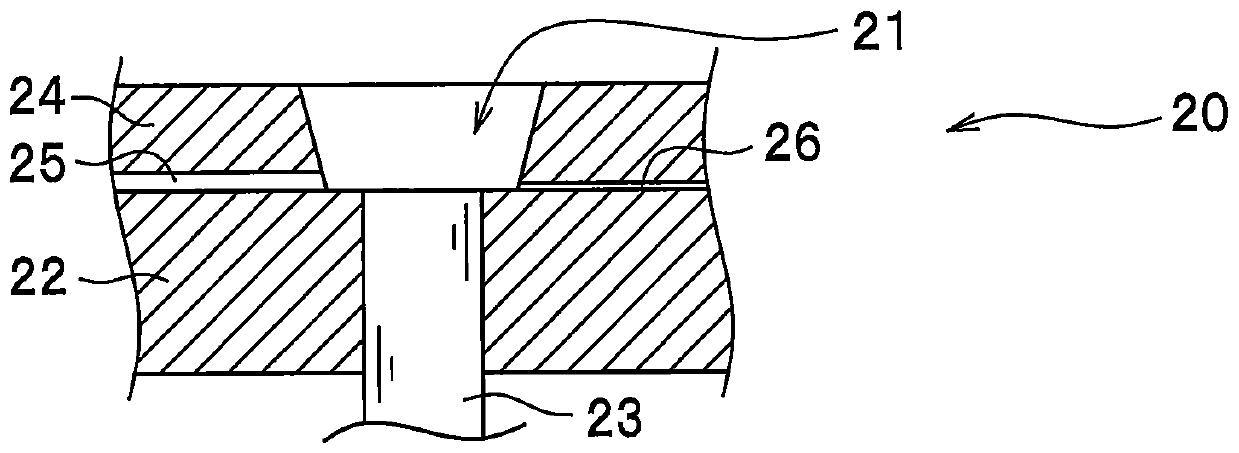

Method of manufacturing package and method of manufacturing light emitting device

PendingCN111128983AReduce manufacturing costReduced manufacturing methodSolid-state devicesSemiconductor devicesDark colorLead frame

Provided are a method for manufacturing a package and a method for manufacturing a light-emitting device, wherein the manufacturing cost is reduced. This method for manufacturing a package includes: apreparation step (S1) for preparing a lead frame provided with a lead and a resin molded body that is integrally molded with the lead and that has a recess for accommodating a light-emitting elementon the upper surface; an arrangement step (S3) in which the resin molded body is arranged in the cavity of the mold in a state in which the inside of the recess of the resin molded body is closed; anadhesion step (S5) in which the cavity is filled with ink having a darker color than the inner surface of the recess, and the ink is adhered to at least a part of the side surface of the resin moldedbody and the upper surface of the resin molded body; and a removal step (S7) in which the resin molded body to which the ink has been adhered is removed from the mold.

Owner:NICHIA CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com