Vehicle front structure and method of manufacturing the vehicle

A manufacturing method and vehicle technology, which can be applied to vehicle parts, bumpers, radiators, etc., can solve the problems of high manufacturing costs, color spots on hook covers, and exposed bottom spraying, and reduce packaging costs, transportation costs, and manufacturing costs. The effect of preventing spraying from revealing the bottom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

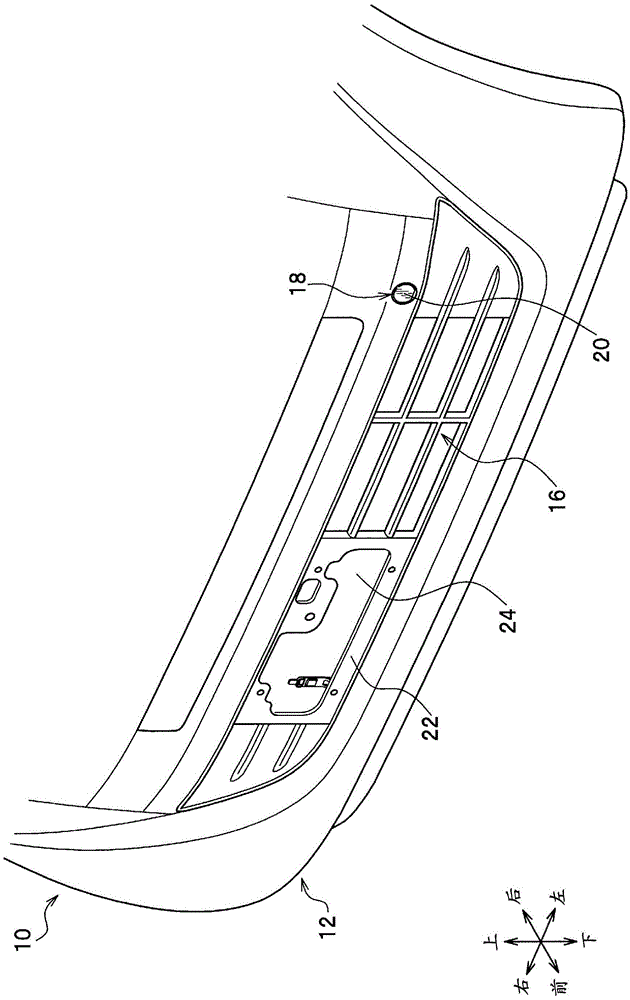

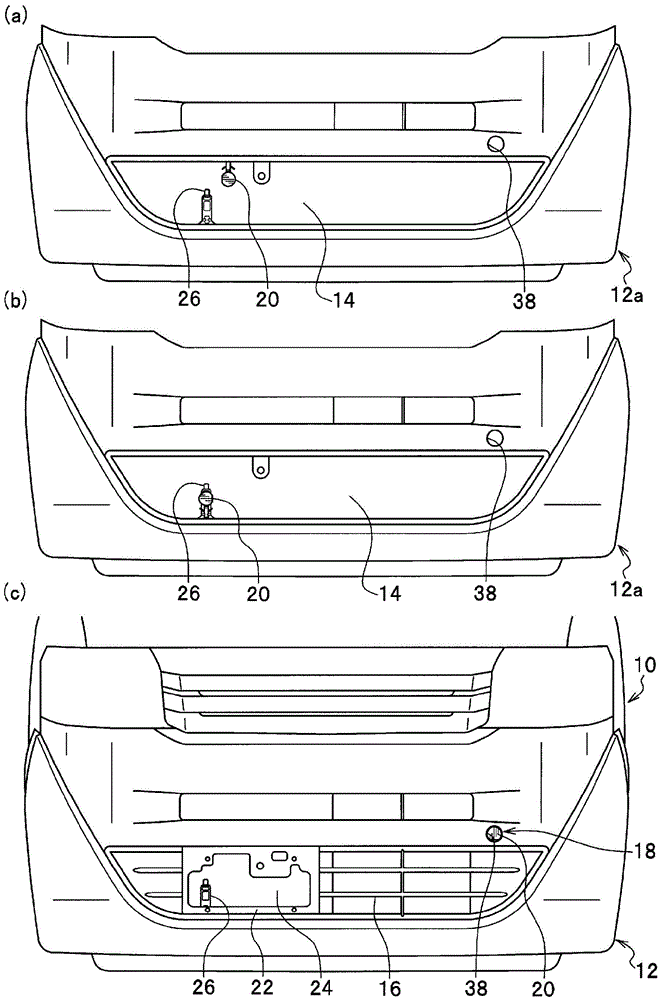

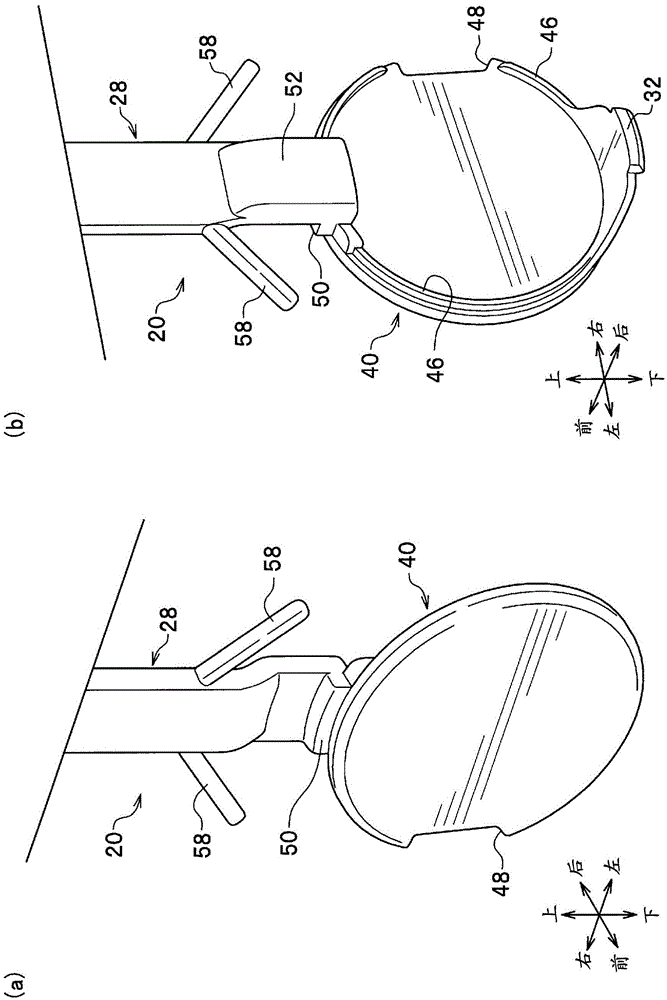

[0040] Next, embodiments of the present invention will be specifically described with reference to appropriate drawings. figure 1 It is a perspective view showing the front portion of a vehicle to which the vehicle front portion structure according to the embodiment of the present invention is applied. In addition, "front and rear" and "up and down" indicated by arrows in each figure indicate the front and rear directions and up and down directions of the vehicle body, and "left and right" indicate the left and right directions viewed from the driver's seat.

[0041] like figure 1 As shown, the vehicle 10 constituted by the finished product is constituted as follows: a bumper face 12 provided at the front end of the vehicle 10; a bumper opening 14 mounted on the bumper face 12 (refer to figure 2 (a), figure 2 (b)) the lower grille member (bumper component) 16 ; and the hook cover 20 attached to the hook cover mounting portion 18 provided on the outer end of the bumper face...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com