Manufacturing method of laminated body

A manufacturing method and laminated body technology, applied in the direction of manufacturing tools, chemical instruments and methods, lamination, etc., can solve problems such as difficulty in using electronic devices, poor operability of substrates, etc., and achieve the effect of reducing defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Hereinafter, modes for carrying out the present invention will be described with reference to the drawings. In each figure, the same or corresponding components are assigned the same or corresponding symbols, and description thereof will be omitted.

[0035] (laminated blocks)

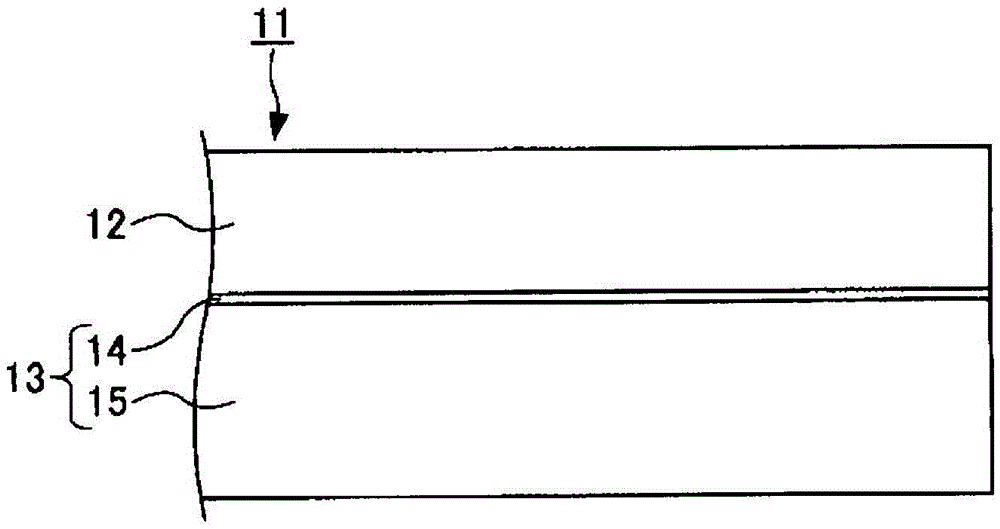

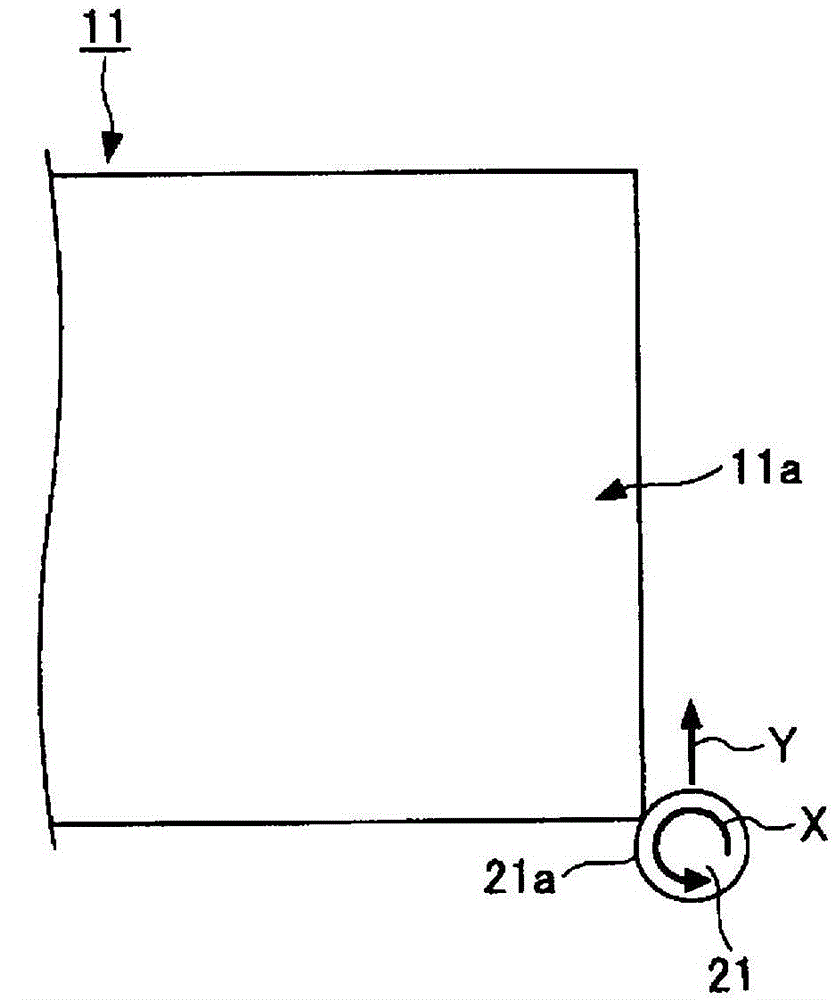

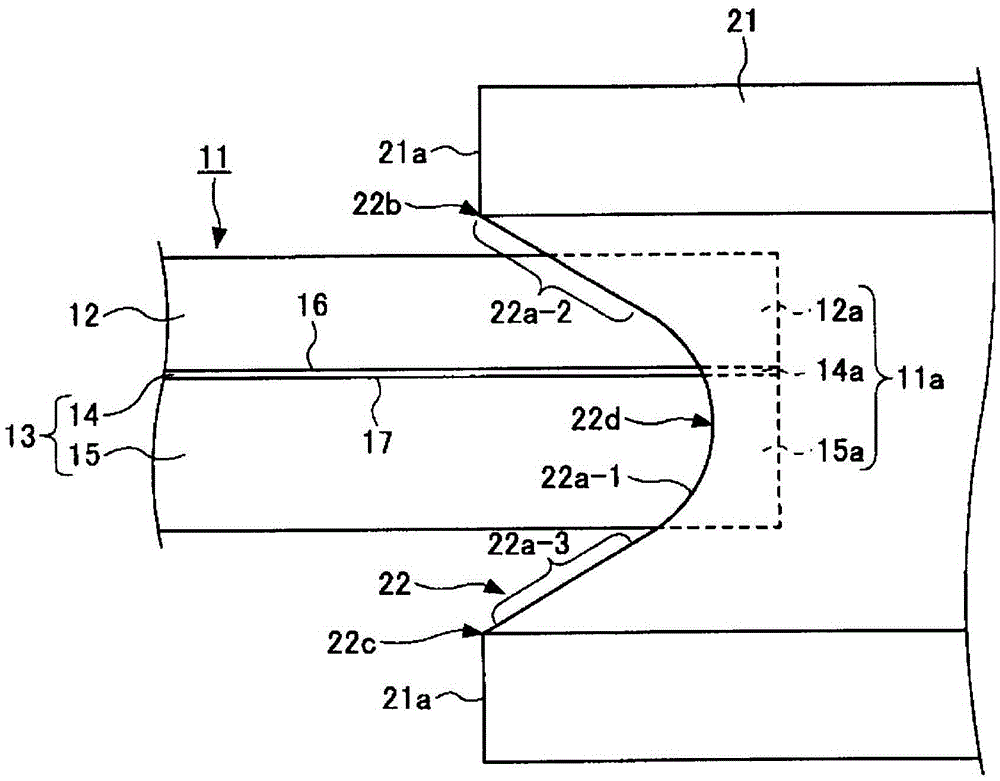

[0036] figure 1 It is a side view of the laminated body block used for the manufacturing method of the laminated body which concerns on one Embodiment of this invention.

[0037] Such as figure 1 As shown, the laminated body block 11 has a base plate 12 and a reinforcing plate 13 for reinforcing the base plate 12 . The reinforcing plate 13 is composed of a resin layer 14 bonded to the substrate 12 in a detachable manner, and a support plate 15 supporting the substrate 12 through the resin layer 14 . The side surface of the substrate 12, the side surface of the resin layer 14, and the side surface of the support plate 15 form one surface.

[0038] The laminate block 11 is used to manufactur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com