Encoder, production method for encoder scale, production method for encoder, and drive device

A manufacturing method and encoder technology, which is applied in the field of encoders, can solve the problems of lower yield, lower precision of pattern making, and obstruction of etching process, etc., and achieve the effect of preventing yield reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

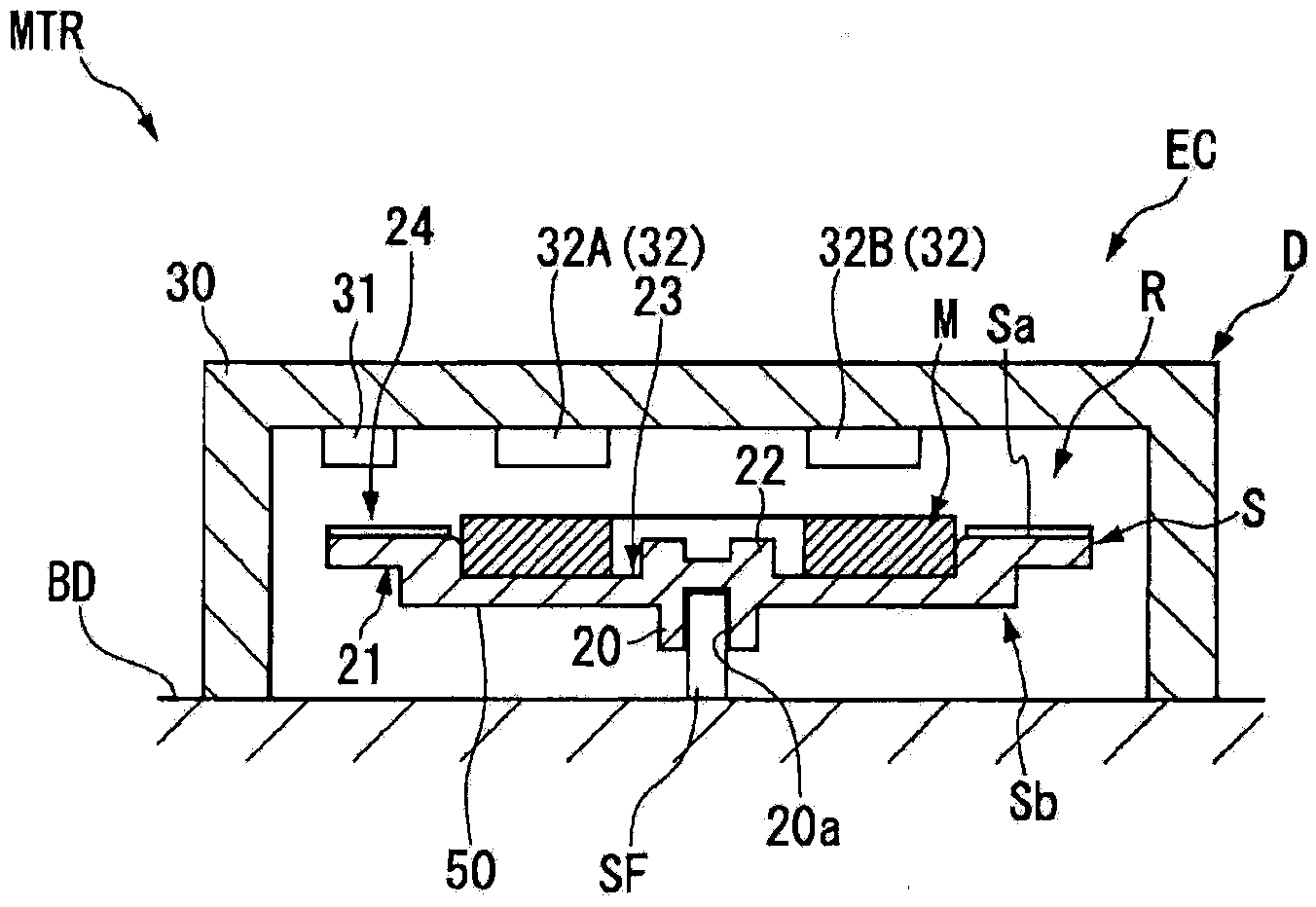

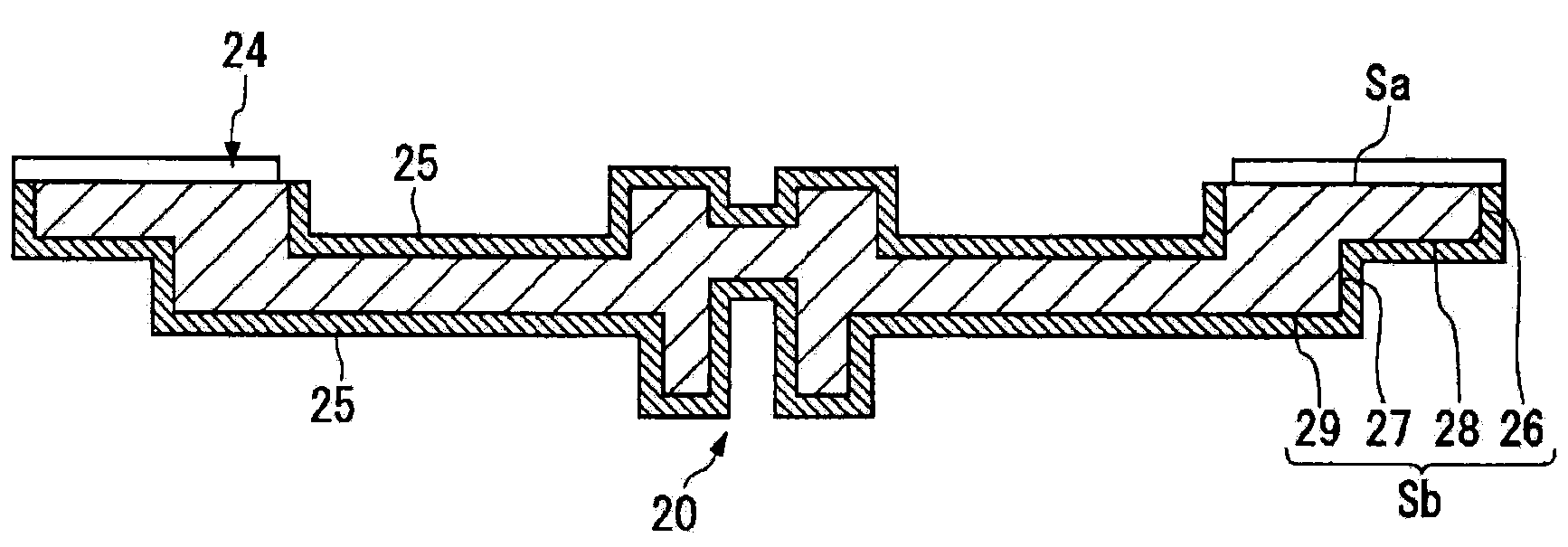

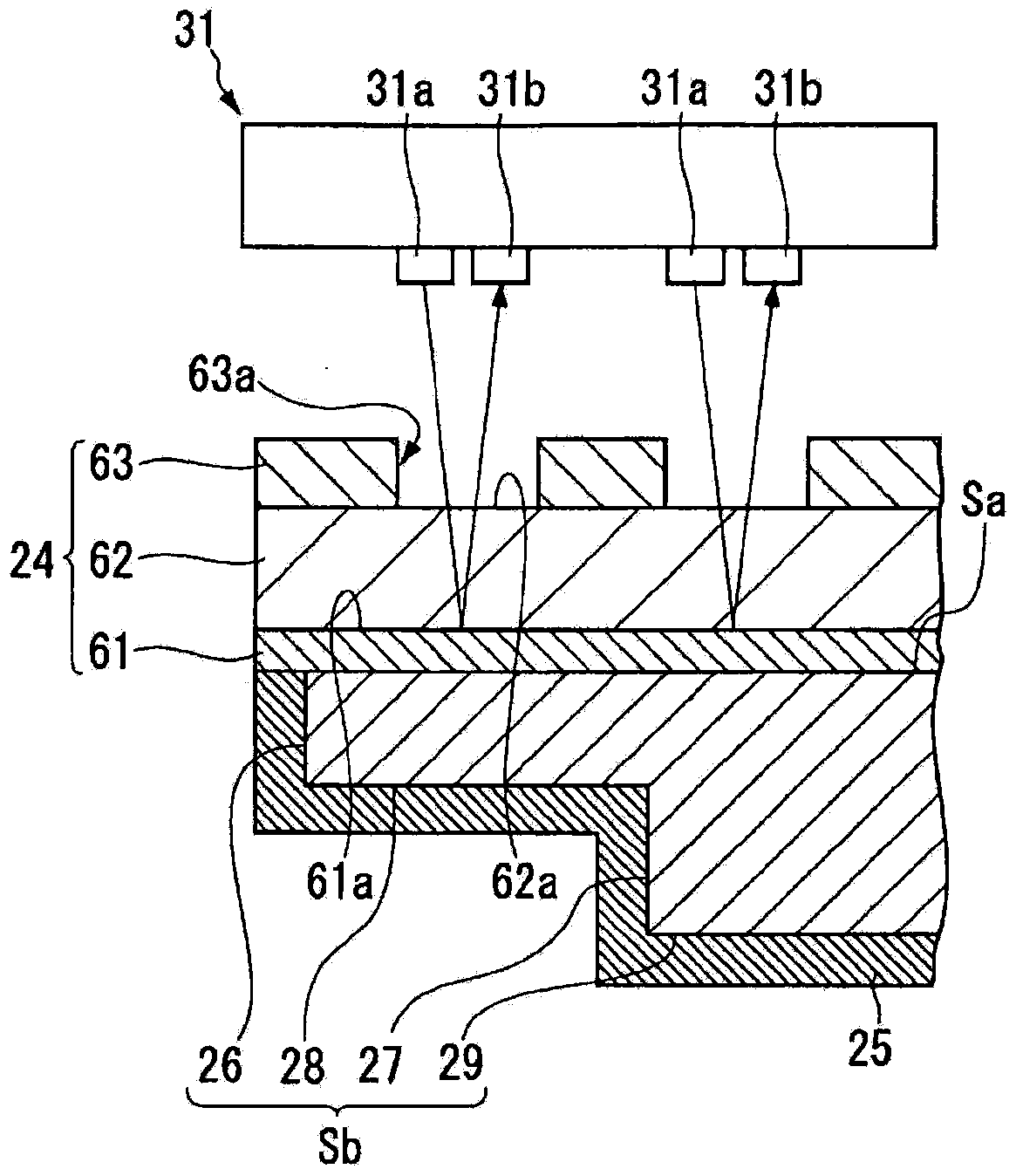

[0029] figure 1 It is a cross-sectional view showing the structure of a motor device MTR as an example of a drive device (measurement object).

[0030] Such as figure 1 As shown, the motor device MTR has: a moving body (rotor), that is, a moving shaft (rotation shaft) SF; a motor body BD that is a drive unit that rotates the rotation shaft SF; and a code for detecting movement information (for example, rotation information) of the rotation shaft SF. device EC. The encoder EC includes a scale portion (rotation portion, scale) R and a detection portion D that moves relatively to the scale portion in order to detect movement information of the moving object. The encoder EC is used in a state where the rotating unit R is accommodated in the casing 30 constituting the detecting unit D. As shown in FIG. In addition, the encoder EC of this embodiment is a structure which t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com