Method of fabricating semiconductor device and method for fabricating electronic device

A manufacturing method and technology of electronic instruments, applied in the field of heat treatment, can solve the problems of high operating cost, high price of manufacturing equipment, difficult substrate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

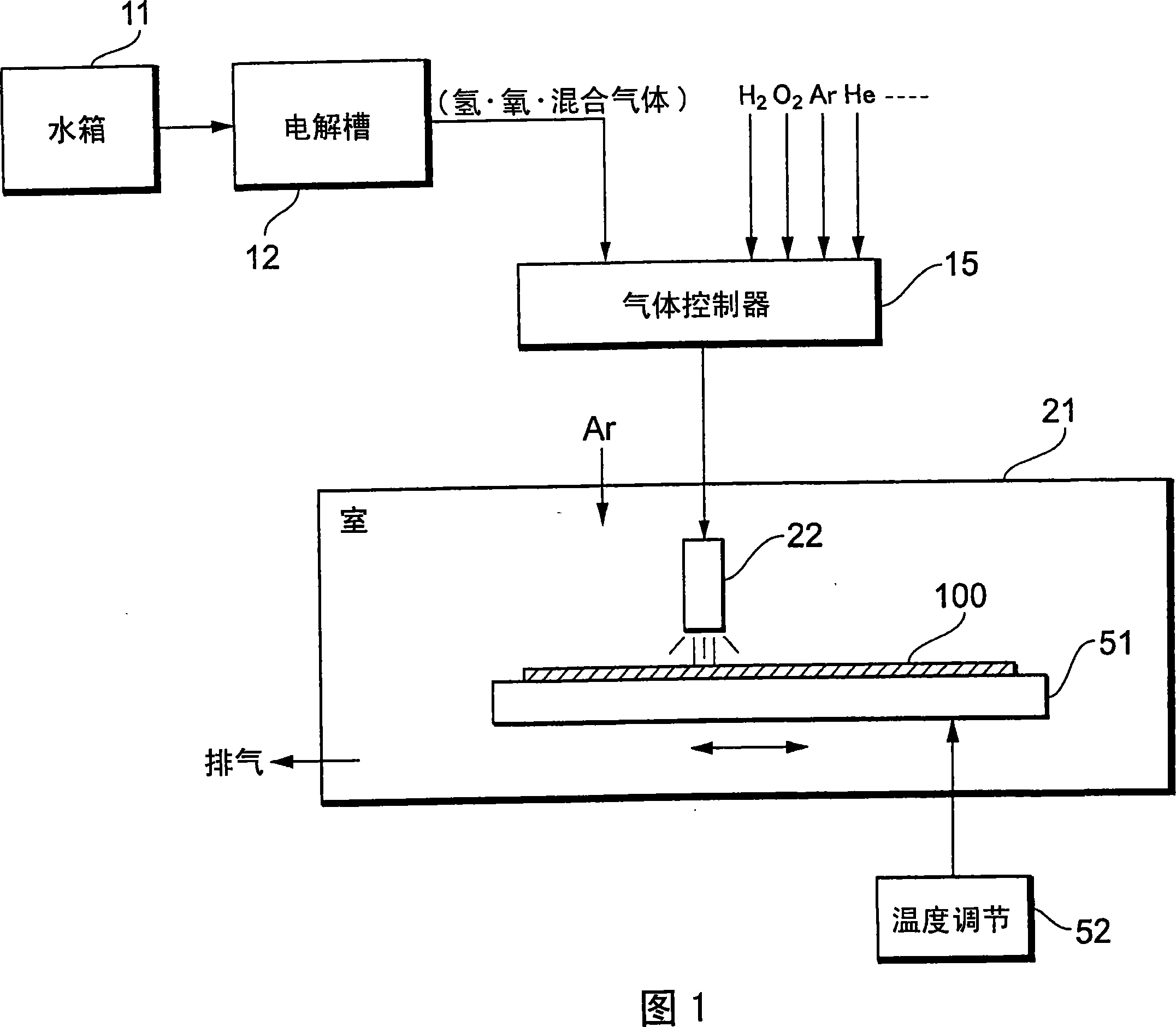

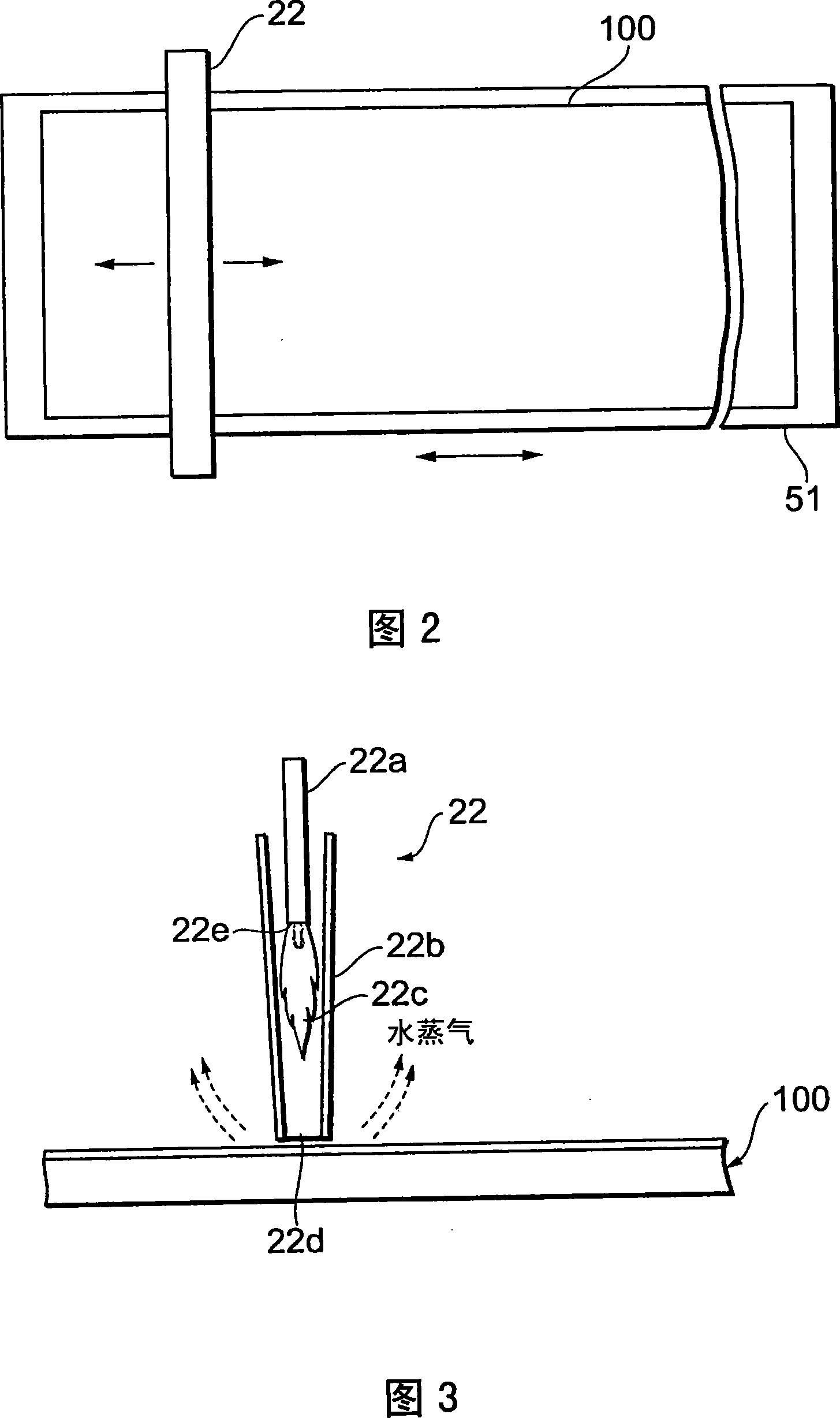

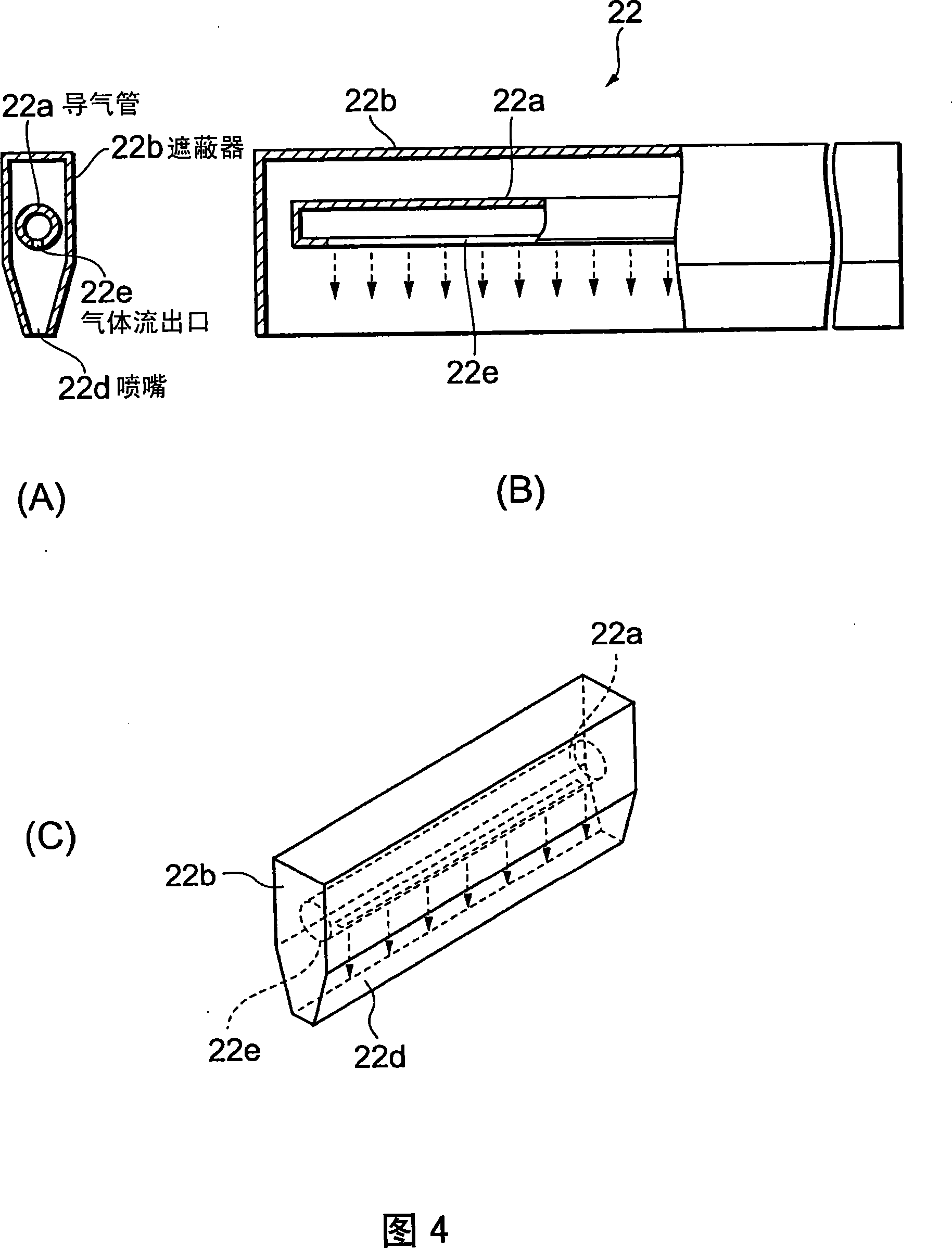

[0042] 1) Semiconductor manufacturing equipment

[0043] First, a semiconductor manufacturing apparatus used for manufacturing a semiconductor device according to this embodiment will be described with reference to FIGS. 1 to 9 .

[0044]FIG. 1 is a diagram showing a configuration example of a semiconductor manufacturing apparatus used for manufacturing a semiconductor device according to the present embodiment. In FIG. 1 , pure water is stored in a water tank 11 , and water is supplied to an electrolysis cell (electrolysis device) 12 . Water is electrolyzed by the electrolytic cell 12 and separated into hydrogen and oxygen. The separated hydrogen and oxygen are supplied to the gas controller 15 . The gas controller 15 is composed of a computer system, a pressure regulating valve, a flow regulating valve, various sensors, etc., and adjusts the supply amount of hydrogen and oxygen (mixed gas) supplied to the downstream gas burner 22 according to a preset program, Supply pres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| coating thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com