Manufacture method of simple metal clips

A manufacturing method, a simple technology, applied in printing, binding, etc., can solve the problems of inconvenient assembly, time-consuming, difficult applicability, poor fixture structure strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

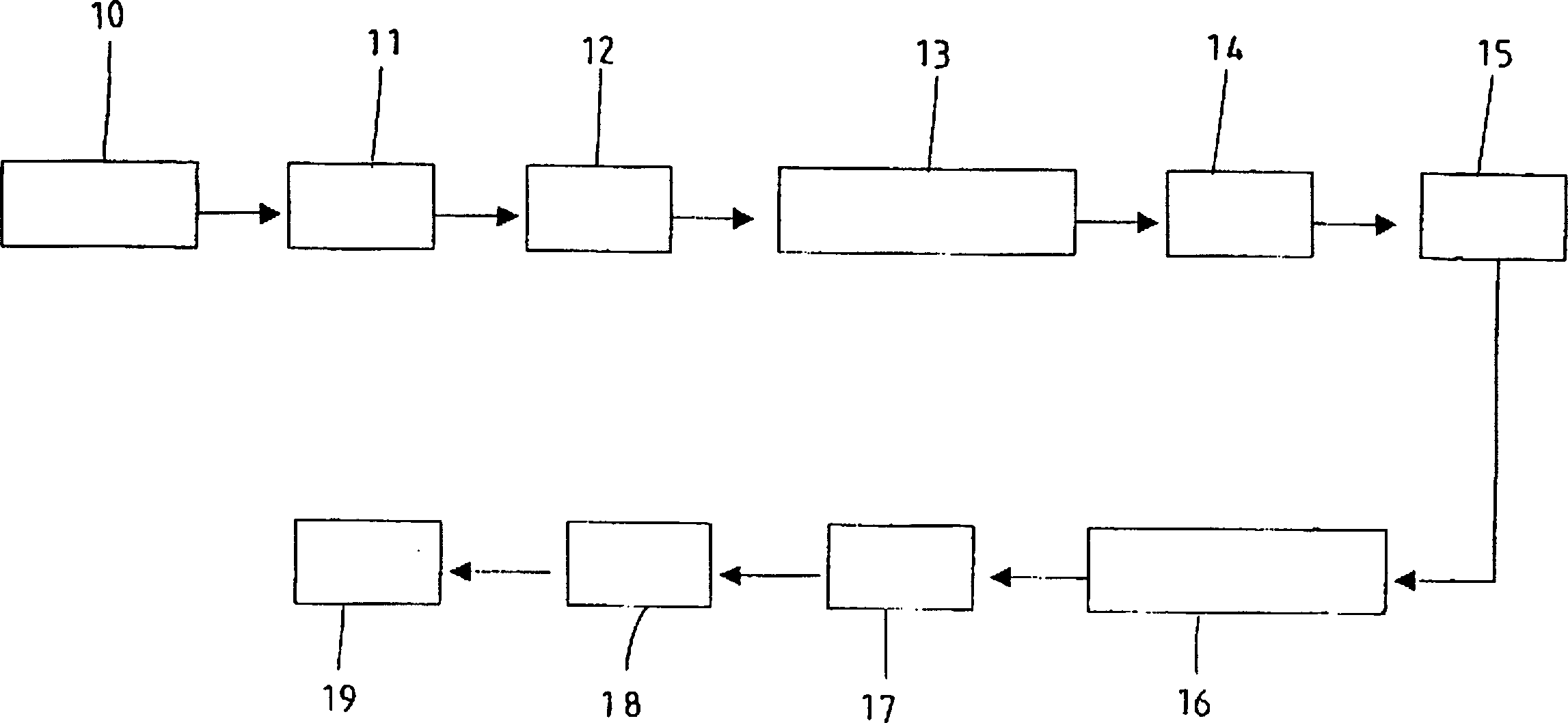

[0026] see figure 1 As shown, the present invention relates to a manufacturing method of a metal simple clip, which includes the following processes in sequence: taking the substrate (10), fixing the hole (11), trimming the edge (12), forming the unit piece (13), folding the lip (14), warping (15), molding elastic portion (16), bending (17), closing (18) and truncation (19) etc. a series of connected processes.

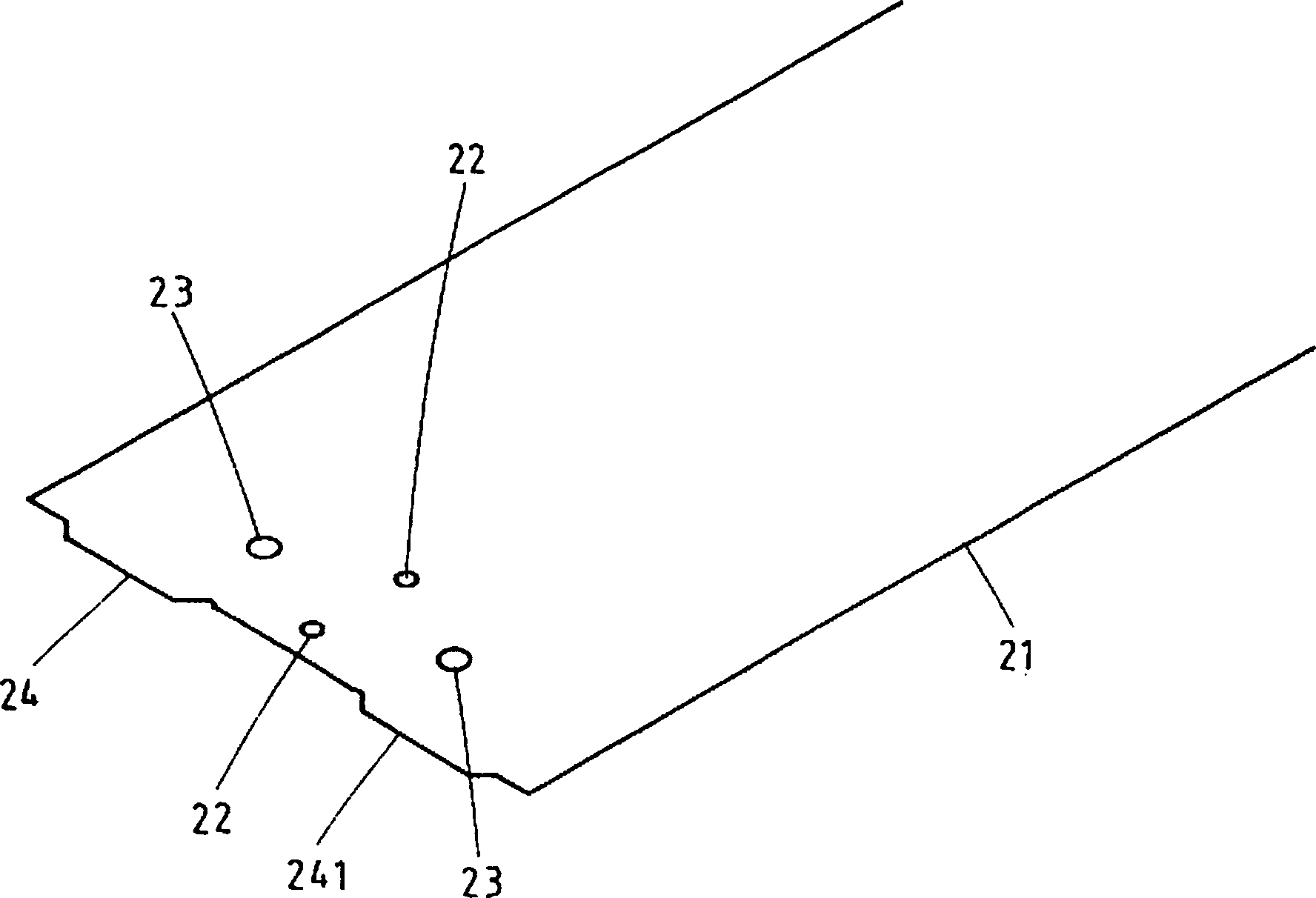

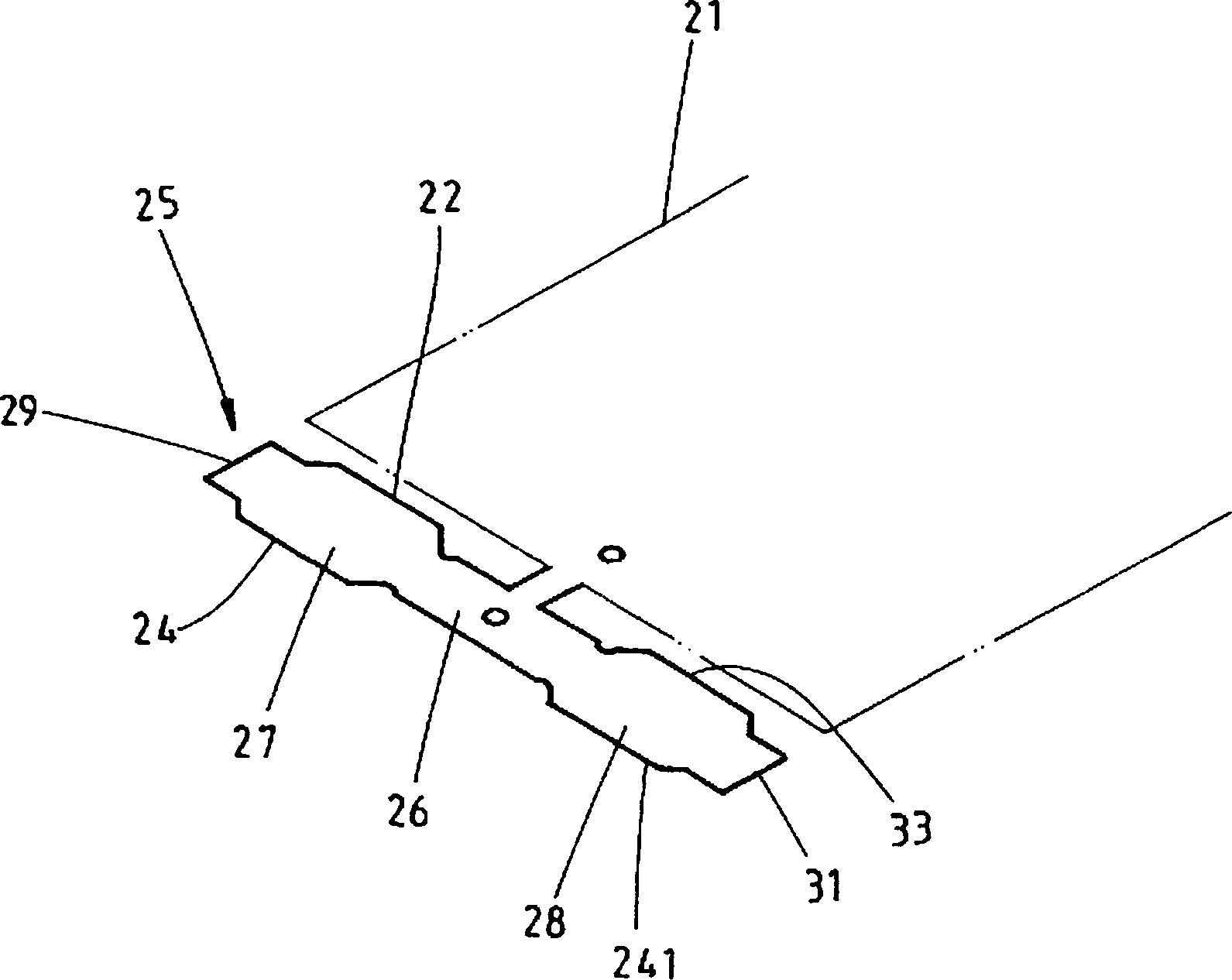

[0027] see figure 1 , 2 As shown, the base plate (21) is a metal plate, and for subsequent continuous processing operations, the metal plate has a considerable length, and can be a coiled metal sheet if necessary.

[0028] Since continuous processing will be carried out on the substrate (21), in order to facilitate the smooth automatic advancement of the substrate, a plurality of central holes (22) arranged in a straight line are provided at the center of the substrate (21). In order to facilitate the cutting action during subsequent processing, several cutting hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com