Piezoelectric ceramic, piezoelectric element, and manufacturing method thereof

A manufacturing method and technology of piezoelectric ceramics, which are applied in the manufacture/assembly of piezoelectric/electrostrictive devices, electrical components, piezoelectric devices/electrostrictive devices, etc. The effect of firing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

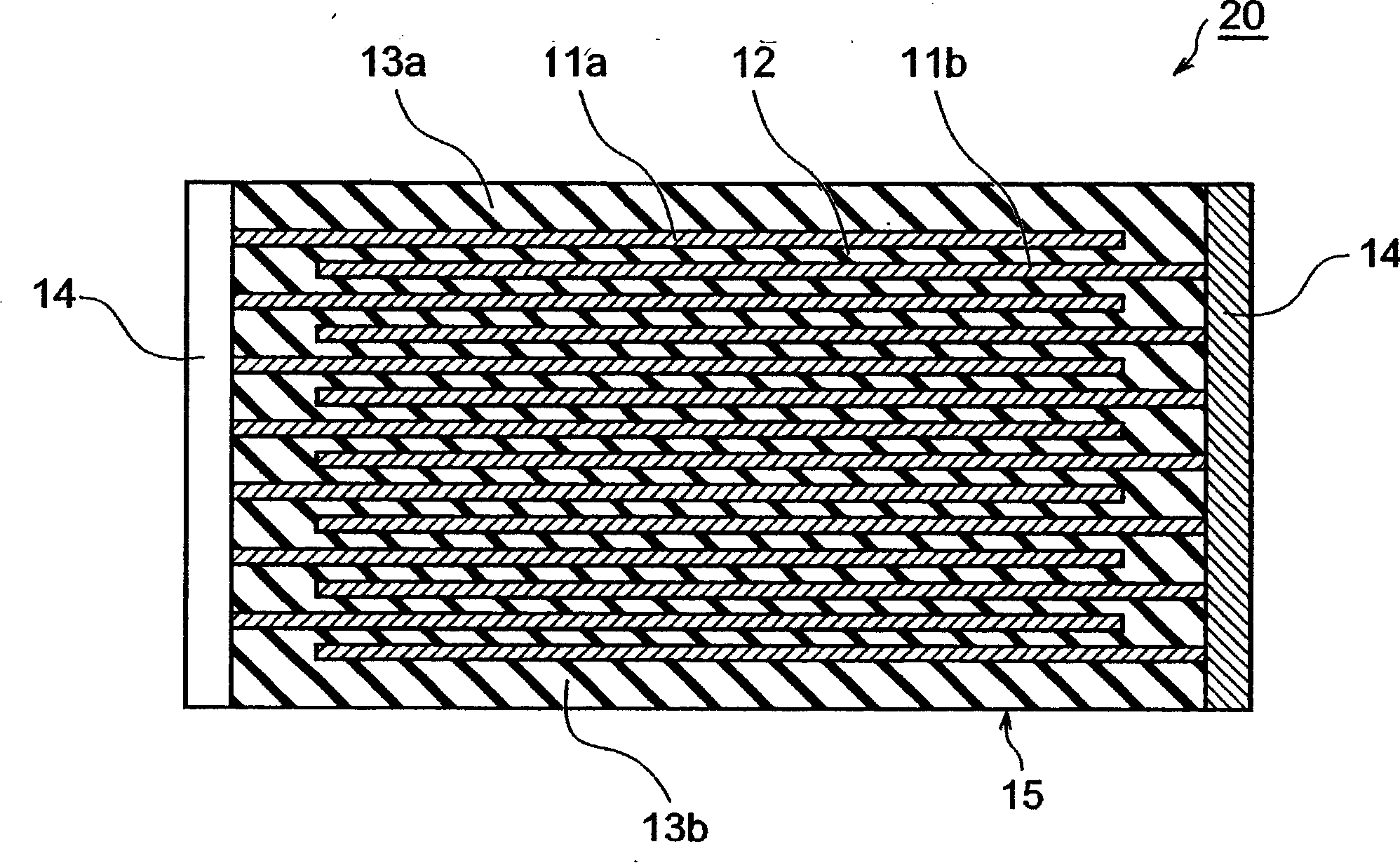

[0090] Hereinafter, the present invention will be described in more detail by way of examples, but the present invention is not limited to these examples.

[0091] [Production of Piezoelectric Ceramics]

[0092] (Production example 1)

[0093] conduct Figure 4 In the steps S11 to S16 and S17 to S20 shown, various piezoelectric ceramics are manufactured.

[0094] That is, first, the composition after glaze firing is Pb 0.993 (Ti 0.47 8Zr 0.522 )O 3 The amount of weighing the main component Pb 3 o 4 、TiO 2 and ZrO 2 , meanwhile, weigh 0.5% by mass of WO relative to the main component 3 . They were mixed with a ball mill to obtain a raw material mixture. In addition, at this time, the value of the average particle diameter is varied within the range of 0.4 to 1.0 μm, and at the same time, the value of (cumulative 90% particle diameter − cumulative 10% particle diameter) is varied within the range of 0.3 to 0.6 μm. , prepared various raw material mixtures.

[0095] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com