Copper sulfate, copper sulfate solution, plating solution, method for producing copper sulfate, method for producing semiconductor circuit board, and method for producing electronic apparatus

A technology of copper sulfate solution and manufacturing method, applied in copper sulfate and other directions, can solve problems such as reduced conductivity and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

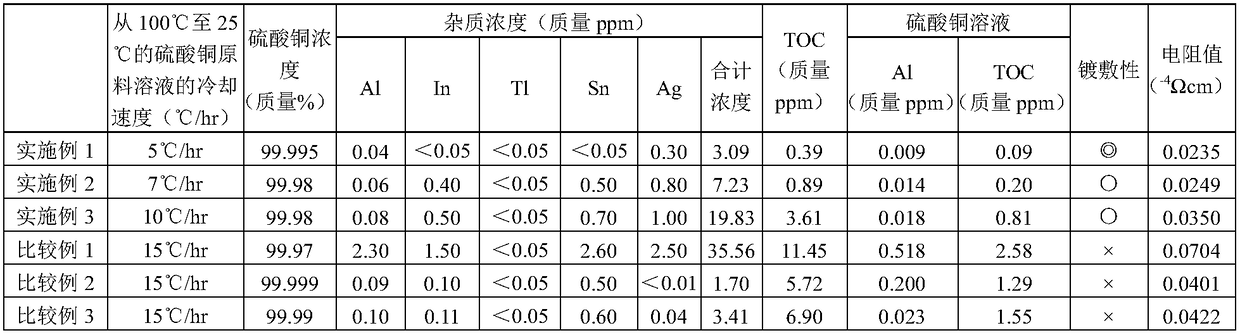

[0123] Hereinafter, although the Example of this invention is shown together with a comparative example, these Examples are provided in order to understand this invention and its advantage more fully, and are not intended to limit invention.

[0124]Commercially available copper sulfate (Cu: 99% or more, Na: 10ppm, Mg: 1.5ppm, Al: 4.5ppm, Ca: 3.9ppm, In: 5.6ppm, Sn: 10ppm, Ag: 3.5ppm) was used as a copper raw material It was mixed with ultrapure water having a resistivity of 15 MΩ·cm or more, and heated and stirred at 100° C. to prepare a copper sulfate raw material solution. Then, the copper sulfate raw material solution was moved to a concentration tank, and kept at a temperature of 100° C. for 2 to 10 hours, thereby evaporating water in the copper sulfate raw material solution and concentrating until the copper concentration became 150 to 250 g / L. The copper sulfate raw material solution heated and concentrated was moved to a crystallization tank, and in the crystallization...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com