Laminated glass and production method for laminated glass

A technology of laminated glass and glass plate, applied in the direction of glass/slag layered products, chemical instruments and methods, layered products, etc., can solve problems such as liquid crystal leakage, worry about aging of seals, and gaps in laminated glass, so as to prevent aging Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

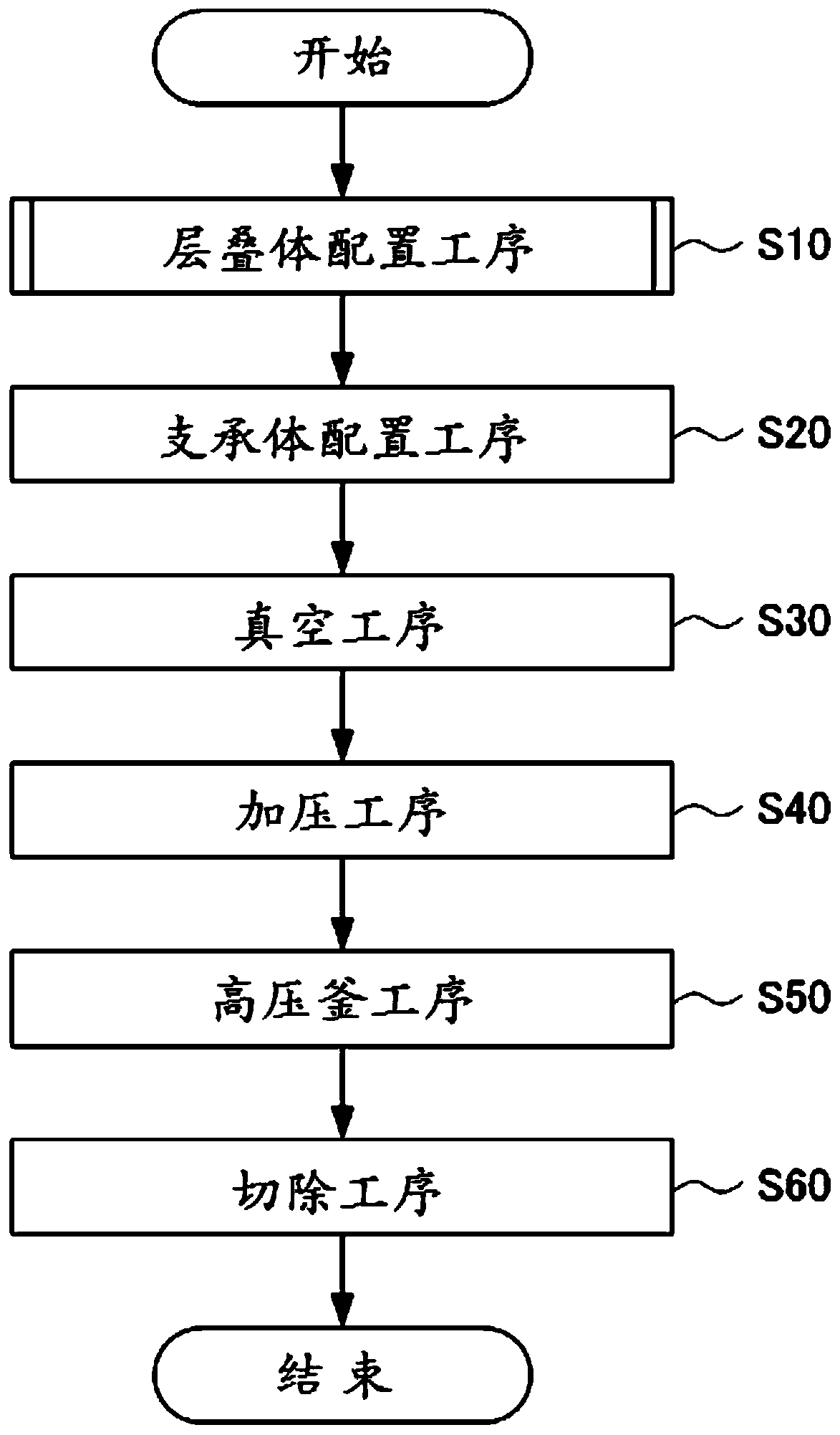

no. 1 approach

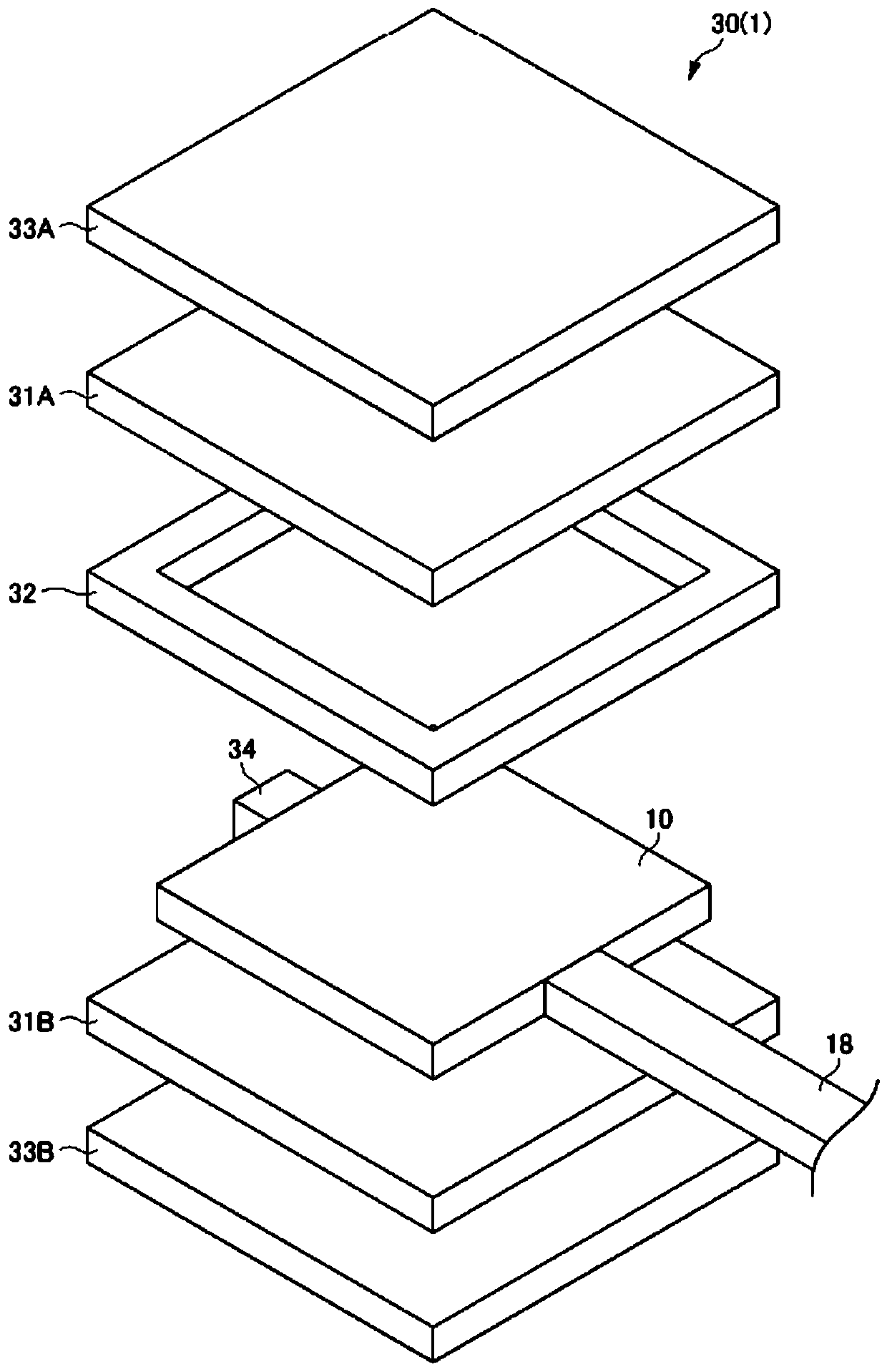

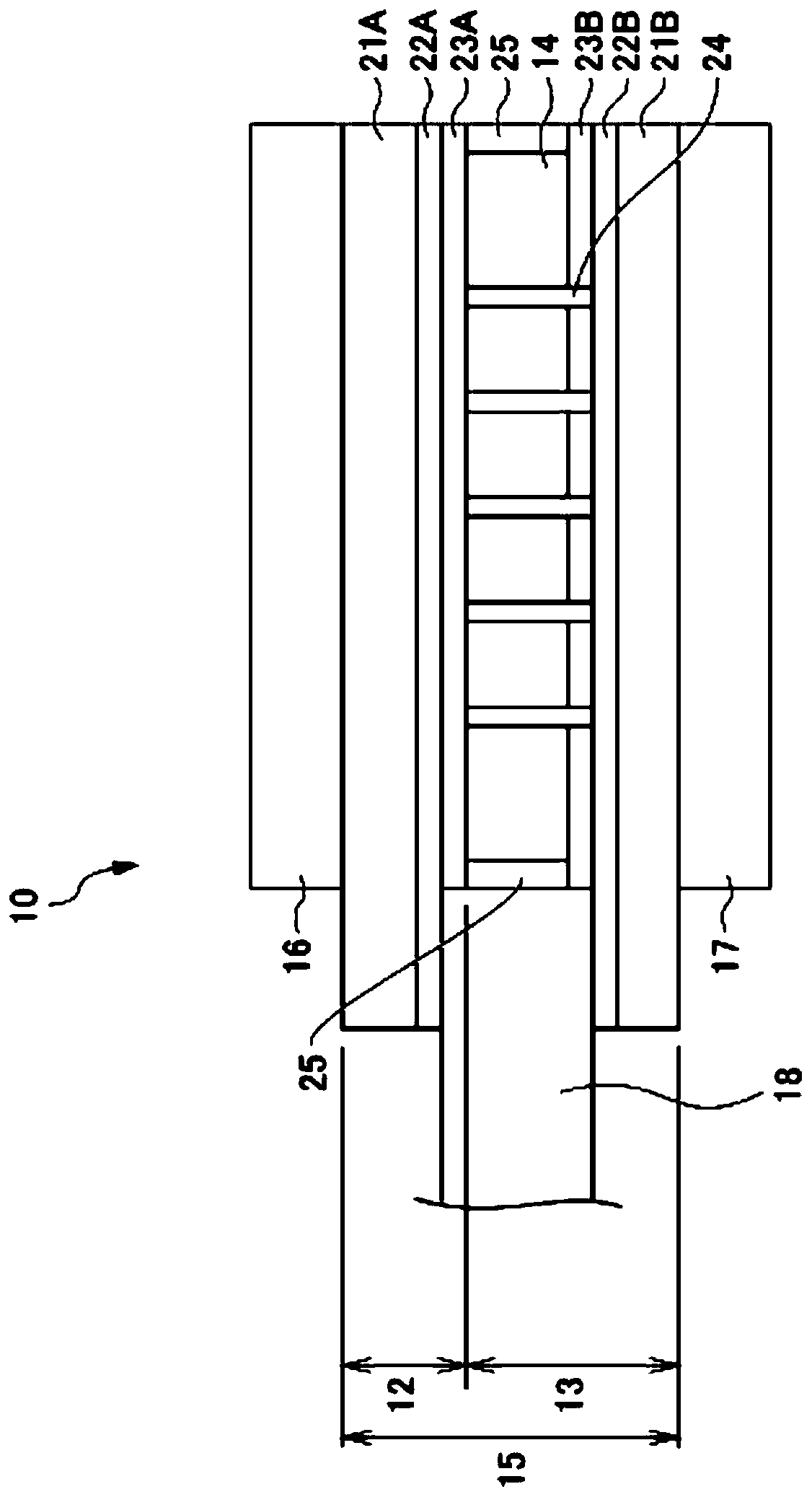

[0059] figure 1 It is an exploded perspective view showing the structure of the laminated body 30 of this embodiment.

[0060] It should be noted that, including figure 1 In addition, each figure shown below is a schematic figure, and the size and shape of each part are exaggerated suitably for easy understanding.

[0061] In addition, in the following description, specific numerical values, shapes, materials, and the like are shown and described, but they can be appropriately changed.

[0062] In this specification, terms that limit shapes or geometric conditions, such as parallel or orthogonal, etc., in addition to expressing strict meanings, realize the same optical function, and have errors that are considered to be parallel or orthogonal. Status is also included.

[0063] In this specification, words such as plate, sheet, and film are used. As a general method of use, these are used in the order of plate, sheet, and film in the order of thickness from thick to thin. i...

no. 2 approach

[0192] Figure 20 It is a cross-sectional view showing a use state where the laminated glass 1A of the second embodiment is attached to a frame body F. FIG. In this 2nd Embodiment and the 3rd Embodiment mentioned later, the structure which fixed and attached laminated glass 1A (1B) to the frame-shaped frame body (window frame) F is demonstrated.

[0193] The laminated glass 1A of the second embodiment has further added components necessary for actual use, but the basic structure is the same as that of the laminated glass 1 of the first embodiment. Therefore, parts that achieve the same functions as those in the above-mentioned first embodiment are assigned the same reference numerals, and redundant descriptions are appropriately omitted.

[0194] Figure 20 The cross section of is cut and shown near the end of the laminated glass 1A in a state where the laminated glass 1A is attached to the frame body F. The laminated glass 1A is constructed with Figure 20 The layer struc...

no. 3 approach

[0209] Figure 21 It is a cross-sectional view showing a use state in which the laminated glass 1B of the third embodiment is attached to a frame body F. FIG.

[0210] The laminated glass 1B of the third embodiment differs from the second embodiment in that it includes light shielding portions 70A and 70B, and its basic structure is the same as that of the laminated glass 1A of the second embodiment. Therefore, parts that realize the same functions as those in the above-mentioned second embodiment are assigned the same reference numerals, and redundant descriptions are appropriately omitted.

[0211] In the third embodiment, two (two layers) of light shielding portions of 70A of light shielding portions and light shielding portion 70B are included.

[0212] 70 A of light shielding parts of 3rd Embodiment are comprised similarly to 70 A of light shielding parts of 2nd Embodiment.

[0213] The light shielding portion 70B of the third embodiment is arranged at a position betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com