Exposure method for forming IC chip image in intermeidate mask using main mask

An exposure method and pattern exposure technology, which are applied to microlithography exposure equipment, originals for photomechanical processing, and exposure devices for photo-engraving processes, etc., can solve problems such as the inability to reduce the number of master masks, and reduce correction cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

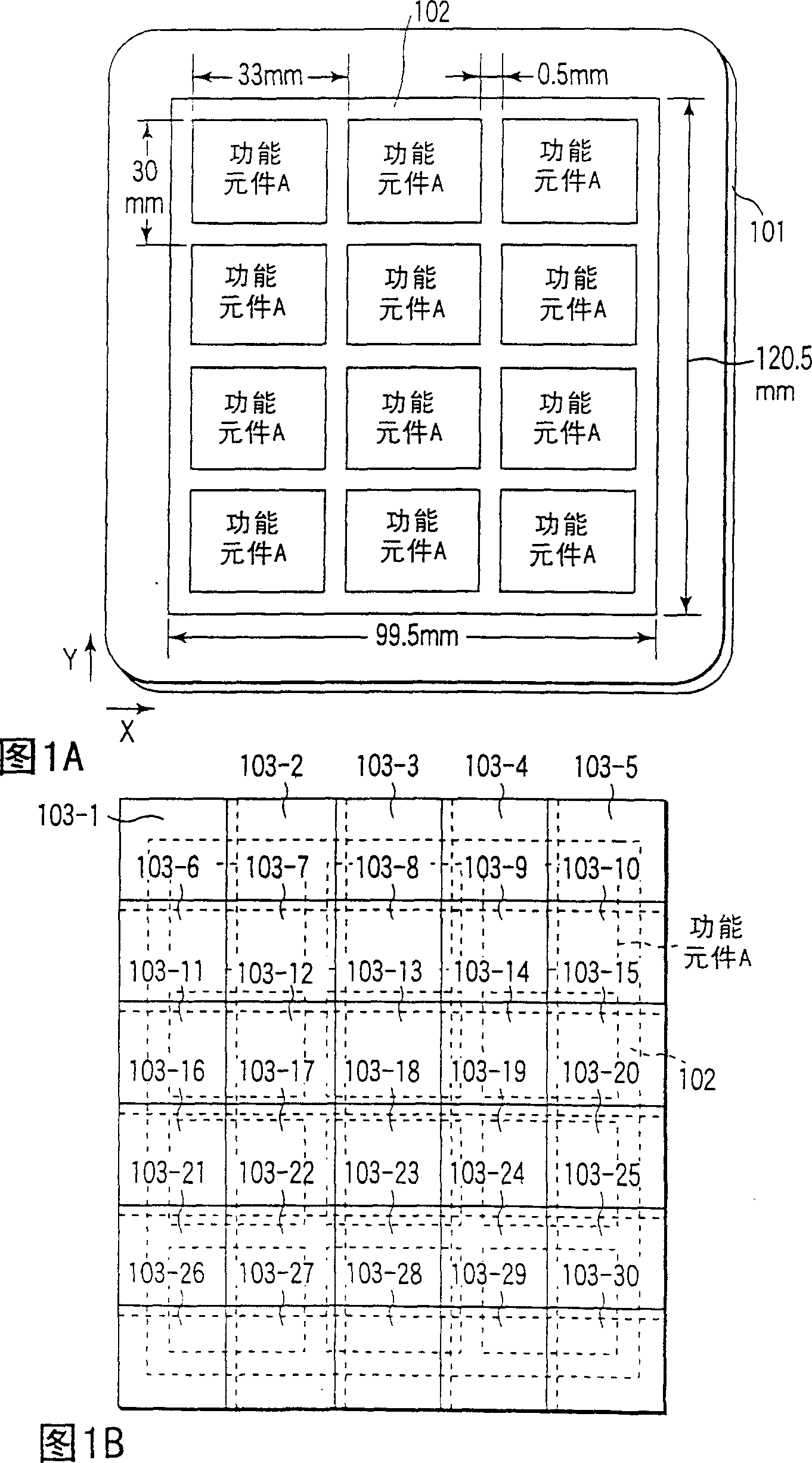

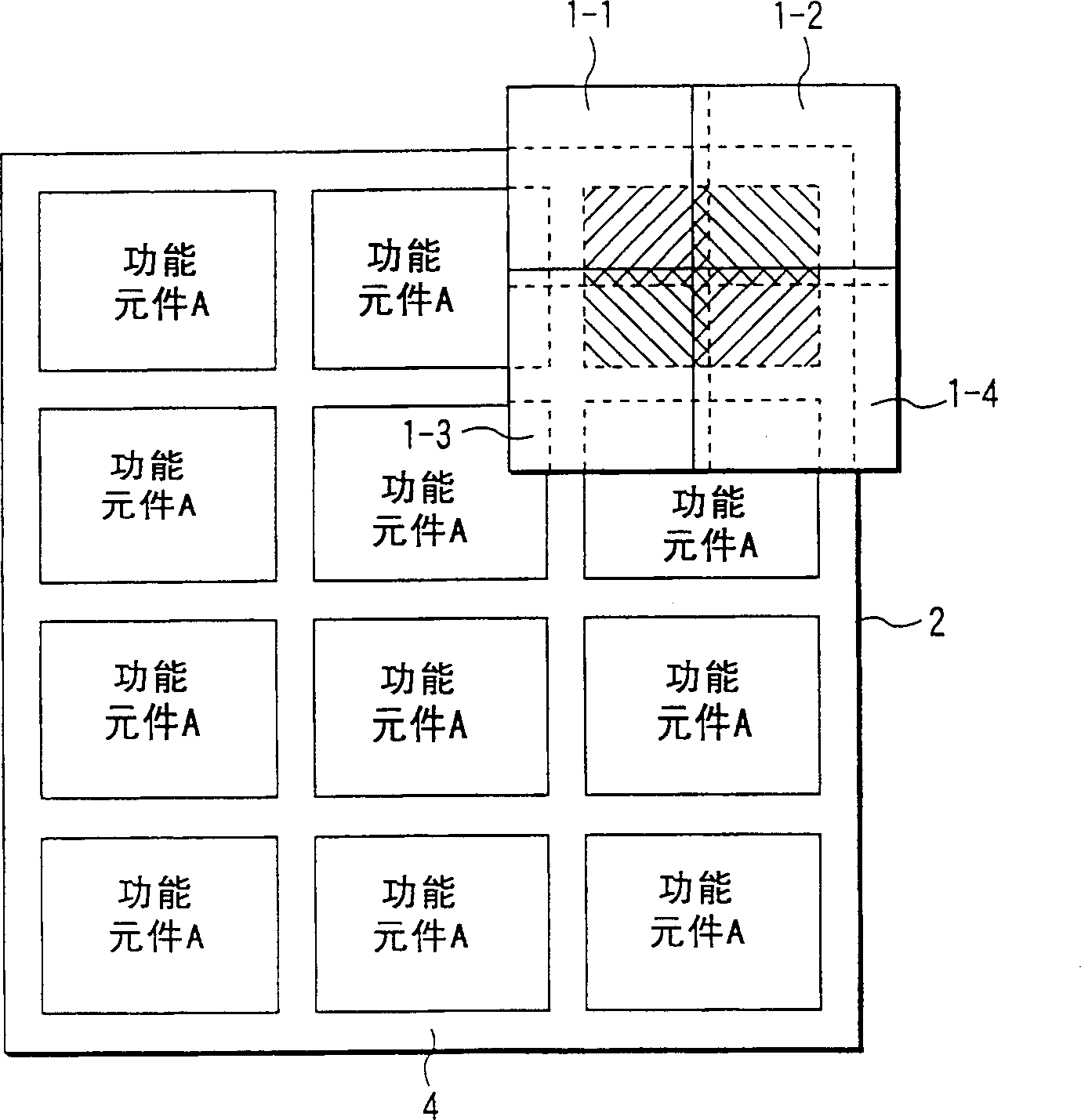

[0054] Preferred Mode of Carrying Out the Invention

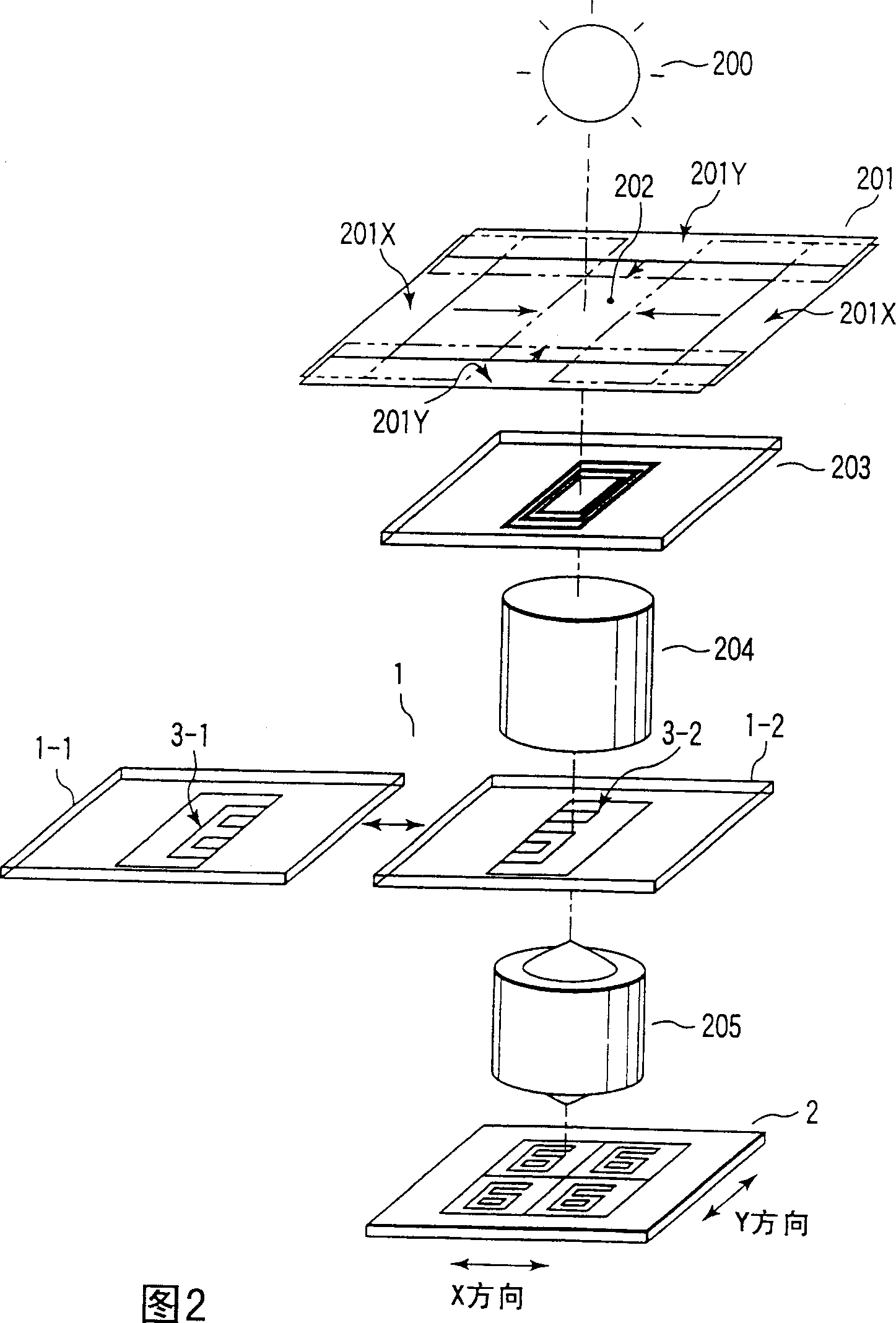

[0055] Before describing the embodiment, first, a schematic configuration of an exposure apparatus used in the present invention will be described. Fig. 2 is a perspective view showing a schematic structure of an exposure apparatus used in the present invention. As shown in FIG. 2 , light irradiated from a light source 200 is incident on a mechanical shade (movable shade) 201 .

[0056] The mechanical shade 201 blocks light irradiated from the light source 200 to limit the exposure area (range) of the master mask 1 . The mechanical shade 201 is composed of, for example, an X shade 201X movable in the X direction, and a Y shade 201Y movable in the Y direction. Furthermore, by using these X shades 201X and Y shades 201Y, the size of the window 202 through which light passes is varied in various ways, and the exposure area is appropriately limited. The light restricted by the mechanical shade 201 is incident on the layer fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com