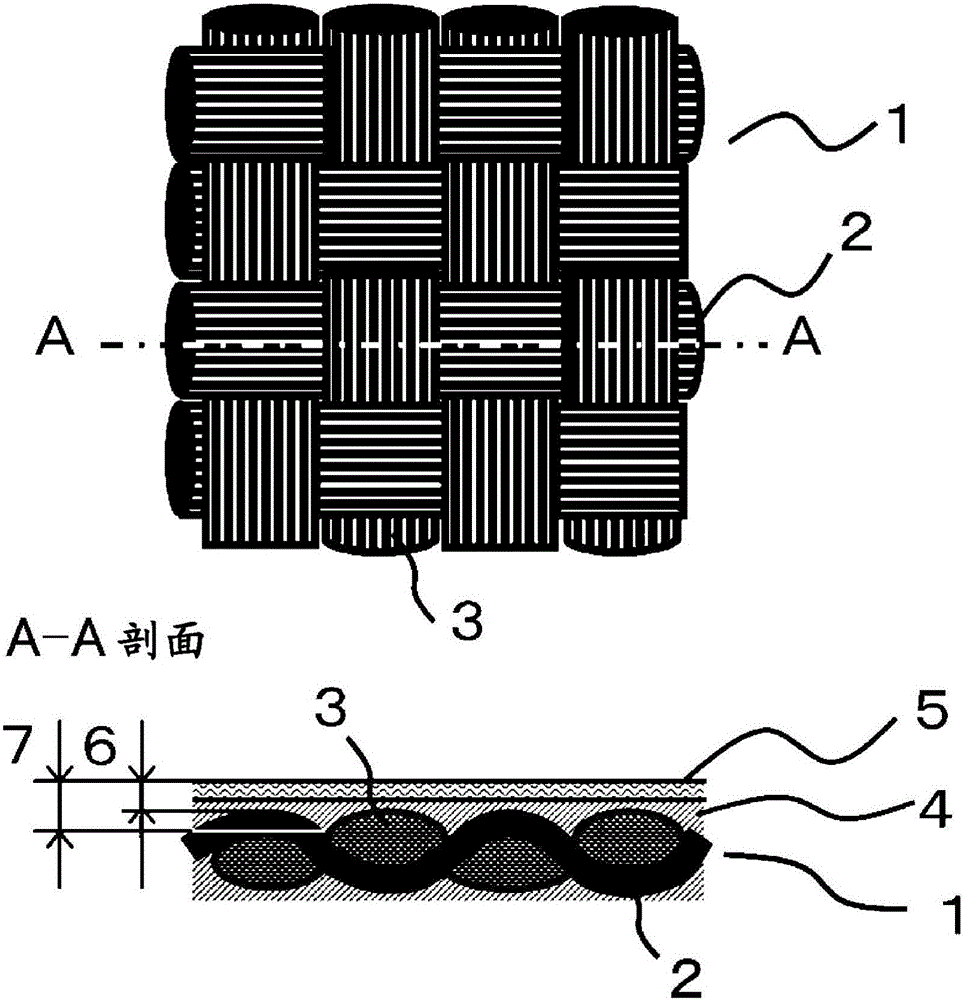

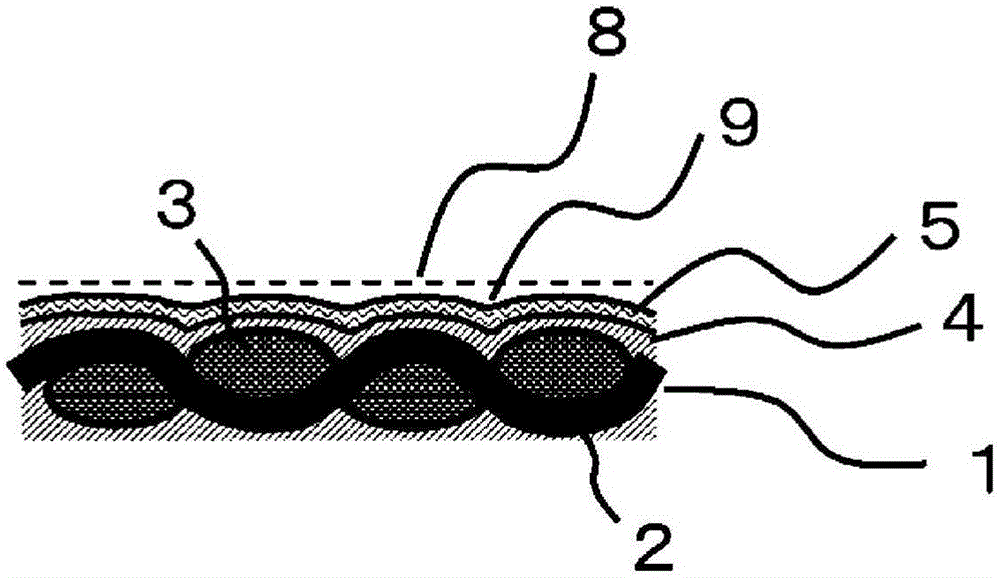

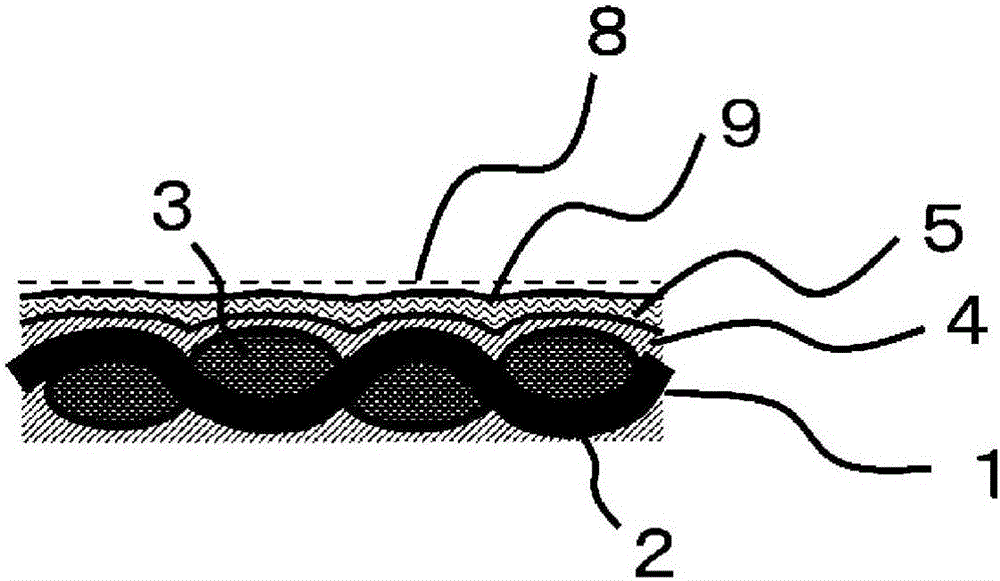

Coated fiber-reinforced resin molding and process for producing same

A technology of fiber-reinforced resin and manufacturing method, which is applied in the direction of coating, etc., can solve the problems of a lot of time-consuming, a lot of work, poor surface smoothness, etc., and achieve the effect of reducing surface unevenness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

[0114] - The fiber-reinforced resin molded article was coated with the resins and coating conditions shown in Table 1, and evaluated. Since the difference between the curing temperature of the matrix resin and the curing temperature of the coating resin is sufficient, and the curing temperature of the coating resin is low, the reflected image of the fluorescent lamp on the surface is very clear without fluctuations. In addition, the WS value is also a result that satisfies Level A.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| surface density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com