Epoxy resin composition, fiber-reinforced composite material and method for producing the same

An epoxy resin and composite material technology, which is applied in the field of liquid epoxy resin composition and the manufacture of fiber reinforced composite materials, can solve the problems of strong coloring, unsuitability for the production of large-scale molded products, and high viscosity of the resin composition, and achieves the surface Small unevenness, excellent surface tone and filling, and fewer pinhole defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~11

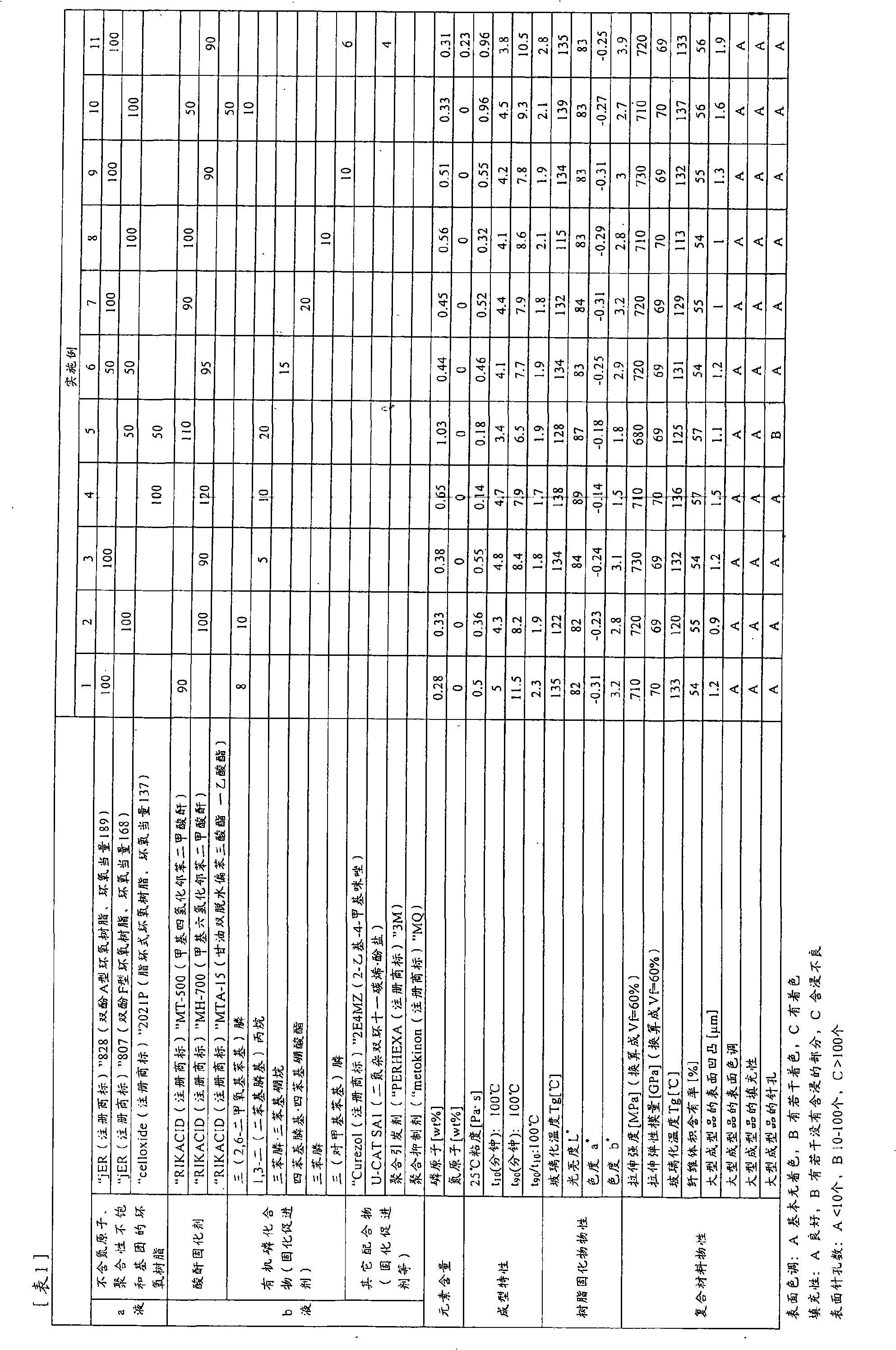

[0223] As shown in Table 1, the epoxy resin composition of the present invention is under molding temperature (100 ℃), t 10 Indicates the long flowable time, t 90 The demoulding time indicated is short, so t 90 / t 10 When it is 3 or less, in the molding of the fiber-reinforced composite material, the filling property to the fiber base material is excellent, and it is extremely effective in shortening the molding time. In addition, the molded cured product is also excellent in color tone, and is preferably used for automotive parts, sporting goods, etc., which utilize reinforcing fibers for design. In addition, the fiber-reinforced composite material of the present invention using the epoxy resin composition has excellent mechanical properties and well-controlled heat resistance (glass transition temperature), and good filling properties even when producing large molded products. Pore defects were also few, and the appearance (surface unevenness, color tone) was also good....

Embodiment 12~15

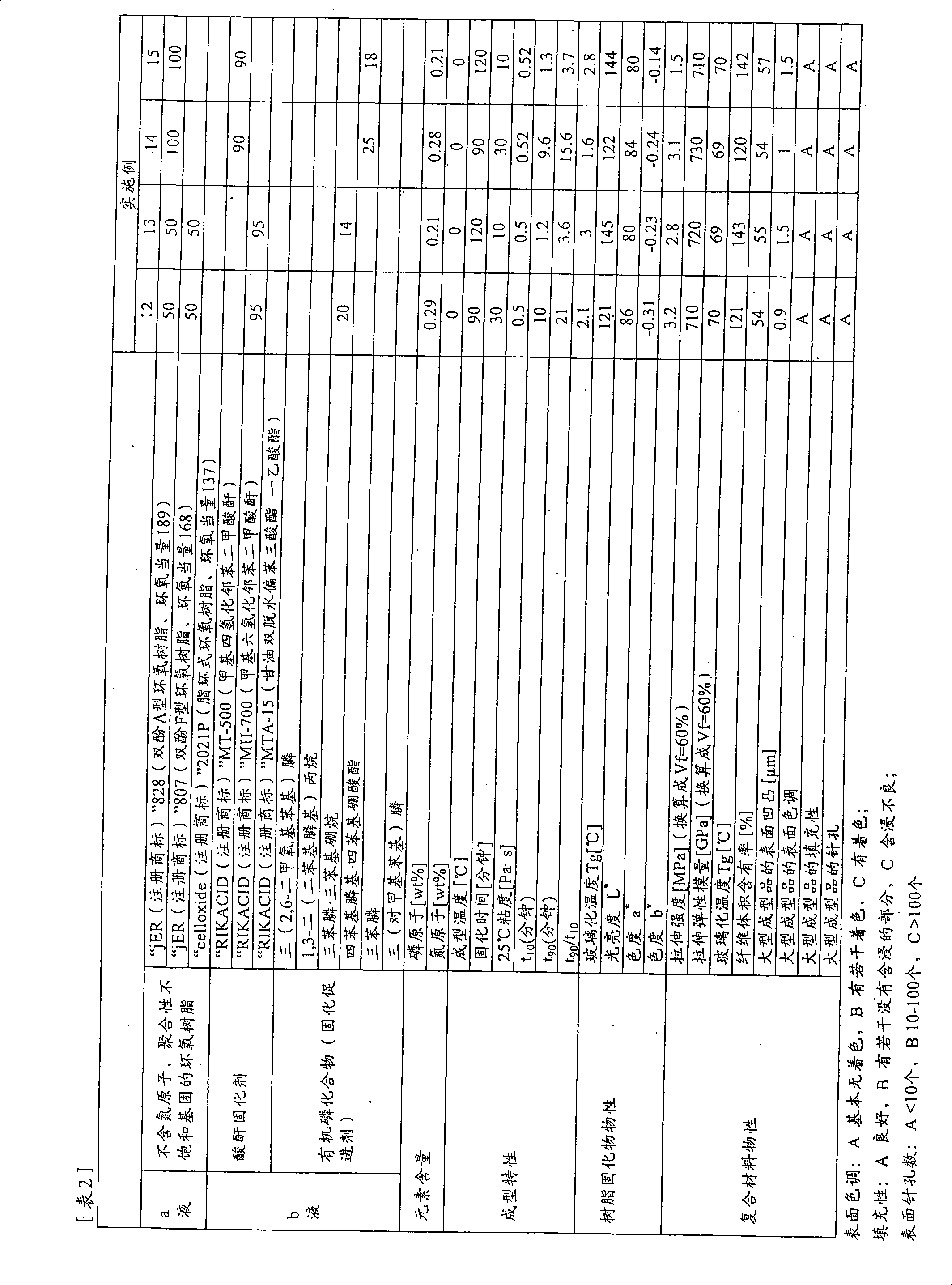

[0226] Table 2 shows examples of molding fiber-reinforced composite materials under molding conditions other than a temperature of 100° C. and a curing time of 20 minutes. Note that the molding temperature and curing time are as shown in Table 2, and the molding properties, cured resin properties, and composite material properties are also values under the molding conditions shown in Table 2. As shown in Table 2, since the epoxy resin composition of the present invention has a long flow time and a short release time even at a molding temperature other than 100°C, when molding a fiber-reinforced composite material, Extremely effective in filling fibrous substrates and reducing molding time.

[0227]

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com