Silicon electrode plate for plasma etching

A plasma and silicon electrode technology, applied in the direction of circuits, discharge tubes, electrical components, etc., can solve problems such as difficulty in suppressing in-plane deviation of specific resistance value, difficulty in uniform etching speed, difficulty in suppressing in-plane deviation, etc., to achieve the realization of in-plane Internal uniformity, suppression of cracks or notches, and suppression of internal strain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

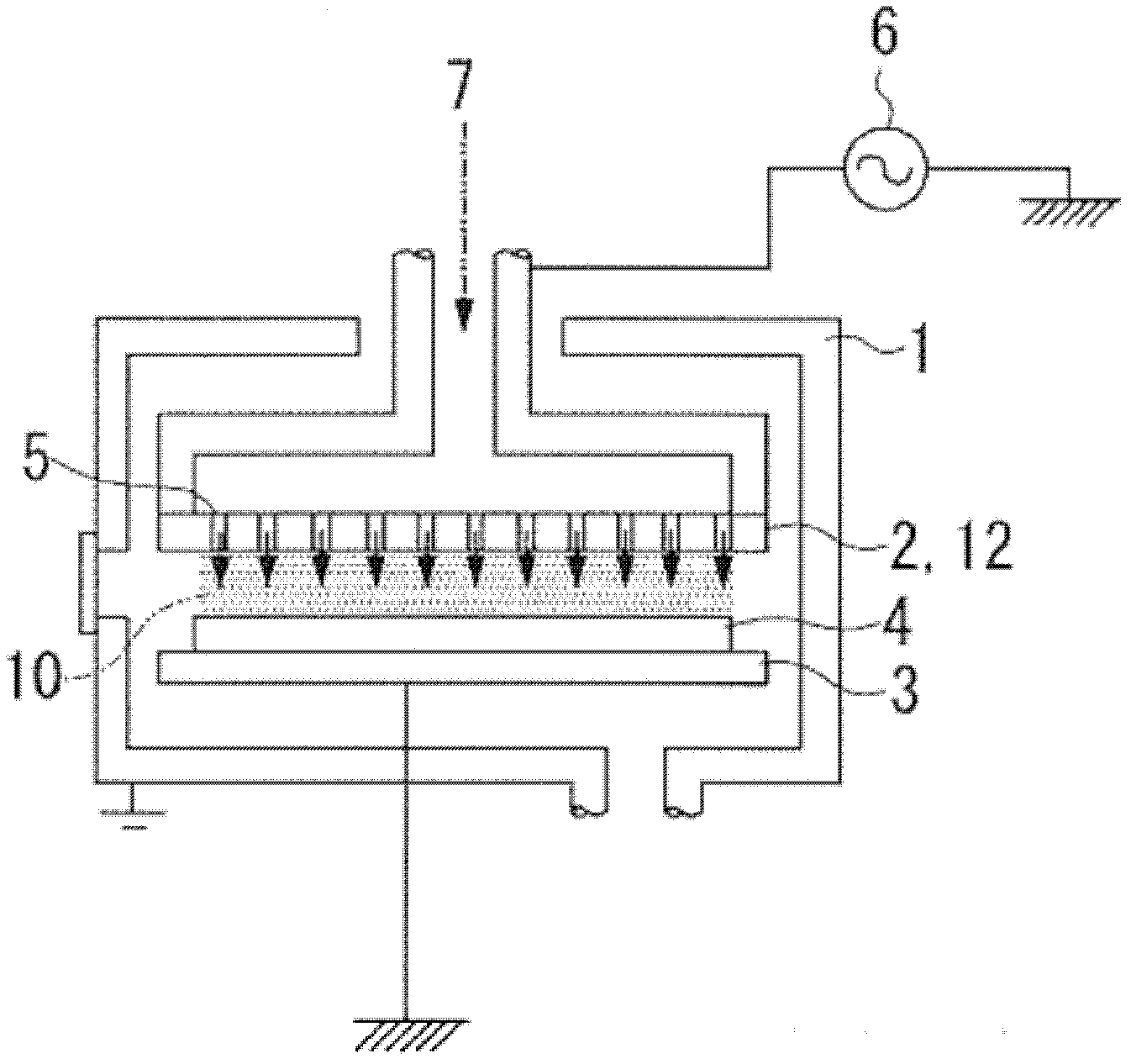

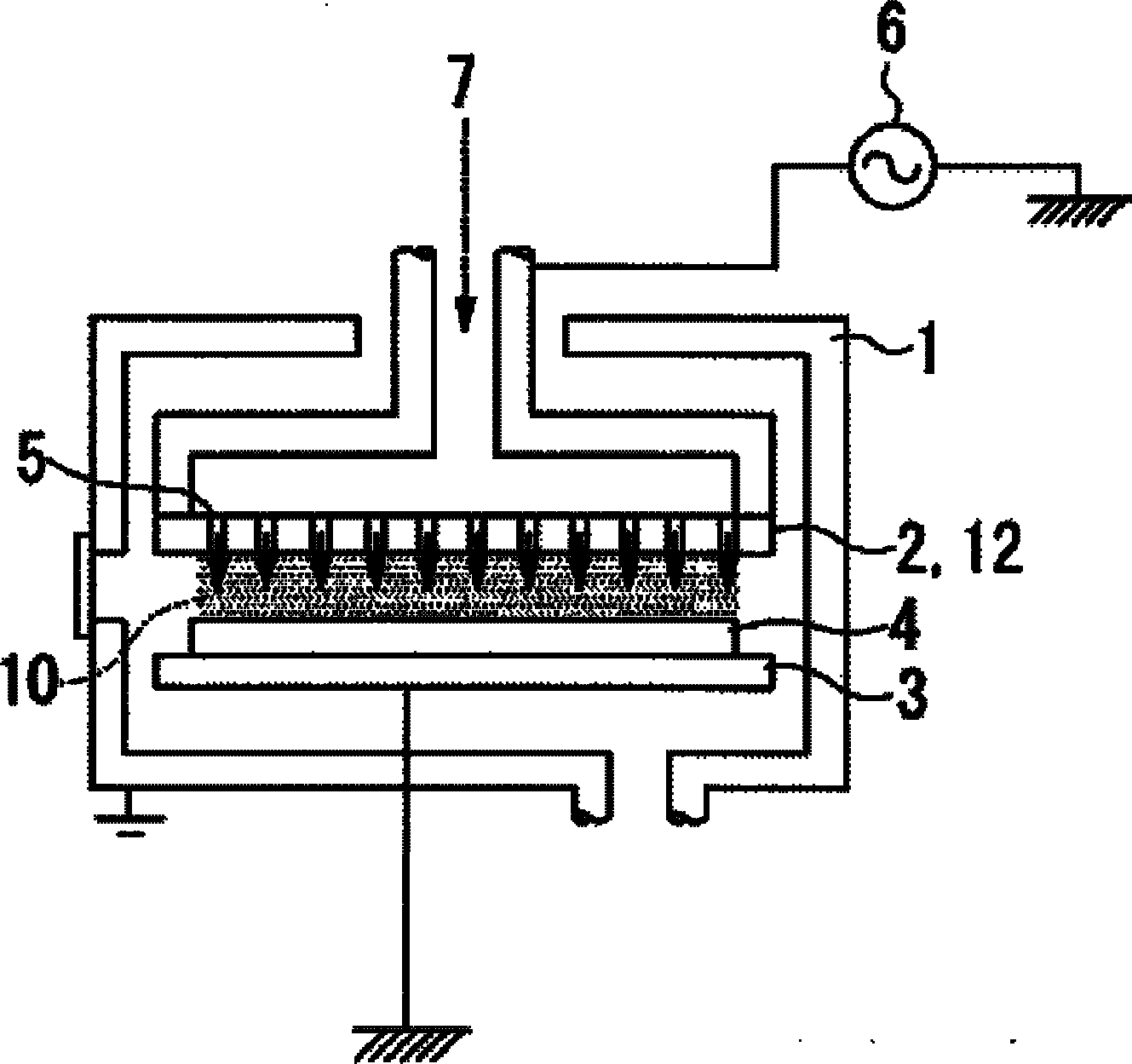

Image

Examples

Embodiment

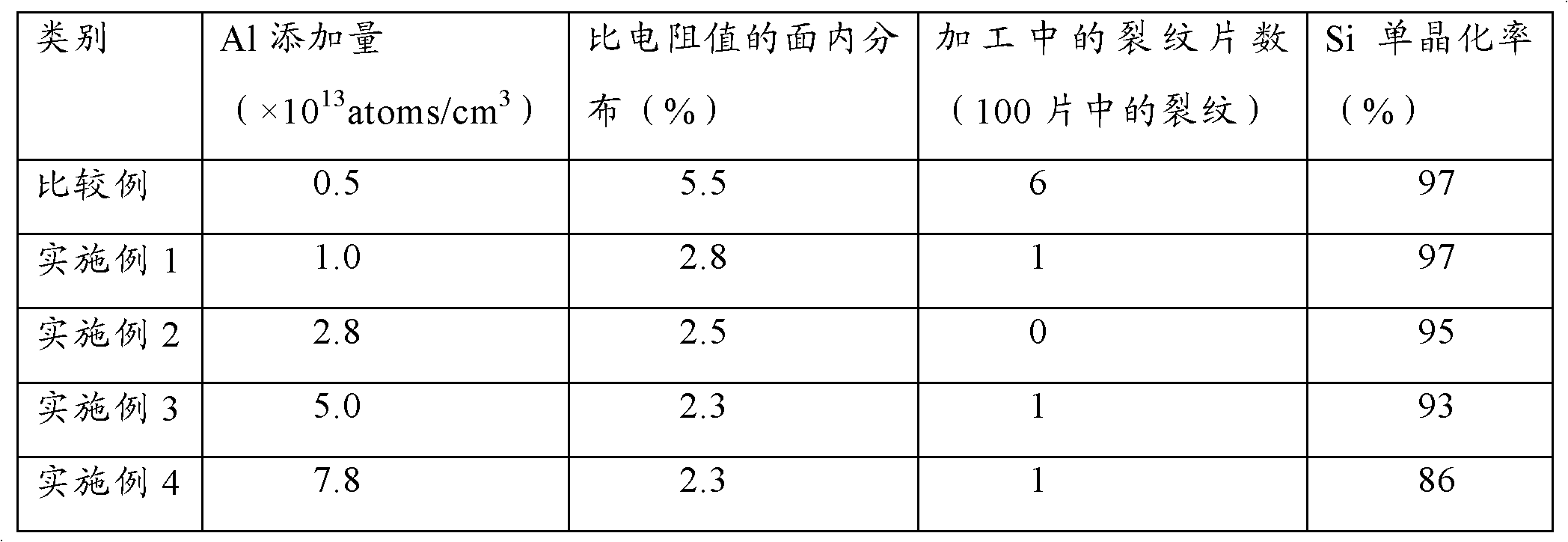

[0032] Next, the evaluation results of Examples of the silicon electrode plate produced according to the present embodiment described above will be described.

[0033] As shown in Table 1, the embodiment of the silicon electrode plate of the present invention is made by changing the addition amount of Al, and the in-plane distribution of the resistance value, the number of cracks in processing (the number of cracks in 100 pieces) and the number of Si single plates are compared respectively. The crystallization rate was investigated. These results are shown in Table 1. And, as a comparative example, it is also made to add less than 1×10 13 atoms / cm 3 The Al silicon electrode plate was evaluated in the same manner, and the results are also shown in Table 1. In addition, in any of the Examples and Comparative Examples, the amount of B added was set to 2×10 14atoms / cm 3 .

[0034] [Table 1]

[0035]

[0036] As judged from the evaluation results, the values of the in-p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com