Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

118results about How to "Suppress abnormal discharge" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

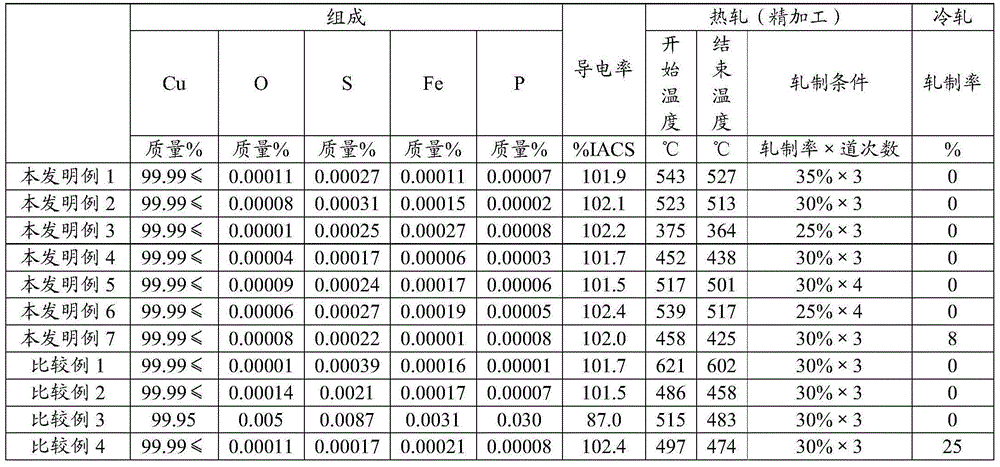

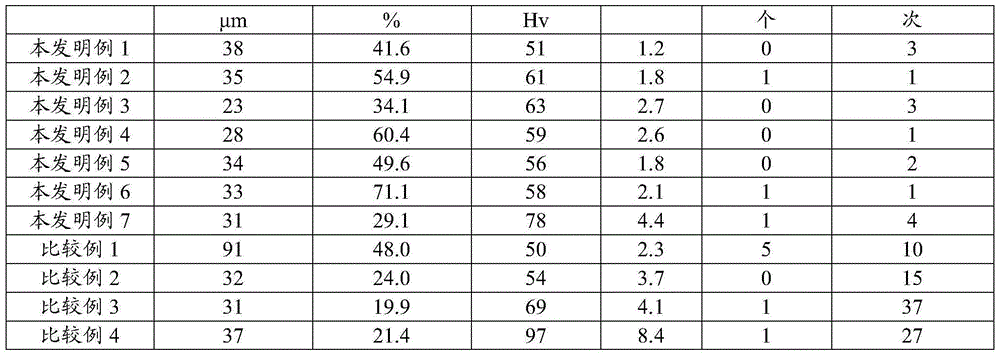

Hot-rolled copper plate

ActiveCN105189792AEasy to processExcellent fatigue propertiesSingle bars/rods/wires/strips conductorsConductive materialCopperGrain boundary

This hot-rolled copper plate is made from pure copper having a purity of 99.99 mass% or greater, the average crystal grain diameter being 40 microns or less, and the (Sigma 3+Sigma 9) grain boundary length ratio (L(sigma 3 + sigma 9) / L), which is the ratio between the total crystal grain boundary length (L) measured by the EBSD method and the sum (L(sigma 3 + sigma 9)) of the Sigma 3 grain boundary length (L sigma 3) and the Sigma 9 grain boundary length (L sigma 9) is 28% or greater.

Owner:MITSUBISHI MATERIALS CORP

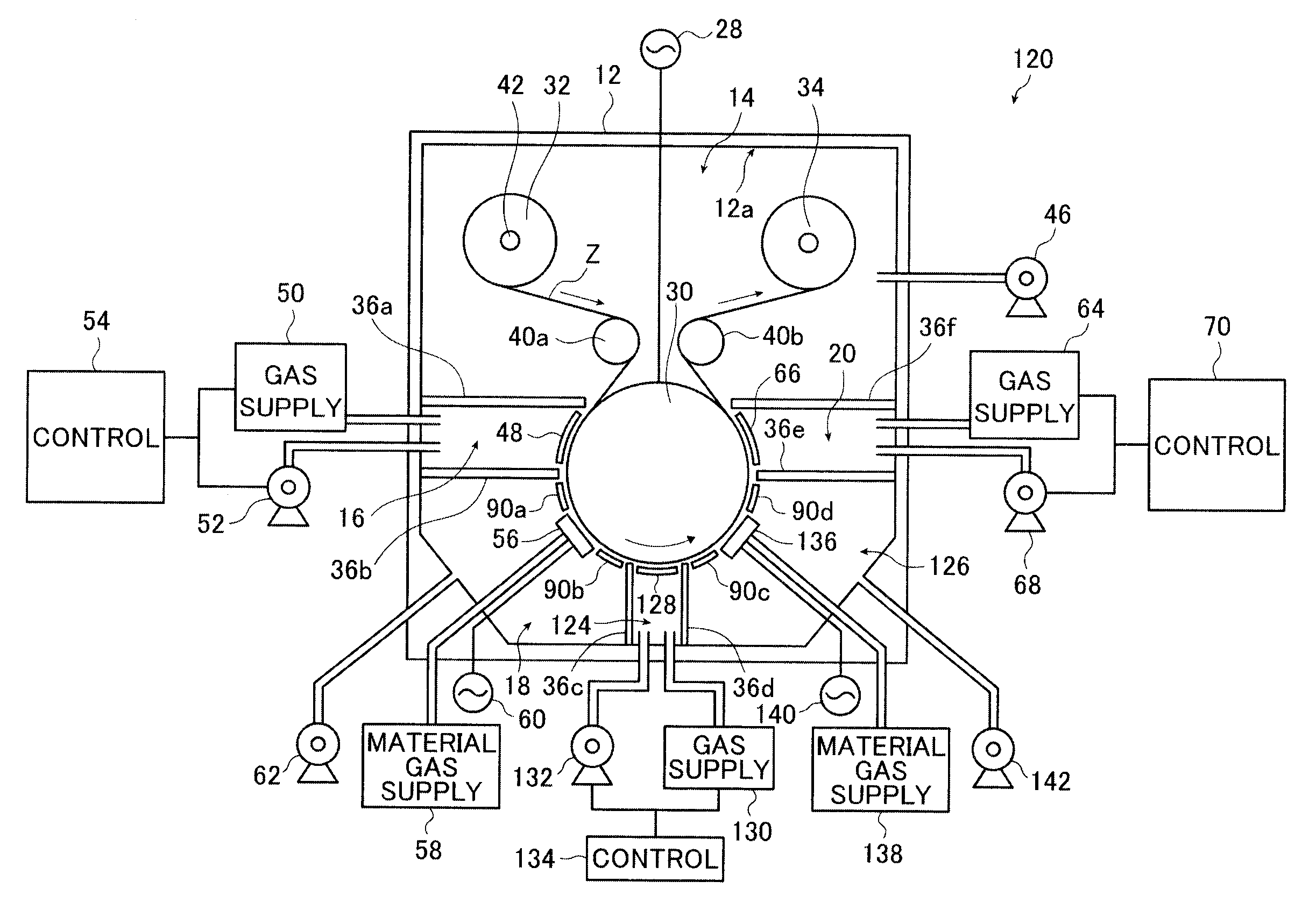

Film deposition method

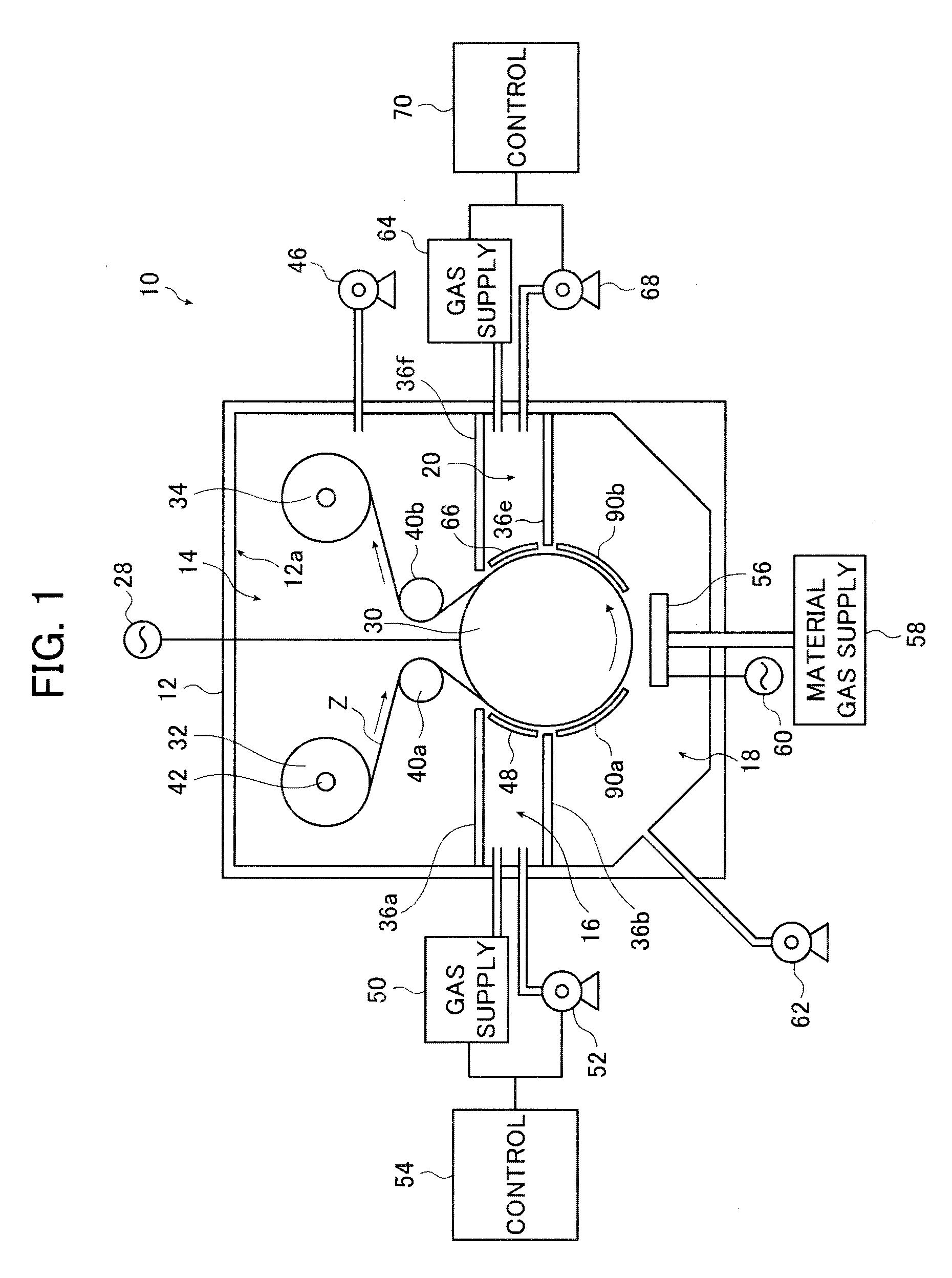

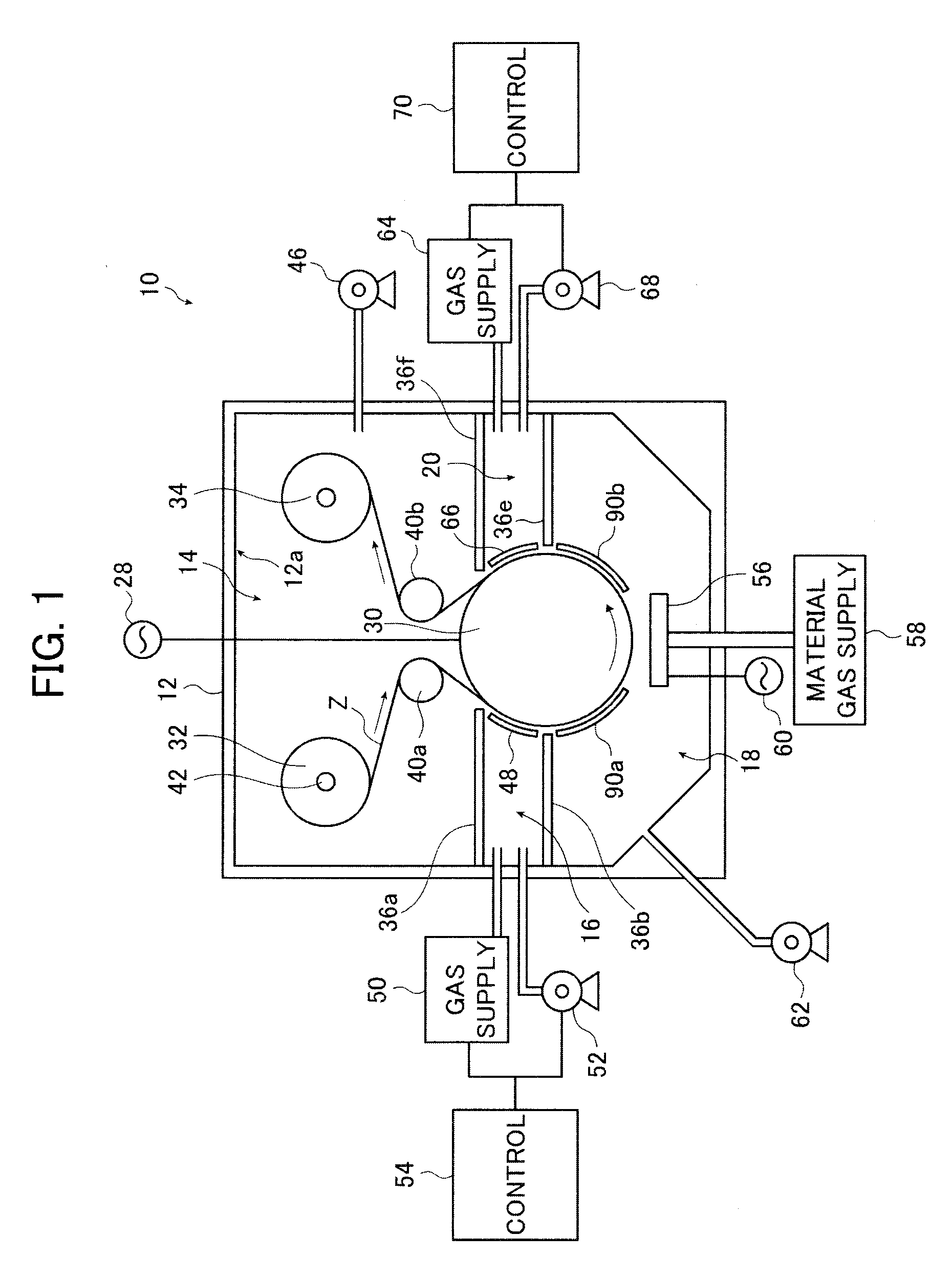

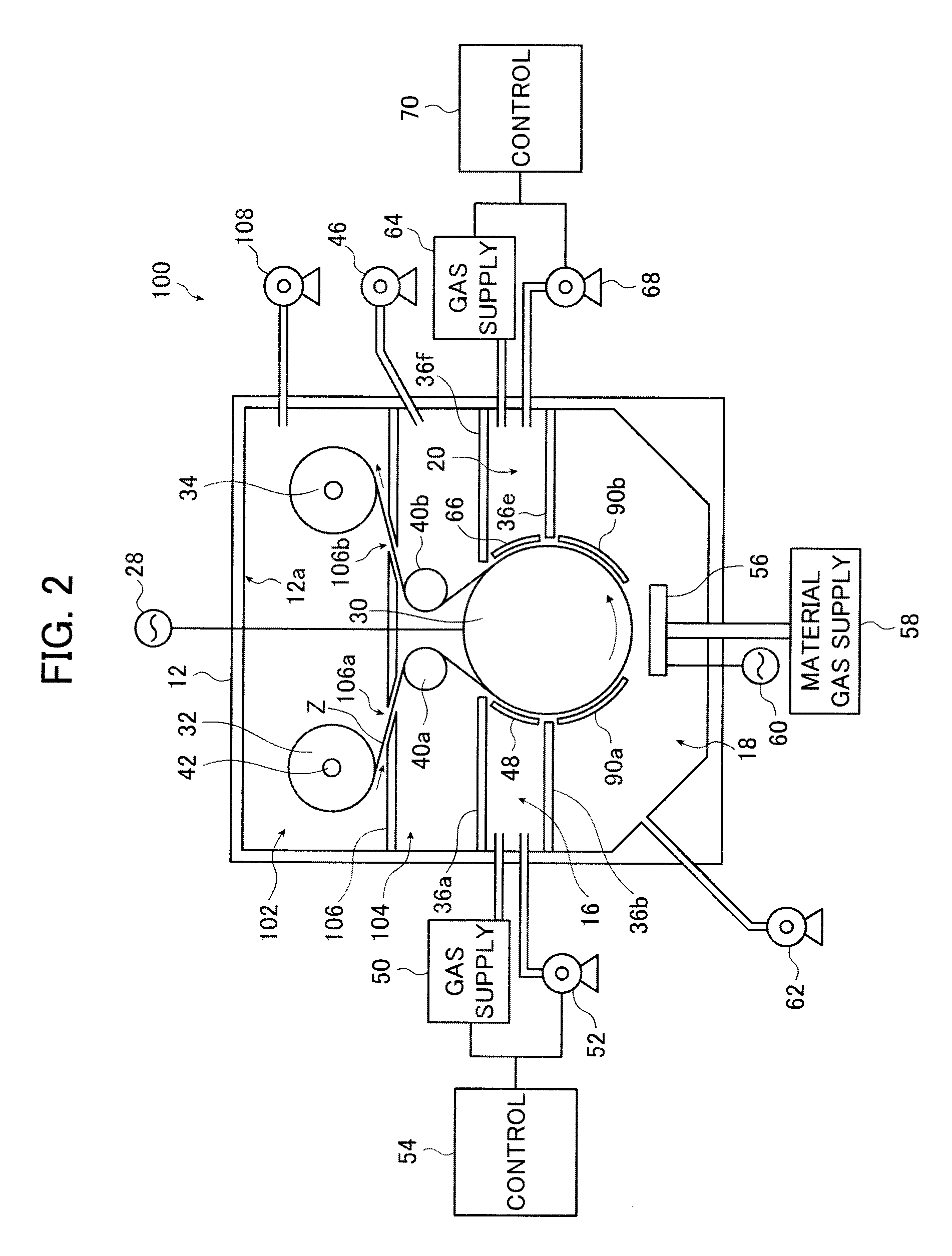

ActiveUS20110064890A1Quality improvementContinuous depositionChemical vapor deposition coatingPlasma techniqueElectric powerPellicle membrane

A film deposition method deposits a film on a surface of a substrate in strip form traveling on a peripheral surface of a cylindrical drum in at least one film deposition compartment around the peripheral surface of the drum. The method disposes previously a differential compartment between one film deposition compartment and a compartment including a wrapping space containing at least one of a first position at which the substrate starts to travel on the drum and a second position at which the substrate separates from the drum, the differential compartments communicating with the compartment including the wrapping space and the film deposition compartment, sets a first pressure of the wrapping space lower than a second pressure of the at least one film deposition compartment and performs film deposition in the film deposition compartment with electric power supplied to the drum.

Owner:FUJIFILM CORP

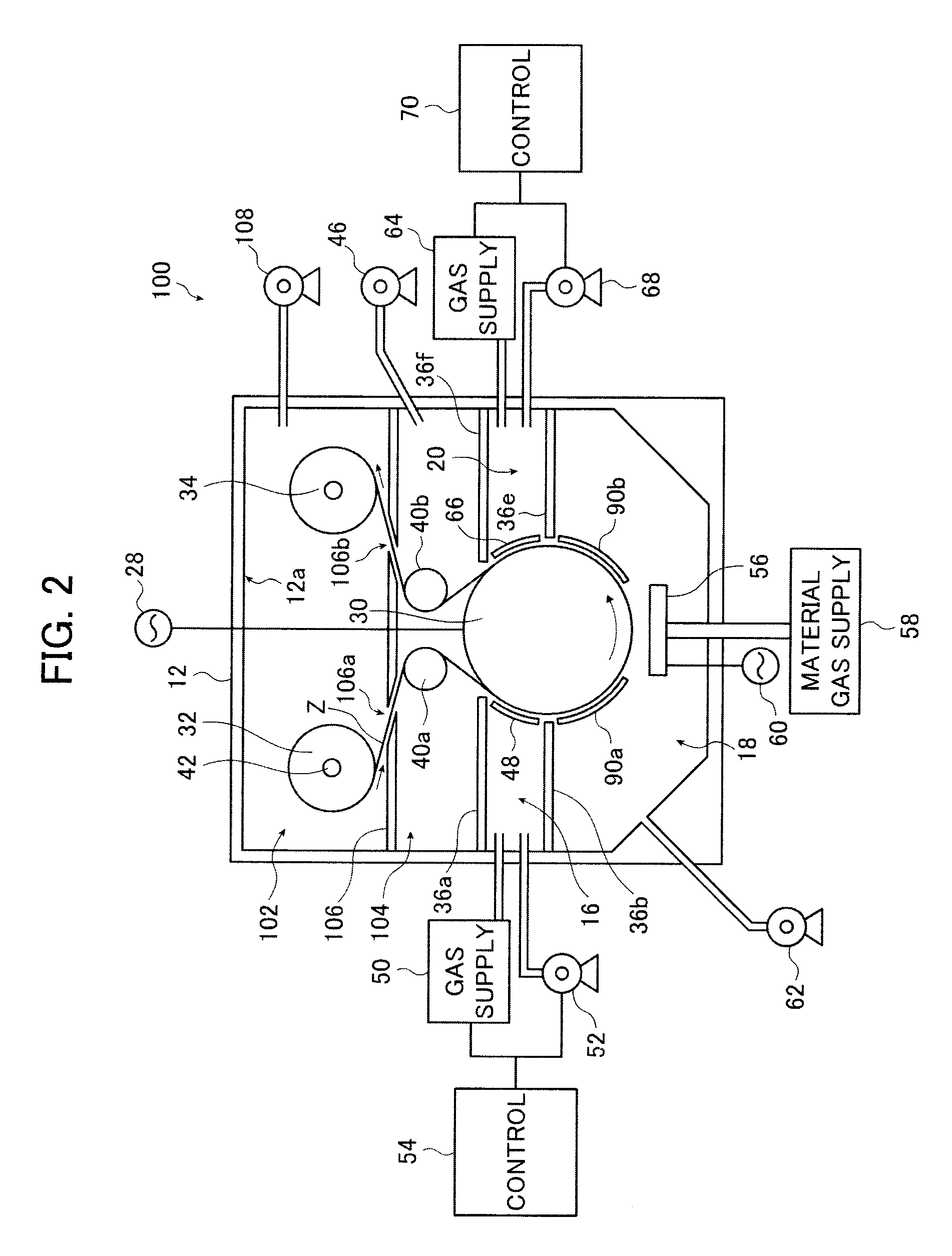

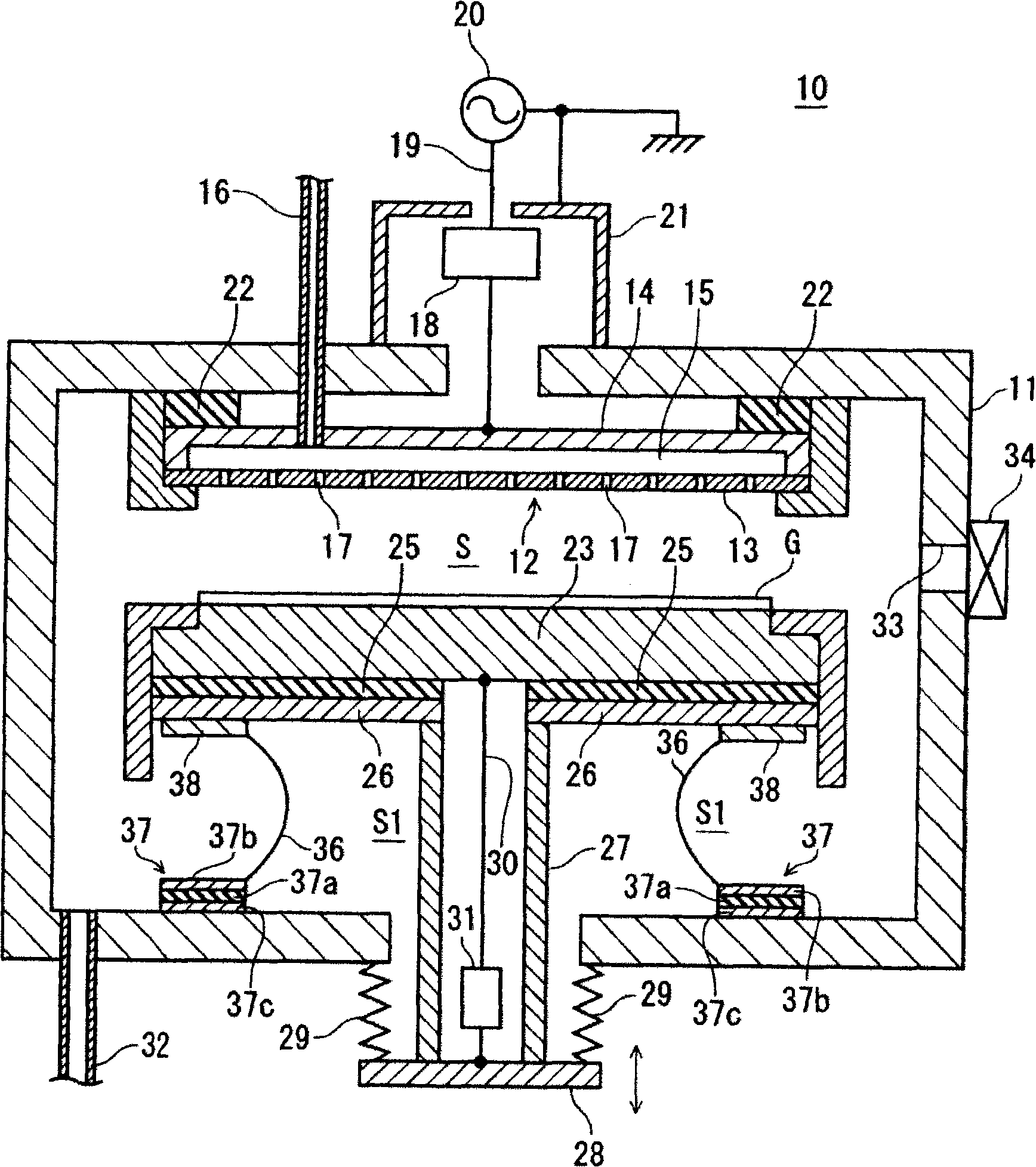

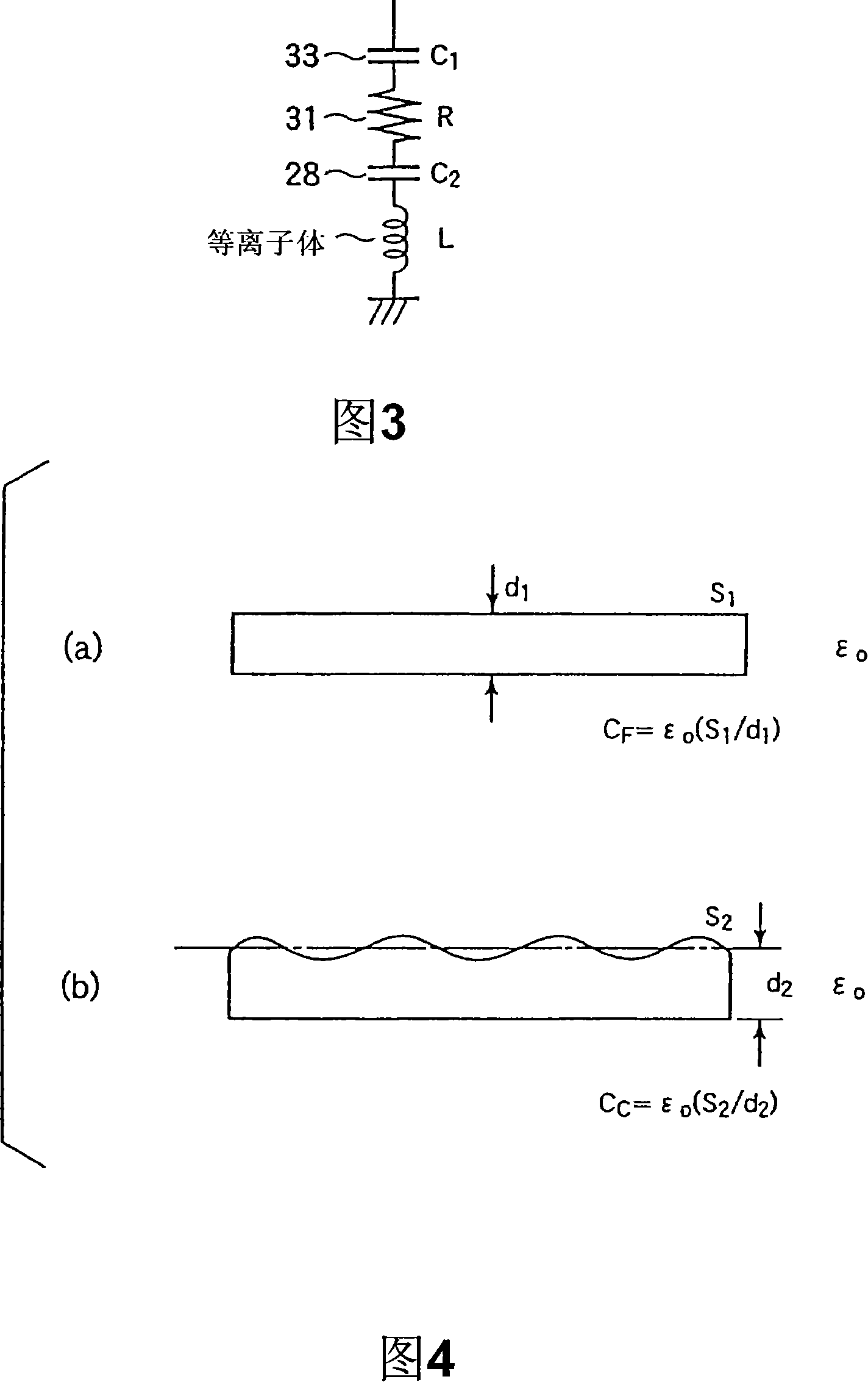

Plasma treatment apparatus and short circuit of high frequency current

InactiveCN101290869AReduce potential differenceSuppress abnormal dischargeElectric discharge tubesSemiconductor/solid-state device manufacturingHigh frequency powerPotential difference

The invention provides a plasma treatment apparatus capable of reducing potential difference between a ground substrate which holds at least either a lower electrode or an upper electrode, and the inner wall of a housing vessel. The plasma treatment apparatus 10 includes: a chamber 11 for housing a glass substrate G; a lower electrode board 23 as a mounting face, which is arranged in the chamber 11 for mounting the glass substrate G; a shower head 12 arranged facing the lower electrode board 23 for supplying raw gas into the chamber 11; a high-frequency power supply 20 connected to the upper electrode 13 of the shower head 12; a ground substrate 26 placed in a state of being spaced apart from the inner wall of the chamber 11, while supporting the lower electrode board 23 through a lower insulation part 25; and a shorting bar 36 for shunting the ground substrate 26 and the inner wall of the chamber 11. A capacitor 37 is interposed between the shorting bar 36 and the inner wall of the camber 11, and is provided on the inner wall of the camber 11.

Owner:TOKYO ELECTRON LTD

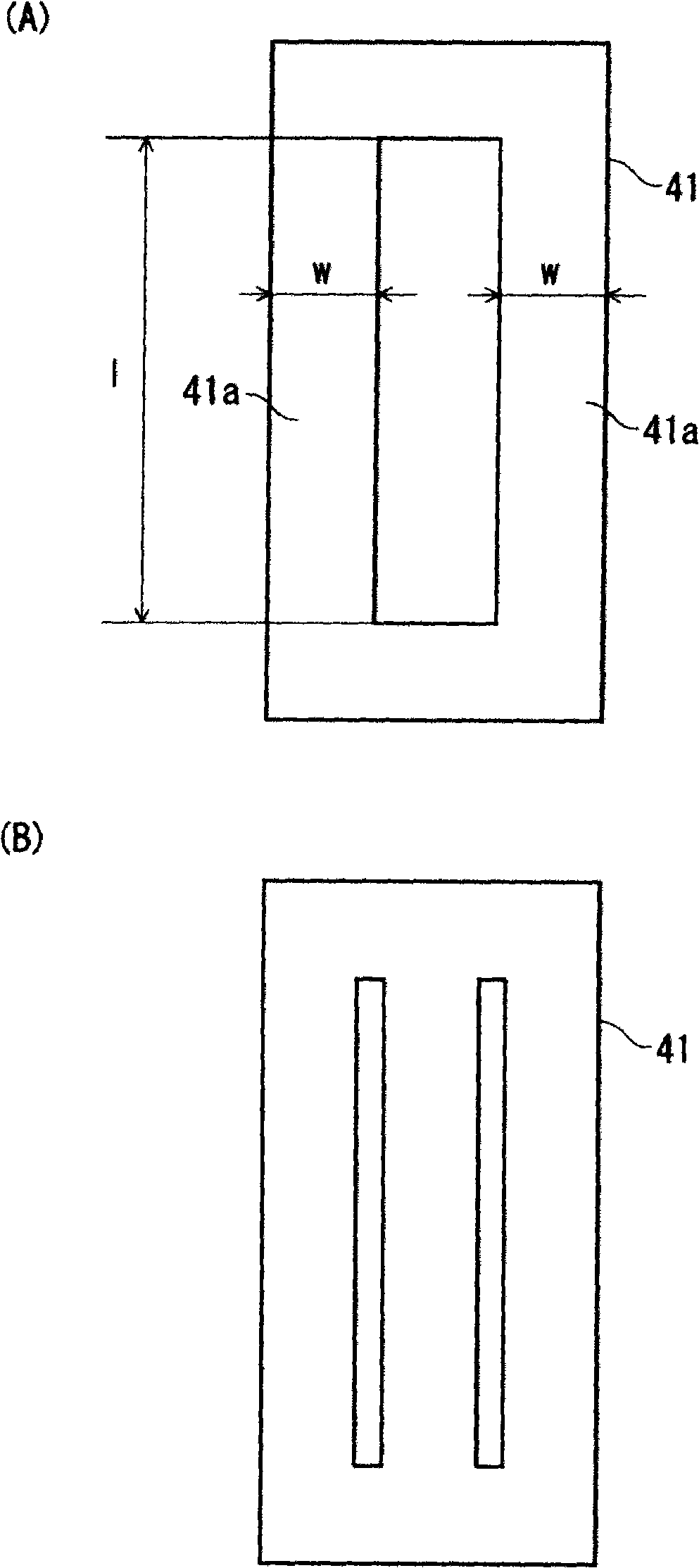

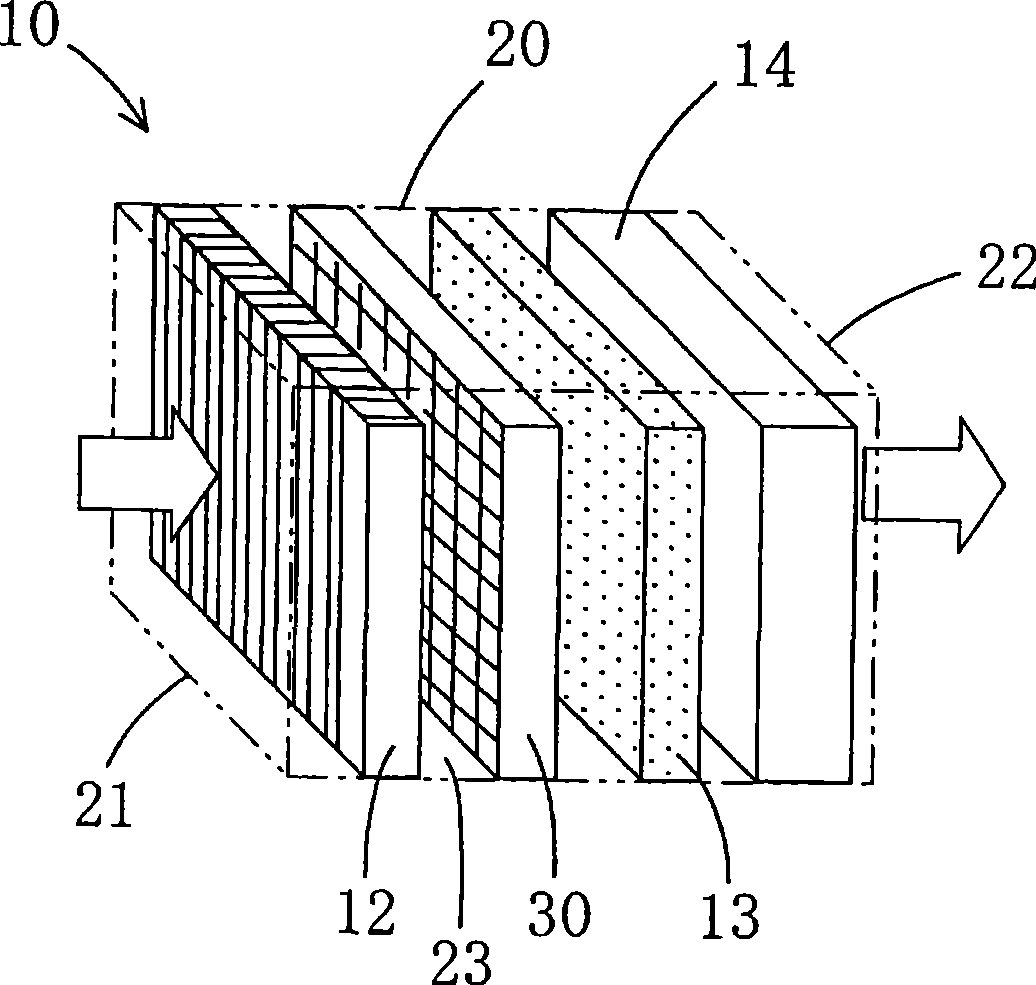

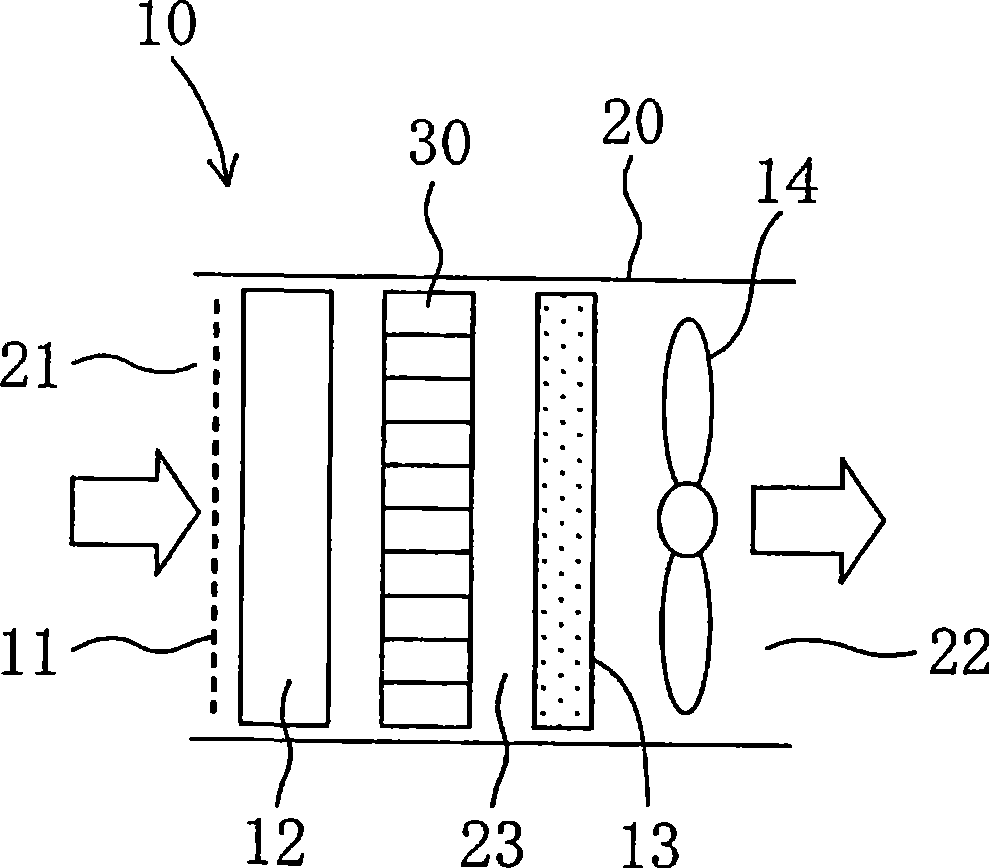

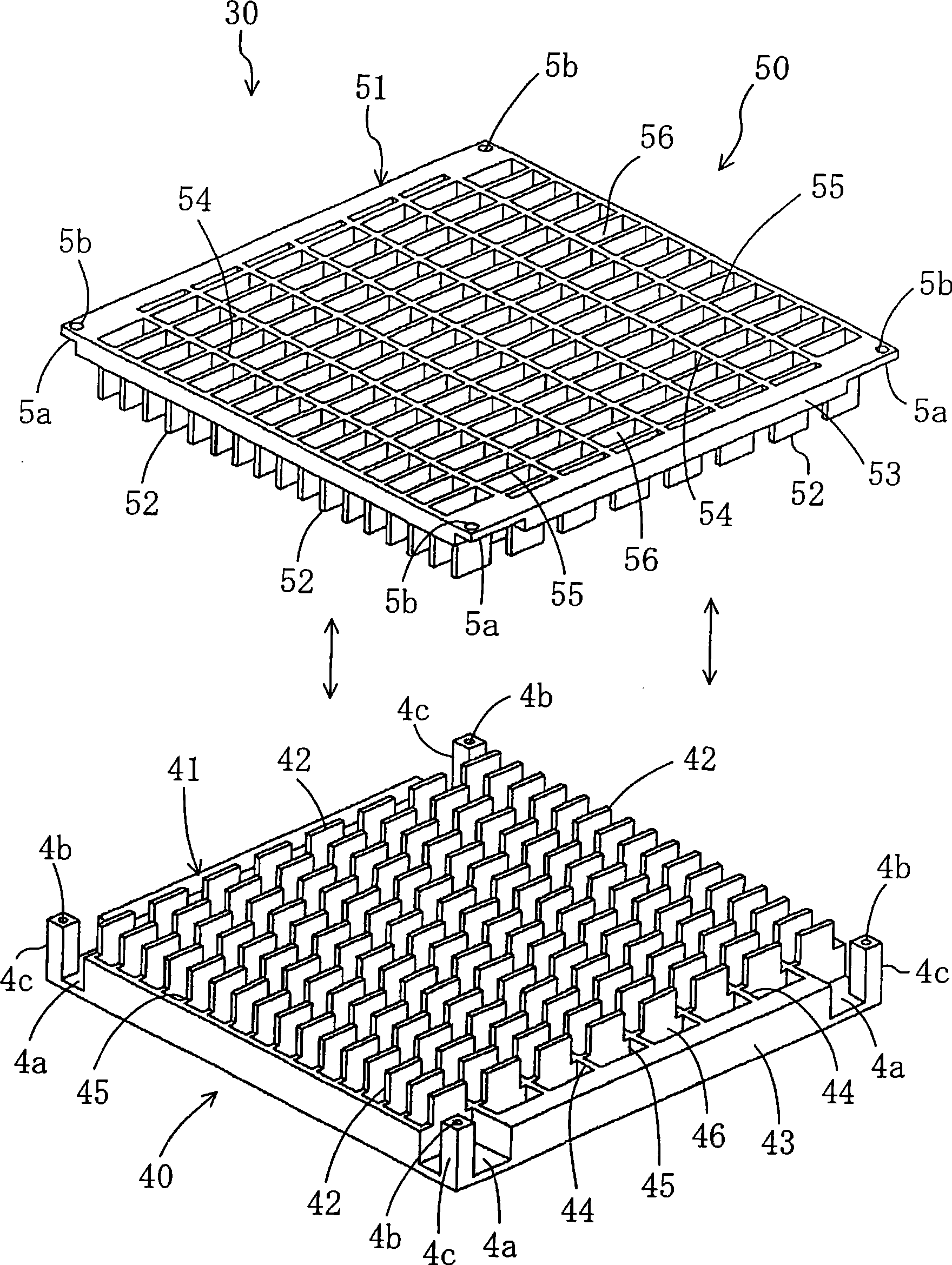

Dust collector

ActiveCN101472682AIncrease dust collection areaSpark suppressionExternal electric electrostatic seperatorElectrode constructionsElectricityEngineering

A dust collector includes a charging part (12) for charging dust with electricity and a dust collecting part (30). Each of a dust collecting electrode (40) and a high-voltage electrode (50) that constitute the dust collecting part (30) includes: a base (41, 51) with a rectangular grid structure having a large number of vent holes (46, 56) formed therein; and projections (42, 52) extending into the vent holes (56, 46) of the opposed electrode (50, 40). The dust collector collects dust by generating an electric field between the dust collecting electrode (40) and the high-voltage electrode (50).

Owner:DAIKIN IND LTD

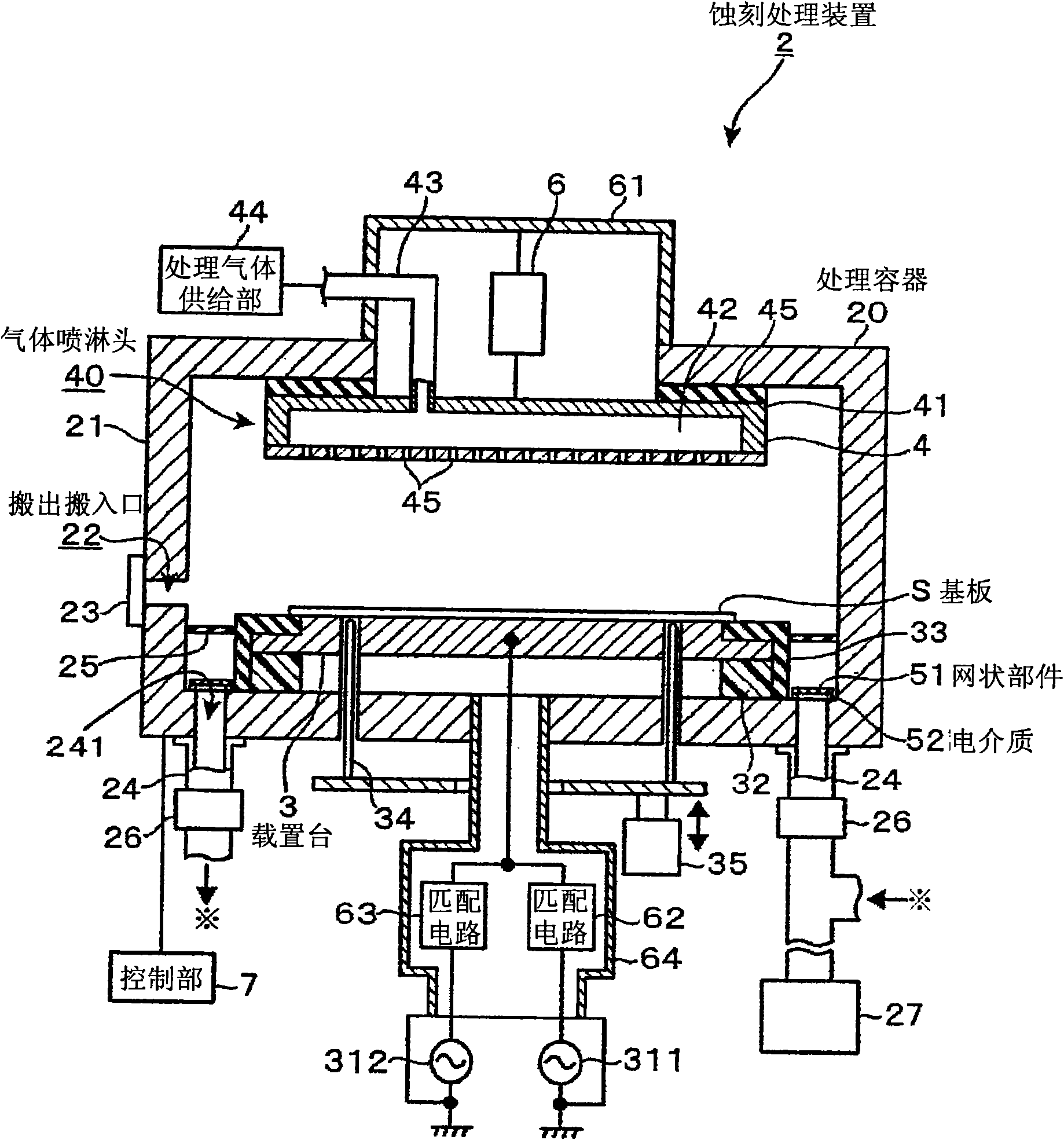

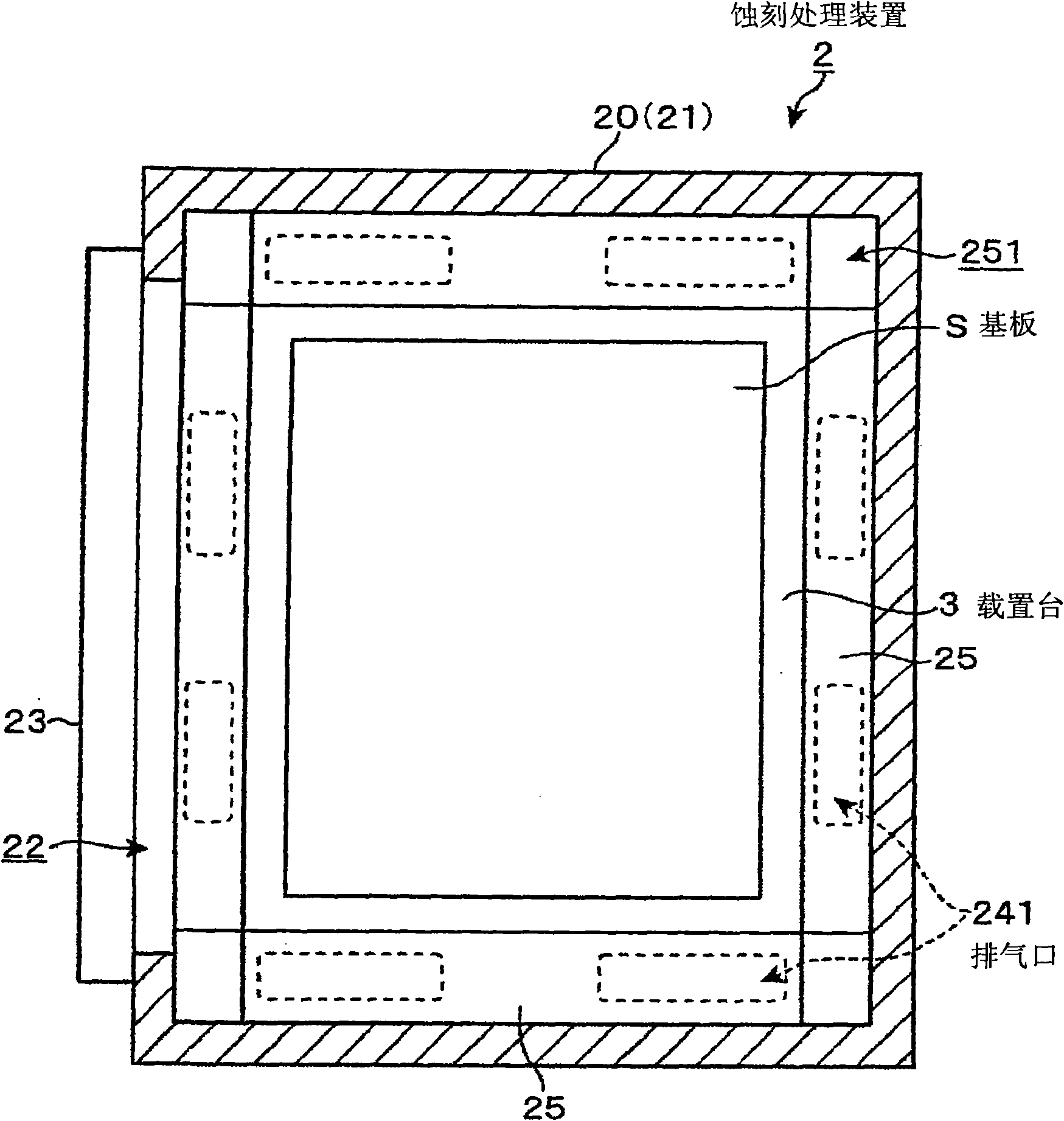

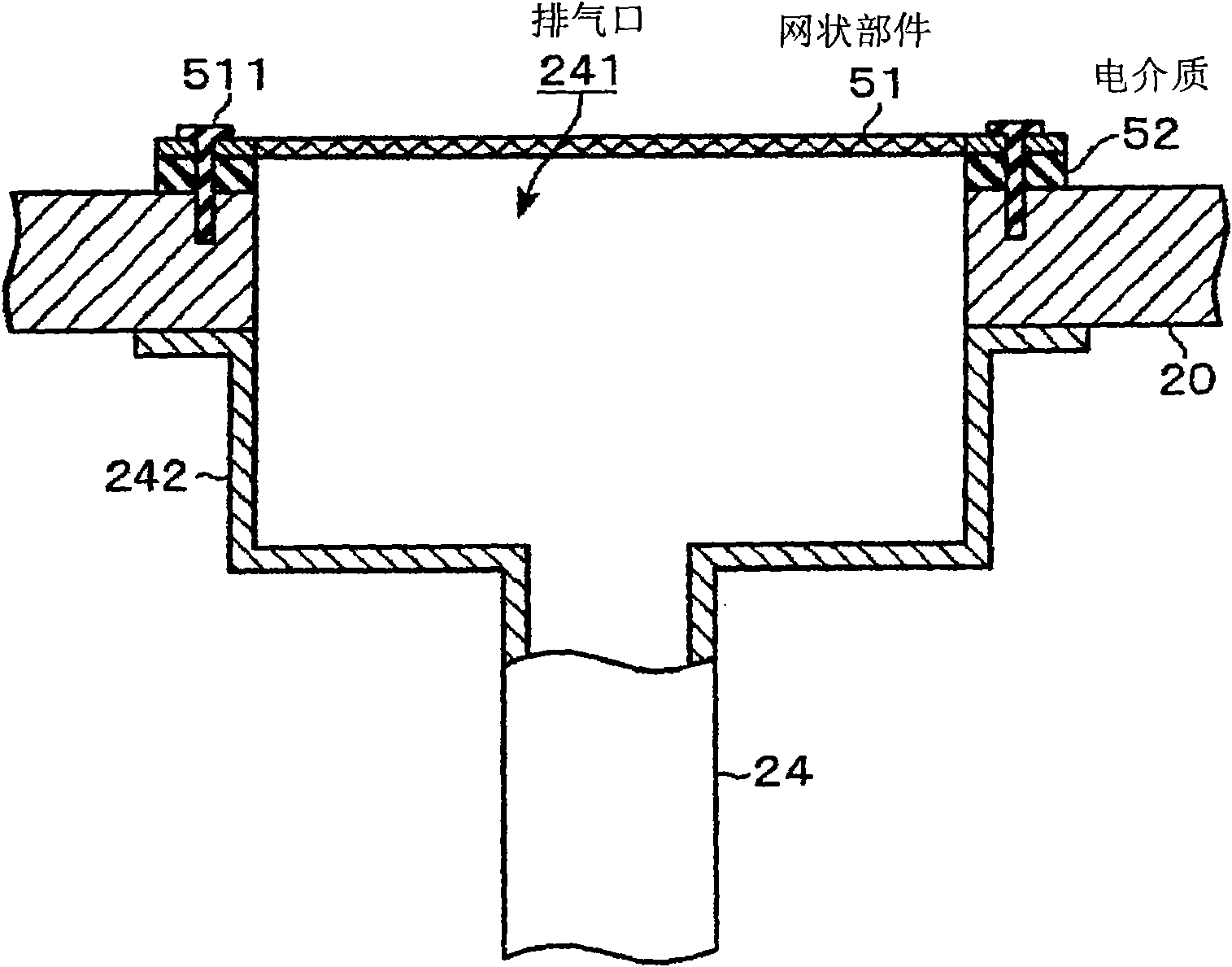

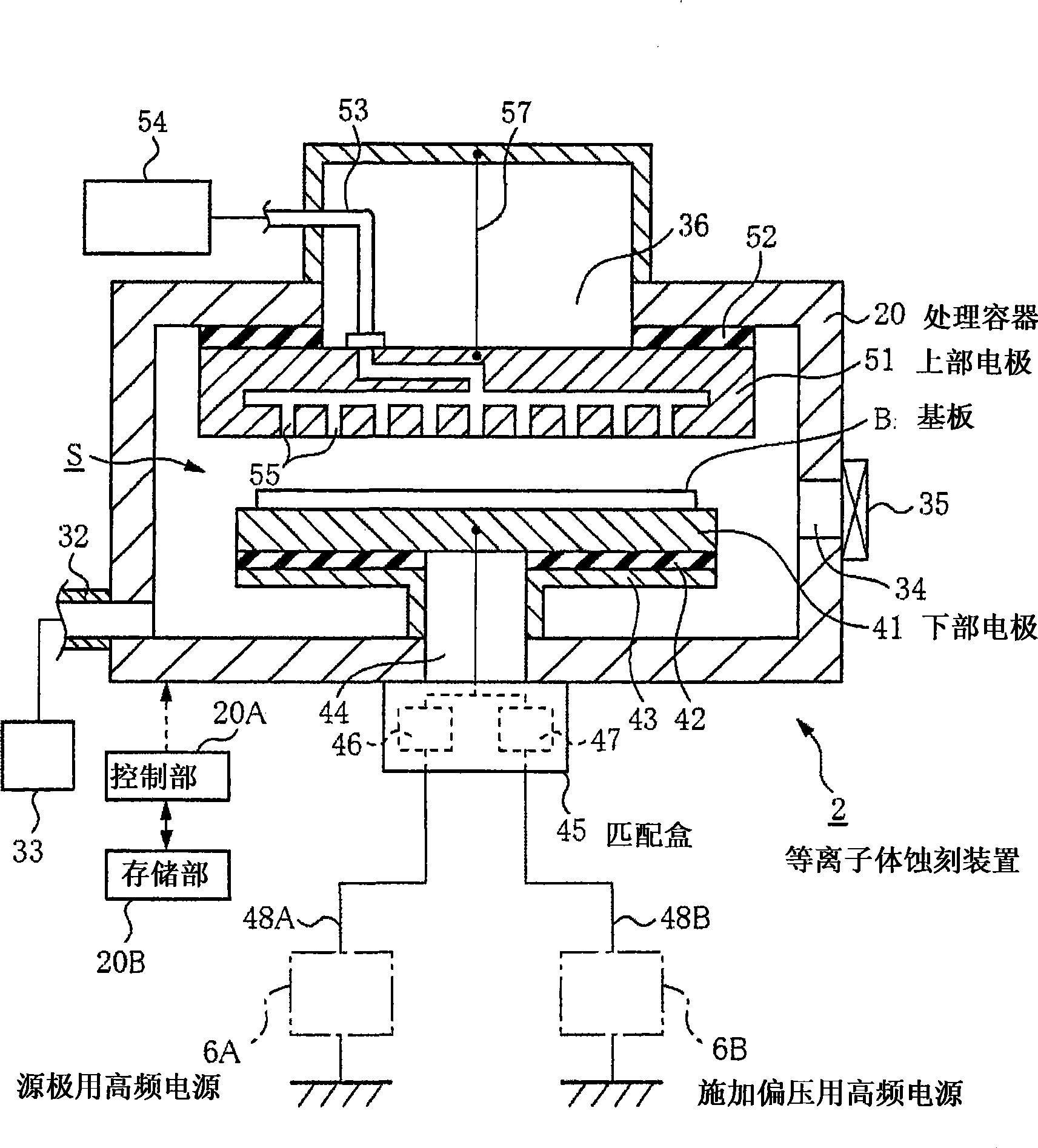

Plasma processing apparatus

ActiveCN101552188ASuppress abnormal dischargeArc suppressionElectric discharge tubesSemiconductor/solid-state device manufacturingPlasma treatmentGas plasma

The present invention provides a plasma processing apparatus, capable of restraining an abnormal discharge from generating between a cathode electrode and a netted member for shrouding an exhaust outlet in a parallel flat-plate type plasma processing apparatus. The plasma processing apparatus (2) applies a high frequency electric force between an anode electrode (gas spray head (40) ) and a cathode electrode (carrying bench (3)) facing with each other in a processing container (20) to implement a plasma treatment to the processing gas and implement a plasma treatment to a processed object (S), wherein a conductive member (netted member 51) having an opening is arranged around the cathode electrode to shroud the exhaust outlet for discharging the processing gas, and an electrolyte (52) is arranged between the conductive member and a conductive wall of the processing container (20).

Owner:TOKYO ELECTRON LTD

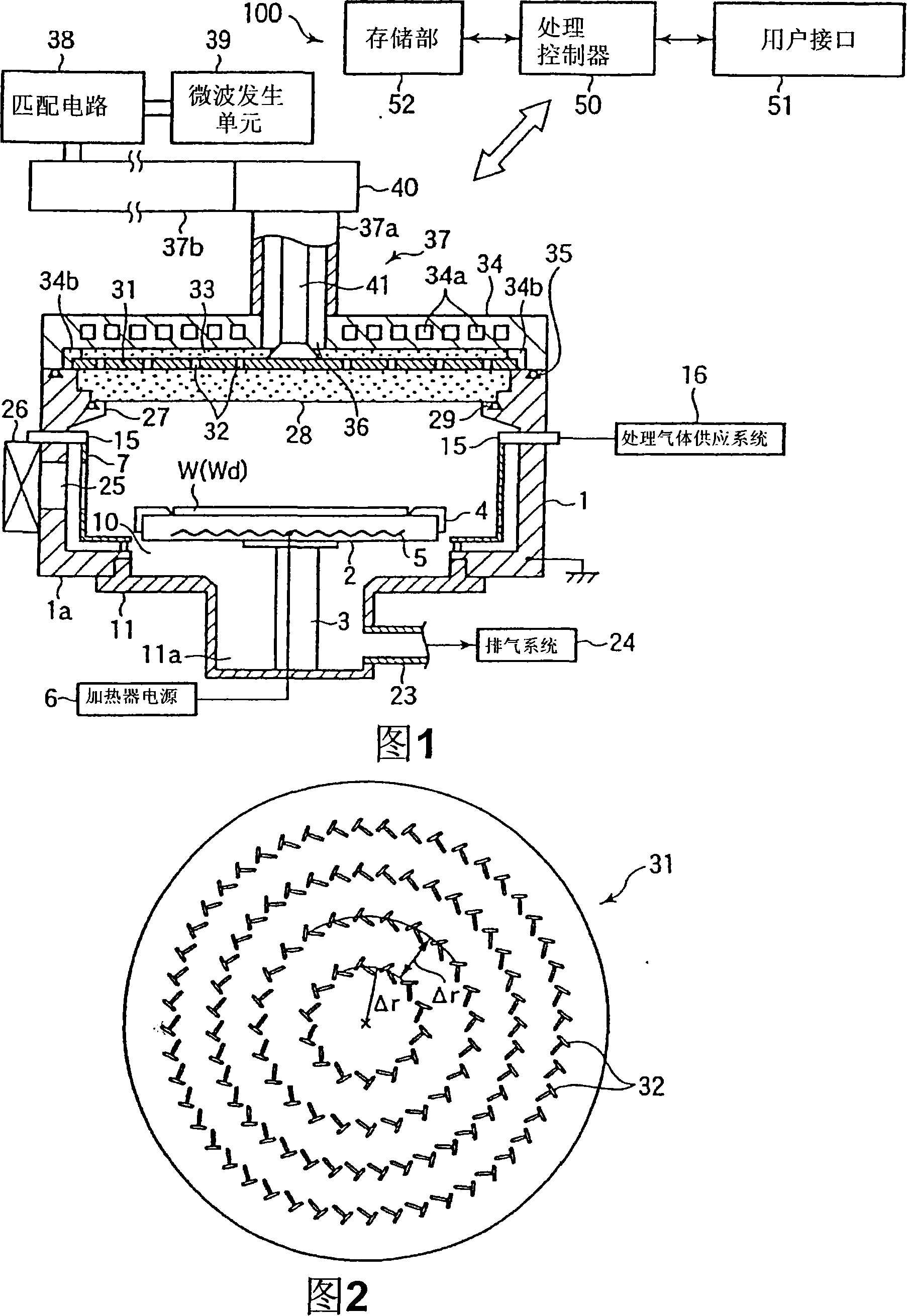

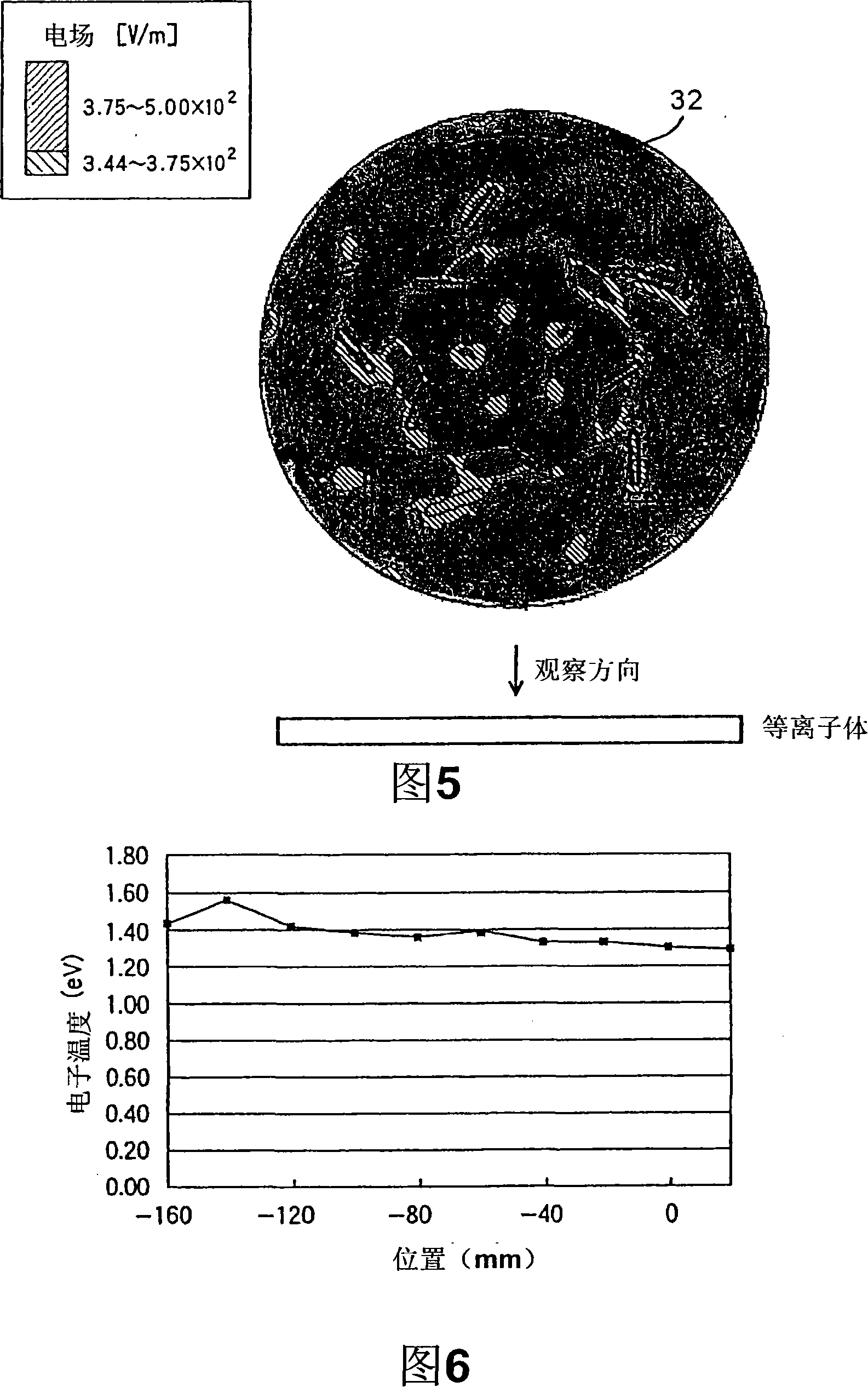

Microwave plasma processing device

InactiveCN101133688ASuppress abnormal dischargeEliminate air gapsElectric discharge tubesSemiconductor/solid-state device manufacturingDielectricMicrowave

A microwave plasma processing device comprising a chamber housing therein a material to be processed, a processing gas supplying means for supplying processing gas into the chamber, a microwave generating source for generating microwave forming the processing gas plasma in the chamber, a wave guiding means for guiding microwave generated in the microwave generating source toward the chamber, a flat antenna consisting of a conductor having a plurality of microwave radiating holes for radiating microwave guided by the wave guiding means toward the chamber, a microwave transmitting plate constituting the top wall of the chamber, transmitting microwave passed through the microwave radiating holes of the flat antenna and consisting of a dielectrics, and a delay plate provided on the opposite side of the microwave transmitting plate of the flat antenna, having a function of shortening the wavelength of microwave reaching the flat antenna and consisting of a dielectrics. The flat antenna and the microwave transmitting plate are substantially in close contact with each other with no air therebetween, the delay plate and the microwave transmitting plate are formed of the same material, and the delay plate, the flat antenna, the microwave transmitting plate and an equivalent circuit formed by the processing gas plasma formed in the chamber satisfy a resonance condition.

Owner:TOKYO ELECTRON LTD

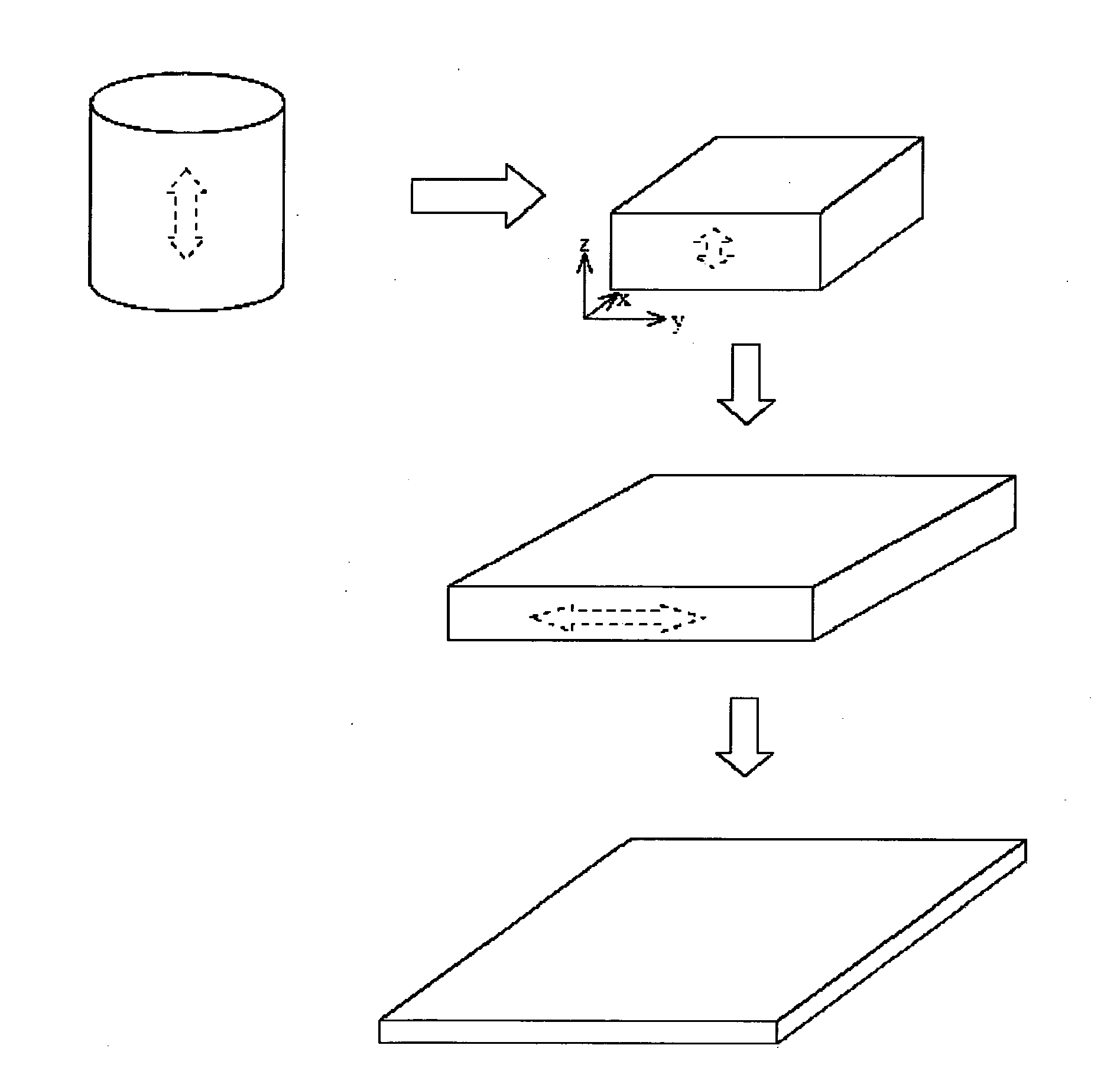

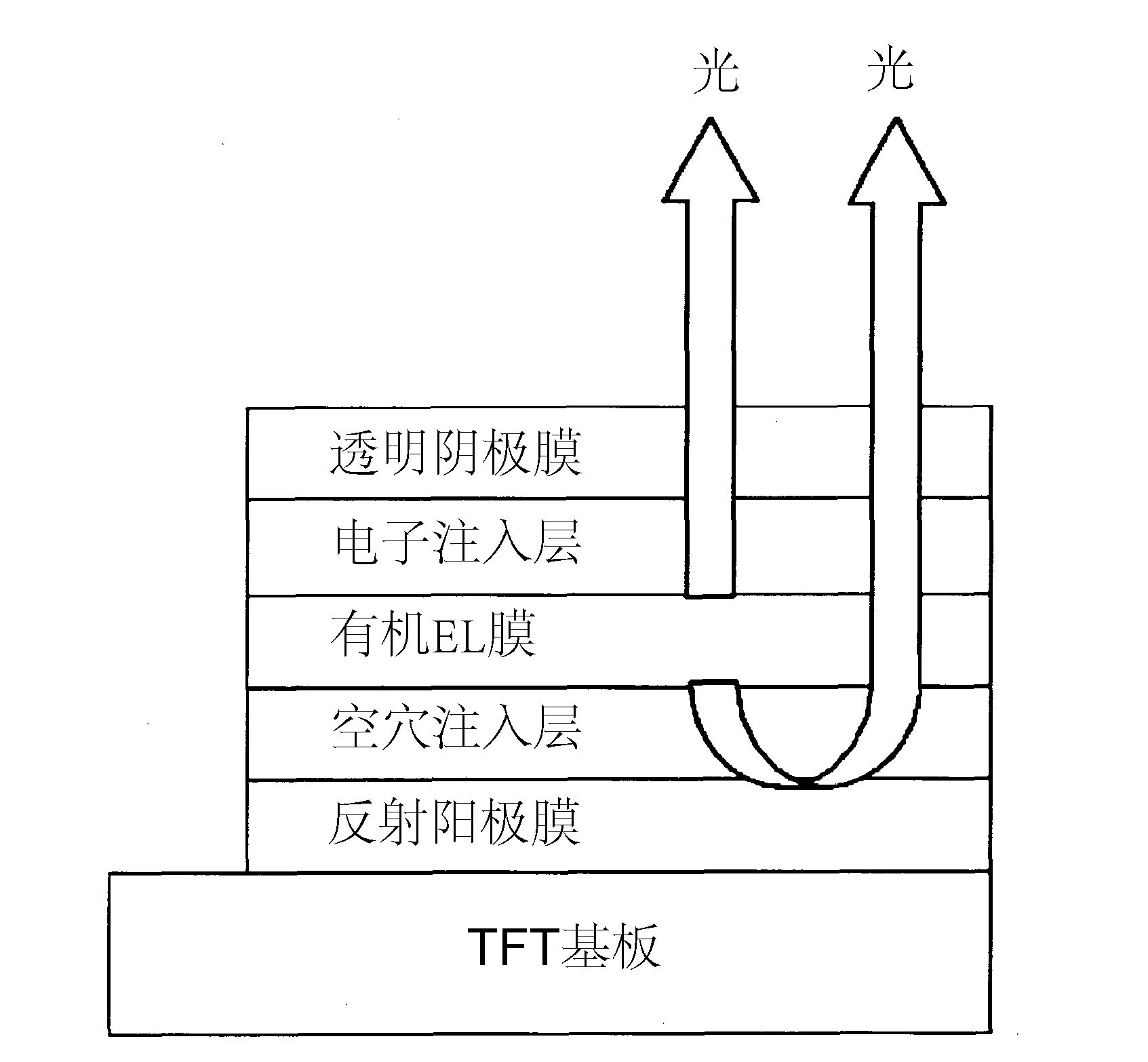

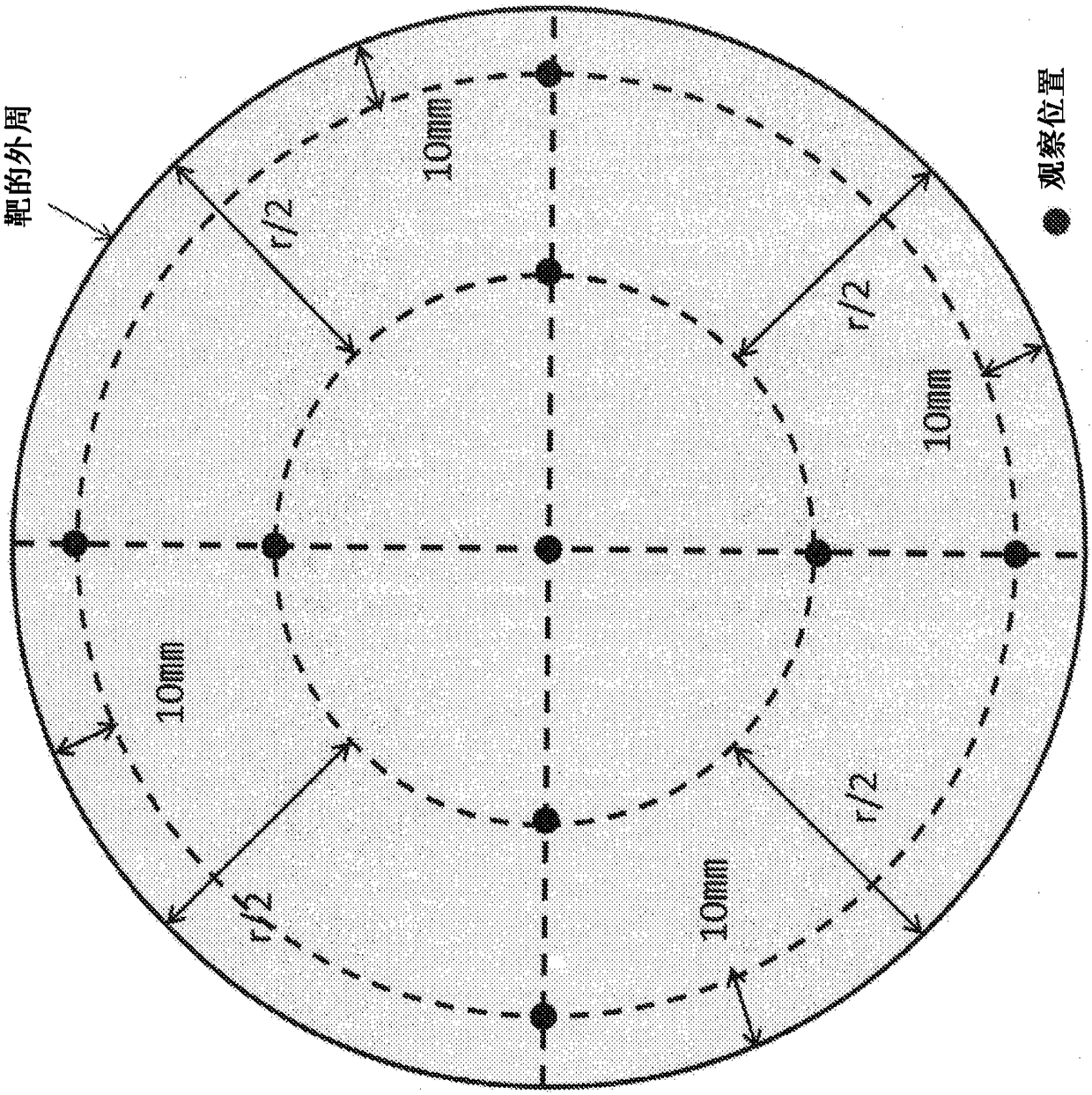

Silver alloy target for forming reflection electrode film for organic el element, and method for manufacturing the silver alloy target

ActiveCN102421931AImprove reflectivityIncreased durabilityElectroluminescent light sourcesVacuum evaporation coatingImpurityAg alloy

Disclosed is a silver alloy target for forming a reflection electrode film for an organic EL element, which has a component composition containing 0.1-1.5 % by mass of In and the balance composed of Ag and unavoidable impurities. The average grain diameter of the crystal grain of the alloy is 150-400 [mu]m, and the variance of the grain diameter of the crystal grains is 20% of the average grain diameter or less.

Owner:MITSUBISHI MATERIALS CORP

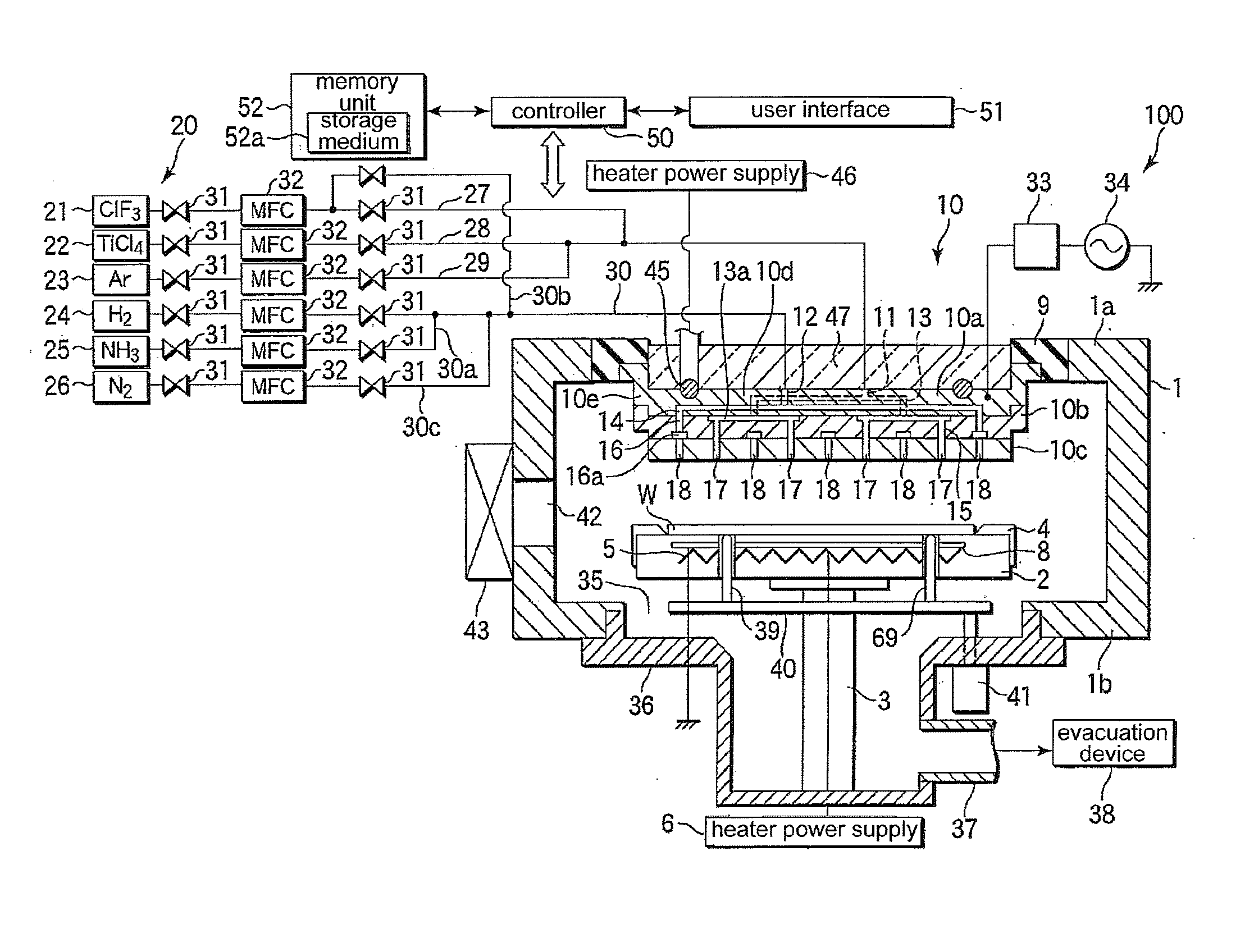

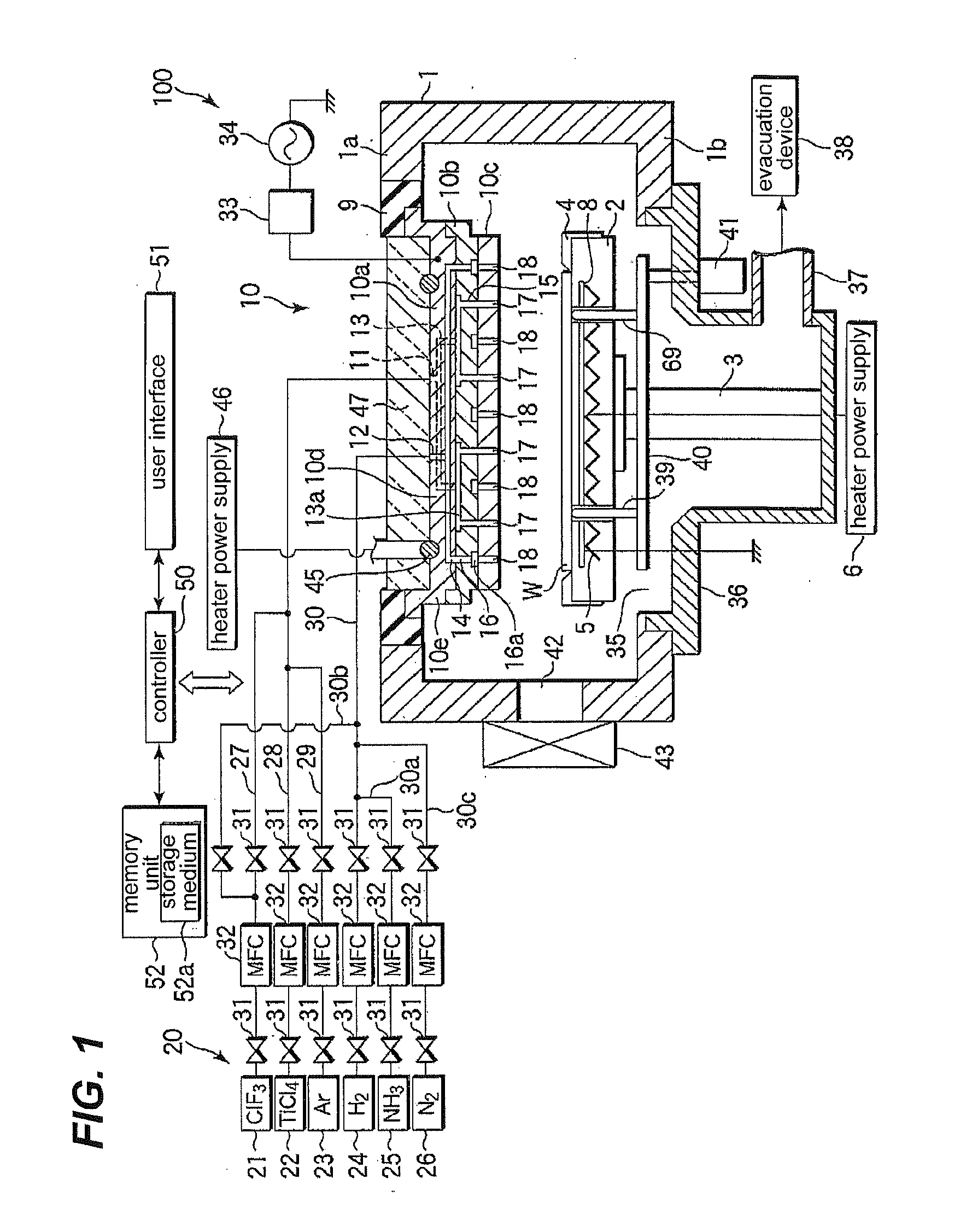

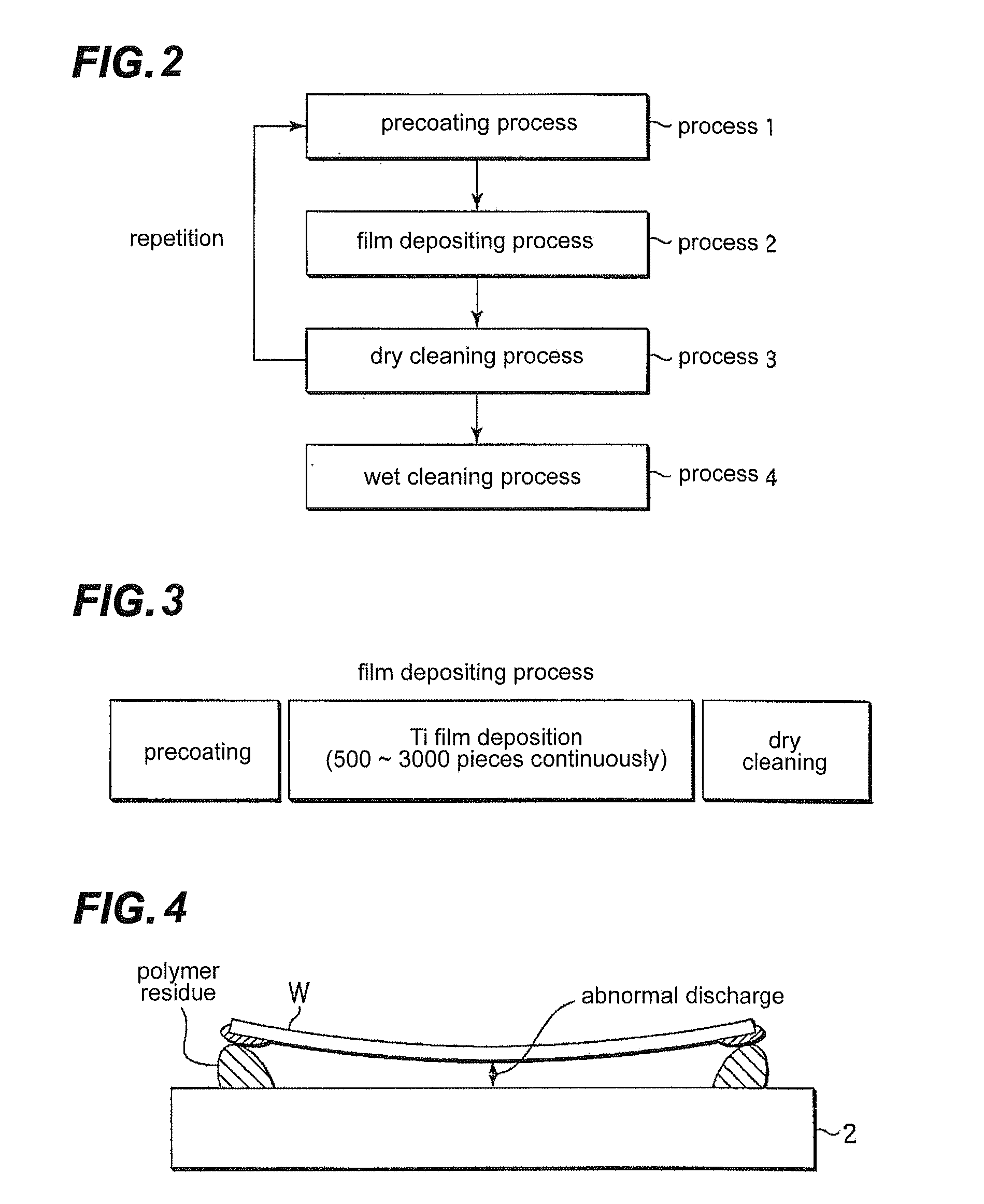

Method of depositing metallic film and memory medium

ActiveUS20110086184A1Suppress abnormal dischargeLiquid surface applicatorsChemical vapor deposition coatingElectrically conductiveMetal

For depositing a metallic film, the following steps are repeatedly conducted: a step in which a precoat film is formed on the inside of a chamber; a step in which two or more substrates to be treated are subjected to the deposition of a metallic film thereon by introducing each substrate into the precoated chamber, placing the substrate on the stage, feeding a treating gas while heating the substrate to generate a plasma of the treating gas, and depositing a metallic film on the substrate by plasma CVD; and a step in which after the film deposition on the substrates has been completed, a cleaning gas is introduced into the chamber to conduct dry cleaning. In the step in which two or more substrates to be treated are subjected to the deposition of a metallic film thereon, a conductive film is formed on the stage one or more times in the course of the step.

Owner:TOKYO ELECTRON LTD

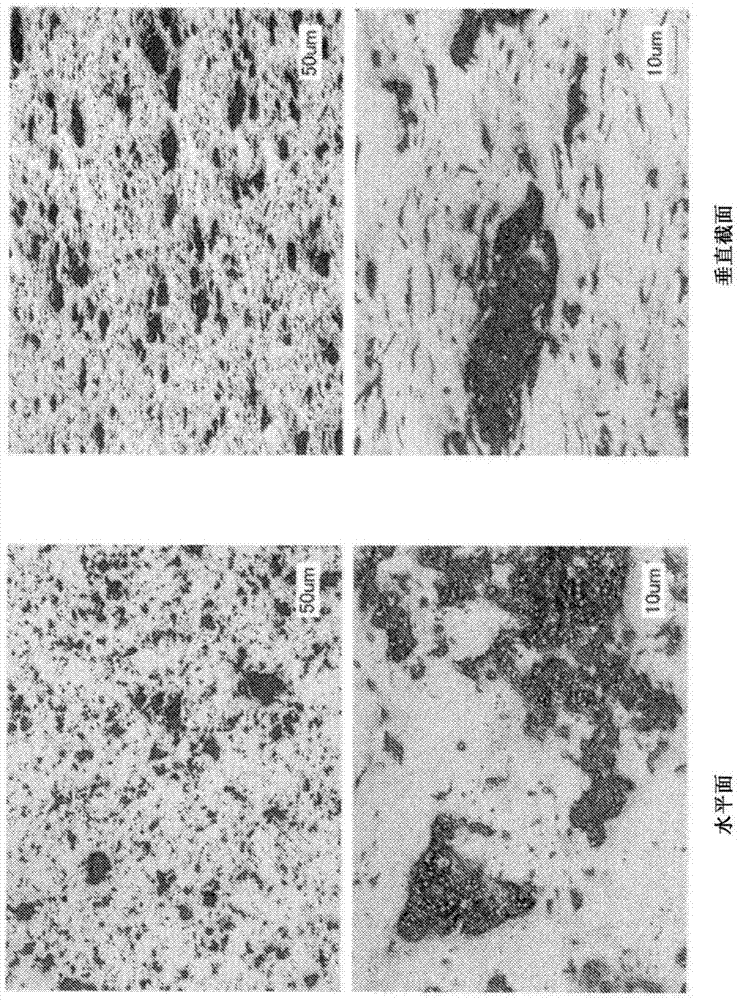

Fe-Pt sintered compact sputtering target and manufacturing method therefor

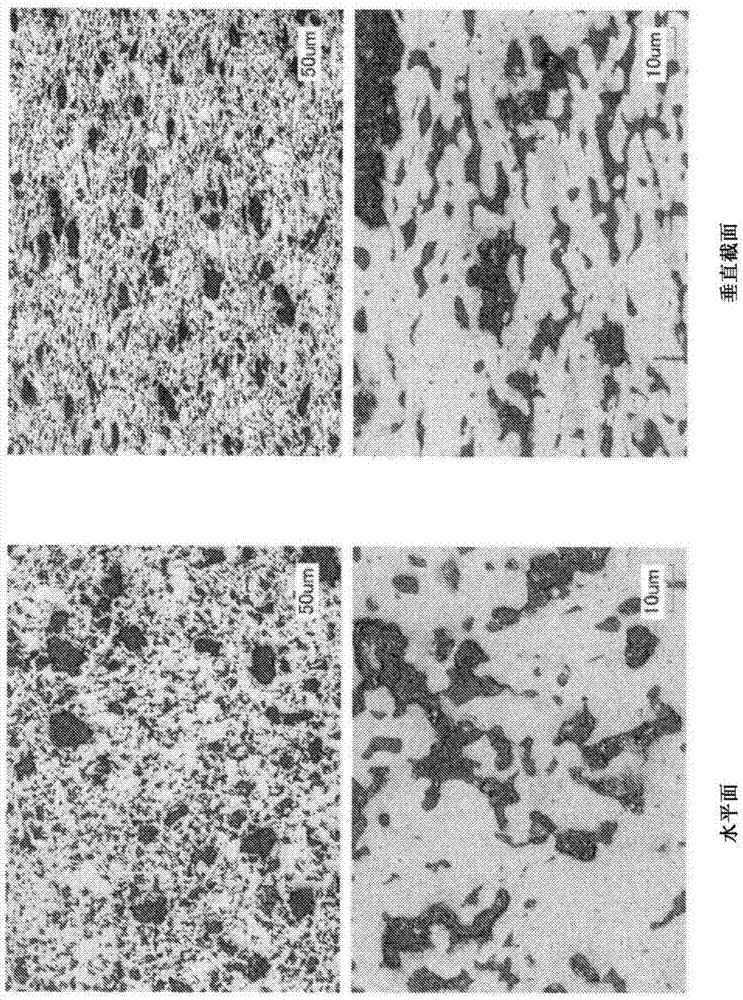

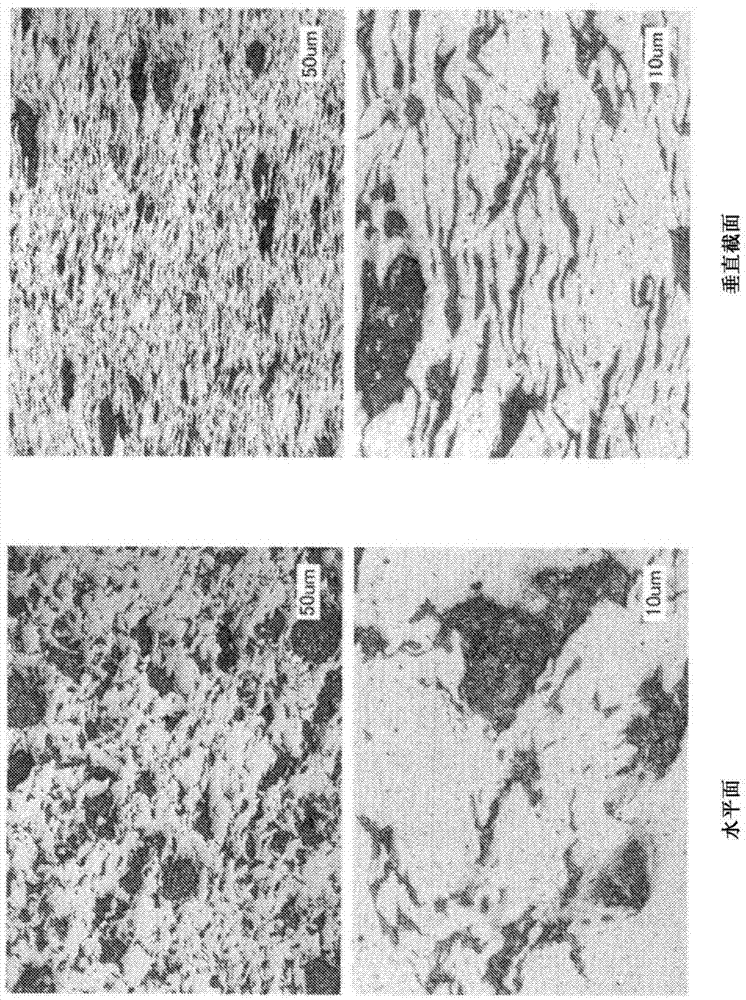

ActiveCN104781446AGood orientationSuppress abnormal dischargeVacuum evaporation coatingSputtering coatingSputteringHeat-assisted magnetic recording

An Fe-Pt sintered compact sputtering target containing BN characterized in that the intensity ratio of the X-ray diffraction peak intensity of a hexagonal BN (002) plane in a plane level with the sputtering surface with respect to the X-ray diffraction peak intensity of a hexagonal BN (002) plane in a cross-section perpendicular to the sputtering surface is 2 or more. The present invention addresses the problem of providing a sputtering target with which manufacture of a magnetic film in thermally assisted magnetic recording media is possible and particles that are generated during sputtering are reduced.

Owner:JX NIPPON MINING & METALS CO LTD

Sputtering target, a joined type sputtering target and a method of making such a joined type sputtering target

ActiveCN101063194AExcellent adhesionEasy to makeVacuum evaporation coatingSputtering coatingAlloyCorrosion resistant

[Object] It is to provide a sputtering target which has an excellent adhesion to films made of Au, Cu or an alloy containing at least one of Au and Cu and also an excellent corrosion resistance and which can be used to form an Mo-Ti alloy film over a large-sized substrate.

Owner:ULVAC INC

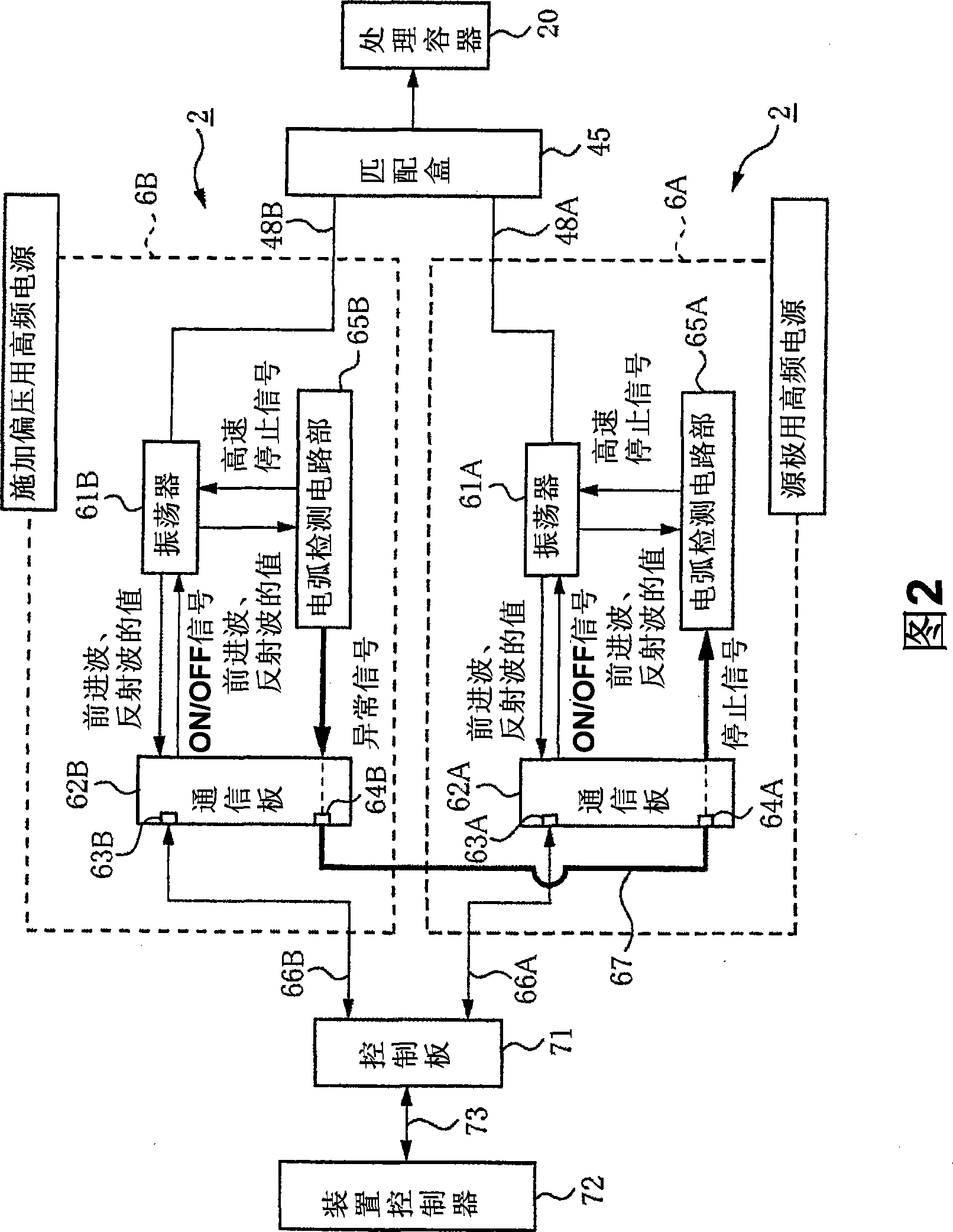

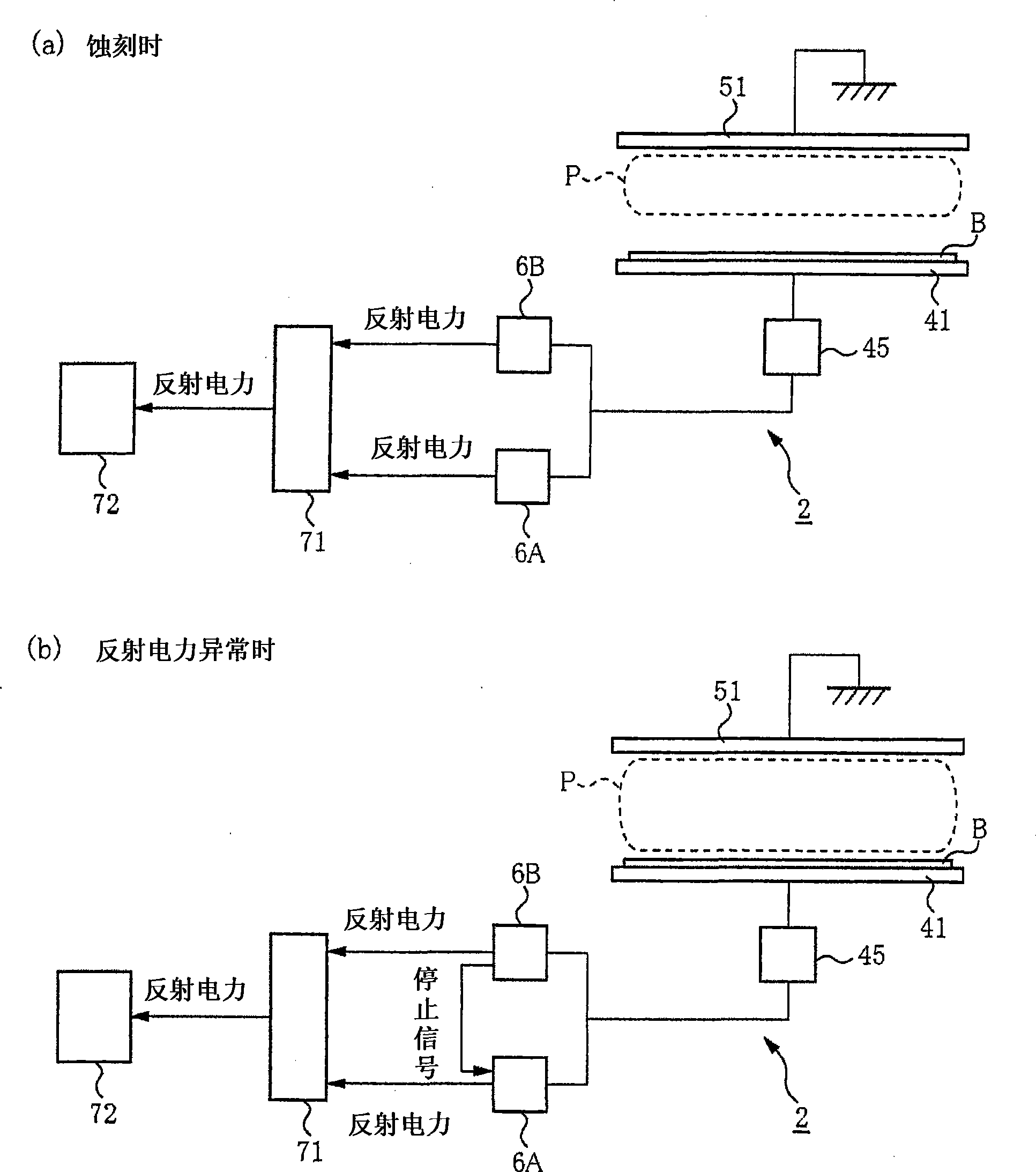

Plasmer processing device, plasmer processing method and storage medium

ActiveCN101389179APrevent or reduce damageSuppress abnormal dischargeElectric discharge tubesSemiconductor/solid-state device manufacturingHigh frequency powerPlasma processing

The invention provides a plasma processing device, a plasma processing method and storage media. In the plasma processing device using a plurality of high frequency power source to perform plasma process, when overlarge reflection waves are generated in at least one high frequency power source, output of the high frequency power source is stopped, meanwhile the output of the other high frequency power source is stopped instantly. The plurality of high frequency power sources respectively comprise: an oscillator, a communication part, an output stopping part for receiving stopping signals and stopping the output of the oscillator through the communication part, an output stopping part of at least one of the high frequency power source in the plurality of high frequency power sources monitors high frequency output from the high frequency power oscillator, the output of the oscillator is stopped in abnormity of high frequency, meanwhile, stopping signals are output to the communication part. In addition, in order to transmit the stopping signals from the monitor part to the other high frequency power source, the communication part of at least one high frequency power source and the communication part of the other high frequency power source are connected.

Owner:TOKYO ELECTRON LTD

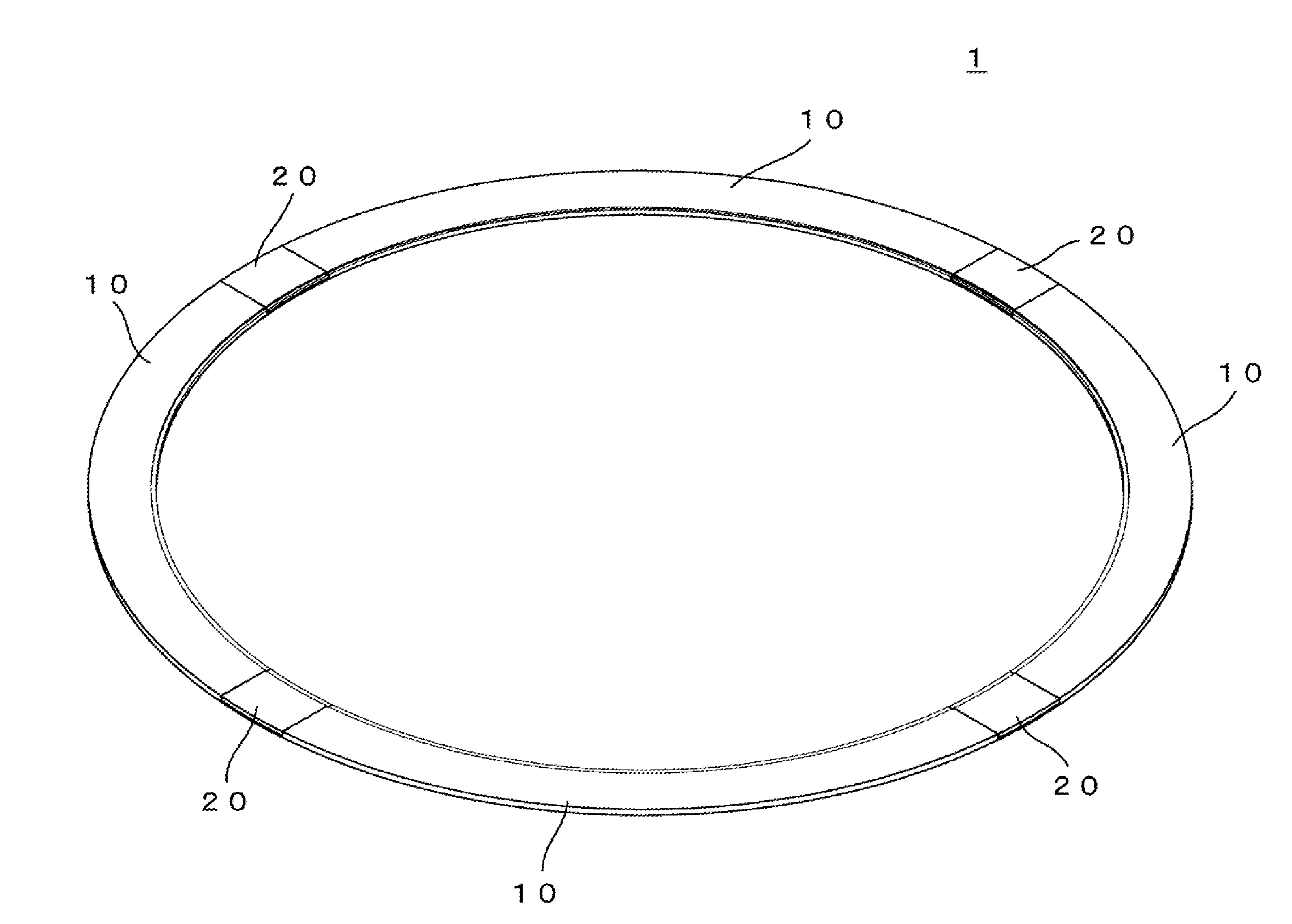

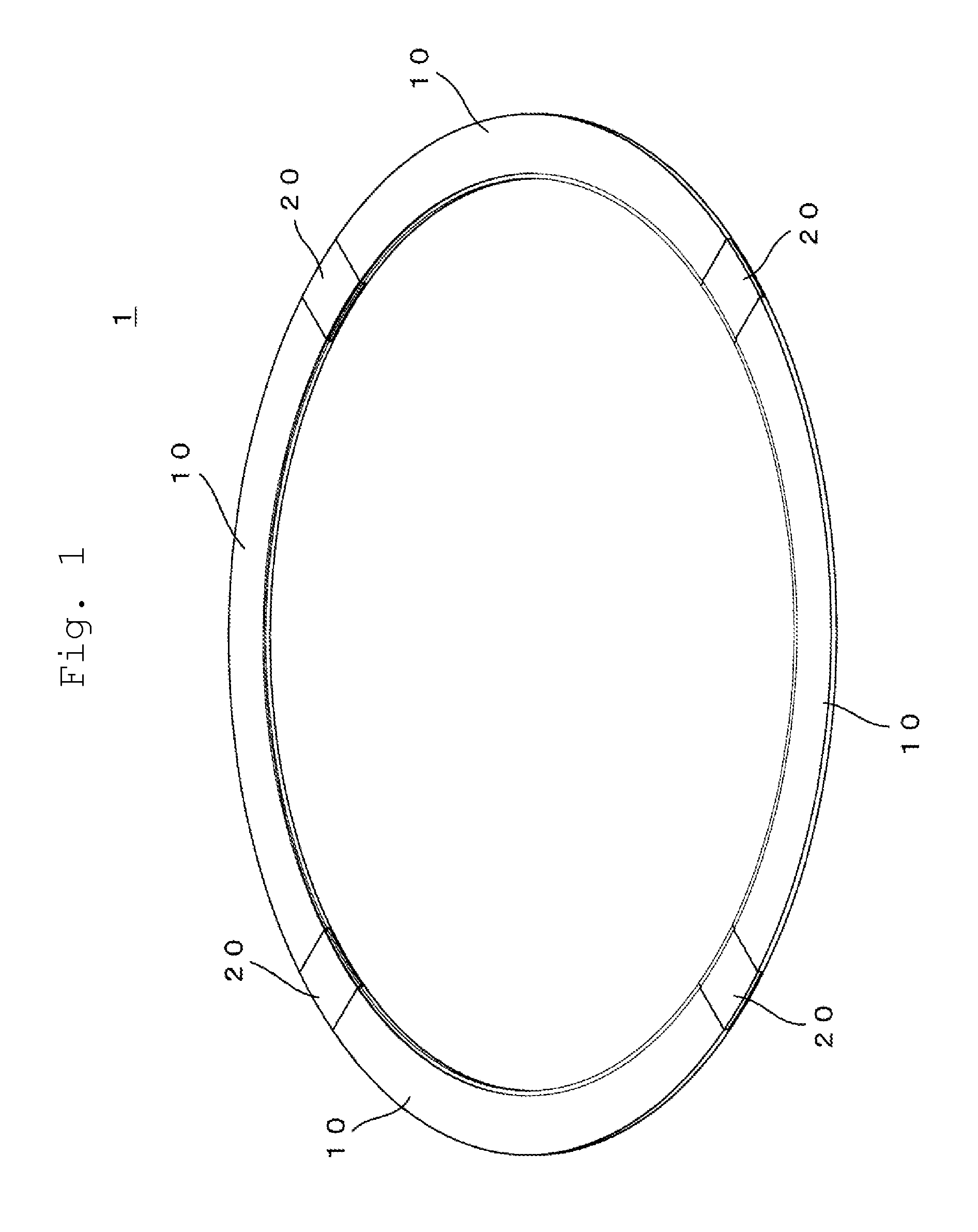

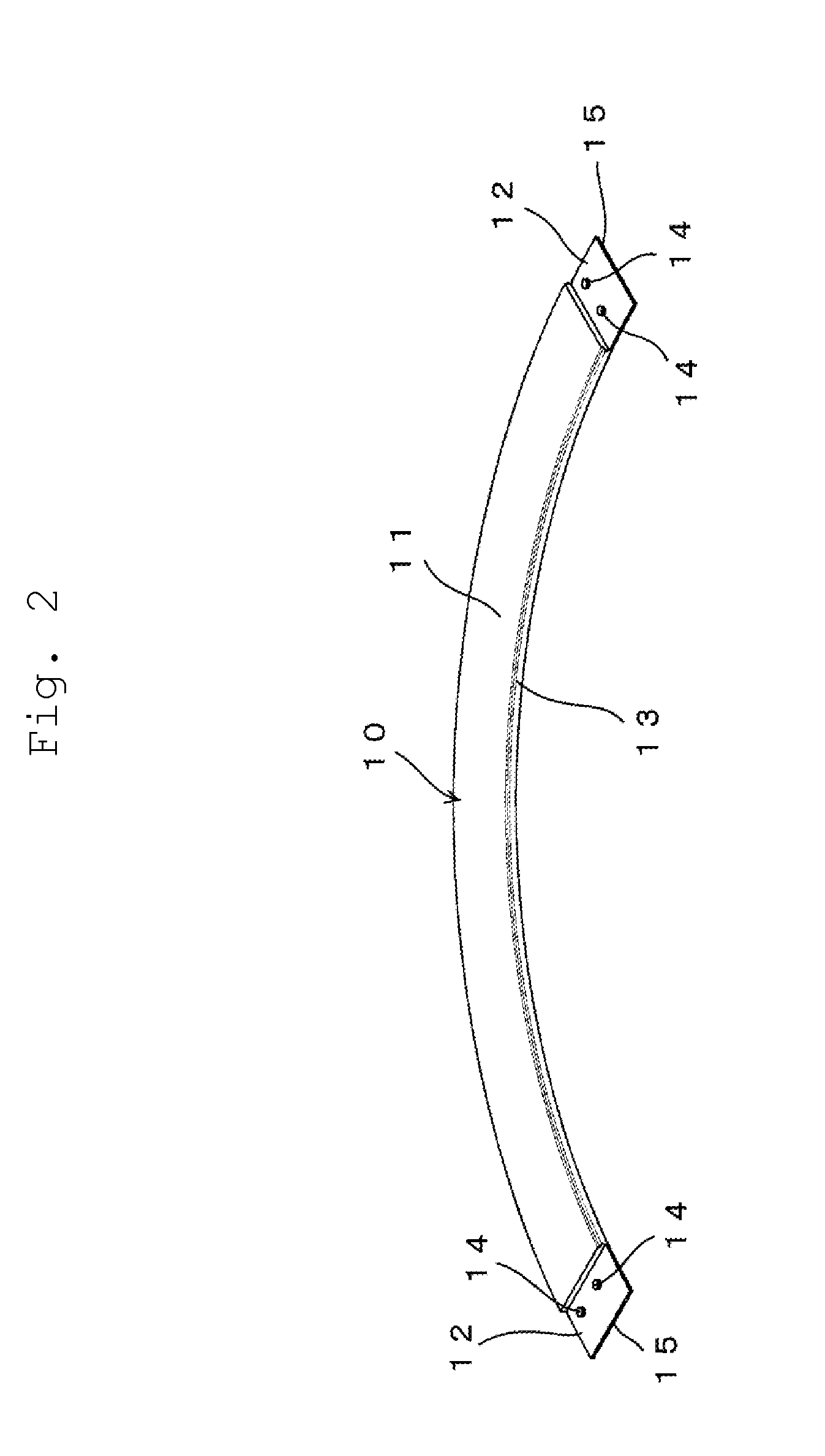

Focus ring

ActiveUS20150243488A1Improve mechanical strengthSuppress abnormal dischargeElectric discharge tubesSemiconductor/solid-state device manufacturingPlasma treatmentPlasma processing

There is provided a focus ring formed without an adhesive that can suppress abnormal electric discharge and obtain uniform plasma environment in a circumferential direction in a plasma processing apparatus. The focus ring includes a plurality of arc-shaped members and a plurality of connecting members connecting the plurality of the arc-shaped members to form a ring shape without an adhesive, and is formed such that a thickness between an upper surface of the connecting member and a bottom surface of a concave fitting portion of the connecting member is greater than a thickness between an upper surface of the arc-shaped member and a bottom surface of a second depression of the arc-shaped member.

Owner:COORSTEK INC

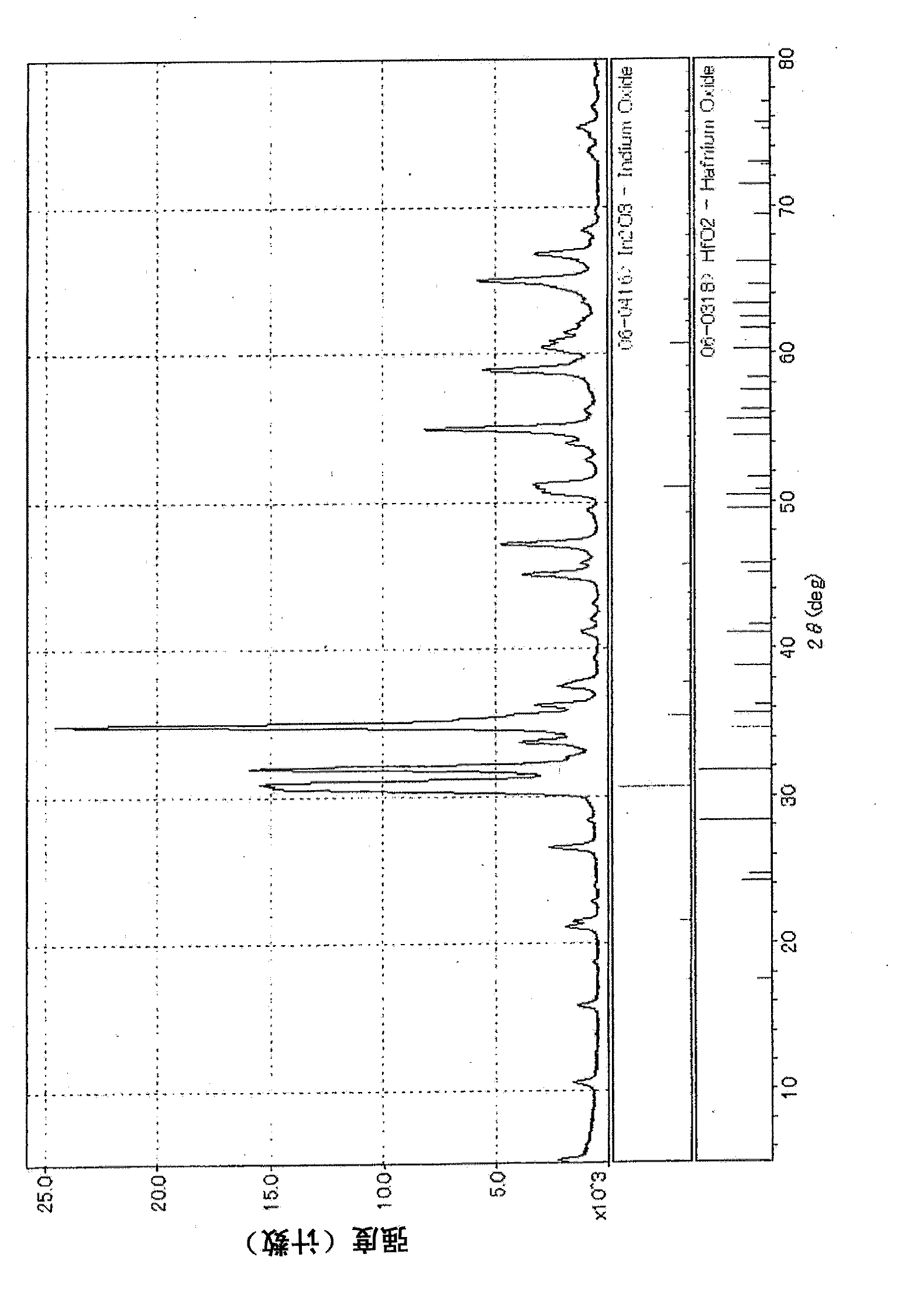

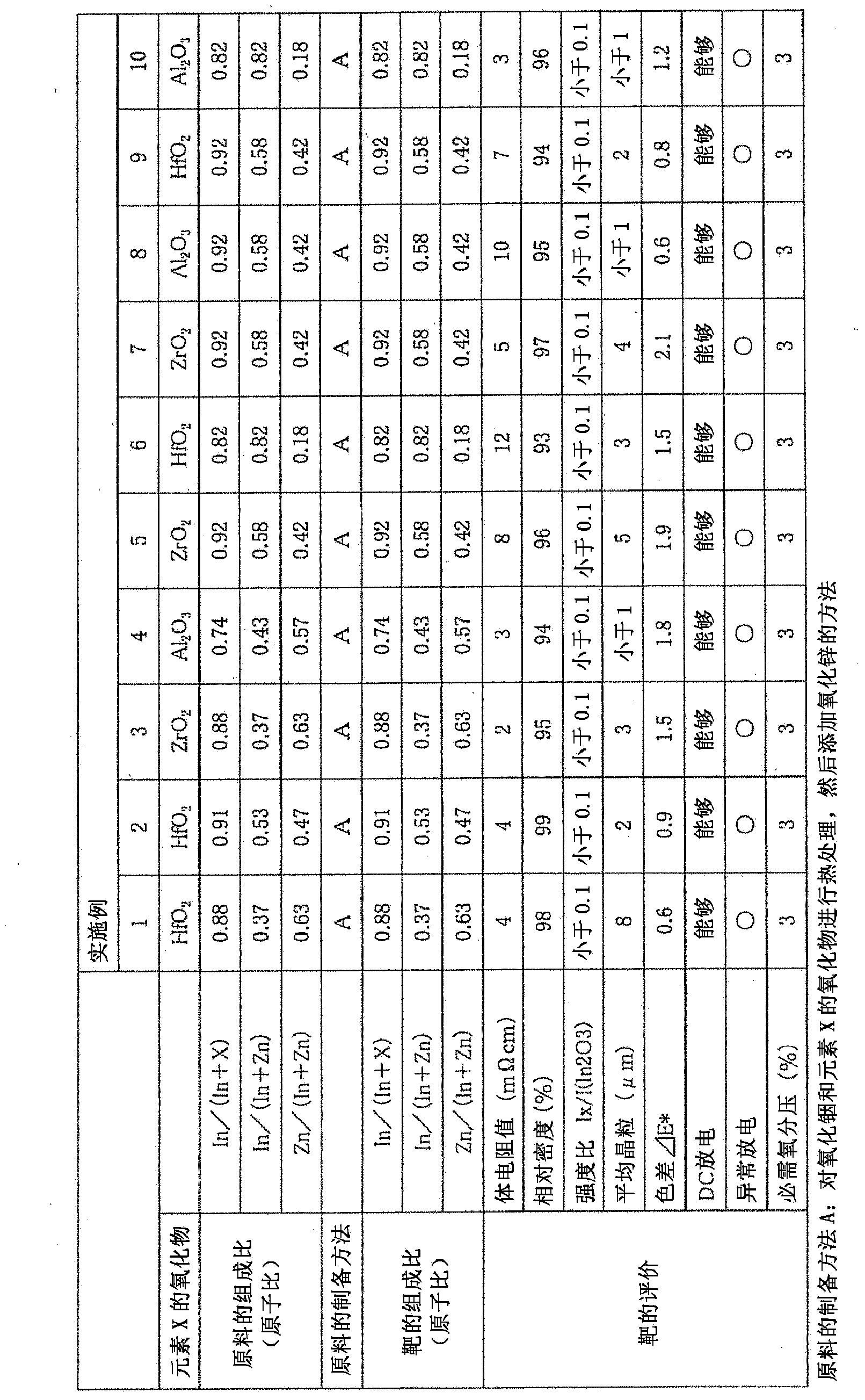

In2O3-ZnO sputtering target

InactiveCN103518003ANot easy to formSuppress abnormal dischargeTransistorVacuum evaporation coatingIndiumHafnium

Owner:IDEMITSU KOSAN CO LTD

Plasma treatment apparatus

InactiveCN101842881AConductiveIncreased durabilityElectric discharge tubesSemiconductor/solid-state device manufacturingTectorial membraneAbnormal discharge

In a plasma oxidization treatment apparatus (100) that supplies high-frequency biasing power to an electrode (7) embedded in a mounting table (5), the surface exposed to the plasma on the inner periphery of a lid part (27) made of aluminum, which functions as a counter-electrode for the mounting table (5), is coated with a protective silicon film (48). An upper liner (49a) and a lower liner (49b) that is formed more thickly than the upper liner are provided on the inner surfaces of a second container (3) and a first container (2), which is adjacent to the silicon film (48), the short-circuiting of or abnormal discharges to these areas is thereby prevented, an appropriate high-frequency current flow path is formed, and power consumption efficiency is improved.

Owner:TOKYO ELECTRON LTD

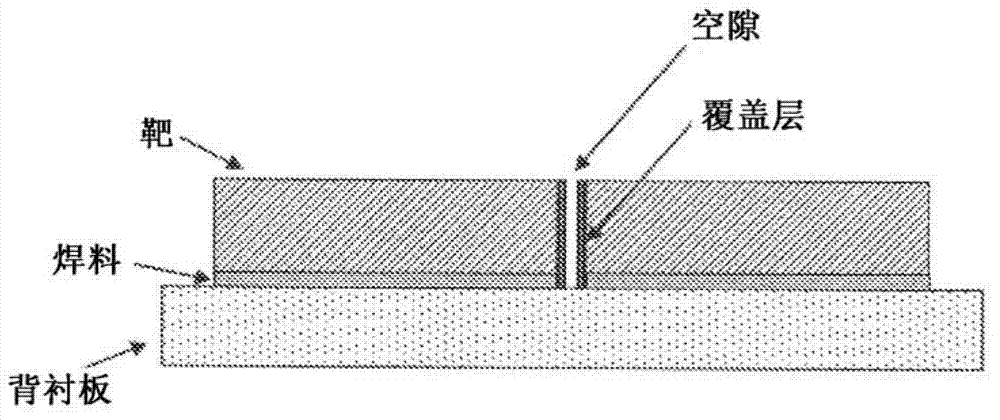

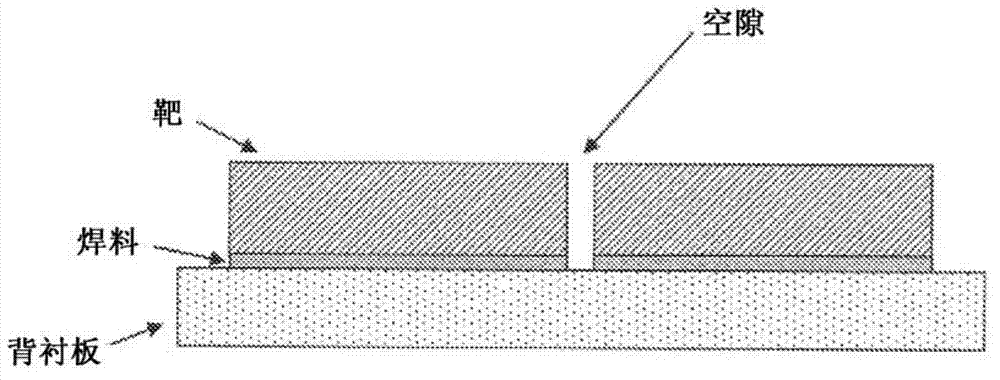

ITO Sputtering Target

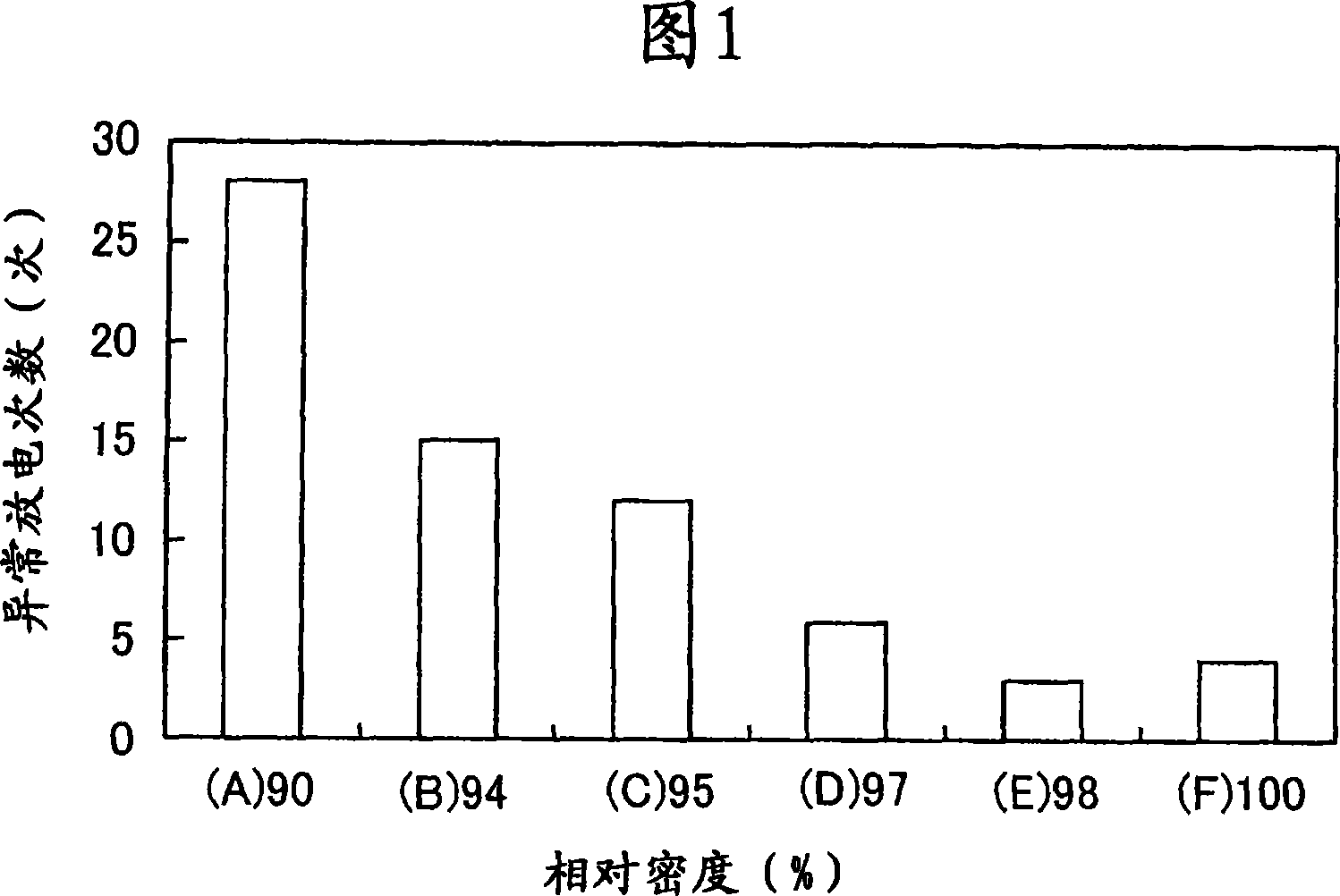

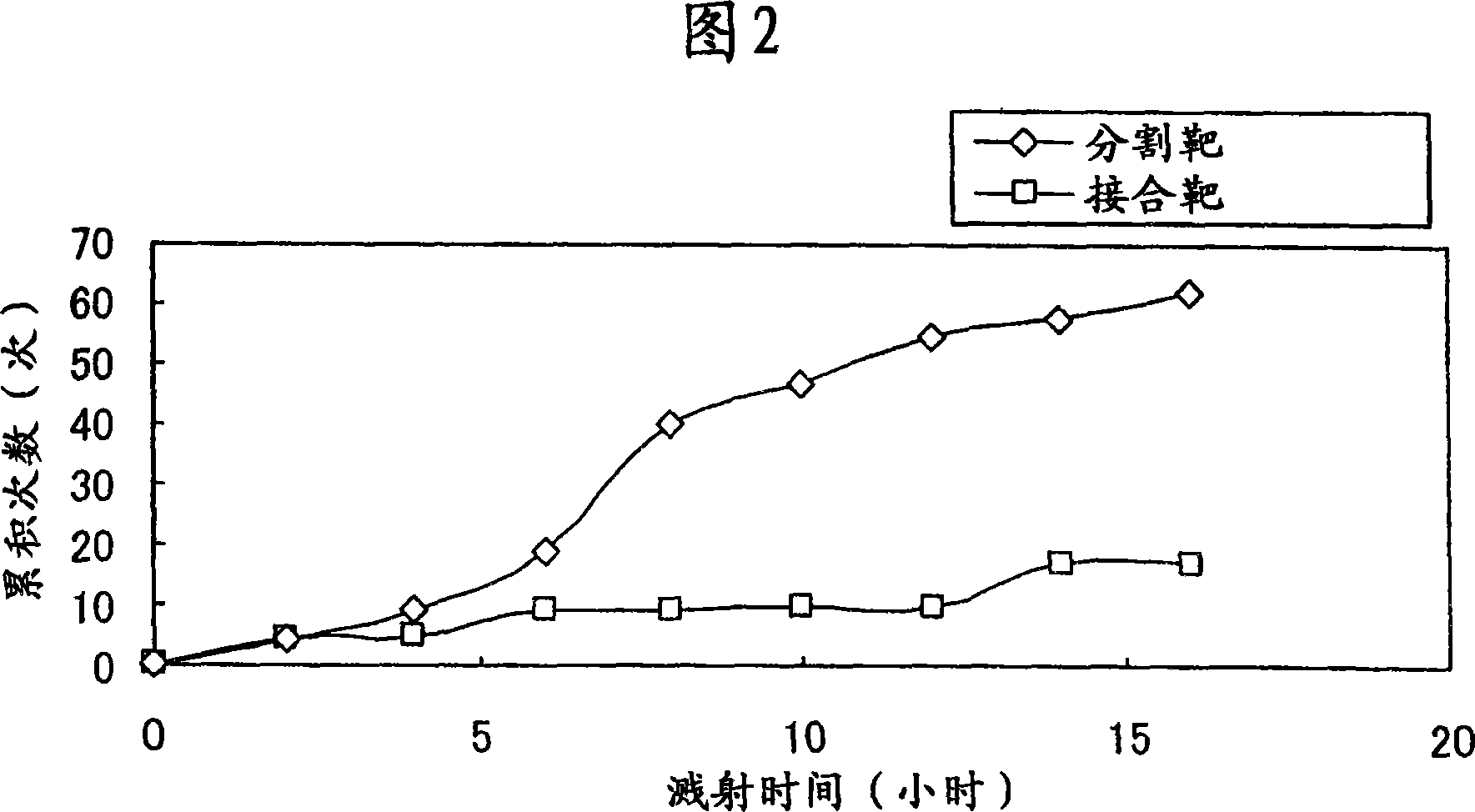

ActiveCN102906301AInhibitionSuppress abnormal dischargeVacuum evaporation coatingSputtering coatingSputteringIndium

Disclosed is an ITO sputtering target which is configured by arranging a plurality of ITO divided targets on a backing plate and bonding the ITO divided targets to the backing plate. The ITO divided targets are provided with a coating layer of one substance, which is selected from among indium, indium alloys and tin alloys, only on clearance-side lateral surfaces between the arranged ITO divided targets. The purpose of the present invention is to provide an ITO sputtering target, especially a sputtering target for a FPD, which is capable of suppressing the generation of nodule or abnormal electrical discharge even during continuous sputtering of divided ITO targets and is also capable of providing a film that is highly uniform in the film characteristics, namely a film wherein the film characteristics of parts of the film formed on the substrate at positions corresponding to the clearance portions are not different from the film characteristics of the other parts of the film.

Owner:JX NIPPON MINING & METALS CO LTD

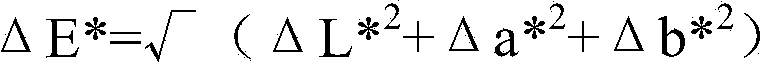

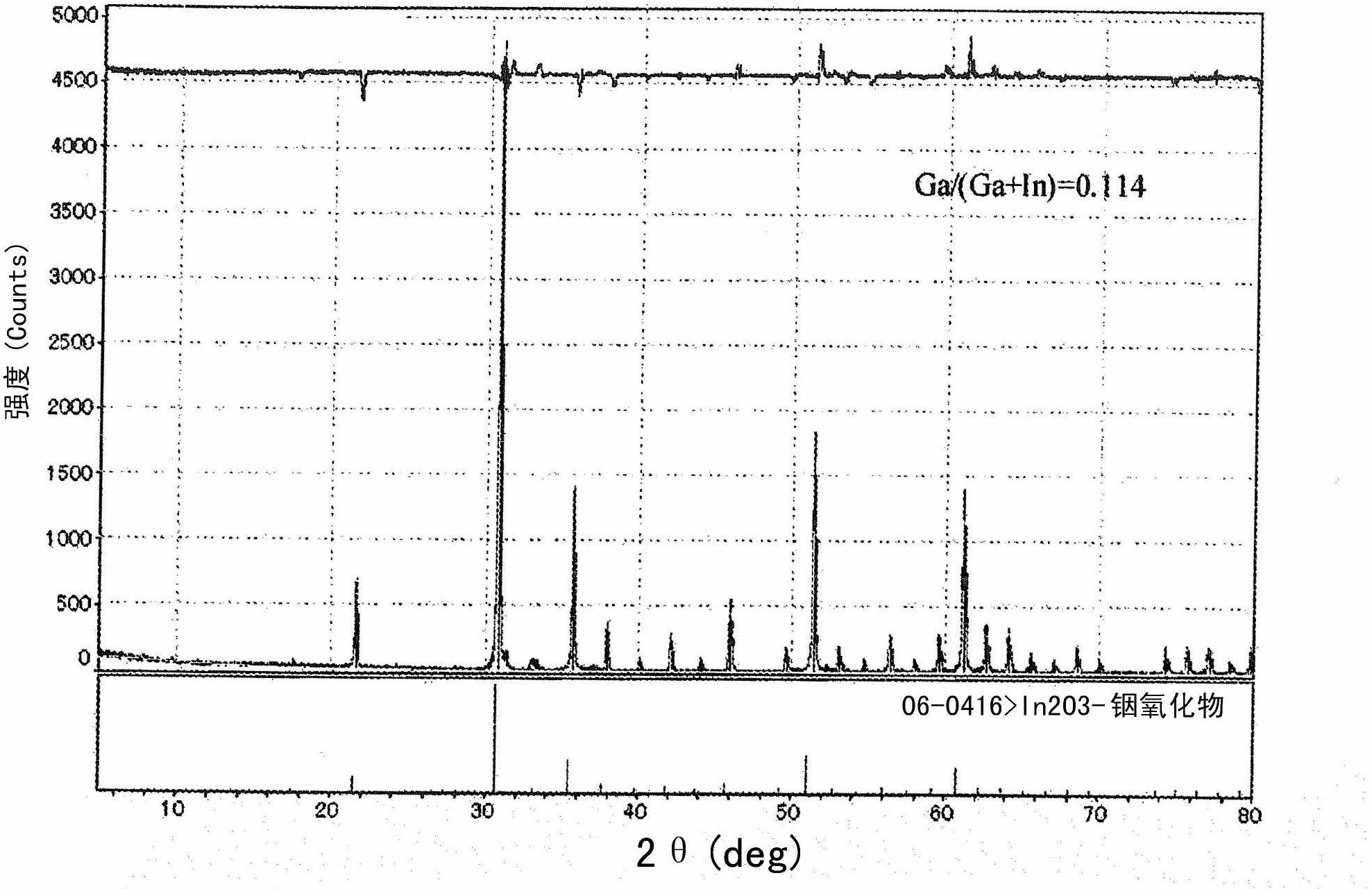

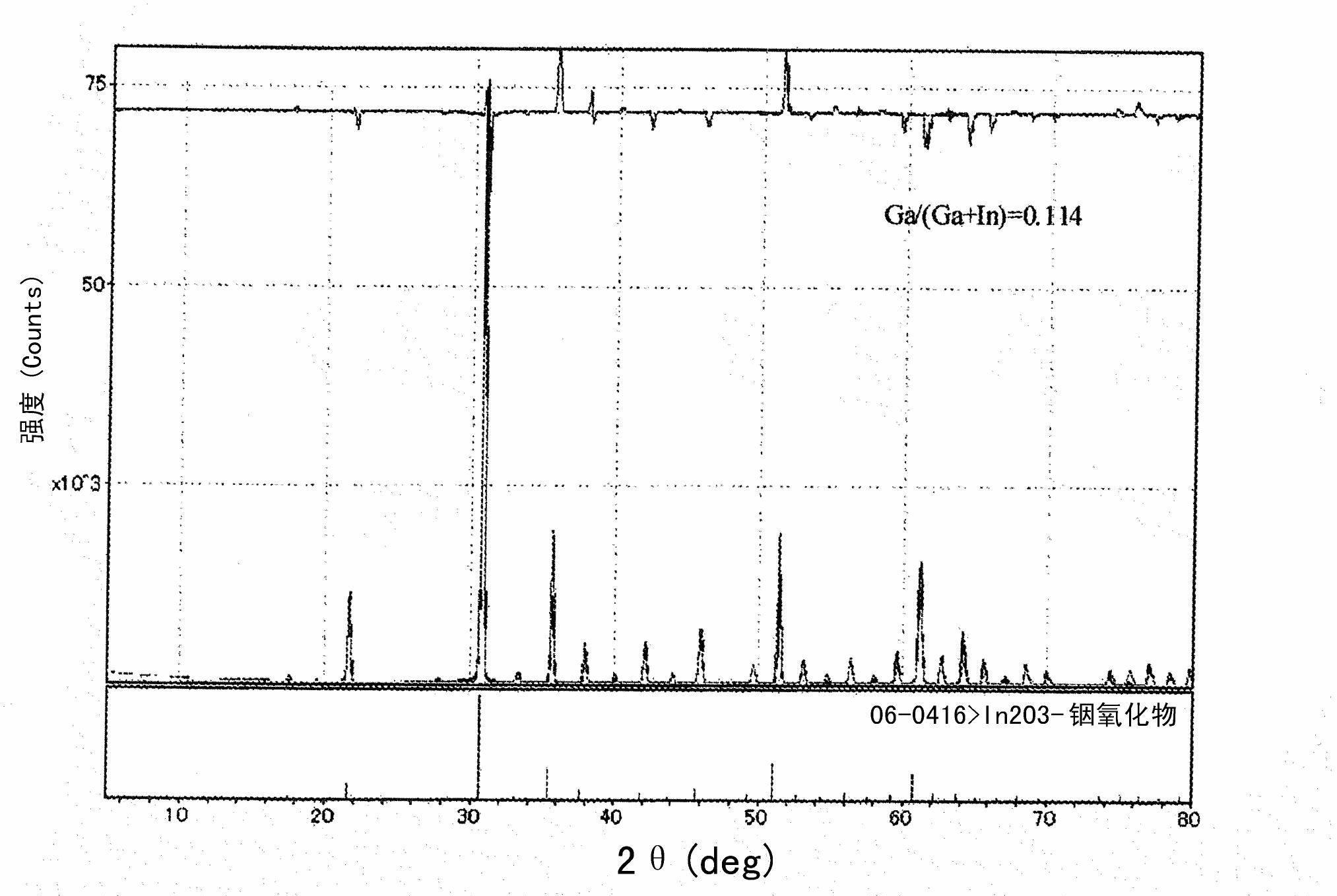

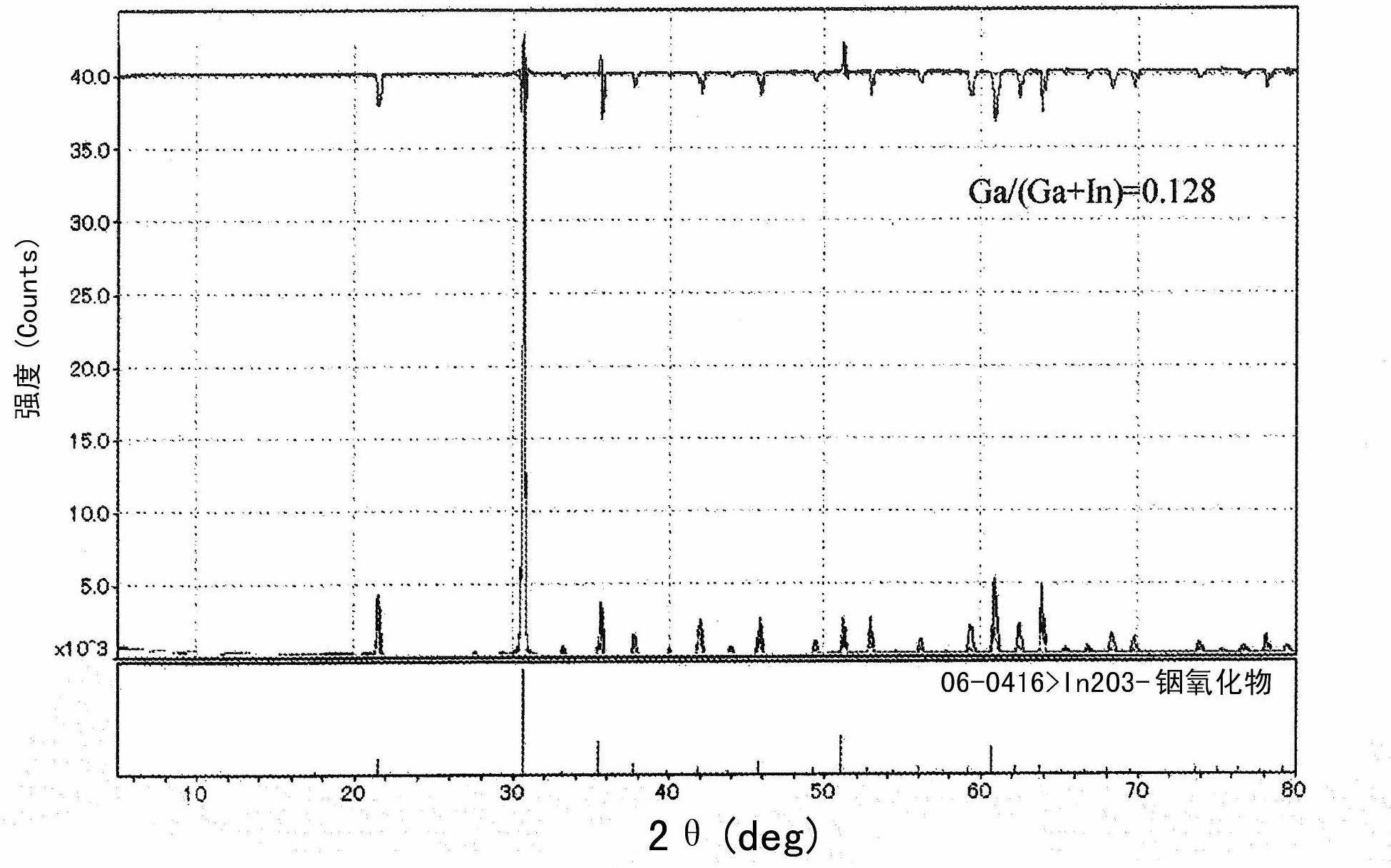

In-ga-o oxide sintered body, target, oxide semiconductor thin film, and manufacturing methods therefor

ActiveCN102652119AGood reproducibilitySuppress abnormal dischargeVacuum evaporation coatingSputtering coatingIndiumCrystal structure

Owner:IDEMITSU KOSAN CO LTD

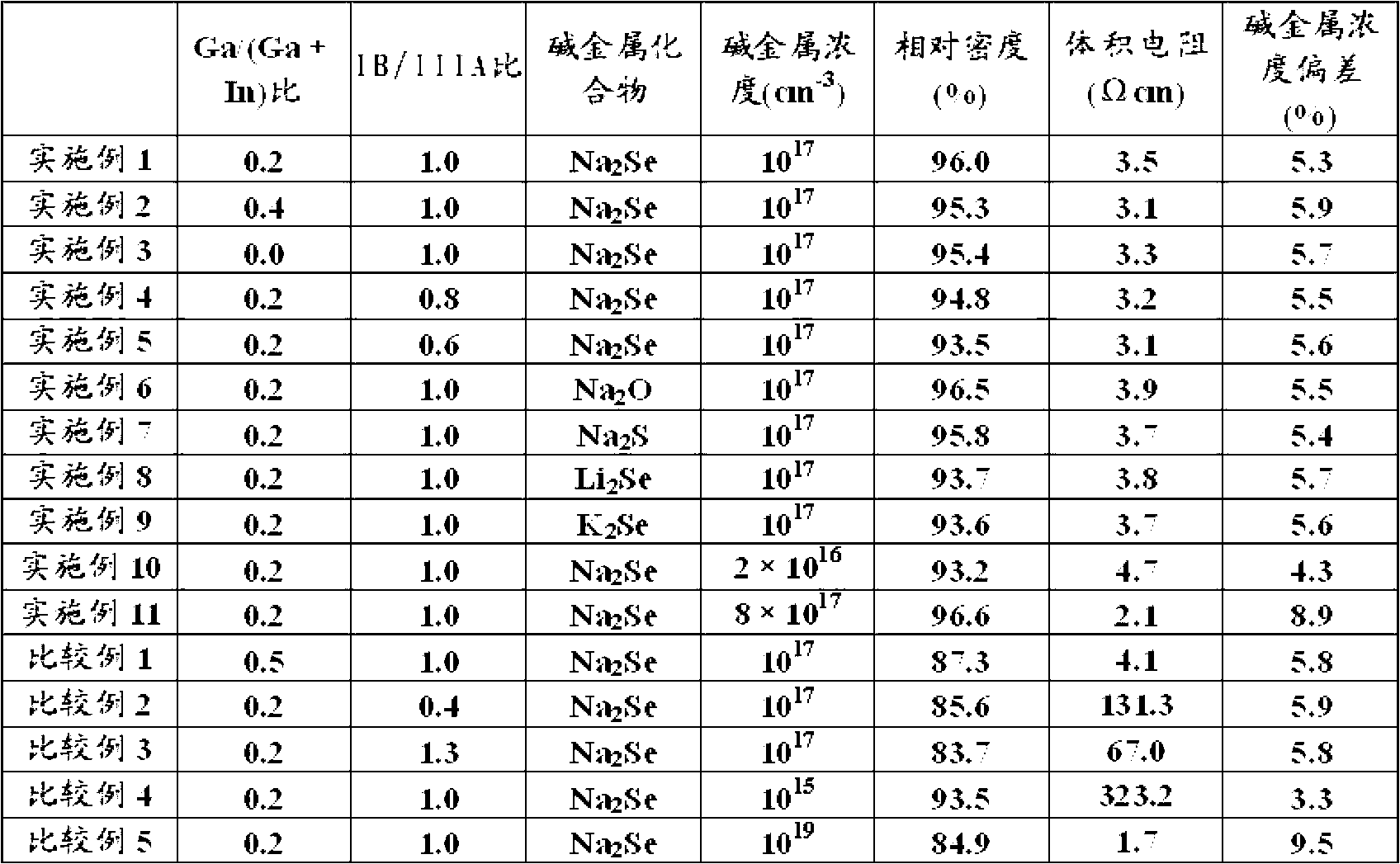

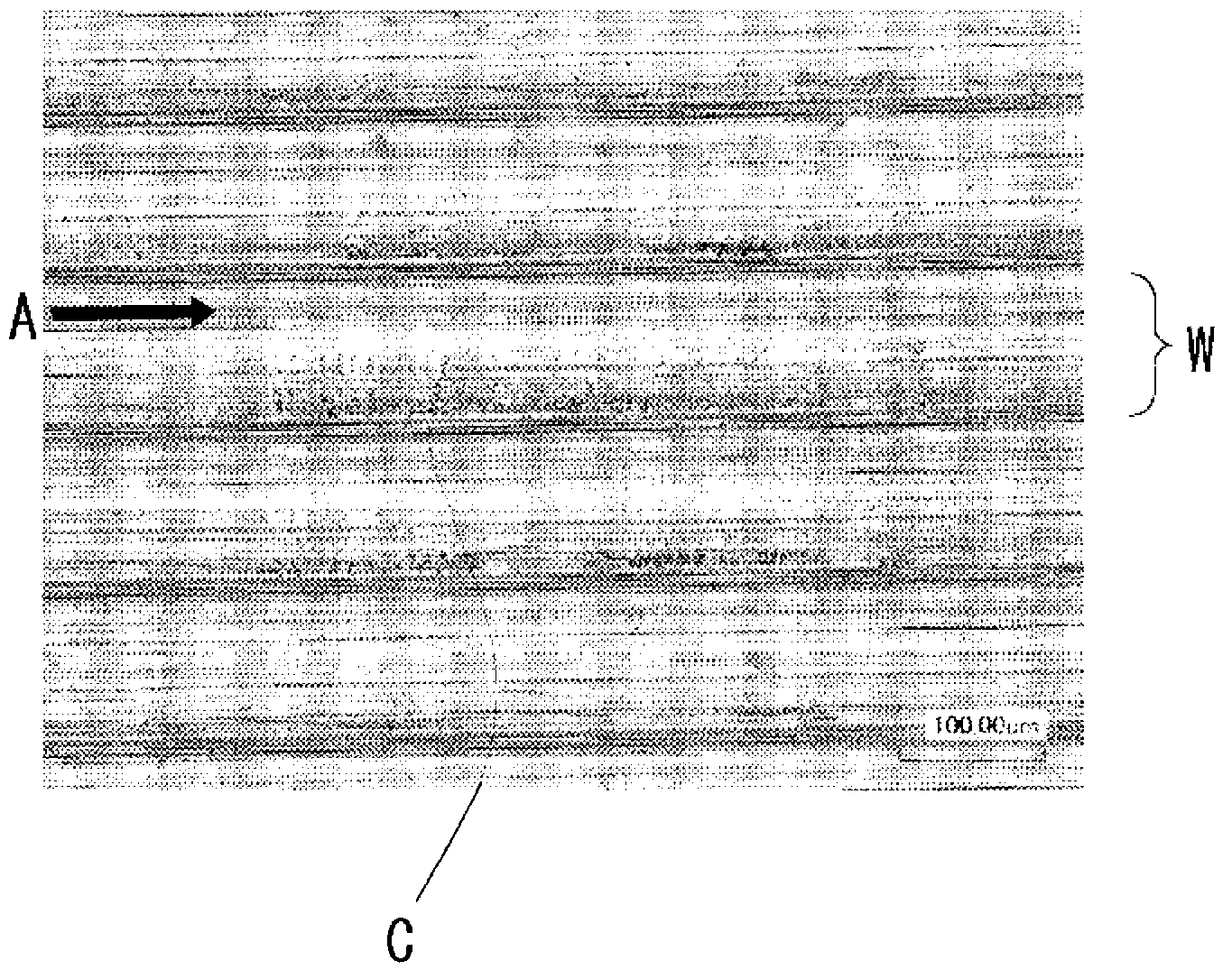

Sputtering target, compound semiconductor thin film, solar cell having compound semiconductor thin film, and method for manufacturing compound semiconductor thin film

ActiveCN102712996AReduce volume resistanceSuppress abnormal dischargeFinal product manufactureVacuum evaporation coatingSputteringCrystal structure

Disclosed is a sputtering target, which contains an alkali metal, is composed of an Ib element, IIIb element and VIb element, and has a chalcopyrite crystal structure. The sputtering target has the chalcopyrite crystal structure composed of a Ib-IIIb-VIb element, said structure being suitable for manufacturing, by sputtering one time, a light-absorbing layer having the chalcopyrite structure composed of the Ib-IIIb-VIb element.

Owner:JX NIPPON MINING & METALS CORP

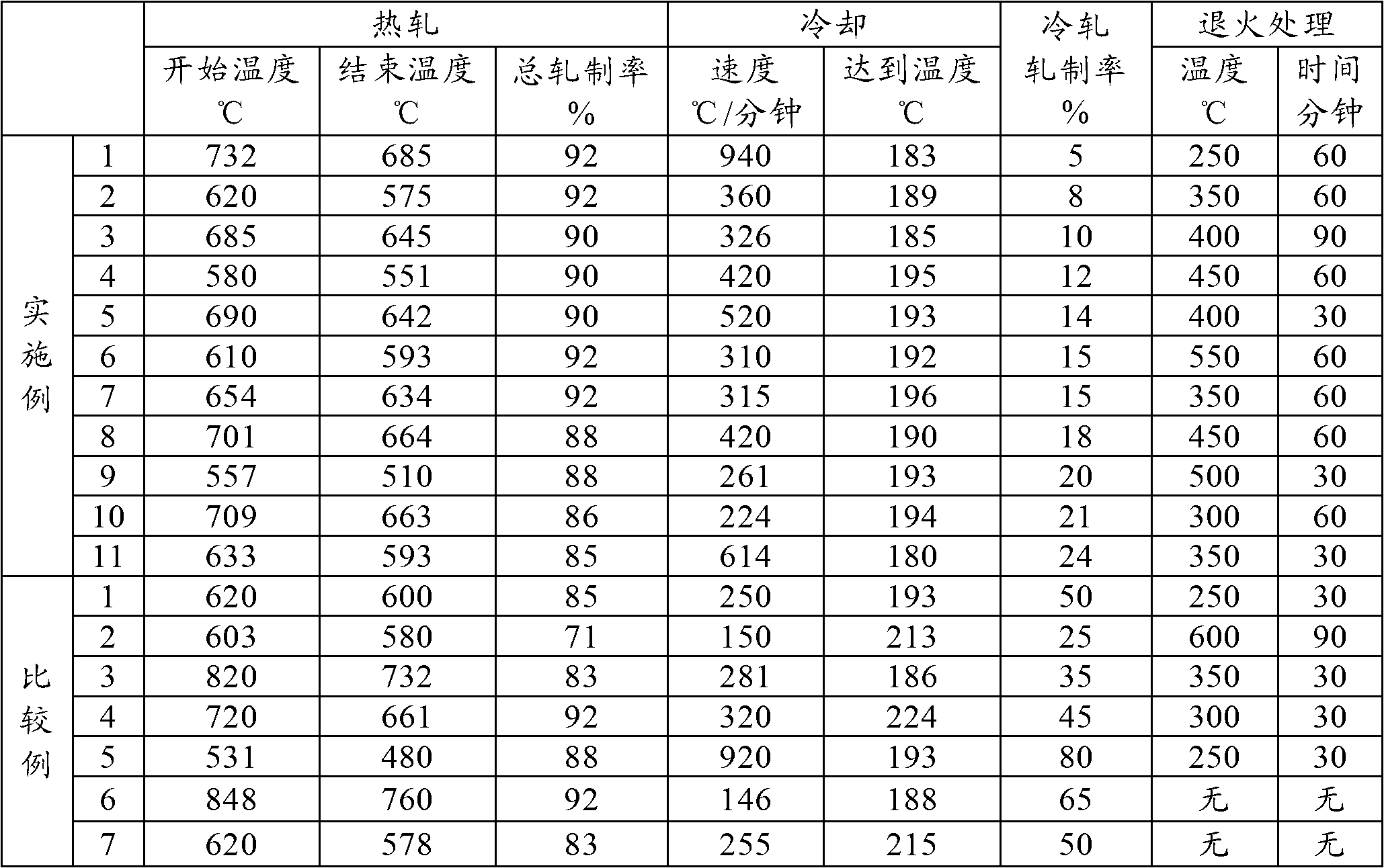

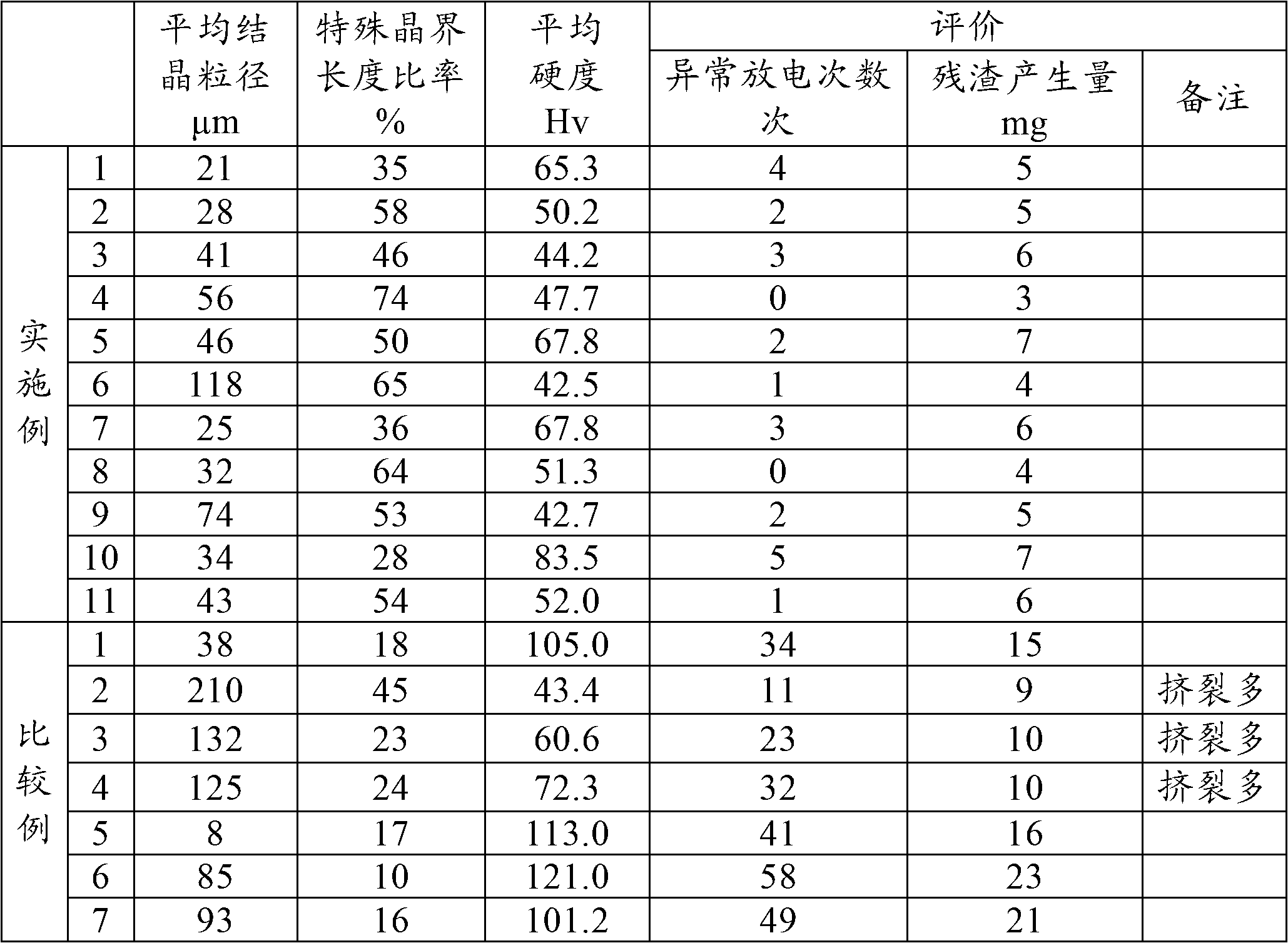

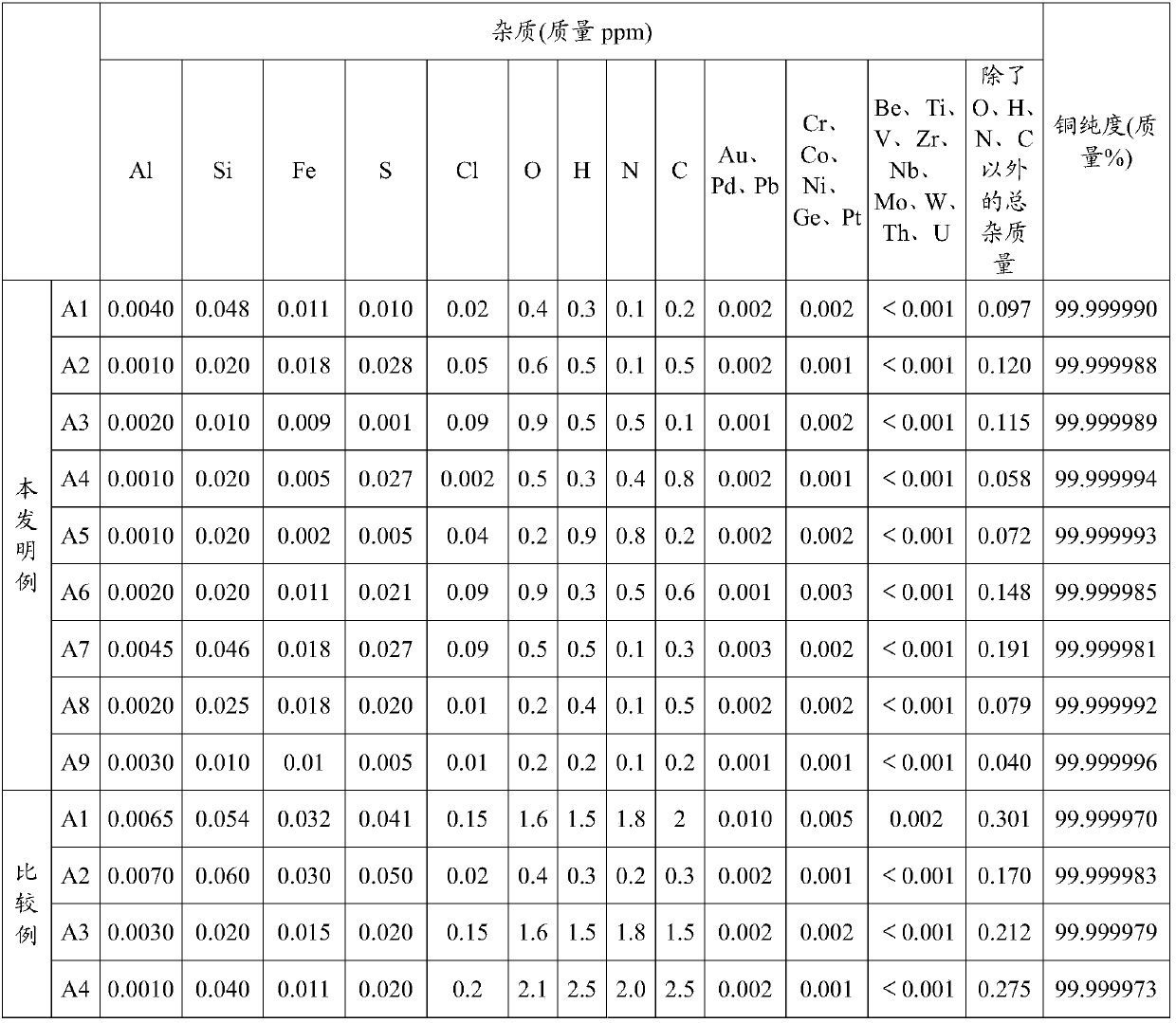

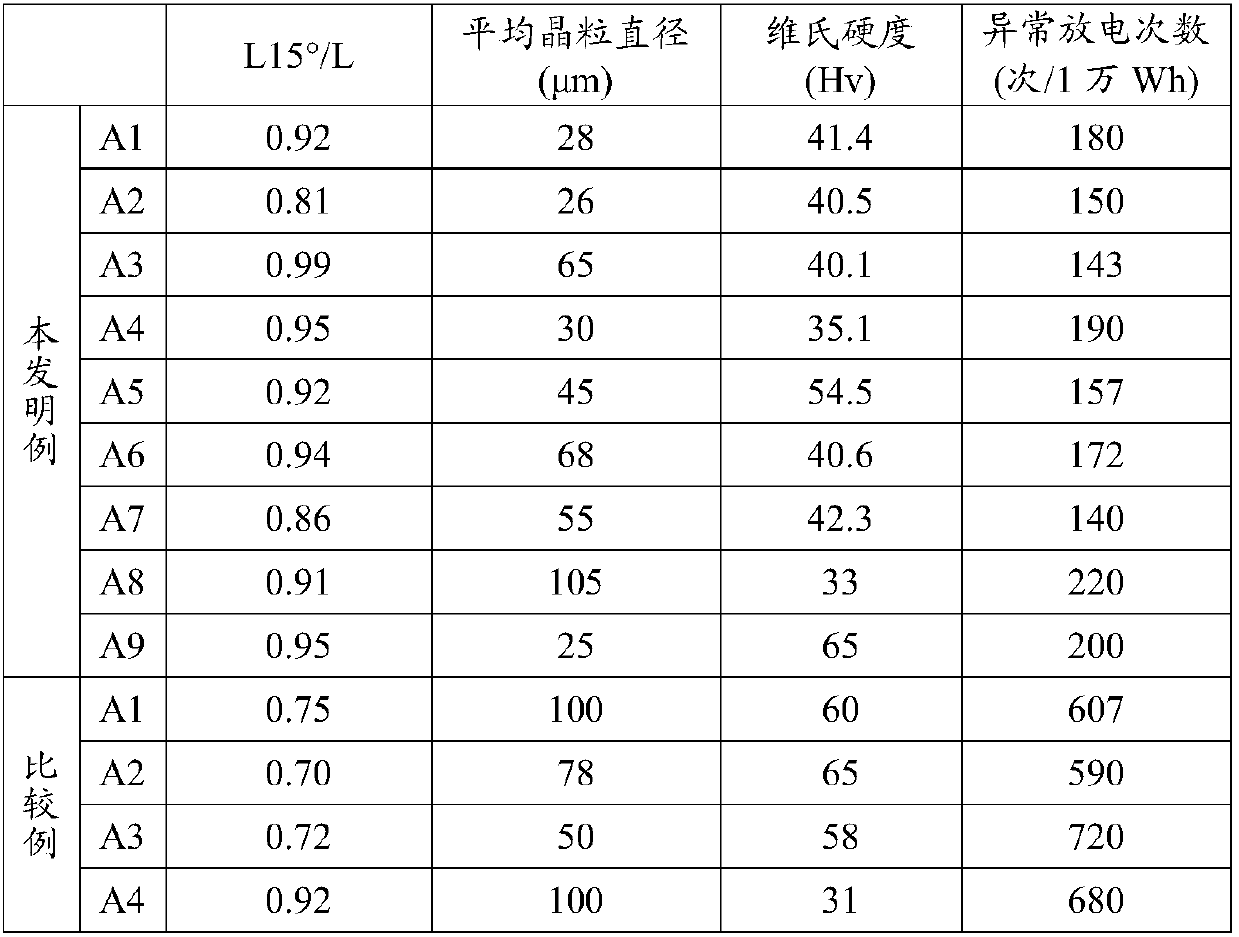

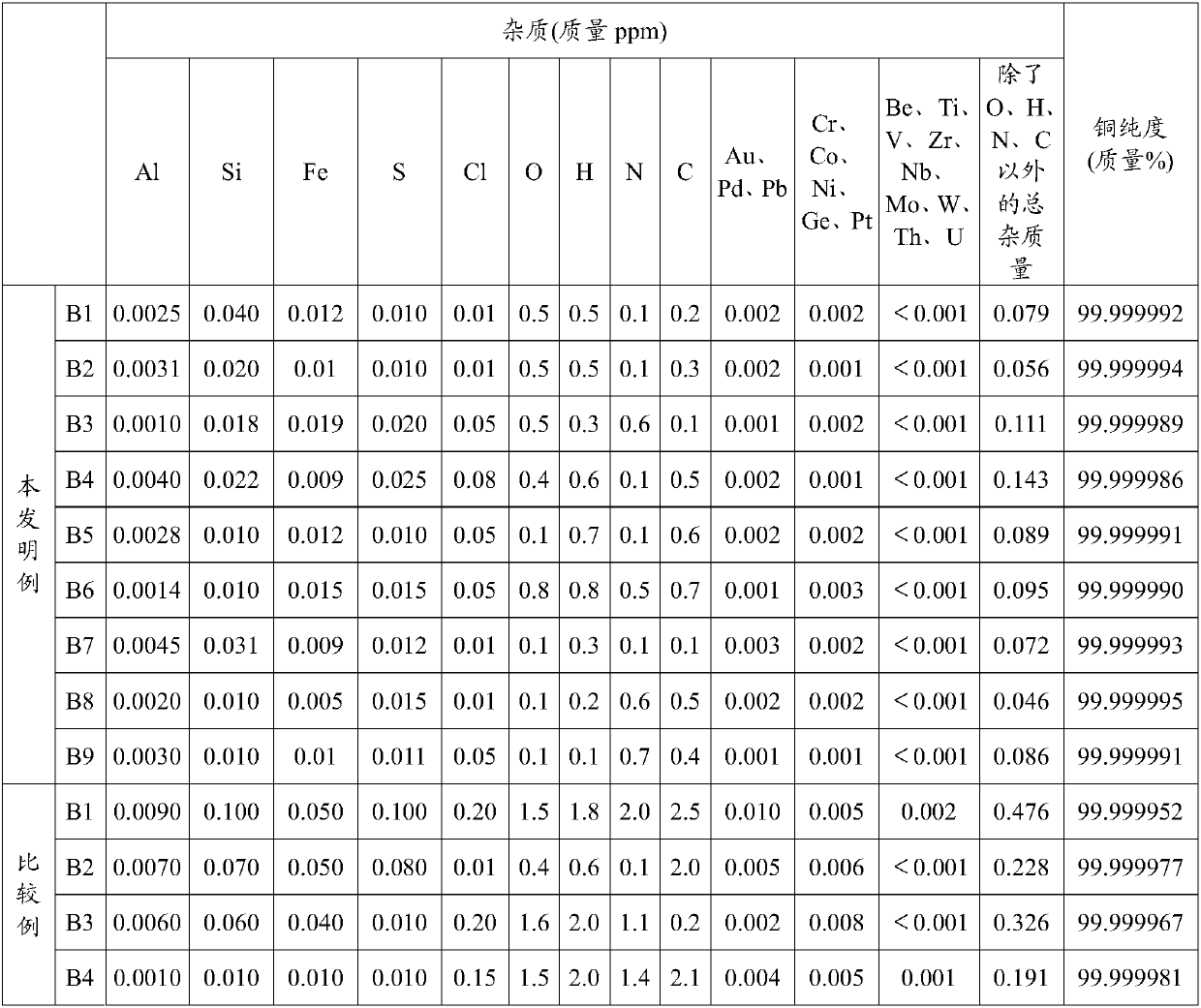

Pure copper plate production method, and pure copper plate

ActiveCN102712987AImproved in-plane dissolution uniformitySuppresses the generation of insoluble residueVacuum evaporation coatingSputtering coatingElectroplatingHardness

Disclosed is a production method for a pure copper plate having a fine crystal structure, a suitable hardness, and a high special grain boundary length ratio. Further disclosed is a pure copper plate which is obtained according to the disclosed production method and which is for targets for sputtering, or anodes for plating, or similar. A pure copper ingot having a purity level of 99.96 weight% or higher is heated to 550-800 DEG C. A hot-rolling process is carried out wherein the rolling rate is 80% or higher and the temperature at rolling completion is 500-700 DEG C. Next, rapid cooling from the rolling completion temperature to 200 DEG C or less is carried out at a cooling speed of 200-1000 DEG C / min, followed by cool rolling at a rolling rate of 5-24%, and annealing.

Owner:MITSUBISHI SHINDOH CO LTD +1

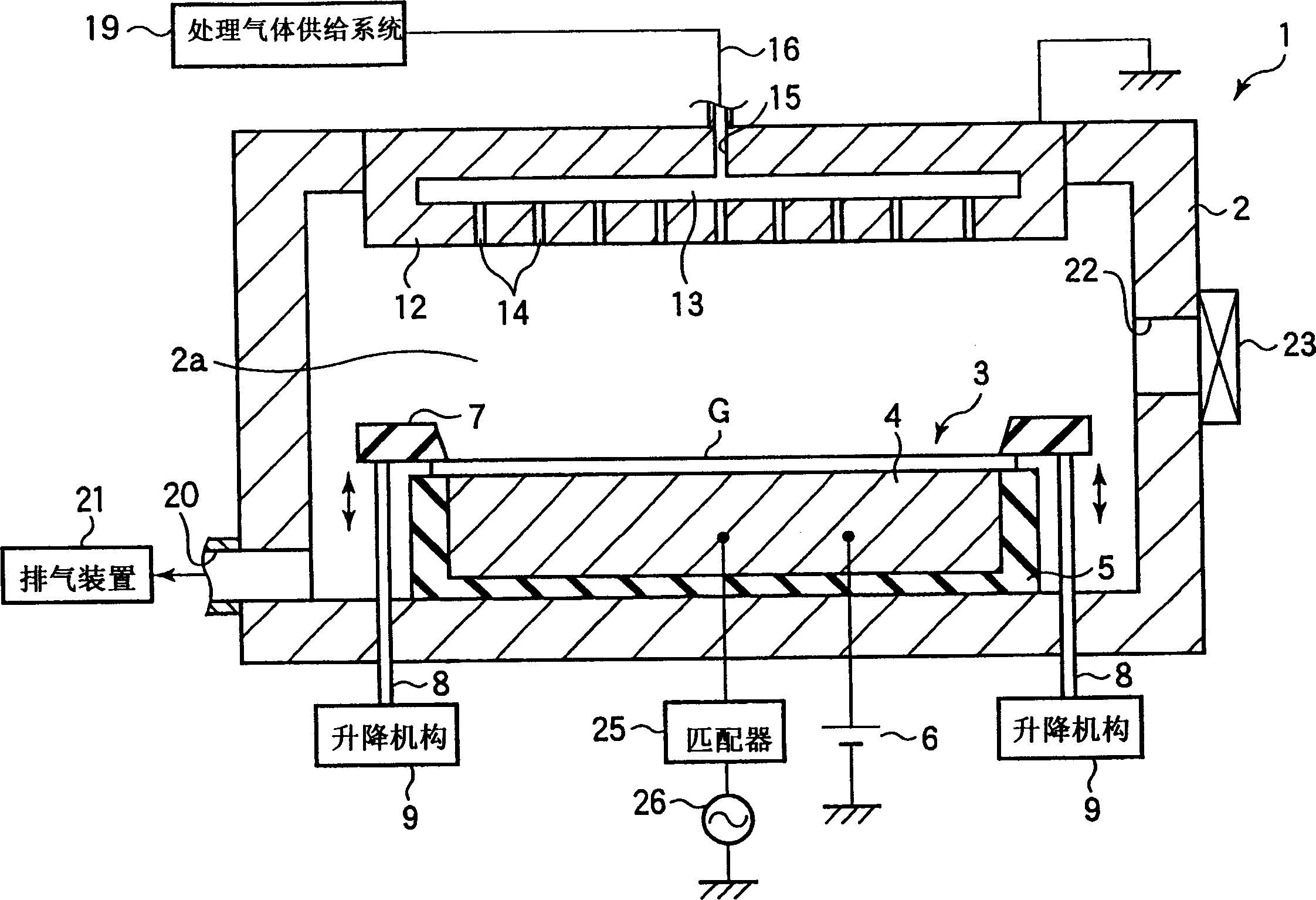

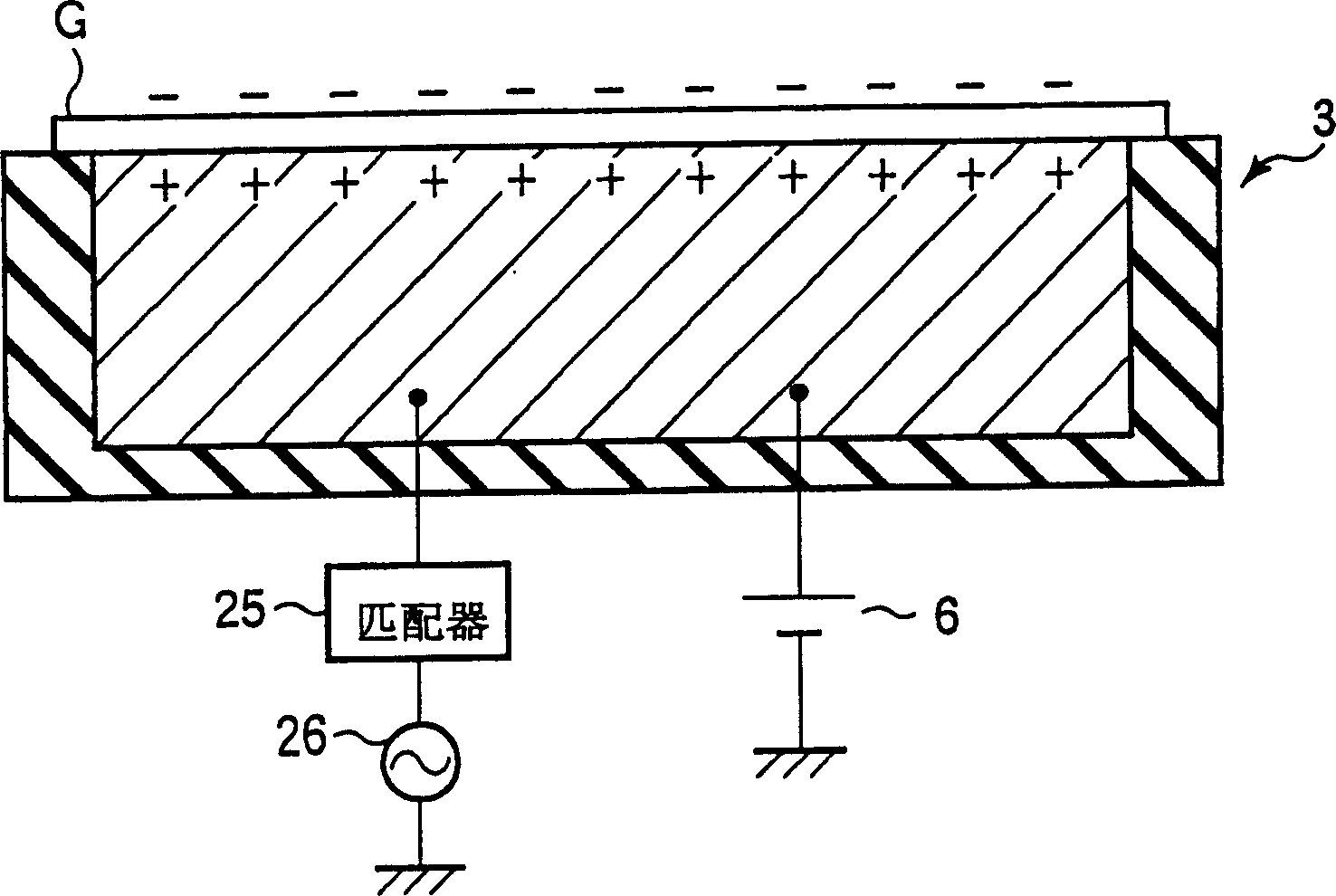

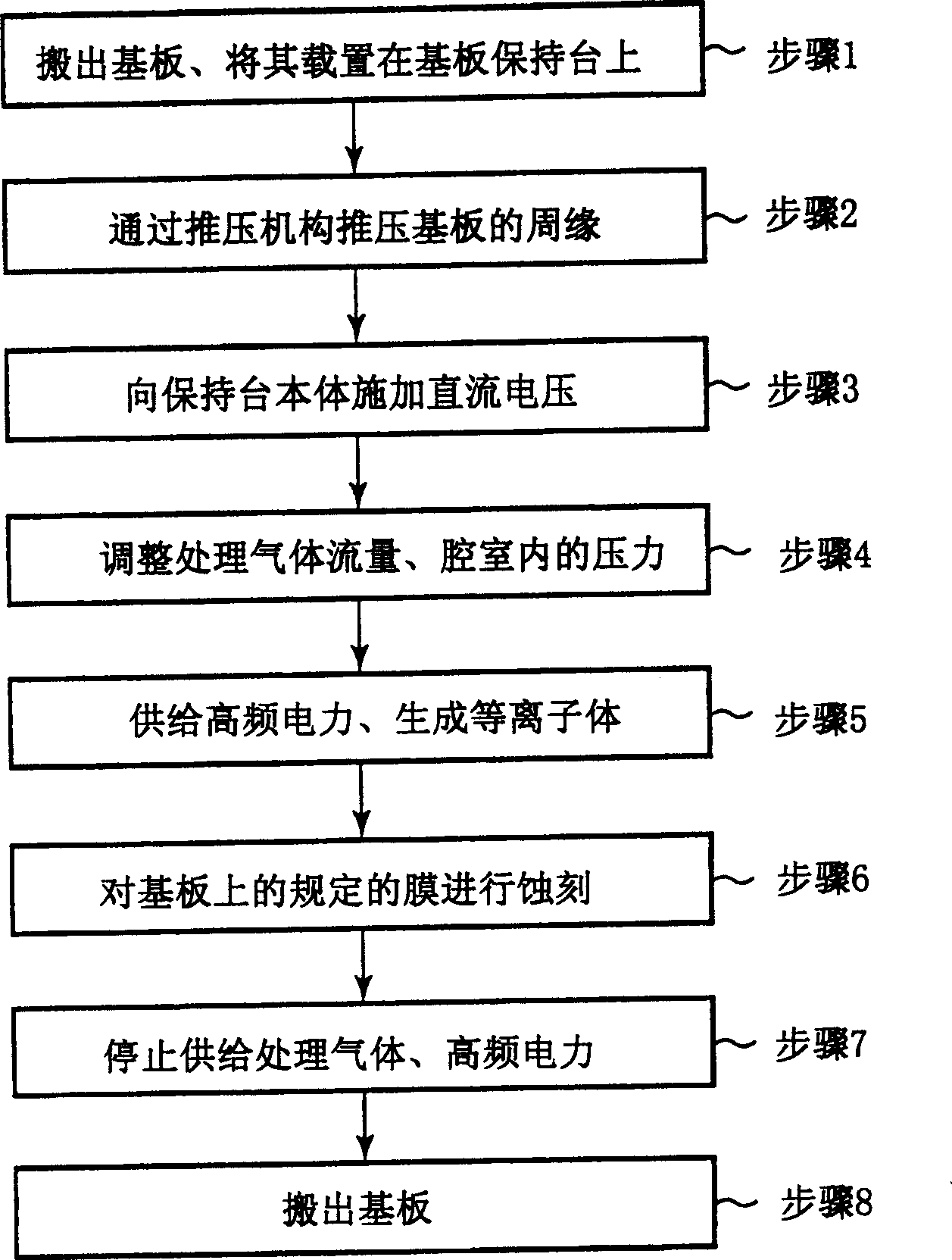

Plasma processing device and method thereof

InactiveCN1477682ASuppress abnormal dischargeElectric discharge tubesSemiconductor/solid-state device manufacturingDirect-current dischargeDielectric substrate

The plasma treatment device, which performs plasma treatment on a dielectric substrate G to be treated, is provided with the electrode 4 on which the substrate G is placed directly, a pressing mechanism 7 which presses the peripheral edge of the substrate G placed on the electrode 4 toward the electrode 4, and a treatment gas supplying mechanism 19 which supplies a process gas to the periphery of the substrate G. The treatment device is also provided with a plasma-generating means 26, which generates a plasma of the process gas in the periphery of the substrate G and and a DC power source 6, which is connected to the electrode 4 and impresses the DC voltage upon the electrode 4. While the pressing mechanism 7 presses the peripheral edge of the substrate G placed on the electrode 4, the substrate G is sucked to the electrode 4 by impressing the DC voltage on the electrode 4.

Owner:TOKYO ELECTRON LTD

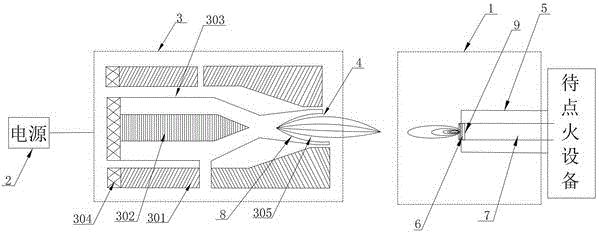

Non-impact self-adaptive trigger ignition device utilizing laminar flow plasma system

ActiveCN106304593AAchieve one ignitionAvoid arc breakingElectric spark ignitersPlasma techniquePlasma jetPlasma generator

The invention discloses a non-impact self-adaptive trigger ignition device utilizing a laminar flow plasma system, and belongs to the technical field of ignition equipment. The non-impact self-adaptive trigger ignition device comprises the laminar flow plasma system and an ignition nozzle. The laminar flow plasma system comprises a power supply, a laminar flow plasma generator and a jet nozzle, wherein the power supply is connected with the laminar flow plasma generator, and the jet nozzle and the laminar flow plasma generator are connected detachably. The ignition nozzle is arranged on equipment to be ignited, and comprises a shell, an ignition electrode and a guide tube, wherein the ignition electrode is arranged at the front end of the guide tube, the guide tube extends into the equipment to be ignited, and the shell is arranged outside the ignition electrode and the guide tube. The central axis of the jet nozzle coincides with the central axis of the ignition nozzle. The central axes of an electric arc channel, the jet nozzle and the ignition nozzle coincide, plasma is emitted along the central axis, an electric arc guidance effect is achieved through the design, the ignition steps are simplified, the ignition difficulty is reduced, ignition is achieved at a time with working gas, and meanwhile stability of laminar flow electric arc hot plasma jet is ensured.

Owner:四川金虹等离子技术有限公司

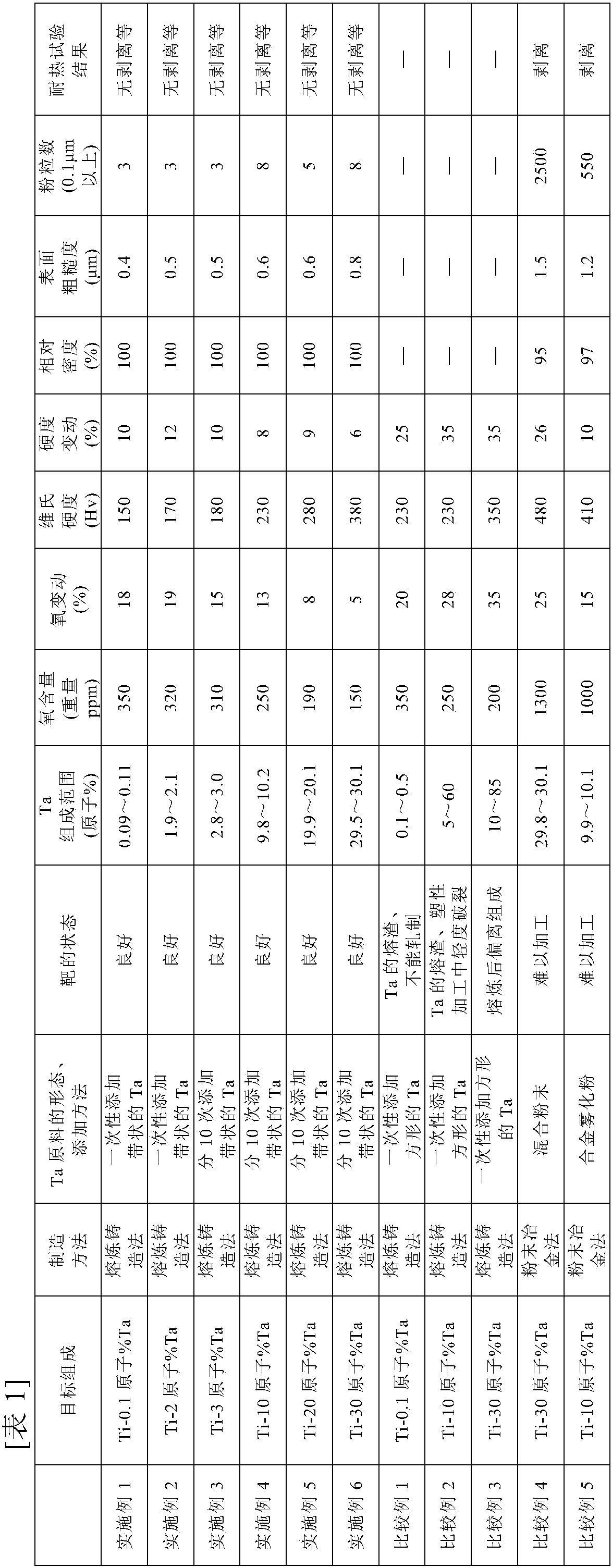

Ti-Ta alloy sputtering target and production method therefor

ActiveCN108291295AReduce hardnessEasy to processElectric discharge tubesVacuum evaporation coatingSputteringHardness

Provided is a sputtering target which comprises 0.1-30 at% of Ta with the remainder being Ti and unavoidable impurities, characterized in that the oxygen content is 400 wtppm or less. Due to low oxygen content and low hardness, the present invention is easily processed and has good surface properties, and thus provides an advantageous effect that enables inhibiting particle generation during sputtering.

Owner:JX NIPPON MINING & METALS CORP

Image forming unit and image forming apparatus

ActiveUS20090311005A1Suppress abnormal dischargeNot easy to accumulateElectrographic process apparatusCorona dischargeElectrical conductorImage formation

Owner:KONICA MINOLTA BUSINESS TECH INC

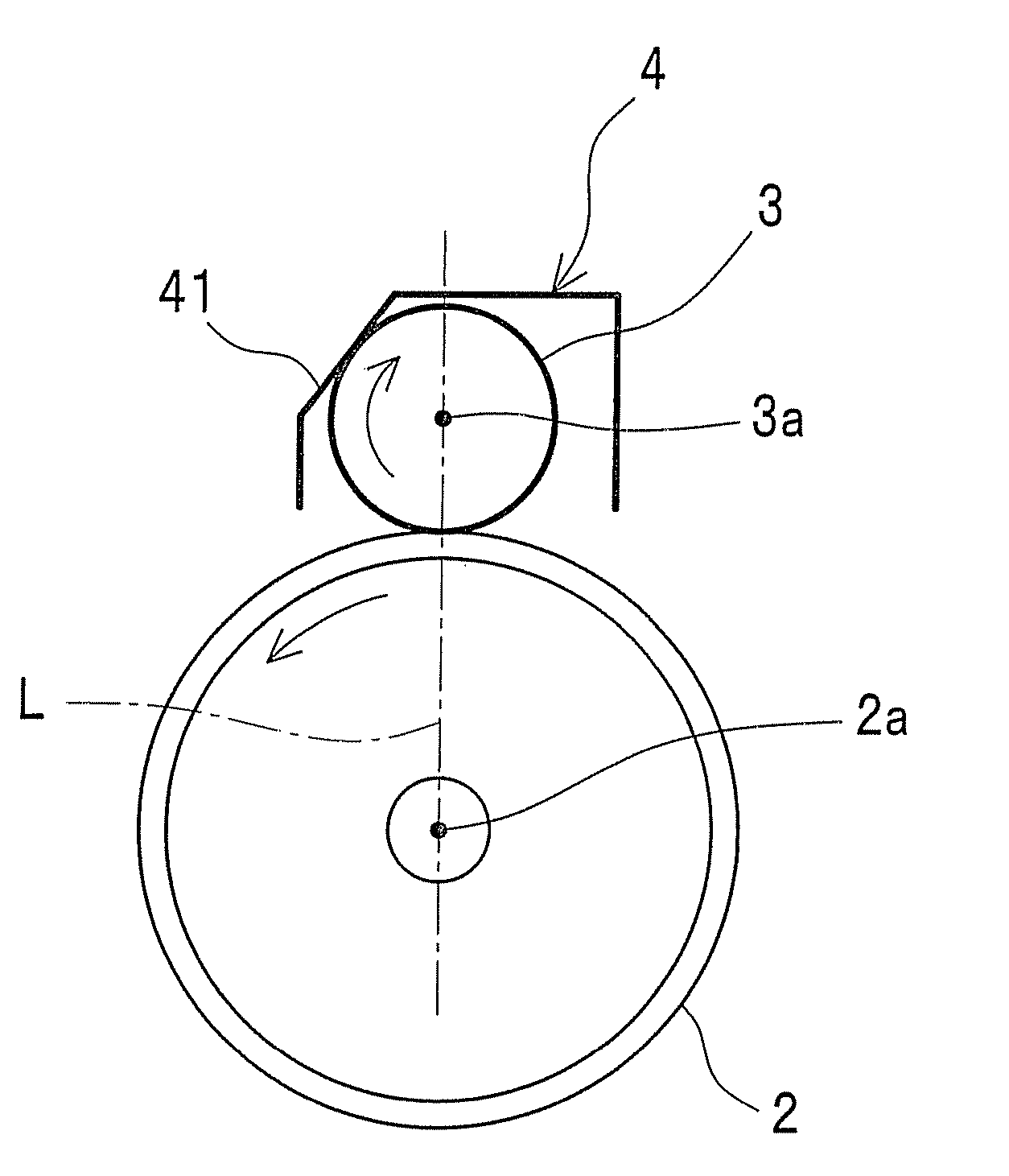

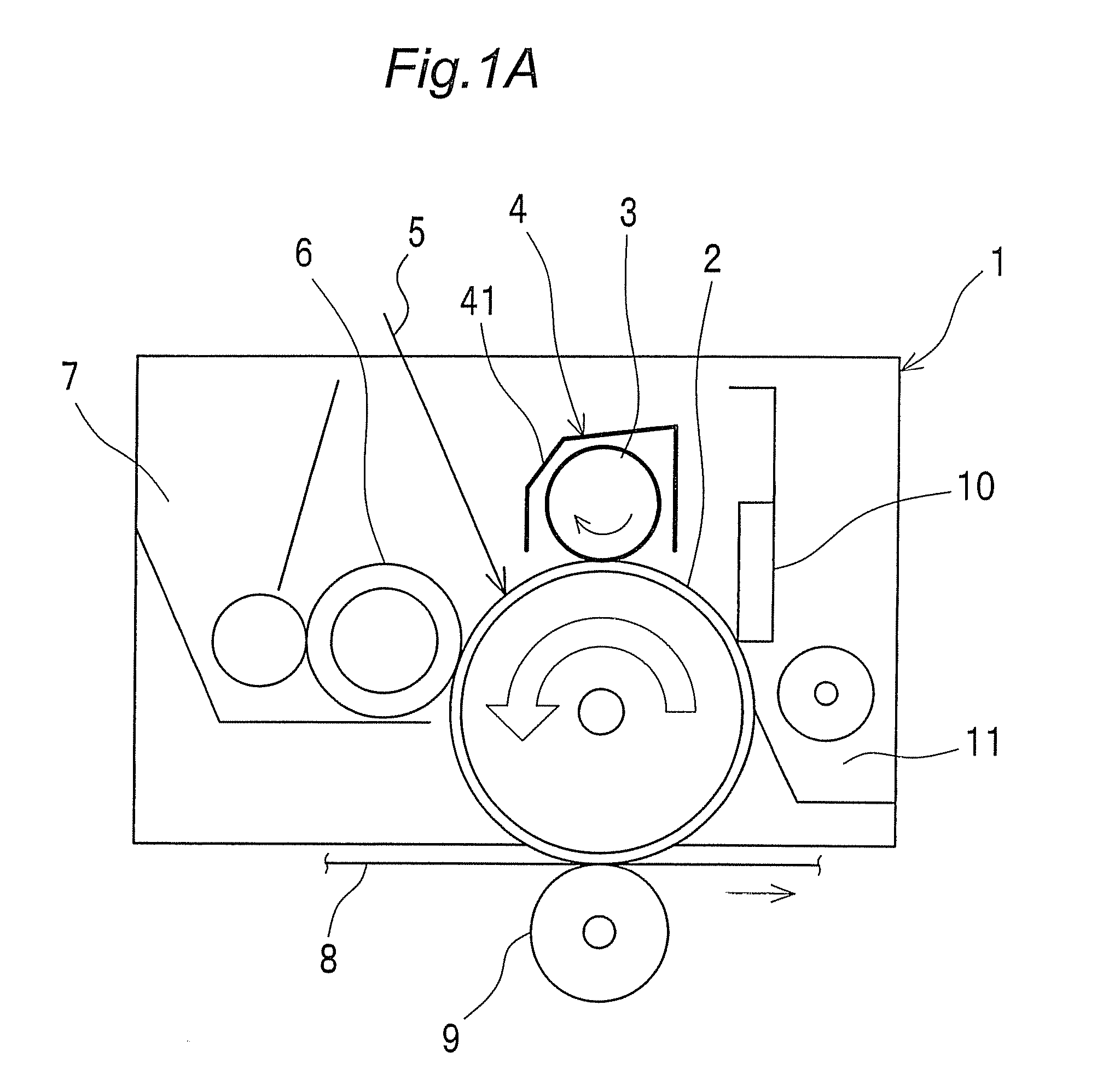

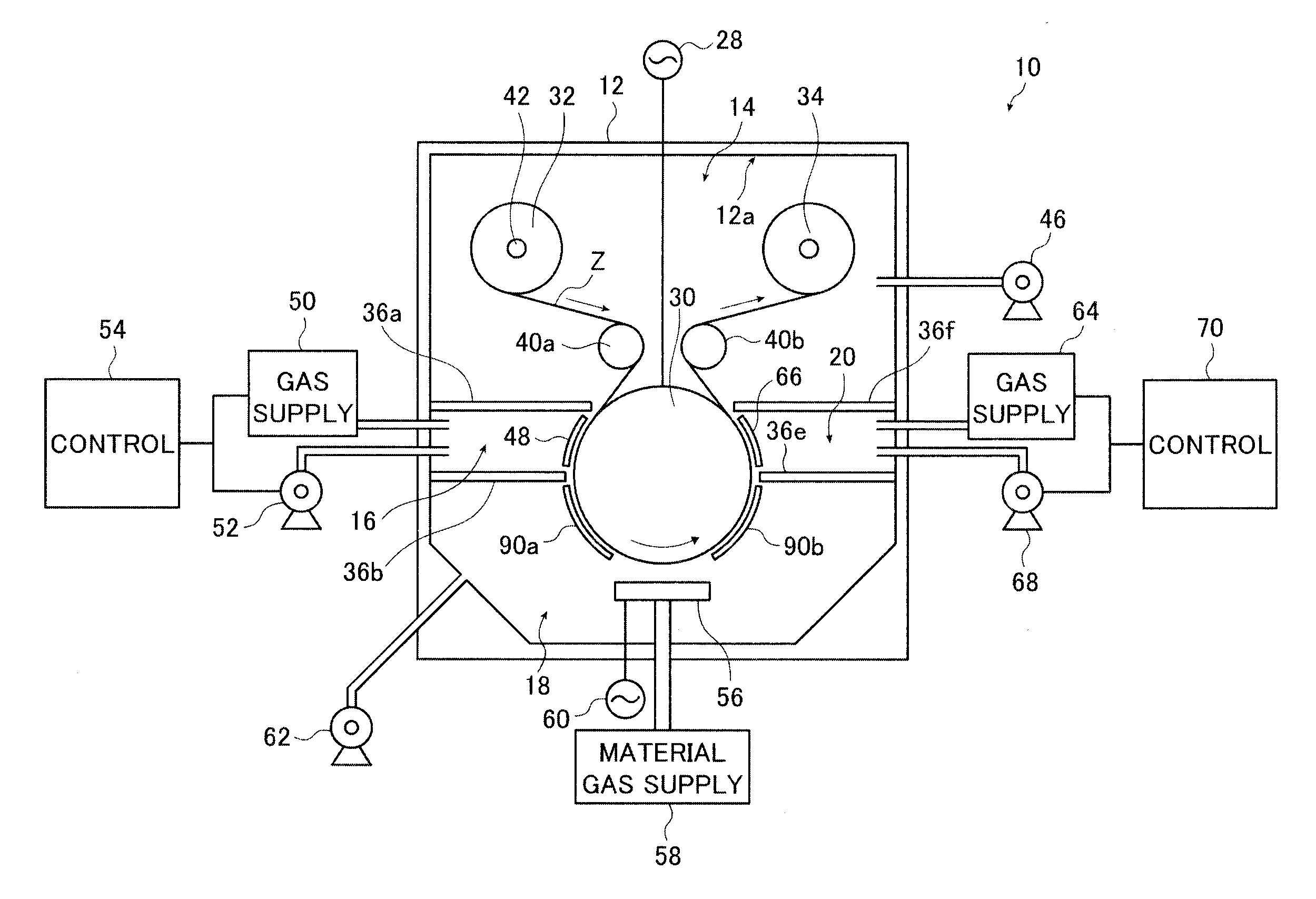

Film deposition method

ActiveUS8592004B2High-quality filmAvoid damageChemical vapor deposition coatingPlasma techniqueElectric powerPellicle membrane

A film deposition method deposits a film on a surface of a substrate in strip form traveling on a peripheral surface of a cylindrical drum in at least one film deposition compartment around the peripheral surface of the drum. The method disposes previously a differential compartment between one film deposition compartment and a compartment including a wrapping space containing at least one of a first position at which the substrate starts to travel on the drum and a second position at which the substrate separates from the drum, the differential compartments communicating with the compartment including the wrapping space and the film deposition compartment, sets a first pressure of the wrapping space lower than a second pressure of the at least one film deposition compartment and performs film deposition in the film deposition compartment with electric power supplied to the drum.

Owner:FUJIFILM CORP

Fe-Pt ferromagnetic sputtering target and method for producing same

ActiveCN103261471AReduce generationSuppress abnormal dischargeVacuum evaporation coatingSputtering coatingAbnormal dischargeNon magnetic

Owner:JX NIPPON MINING & METALS CORP

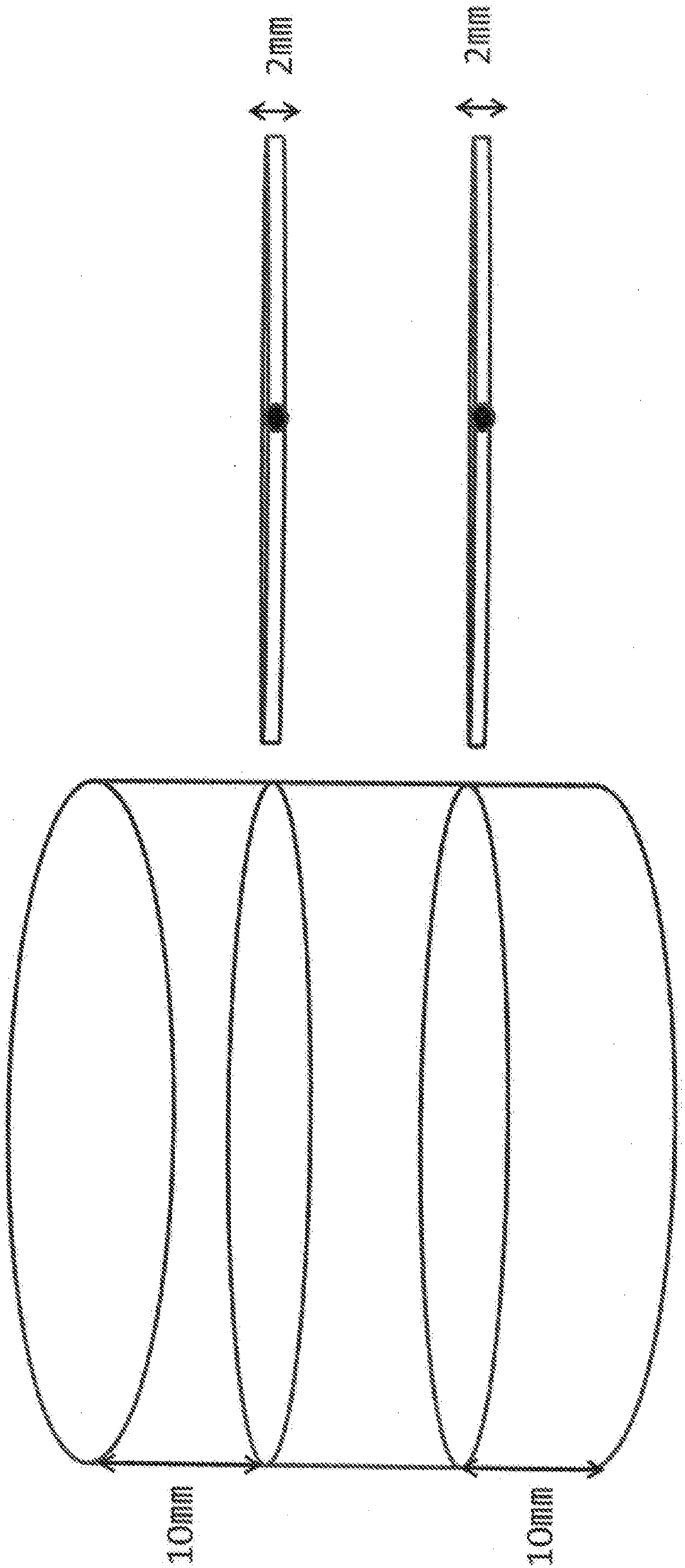

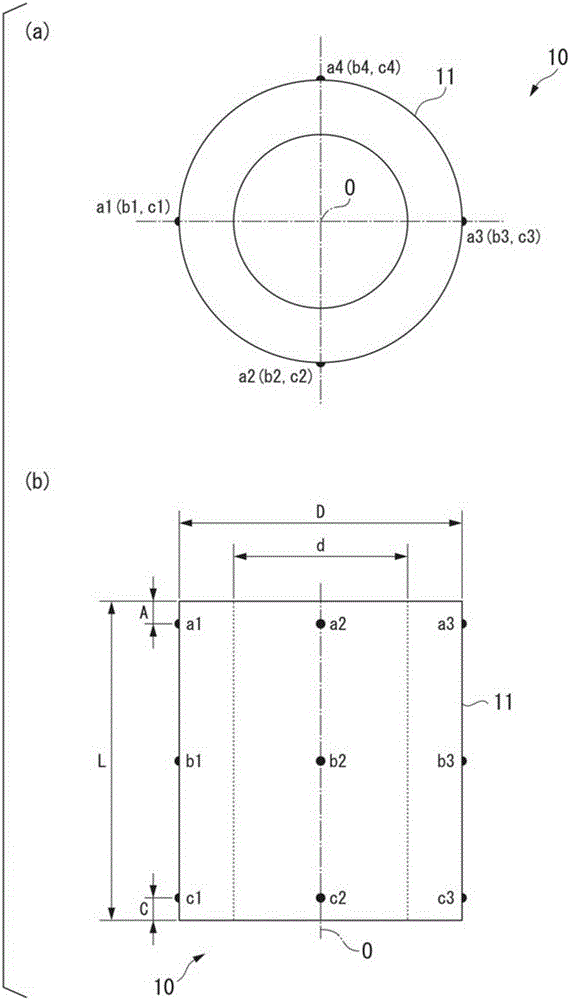

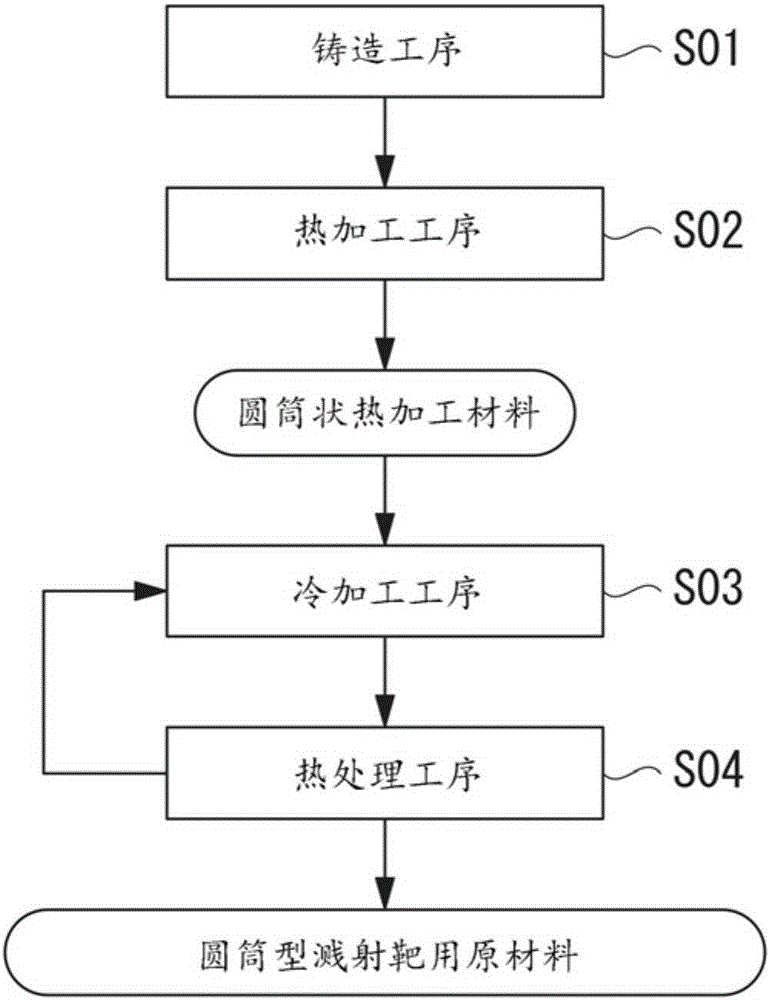

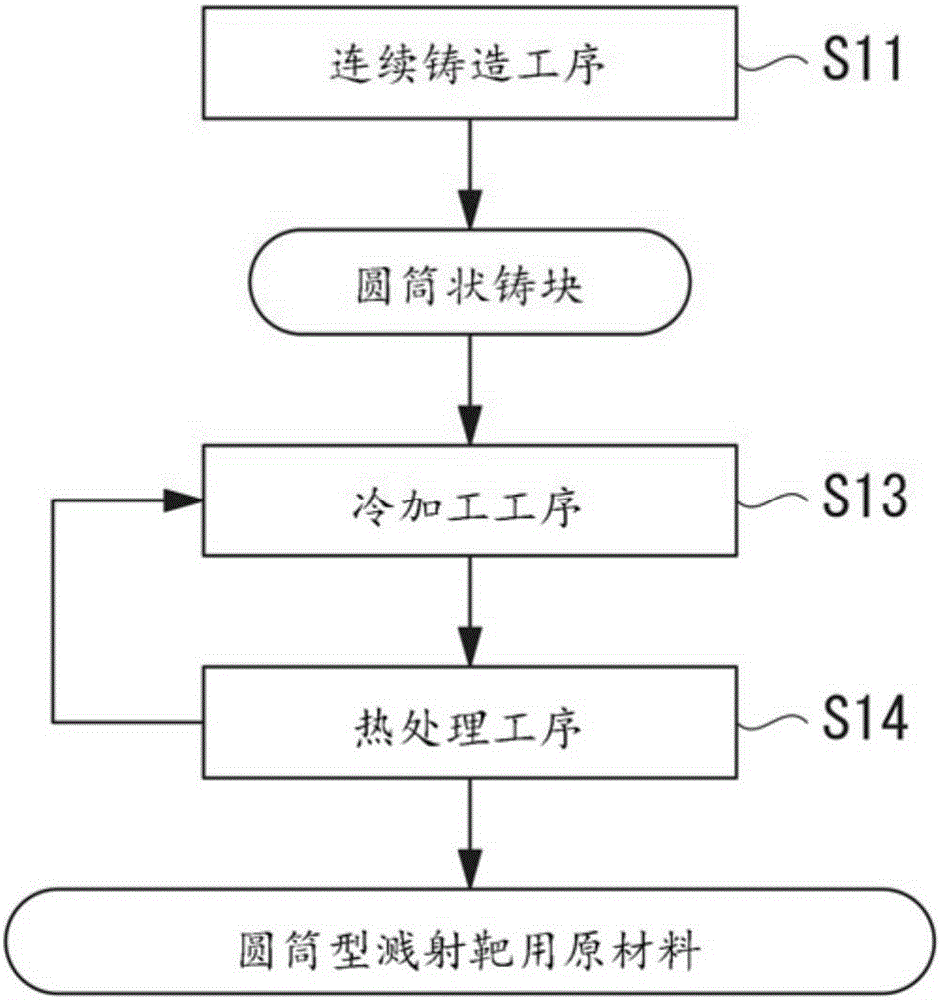

Material for cylindrical sputtering target

ActiveCN105209658ASuppress abnormal dischargeElectric discharge tubesVacuum evaporation coatingGrain boundaryCopper alloy

A material for a cylindrical sputtering target comprising copper or a copper alloy, wherein, when a special grain boundary length ratio L[sigma]N / LN in the crystalline structure of the outer peripheral surface is defined by a unit total grain boundary length LN per unit area of 1 mm2 and a unit total special grain boundary length L[sigma]N per unit area of 1 mm2 as measured by EBSD, the average value of the special grain boundary length ratio L[sigma]N / LN measured in the outer peripheral surfaces of both ends in the axial (O) direction and in the outer peripheral surface of the middle is 0.5 or greater, the measured values are all within a range of + / -20% of the average value of the special grain boundary length ratio L[sigma]N / LN, the total of the impure element contents for Si and C is 10 ppm by mass or less, and the O content is 50 ppm by mass or less.

Owner:MITSUBISHI MATERIALS CORP

Electric dust collecting unit

InactiveCN101098756AAchieve thinningImprove dust collection effectDeodrantsExternal electric electrostatic seperatorElectrical and Electronics engineeringElectrode

An electric dust-collecting unit having improved dust collecting performance and thinned. The electric dust-collecting unit has needle-like electrodes (201) each having a sharp tip section (205) in the downstream direction, parallel electrodes (203) arranged in parallel to the needle-like electrodes (201), and open electrodes (204) provided on the downstream side, facing the sharp tip sections (205) of the needle-like electrodes (201). The parallel electrodes (203) and the open electrodes (204) are disposed in a substantially U shape so as to surround the needle-like electrodes (201). Discharge from the needle-like electrodes (201) to the opposite electrodes is made in many directions, which improves dust-collecting performance. Further, the needle-like electrodes (201) can be placed close to the open electrodes (204), so that the electric dust-collecting unit can be thinned.

Owner:PANASONIC CORP

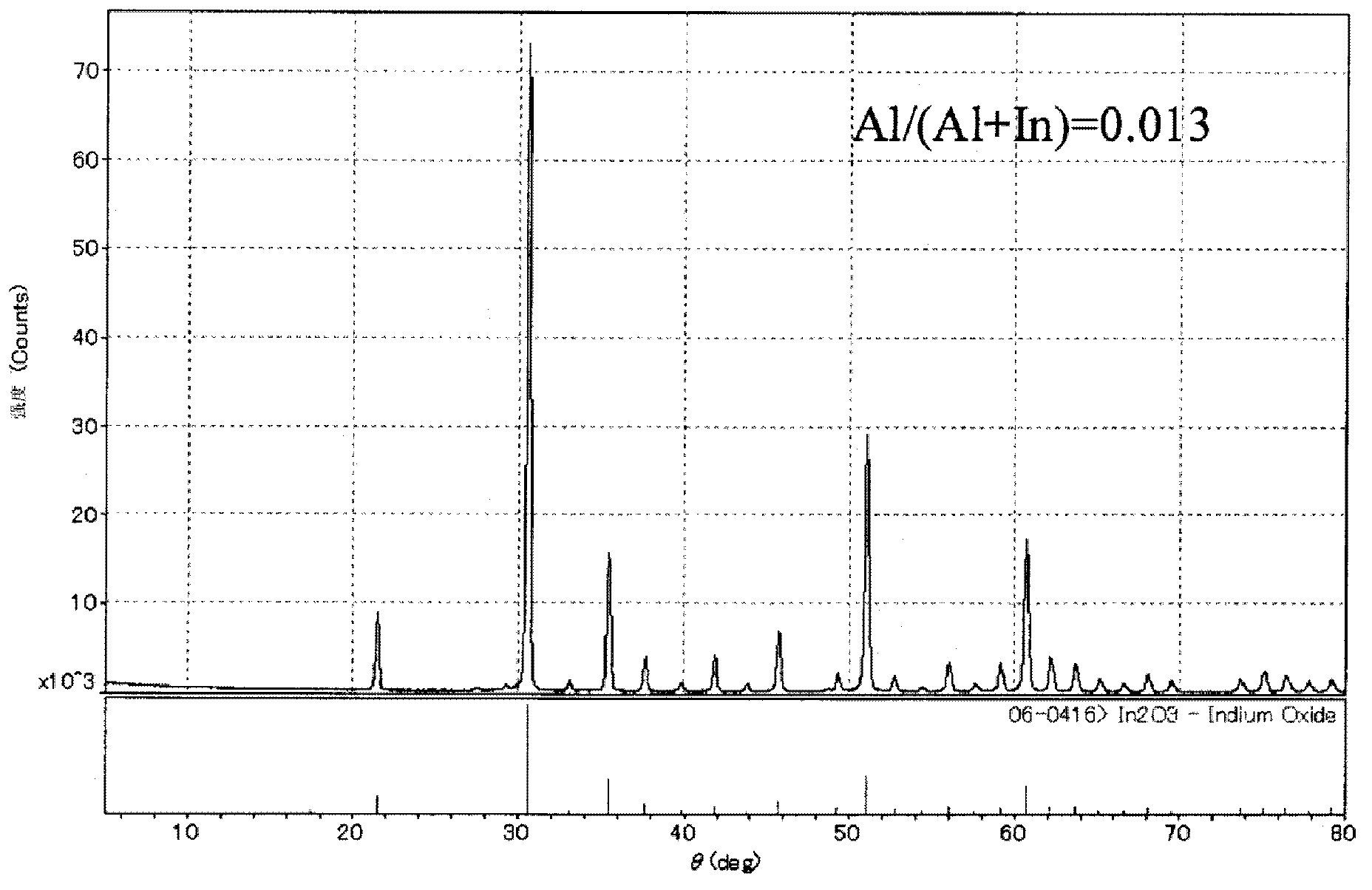

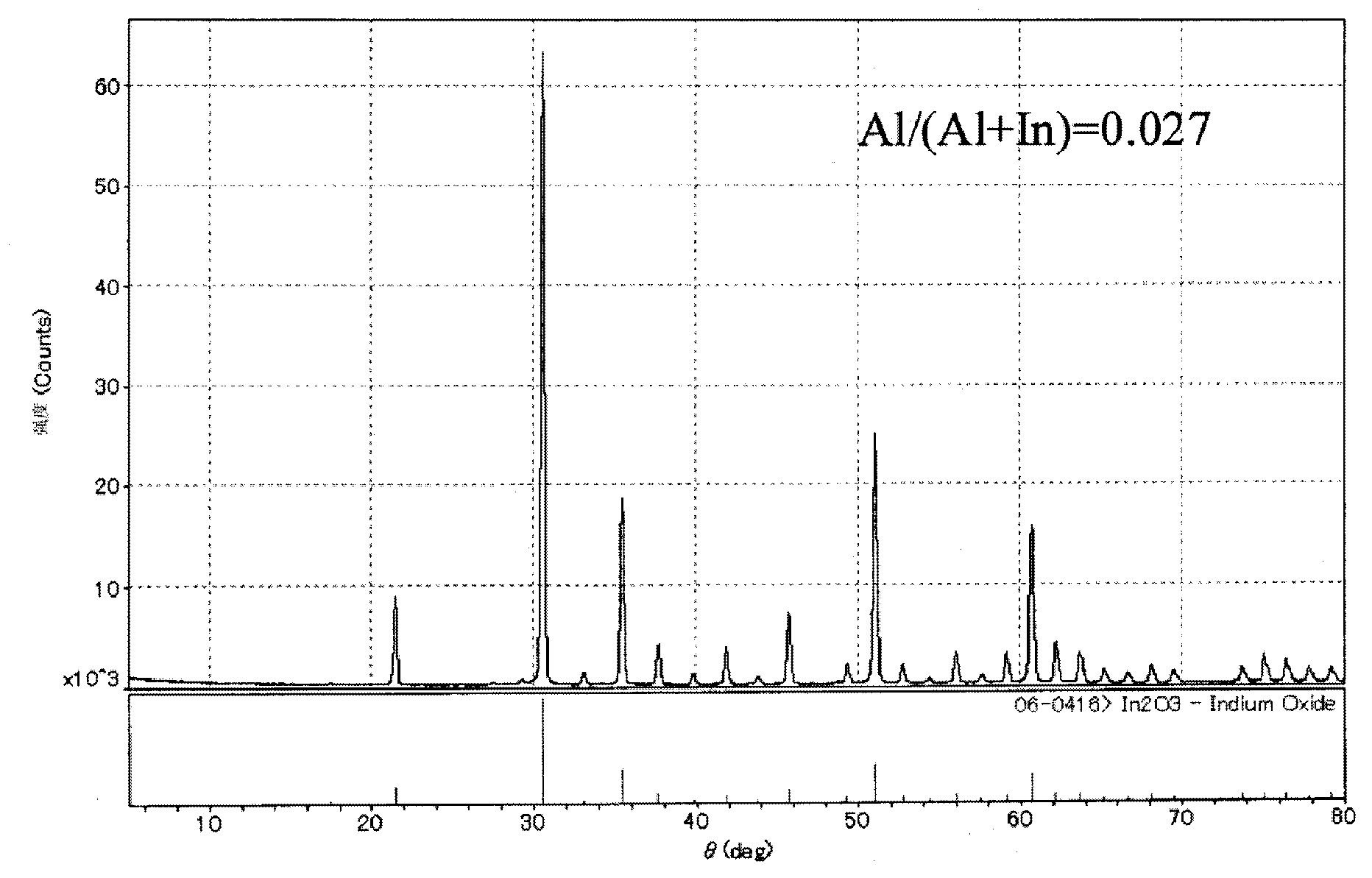

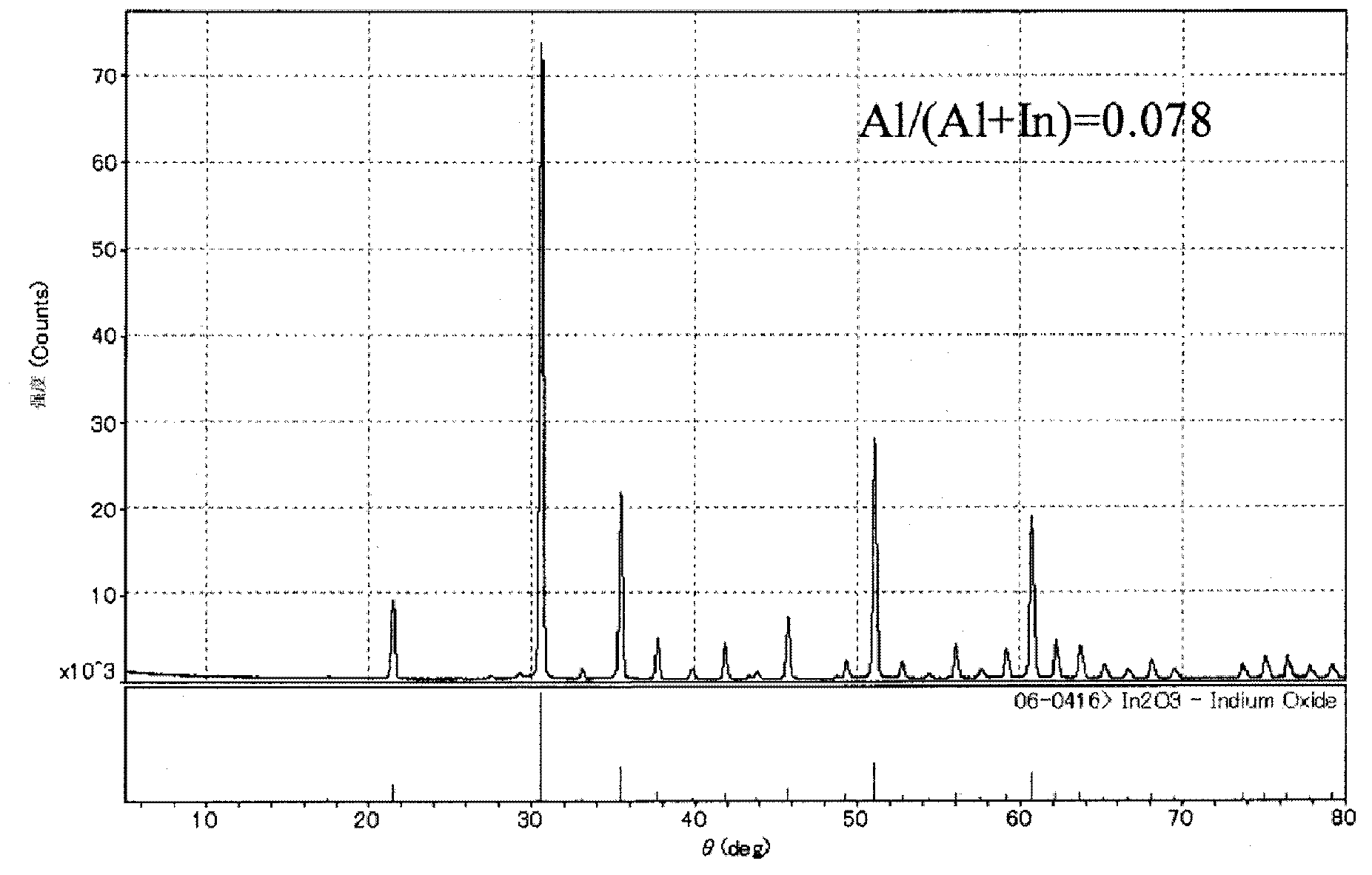

Sintered oxide material, target comprising same, and oxide semiconductor thin film

A sintered oxide material comprising an oxide of indium and an oxide of aluminum, wherein the atomic ratio Al / (Al+In) is 0.01 to 0.08.

Owner:IDEMITSU KOSAN CO LTD

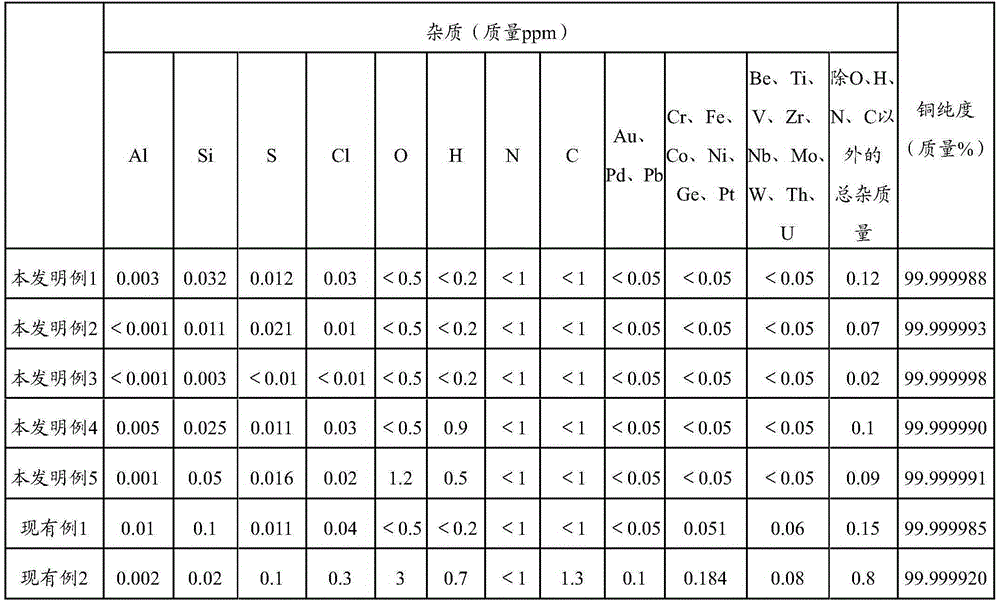

High purity copper sputtering target material

ActiveCN107923034ASmall diameterSuppression of bumpsPhotography auxillary processesElectric discharge tubesSputteringPhysical chemistry

Provided is a high purity copper sputtering target material characterized in that Cu purity excluding O, H, N and C is at least 99.99998 mass%, Al content is 0.005 mass ppm or less, Si content is 0.05mass ppm or less, Fe content is 0.02 mass ppm or less, S content is 0.03 mass ppm or less, Cl content is 0.1 mass ppm or less, O content is 1 mass ppm or less, H content is 1 mass ppm or less, N content is 1 mass ppm or less, and C content is 1 mass ppm or less.

Owner:MITSUBISHI MATERIALS CORP

Copper material for high-purity copper sputtering target, and high-purity copper sputtering target

ActiveCN105339527ASuppress abnormal dischargeStable film formationPhotography auxillary processesElectric discharge tubesSputteringCopper

This copper material for a high-purity copper sputtering target is such that the purity of Cu excluding O, H, N, and C is in a range of 99.999980 to 99.999998 mass%, the Al content is 0.005 mass ppm or less, and the Si content is 0.05 mass ppm or less.

Owner:MITSUBISHI MATERIALS CORP

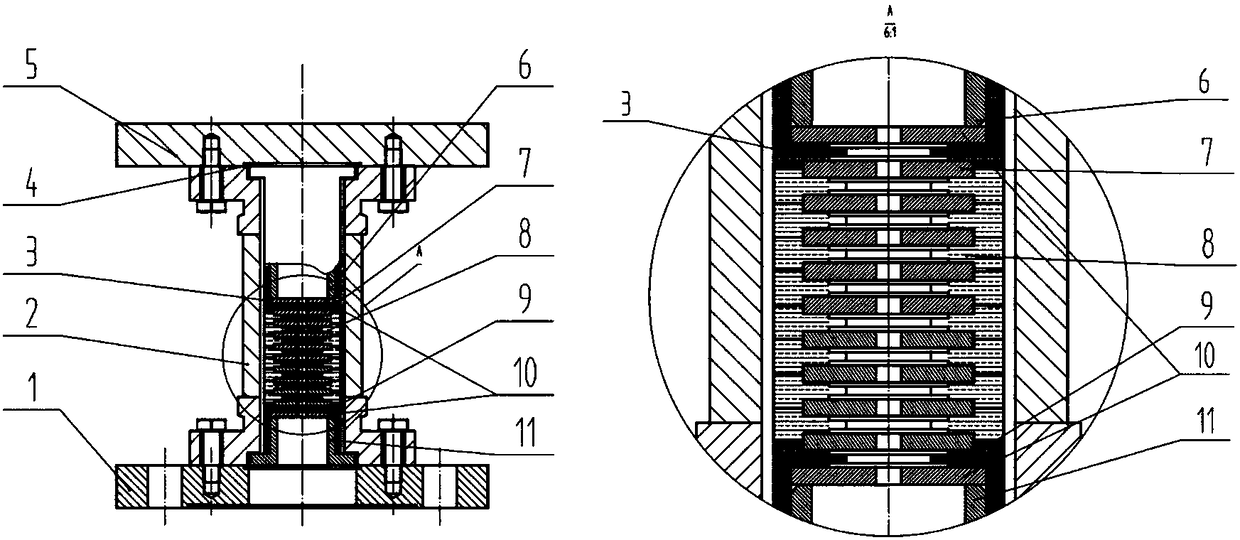

Multi-gap pseudospark electron beam source capable of suppressing flashover

ActiveCN108063079AImprove breakdown voltageSuppress abnormal dischargeSolid cathode detailsBeam sourceAbnormal discharge

The invention discloses a multi-gap pseudospark electron beam source capable of suppressing flashover. The multi-gap pseudospark electron beam source capable of suppressing flashover comprises a blindflange, a ceramic isolation sleeve and a through hole flange which are connected in sequence, hollow electrodes which are symmetrically placed at two ends inside the ceramic isolation sleeve and insulation sleeves thereof, and middle electrode and middle insulation plates which are alternatively superposed in the ceramic isolation sleeve. the hollow electrodes located at the two ends, the insulation sleeves thereof and the middle electrodes located in the middle for electron beam focusing and acceleration form a discharging cavity. A multi-gap pseudospark electron beam source capable of suppressing flashover can be acquired and a high-energy electron beam can be obtained. The multi-gap pseudospark electron beam source effectively suppresses abnormal discharge in a pseudospark discharge process through protecting the edge of a metal pole plate and cutting and hindering formation of flashover along the surface, the energy of the electron beam is improved, and the discharge stability andthe reliability are improved.

Owner:SHANGHAI JIAO TONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com