Sputtering target, compound semiconductor thin film, solar cell having compound semiconductor thin film, and method for manufacturing compound semiconductor thin film

A manufacturing method and sputtering target technology, which is applied in the field of sputtering targets, can solve problems such as high volume resistance, difficulty in making crystallinity, and easy breakdown, and achieve the effects of reducing volume resistance, suppressing abnormal discharge, and reducing redundant processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

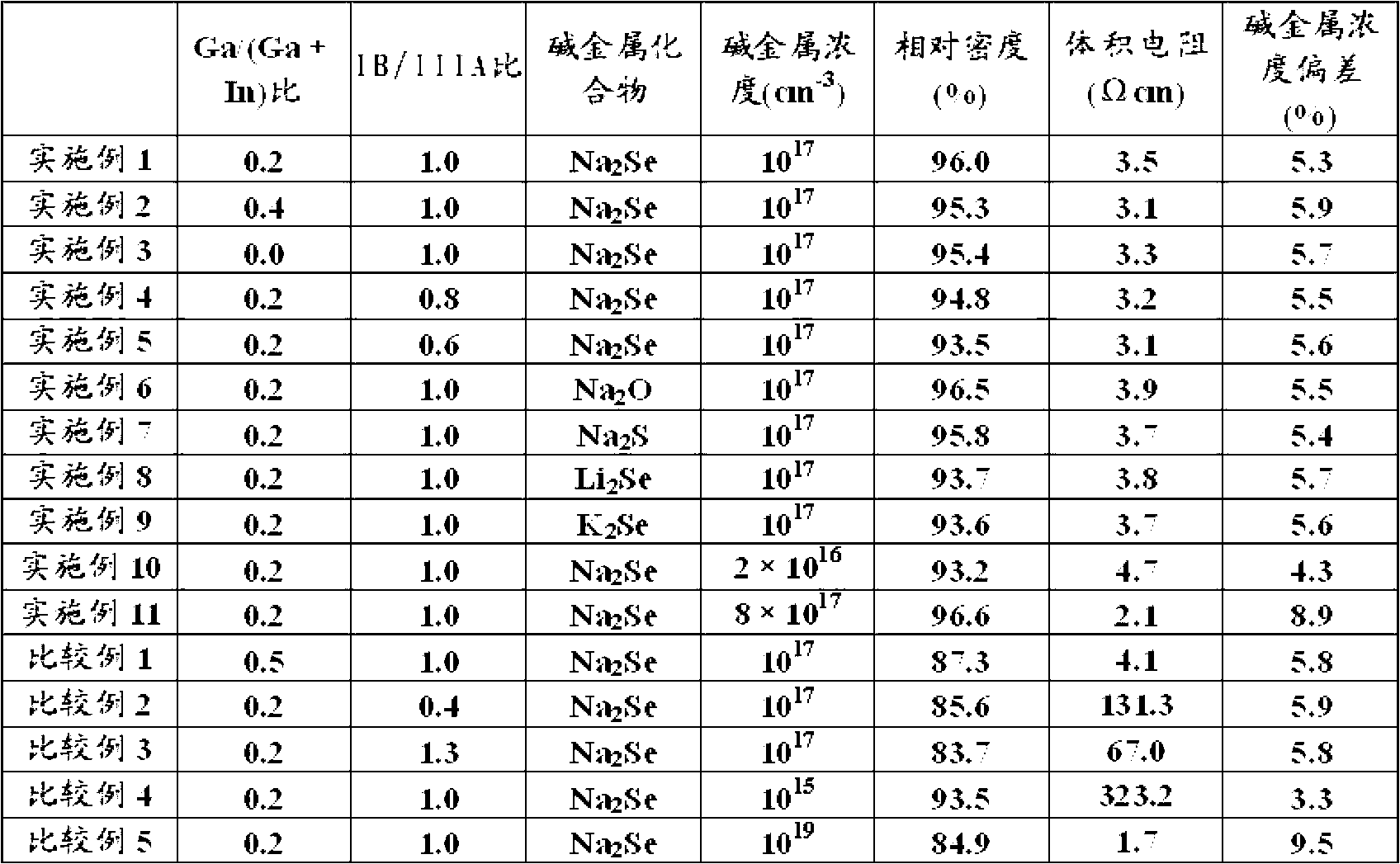

[0082] Weigh raw materials Cu, In, Ga, Se and Na 2 For Se, Ga / (Ga+In), which is the atomic ratio of Ga and In, is 0.2, and Cu / (Ga+In), which is the atomic ratio of Cu as a group IB element to the total of Ga and In as a group IIIA element, is 0.2. In) is 1.0, so that the concentration of Na is 10 17 cm -3 .

[0083] Next, these raw materials are put into a quartz ampoule, the inside is evacuated, sealed, and synthesized in a heating furnace. The heating program is set as follows: from room temperature to 100°C at a heating rate of 5°C / minute, then to 400°C at a heating rate of 1°C / minute, and then to 400°C at a heating rate of 5°C / minute Speed is heated up to 550 DEG C, then, is heated up to 650 DEG C with the heating rate of 1.66 DEG C / min, then, keeps 8 hours at 650 DEG C, then, reaches room temperature after cooling in furnace with 12 hours.

[0084] The Na-added CIGS synthetic raw material powder obtained above was passed through a 120-mesh sieve, and then subjected ...

Embodiment 2~3

[0092] In embodiment 2, the atomic number ratio of Ga and In is set as Ga / (Ga+In)=0.4, and in embodiment 3, the atomic number ratio of Ga and In is set as Ga / (Ga+In)= 0.0, except that, under the same conditions as in Example 1, preparation of a sintered body and preparation of a thin film were performed. The results of the properties of the sintered body and the thin film are similarly shown in Table 1.

[0093] As shown in the above Table 1, in Example 2, the relative density is 95.3%, the volume resistance value is 3.1Ωcm, and the alkali concentration deviation is 5.9%. In Example 3, the relative density is 95.4%, and the volume resistance value is 3.3 Ωcm and the concentration variation of the alkali metal were 5.7%, both showing good values for achieving the object of the present invention.

Embodiment 4~5

[0095] Cu / (Ga+In)=0.8 and Cu / (Ga+In)=0.6 respectively, except that Cu / (Ga+In)=0.6 are respectively set as Cu / (Ga+In)=0.6 with respect to the total atomic ratio of Cu which is a group IIIA element with respect to Ga and In which are a group IIIA element, Under the same conditions as in Example 1, production of a sintered body and production of a thin film were performed. The results of the properties of the sintered body and the thin film are similarly shown in Table 1.

[0096] As shown in the above table 1, in embodiment 4, the relative density is 94.8%, the volume resistance value is 3.2Ωcm, and the alkali concentration deviation is 5.5%, and in embodiment 5, the relative density is 93.5%, and the volume resistance value is 3.1 Ωcm and the concentration variation of the alkali metal were 5.6%, both showing good values for achieving the object of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com