High-impact-resistance anti-static ultra-high molecular weight polyethylene composite material and preparation method thereof

An ultra-high molecular weight, composite material technology, applied in the field of high-impact and anti-static ultra-high molecular weight polyethylene composite materials and its preparation, can solve the problems of large carbon black filling, the influence of the mechanical properties of the matrix, and the difficulty of forming and processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

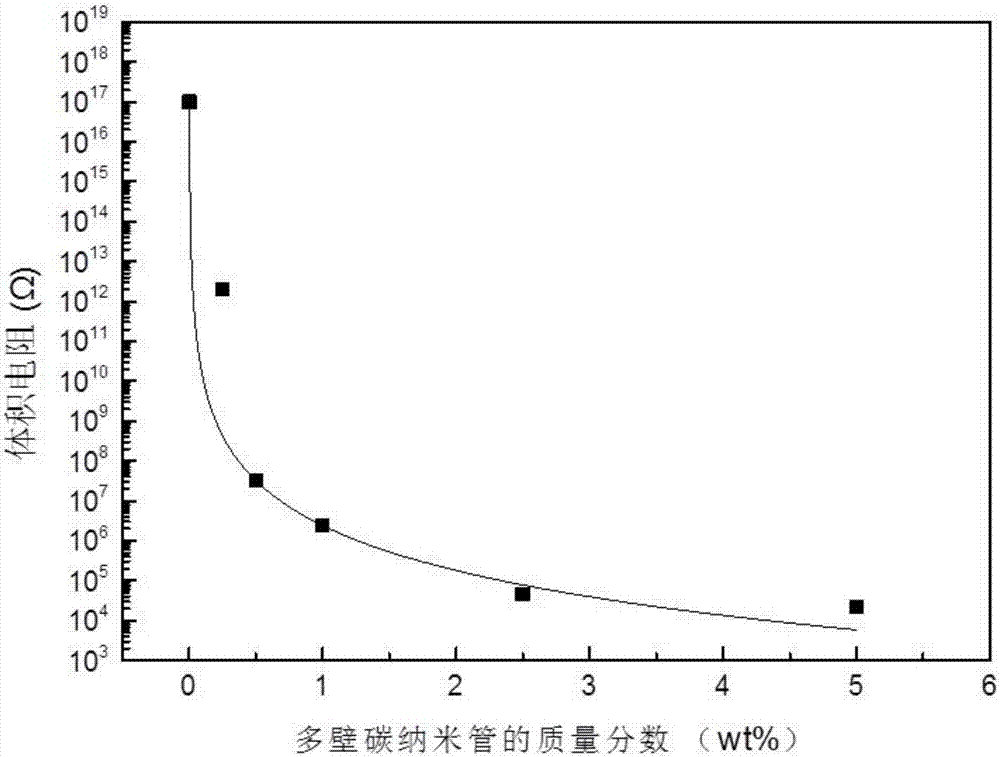

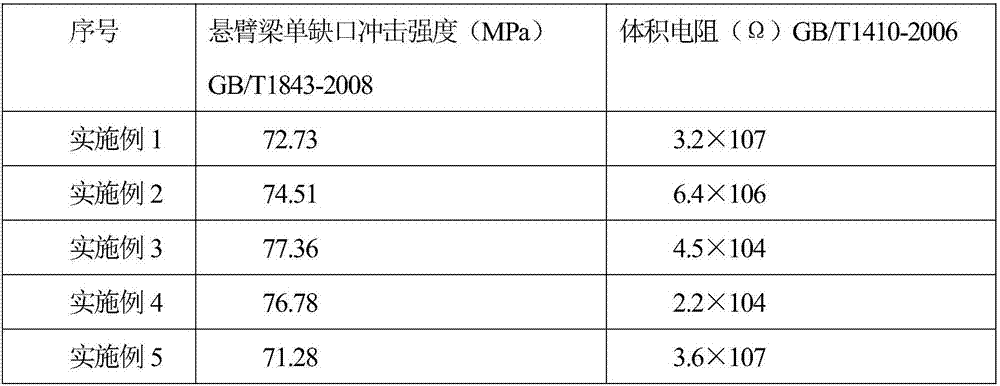

[0019] One aspect of the present invention provides an ultra-high molecular weight polyethylene composite material, which includes a product obtained by compounding multi-walled carbon nanotubes and ultra-high molecular weight polyethylene at an ultra-high rotational speed; wherein, the multi-walled carbon nanotubes in the composite material The mass percentage of the tube is 0.5-5%.

[0020] Another aspect of the present invention provides a method for preparing the above-mentioned composite material, comprising the following specific steps:

[0021] (1) The ultra-high molecular weight polyethylene powder is placed in a vacuum drying oven, and vacuum-dried at 60° C. for 12 hours;

[0022] (2) Accurately weigh 95-99.5wt% of the dried ultra-high molecular weight polyethylene powder, stir in a high-speed mixer for 60-120s, and the rotating speed is 20000-30000r / min;

[0023] (3) Accurately weigh 0.5-5% of the multi-walled carbon nanotube powder and add it to the ultra-high mole...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com