Method of mfg. semiconductor device

A manufacturing method and semiconductor technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of rising manufacturing cost, complicated manufacturing process, and high manufacturing unit price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

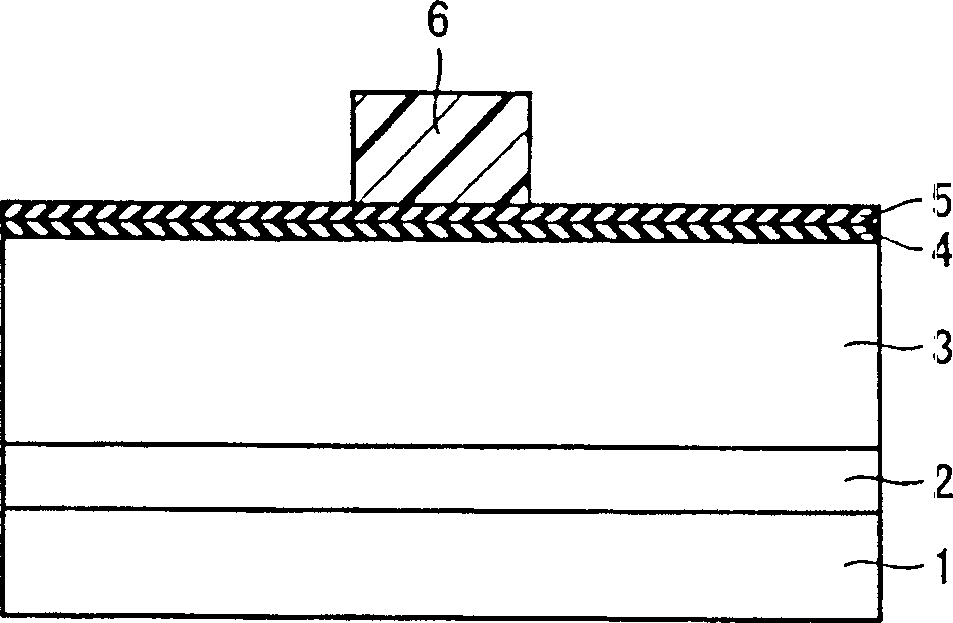

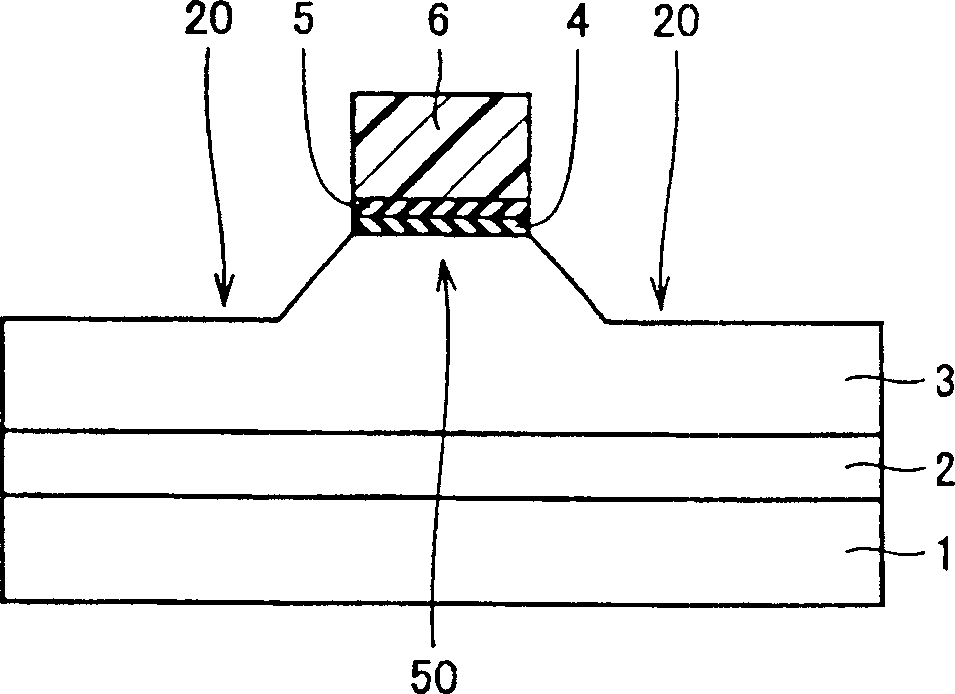

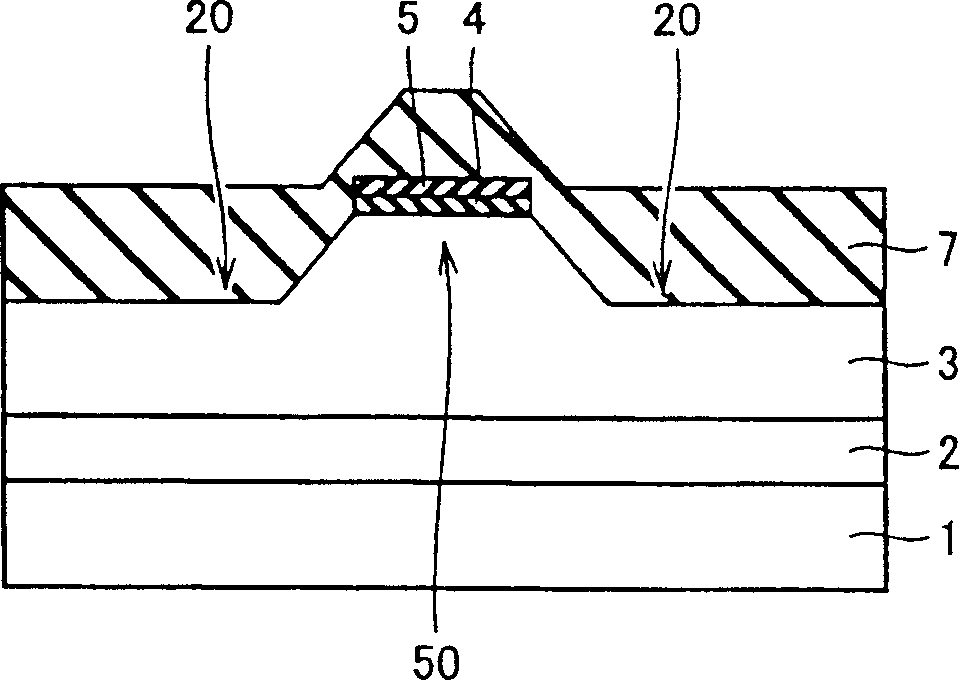

[0036] Specific embodiments of the present invention will be described below based on the drawings.

[0037] Refer to the following Figure 1 to Figure 11 The manufacturing process of the semiconductor device including the element isolation region of this embodiment will be described.

[0038] First, if figure 1 As shown, on the P-type silicon substrate 1, N + Type buried layer 2. in N + On the N-type buried layer 2, an N-type epitaxial silicon layer 3 is formed. Also, the P-type silicon substrate 1, N + The N-type buried layer 2 and the N-type epitaxial silicon layer 3 are examples of the "semiconductor substrate" of the present invention. Furthermore, on the N-type epitaxial silicon layer 3, a silicon oxide film (SiO 2 film) 4. On the silicon oxide film 4, a Si with a thickness of about 100 nm is formed as a stopper film by a CMP process. 3 N 4 Film 5. Moreover, in Si 3 N 4 A resist film 6 is formed in a predetermined area of the film 5 .

[0039] Next, if ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com