AC drive type plasma display device for electro-optical plate and its manufacturing method

An AC drive and plasma technology, applied in the direction of AC plasma display panel, plasma, electrode system manufacturing, etc., can solve the problem of driving voltage increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

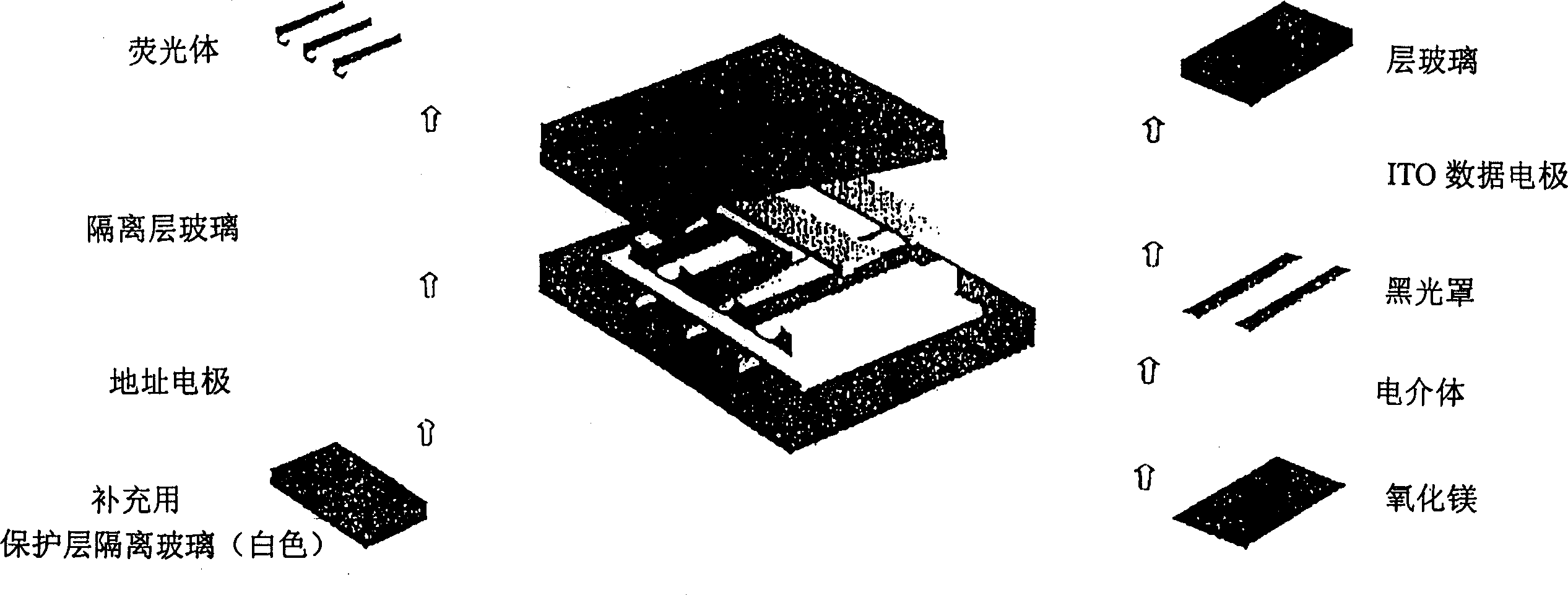

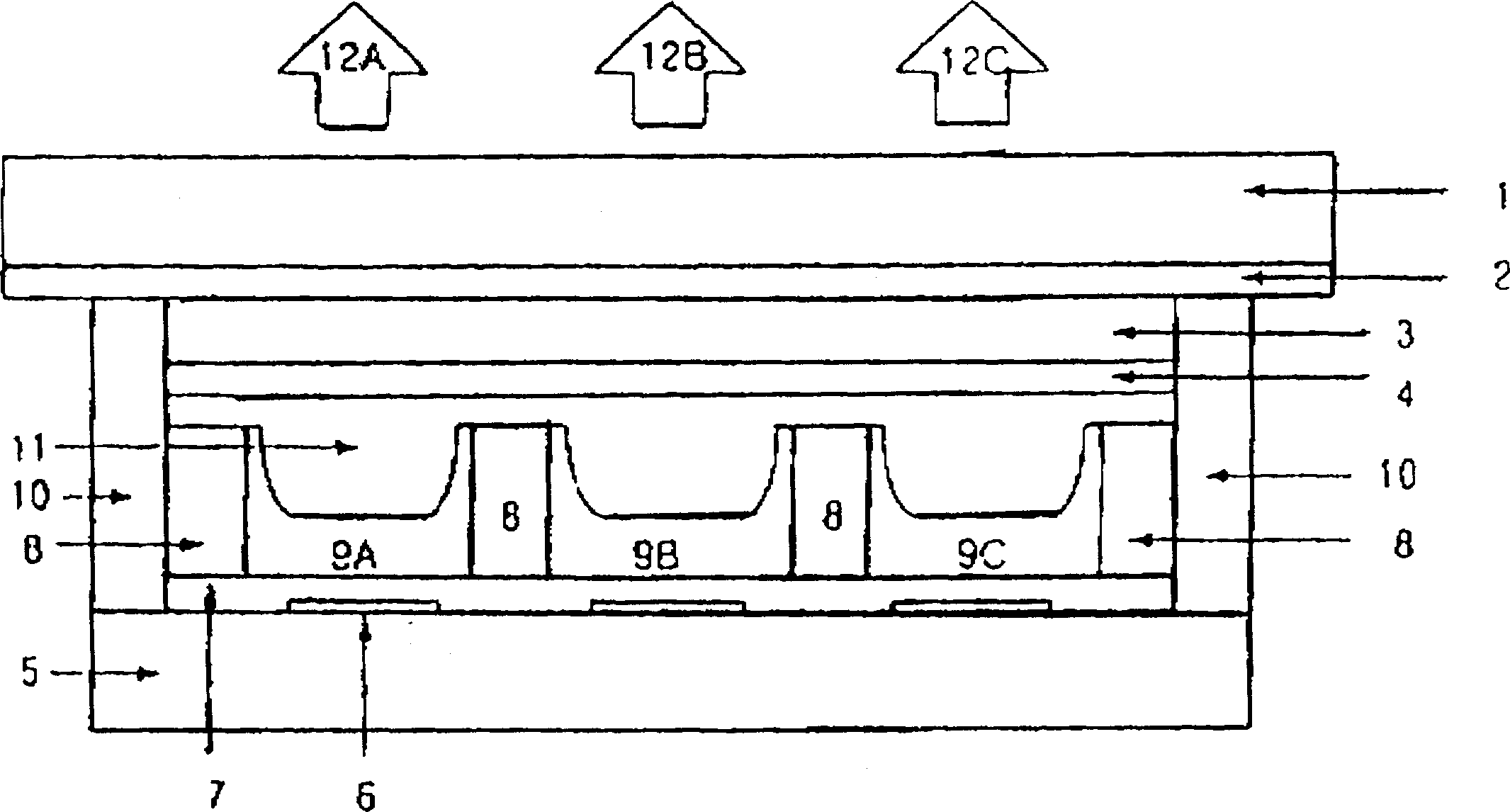

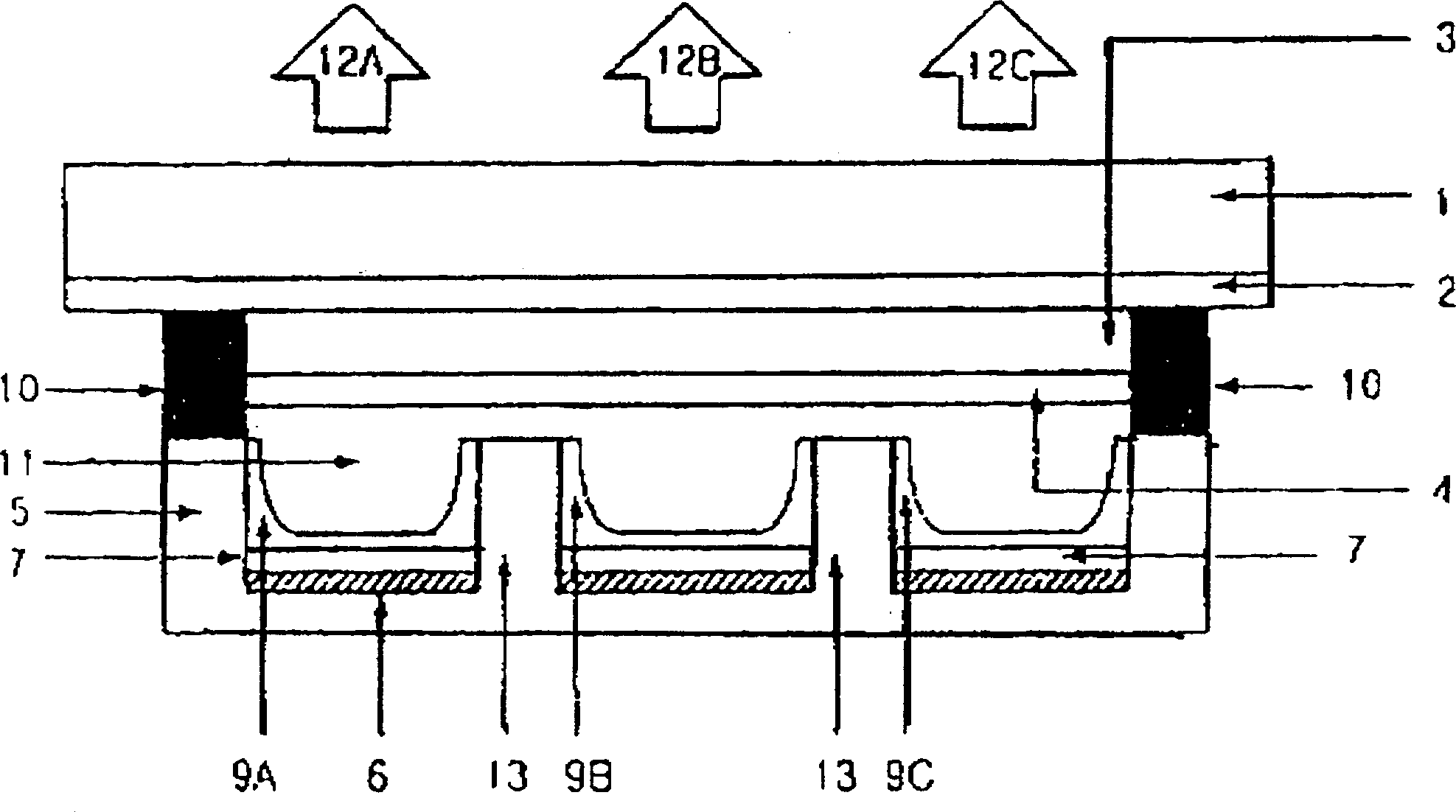

[0028] figure 2 It is an exploded perspective view of an AC-driven plasma display device for an electro-optical panel of the present invention, image 3 for the sectional view.

[0029] figure 2 It is the structure of the known PDP display device for wall-mounted TVs, which is improved to be suitable for PDP electro-optic panels, that is, a PDP electro-optic panel structure that can be driven at low voltage and can be manufactured at low cost; it basically has a front glass substrate / transparent Structure of electrode / transparent dielectric / protective film / discharge tank (cell) / phosphor / white dielectric / metal electrode / back glass substrate (the front glass substrate 1 shown in the figure can actually be rotated by 90 degrees) .

[0030] Therefore, the structural feature of the present invention is that the front glass substrate 1 after cutting is formed with a transparent electrode 2 and a protective film 4 above and below it; and the back glass substrate 5 that is also c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com