Semiconductor device manufacturing method

一种制造方法、半导体的技术,应用在半导体/固态器件制造、半导体器件、半导体/固态器件零部件等方向,能够解决定位部件倾斜配置等问题,达到抑制品质降低、可靠接合的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

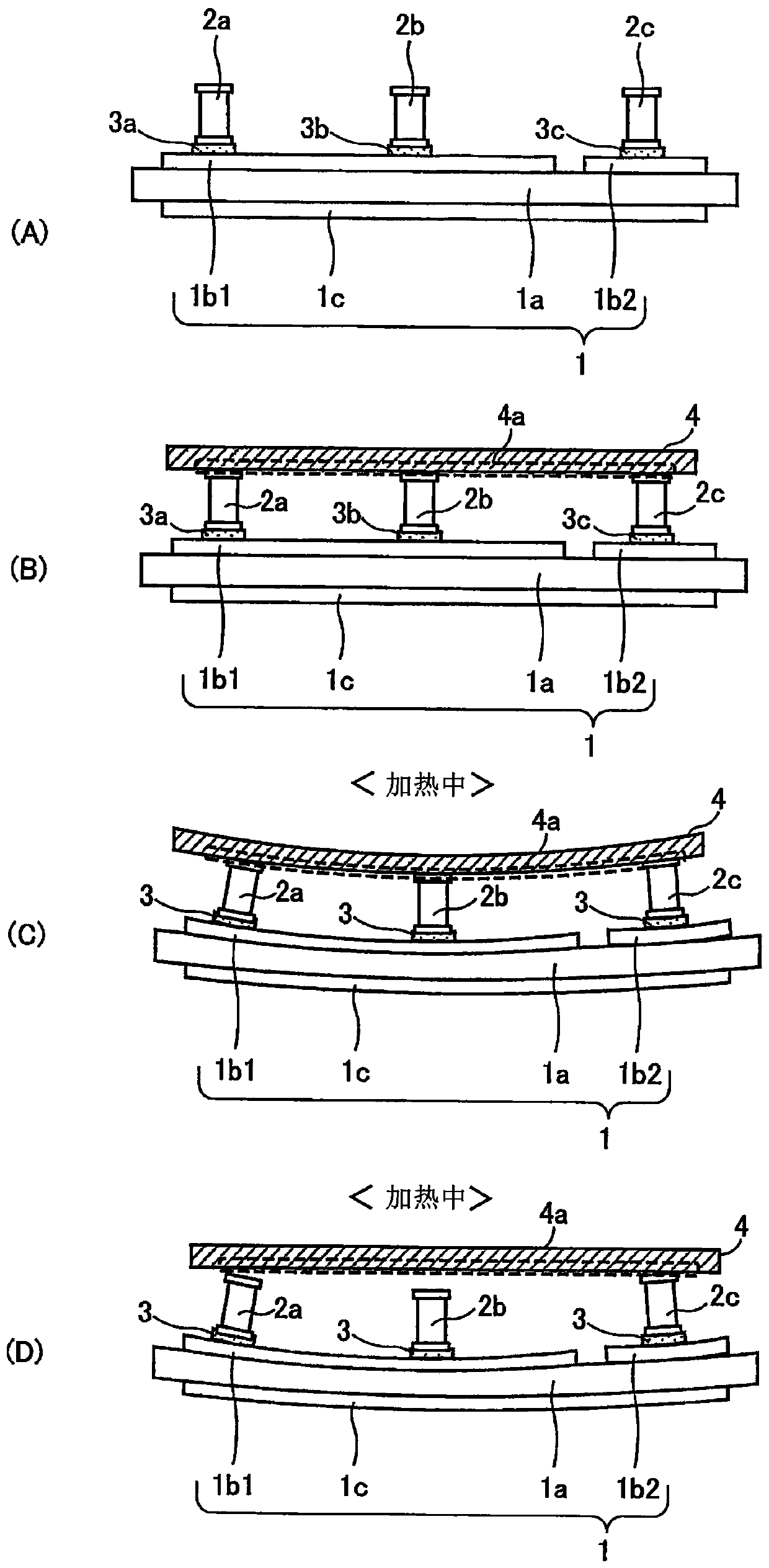

[0067] Below, with reference to the accompanying drawings, use figure 1 A method of manufacturing the semiconductor device according to the first embodiment will be described. figure 1 It is a figure for demonstrating each process of the manufacturing method of the semiconductor device of 1st Embodiment. It should be stated that in figure 1 (A)~ figure 1 (C) is a side view showing, in time series, the steps related to the reflow soldering step in the manufacturing method of the semiconductor device. in addition, figure 1 (D) shows for figure 1 Reference example of the process of (C).

[0068] First, a multilayer substrate 1 and a plurality of contact members 2a to 2c are prepared. The laminated substrate 1 has an insulating layer 1a, circuit pattern layers 1b1 and 1b2 formed on the front surface of the insulating layer 1a, and a metal layer 1c formed on the back surface of the insulating layer 1a and having a larger area than the circuit pattern layers 1b1 and 1b2. In suc...

no. 2 Embodiment approach

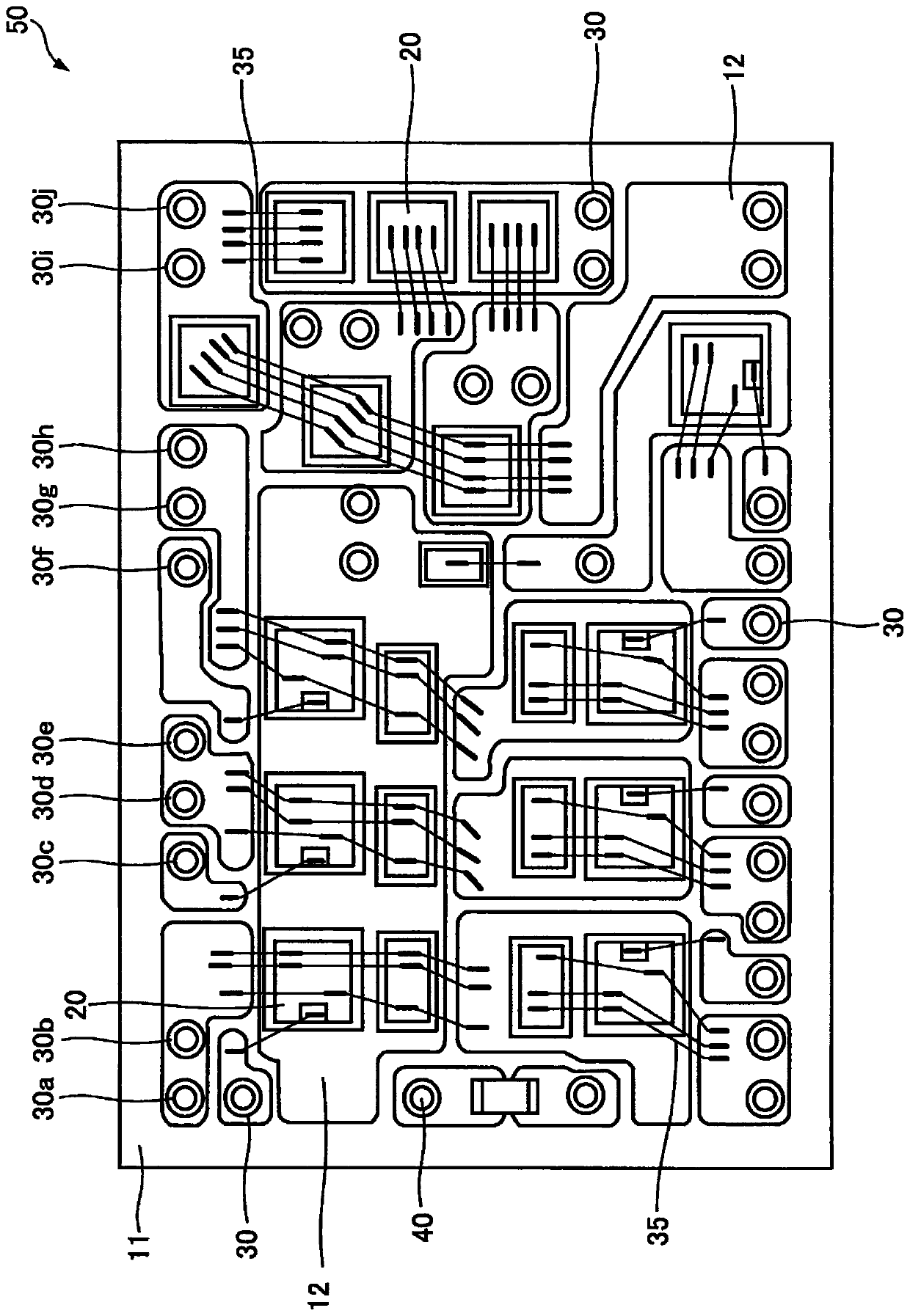

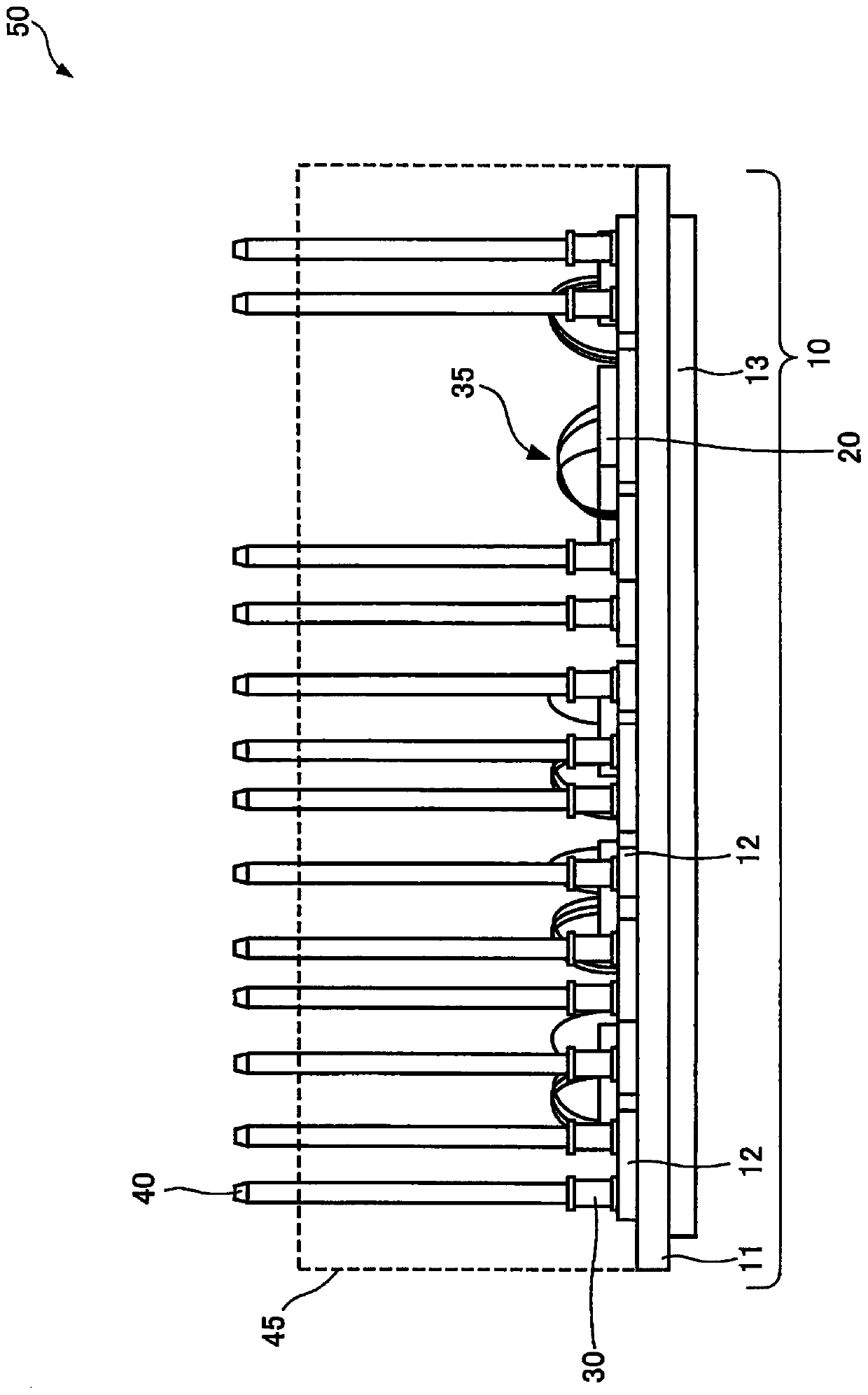

[0075] In the second embodiment, the method of manufacturing the semiconductor device according to the first embodiment will be described more specifically. First, use figure 2 with image 3 A semiconductor device will be described. figure 2 It is a plan view showing the semiconductor device of the second embodiment, image 3 It is a side view showing the semiconductor device of the second embodiment. should be explained, figure 2 Illustration of packaged components is omitted. exist image 3 In , packaged components are indicated by dotted lines. In addition, in the second embodiment, the plurality of circuit pattern layers 12, the plurality of semiconductor elements 20, the plurality of contact members 30, the plurality of bonding wires 35, and the plurality of external connection terminals 40 are not distinguished, and the same symbols are attached. and are described with the same symbols. In addition, about the structure other than these structures, a plurality ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com