Jaw clutch

A jaw clutch, clutch technology, applied in clutches, fluid drive clutches, mechanical drive clutches, etc., can solve problems such as affecting measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

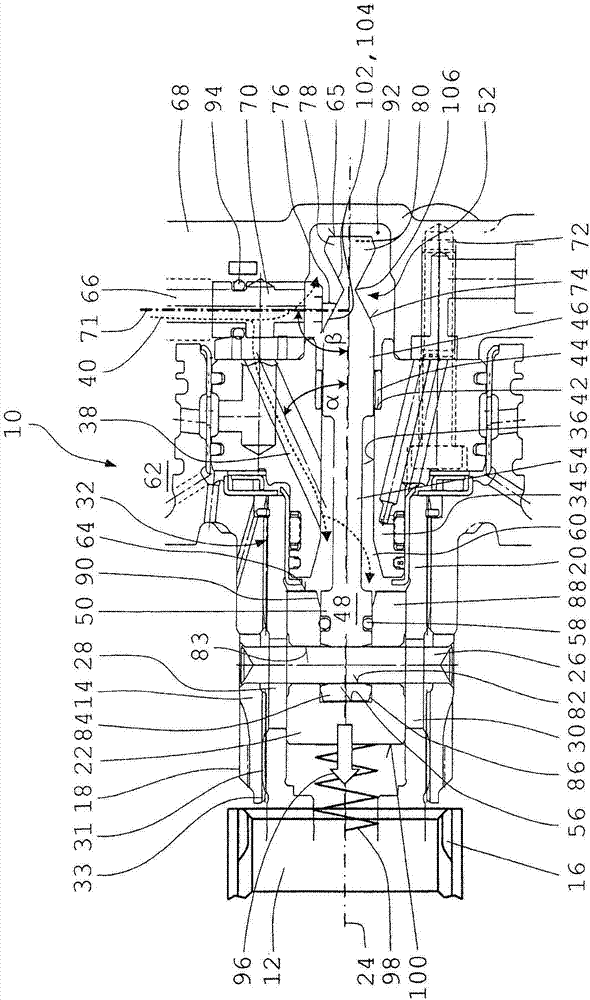

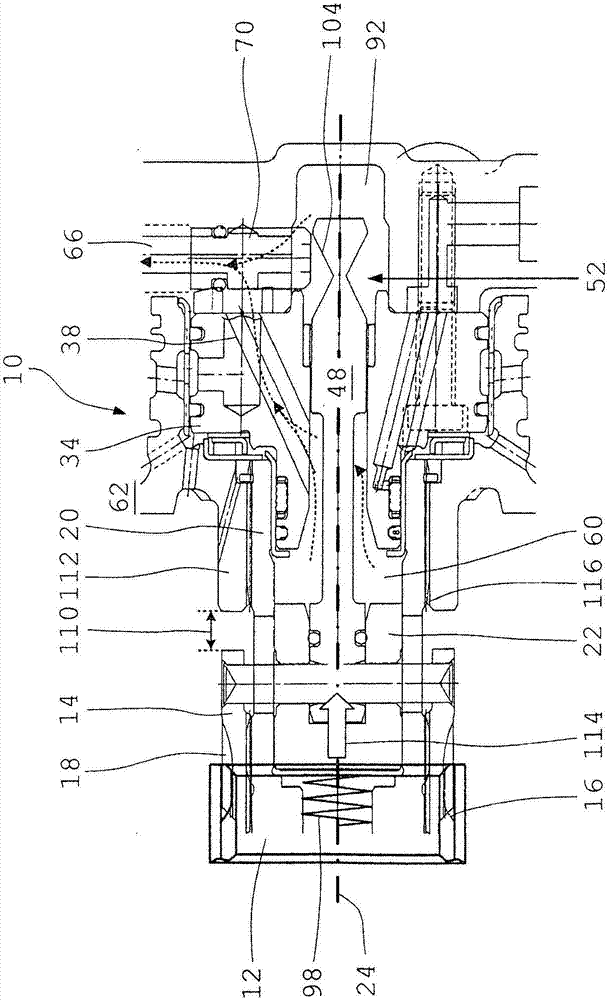

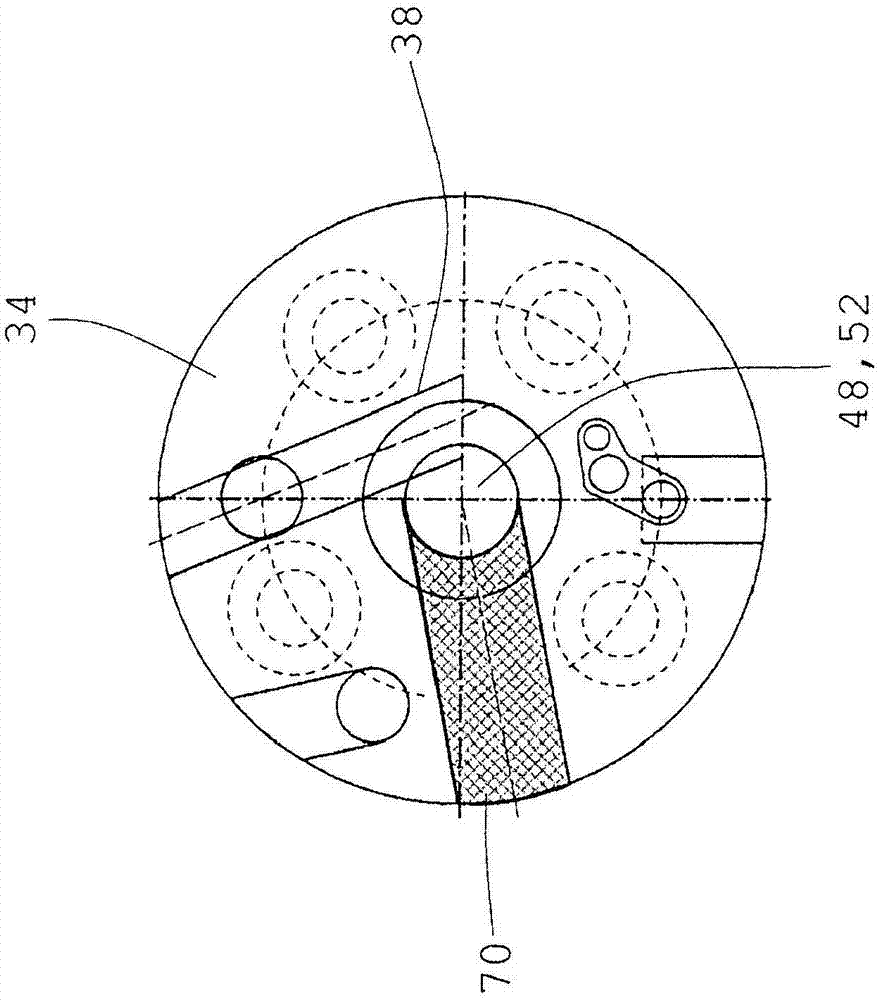

[0030] exist Figures 1 to 3 The jaw clutch 10 shown in FIG. 1 has a fixed clutch part 12 and an axially movable clutch part 14 . The two clutch parts 12 , 14 are each substantially hollow-cylindrical, wherein the fixed clutch part 12 has an axial inner toothing 16 and the axially movable clutch part 14 has an axial outer toothing 18 . , the teeth of the inner tooth part and the outer tooth part cooperate with the tooth slots of the corresponding other tooth part. The two clutch parts 12 , 14 are arranged coaxially with one another, so that the movable clutch part 14 , which is smaller in diameter, is partially displaceable in the axial direction into the fixed clutch part 12 . This results in a form-locking connection which enables a torque transmission between the two clutch parts 12 , 14 .

[0031] For actuating the dog clutch 10 , it also has an approximately hollow-cylindrical cylinder housing 20 in which a pot-shaped piston 22 is accommodated so as to be displaceable c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com