A device for removing liquid accumulation on the piston of a dry gas cabinet

A technology of removal device and gas tank, which is used in gas/liquid distribution and storage, adjustable-capacity gas storage tanks, mechanical equipment, etc., can solve the problem that the inclination of the piston is difficult to guarantee, the normal production of the gas system has a great impact, and it is safe and reliable. It can eliminate problems such as unguaranteed performance, and achieve the effect of eliminating the phenomenon of shutdown and maintenance, the structure is simple and easy to implement, and the piston inclination exceeding the standard is eliminated.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings; it should be understood that the preferred embodiments are only for illustrating the present invention, rather than limiting the protection scope of the present invention.

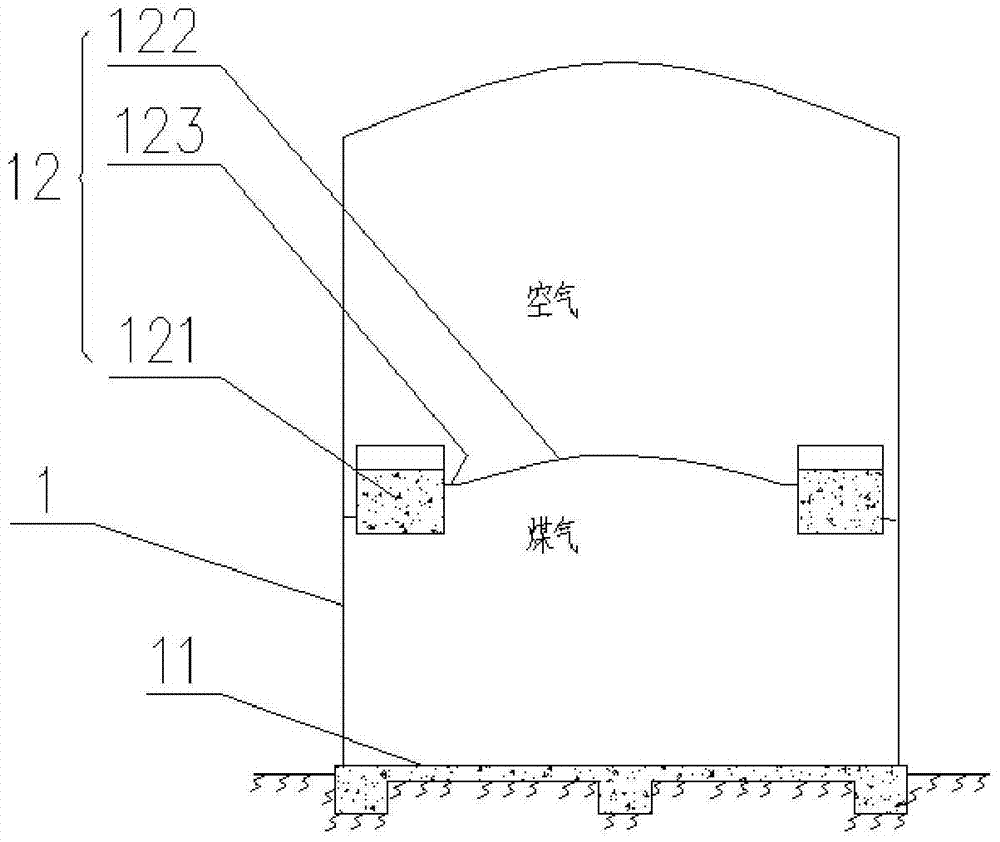

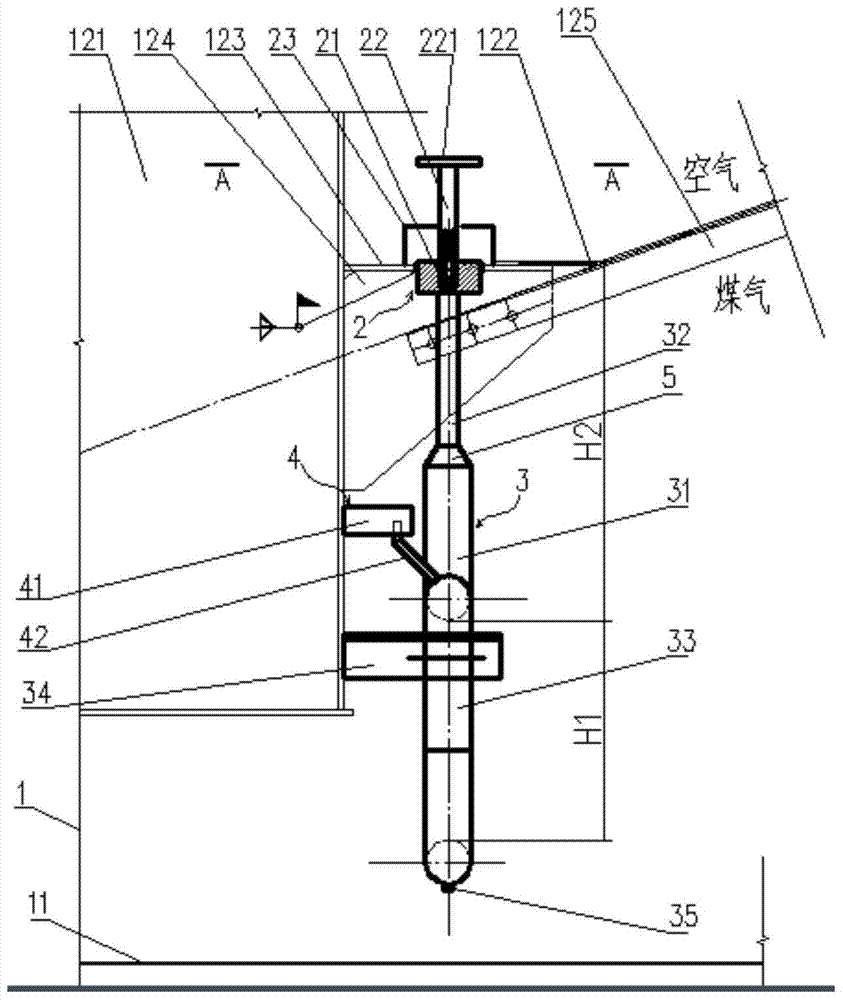

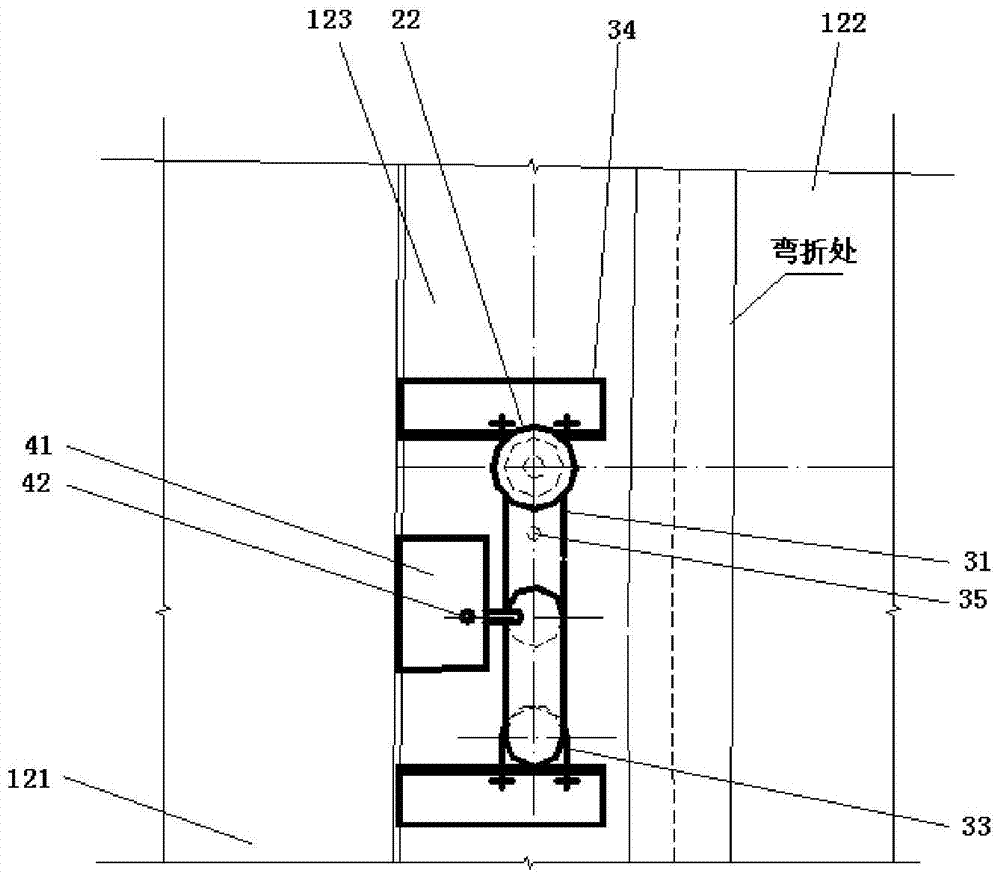

[0029] Such as Figure 1-3 As shown, the present invention provides a device for removing liquid accumulation on the piston of a dry gas cabinet. The dry gas cabinet 1 includes a bottom plate 11 and a piston 12, wherein the piston 12 is mainly composed of a piston box beam 121 and a piston arch. The piston The arch includes a piston arch high plate 122, a piston arch low plate 123 connected with the piston arch high plate 122, a support 124 for fixedly supporting the piston arch low plate 123, and an arch beam 125 for fixing and supporting the piston arch high plate 122. 124 is affixed on the piston box beam 121, and the arch beam 125 is affixed to the support 124; alon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com