Method for controlling a fluid coupling

A technology of hydraulic coupler and control fluid, applied in clutches, clutches, fluid clutches, etc., can solve the problems of bearing damage, heating to higher than 55℃ or 60℃, inaccurate time reservation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

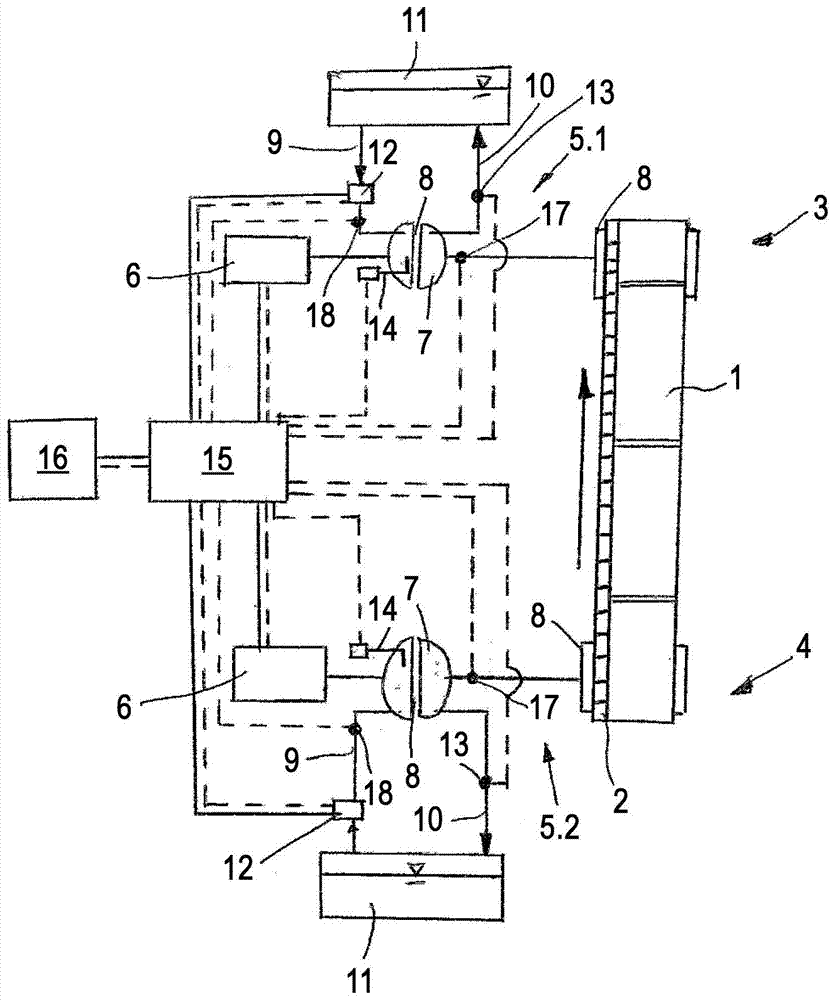

[0033] exist figure 1 shows a belt conveyor, for example as it is used in the mining industry. The conveyor belt 1 is driven by a chain 2 . The chain 2 is again driven in the region of the head 3 of the conveyor belt and the tail 4 of the conveyor belt by a respective dedicated drive train 5.1, 5.2.

[0034] A drive motor 6, here in the form of an electric motor, is arranged in each drive train 5.1, 5.2. Each drive motor 6 drives a drive pulley 8 for the chain 2 via a fluid coupling 7 . Each drive train 5.1, 5.2 can also be provided with several electric motors and / or hydraulic couplings.

[0035] Each hydrodynamic coupling 7 is filled with working medium via the inlet 9 and emptied of the working medium via the outlet 10 . Instead of the working chamber 8 shown here, the coupling hydrodynamics can also be designed with two parallel working chambers. A working medium, for example water, is supplied from a working medium storage container 11 , which is shown here as a conta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com