Method for producing silicon monocrystal

A manufacturing method and technology of single crystal silicon, applied in the direction of single crystal growth, single crystal growth, chemical instruments and methods, etc., can solve problems such as defects, and achieve the effect of reducing carbon concentration and preventing poor pinholes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

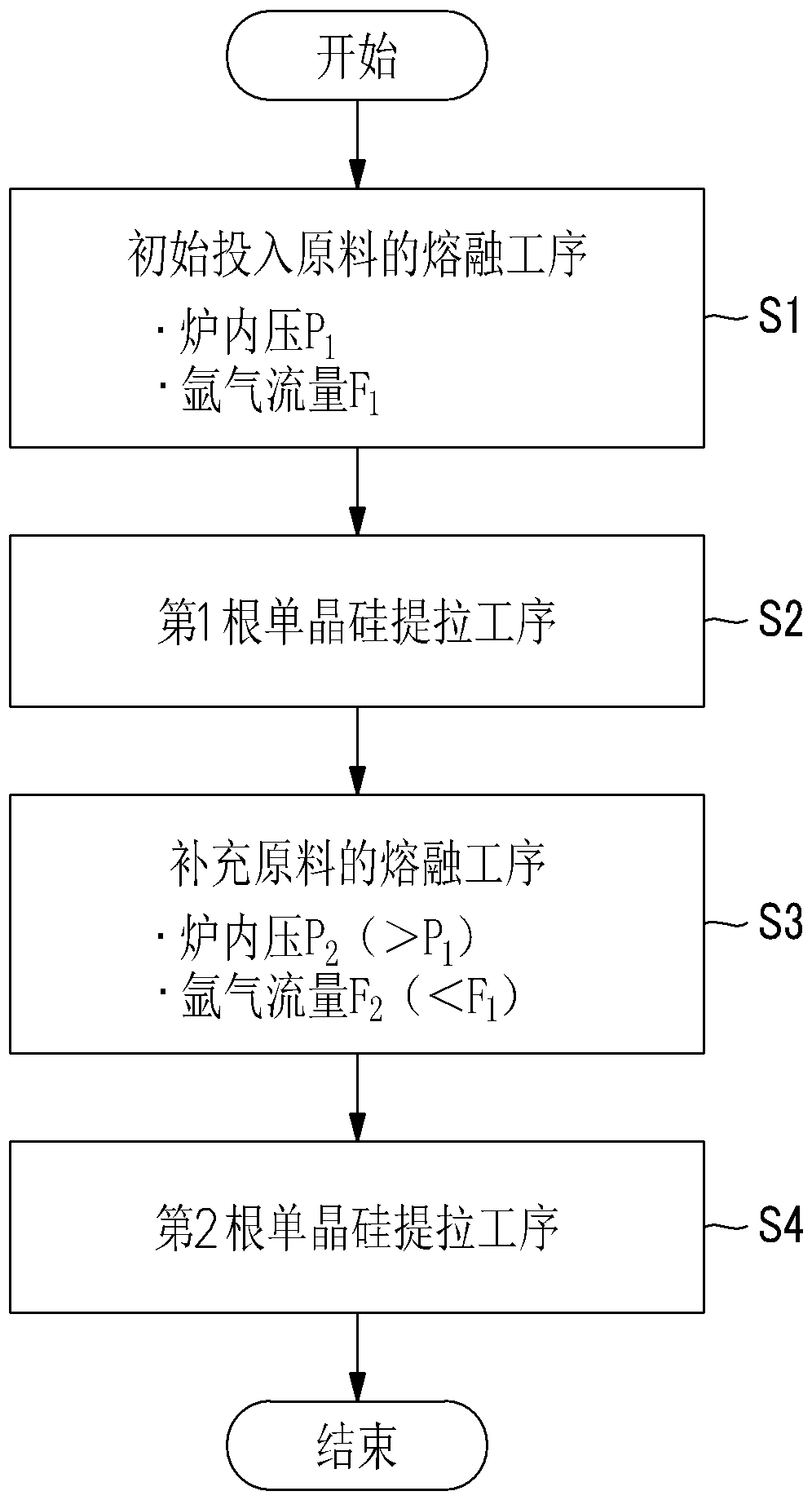

[0024] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the drawings.

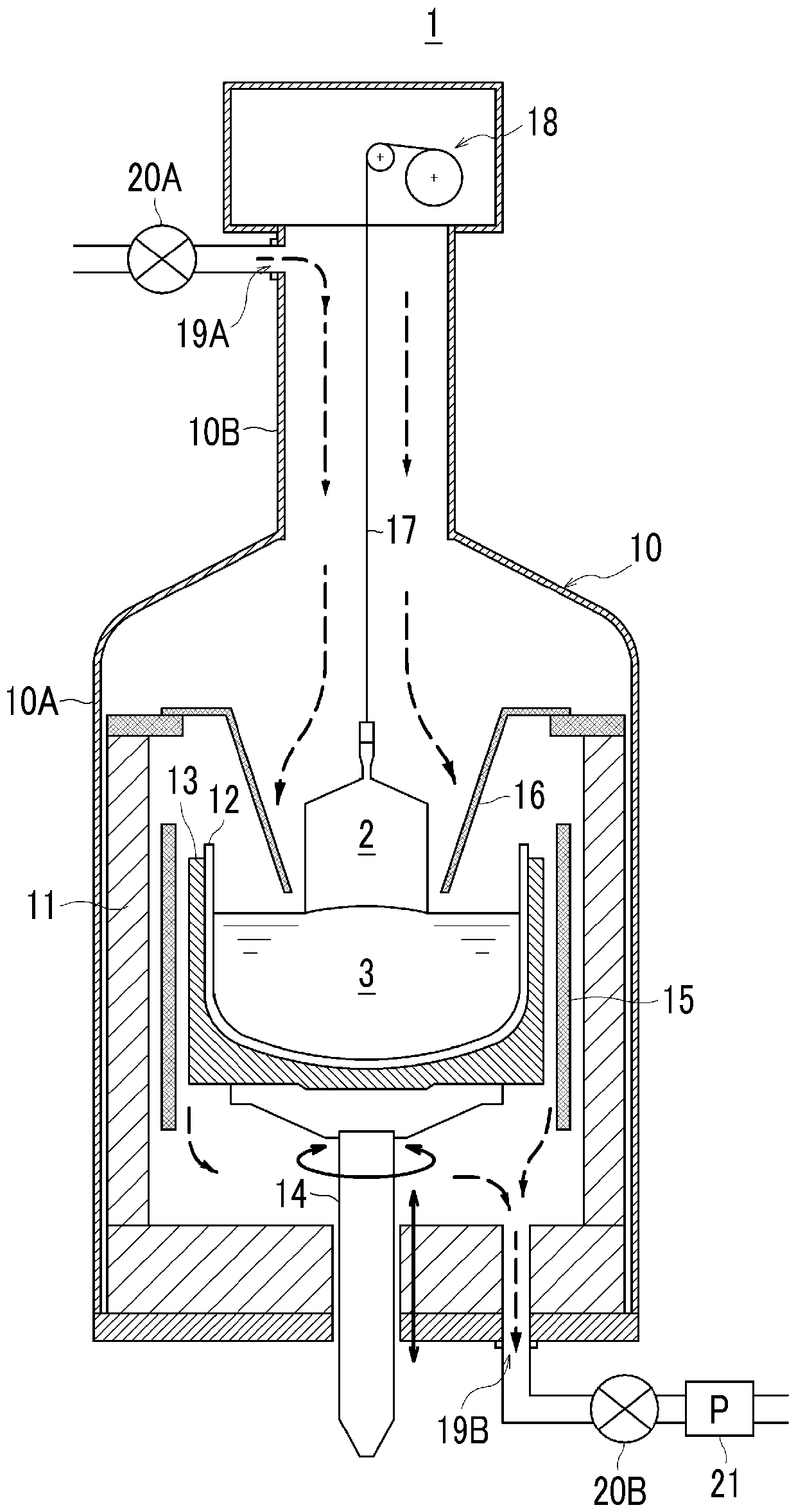

[0025] figure 1 It is a longitudinal sectional view showing the structure of a silicon single crystal pulling device according to an embodiment of the present invention.

[0026] Such as figure 1 As shown, the single crystal silicon pulling device 1 includes: a chamber 10; a heat insulating material 11 arranged along the inner surface of the chamber 10; a quartz crucible 12 arranged in the center of the chamber 10; a base 13 made of carbon , supporting the quartz crucible 12; the rotating support shaft 14 supports the pedestal 13 in a liftable manner; the heater 15 is arranged around the pedestal 13; the substantially inverted conical heat shield 16 is arranged on the pedestal 13 above; a wire 17 for single crystal pulling is disposed above the base 13 and coaxial with the rotation support shaft 14 ; and a wire coiling mechanism 18 is disposed abov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com