Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

125results about How to "Reduce flocculation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

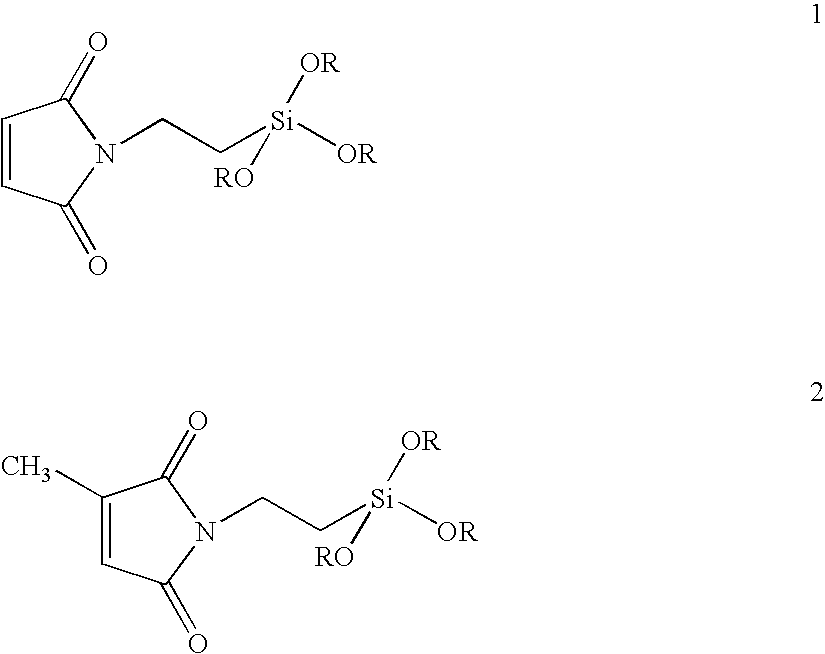

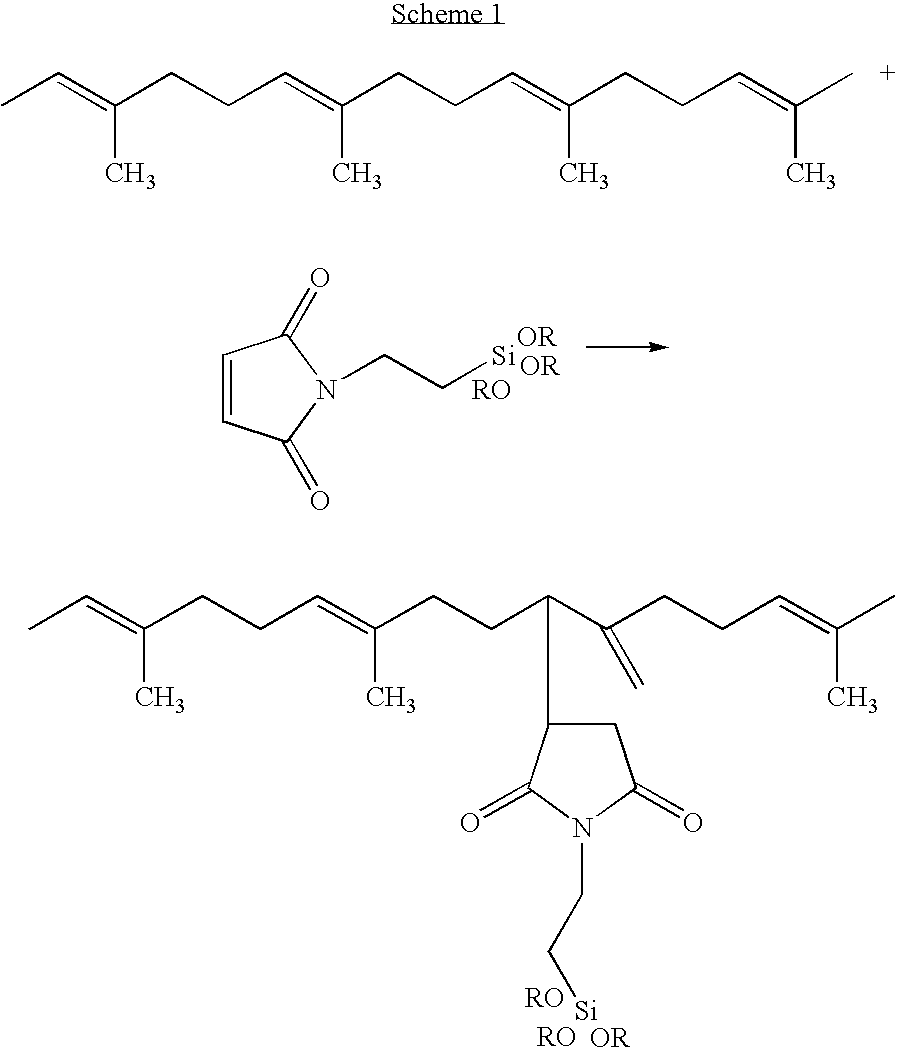

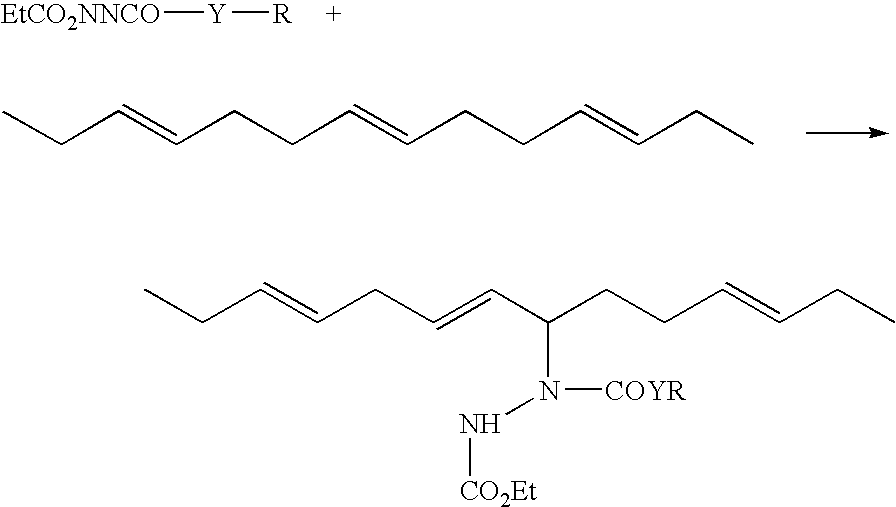

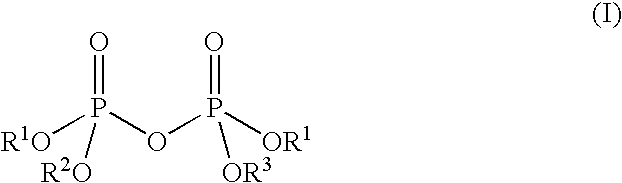

Rubber compositions containing non-sulfur silica coupling agents bound to diene rubbers

ActiveUS20100132868A1Improve suppression propertiesReduced filler flocculationPigmenting treatmentPneumatic tyre reinforcementsElastomerDynamic viscoelasticity

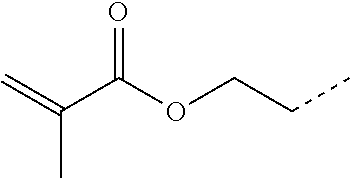

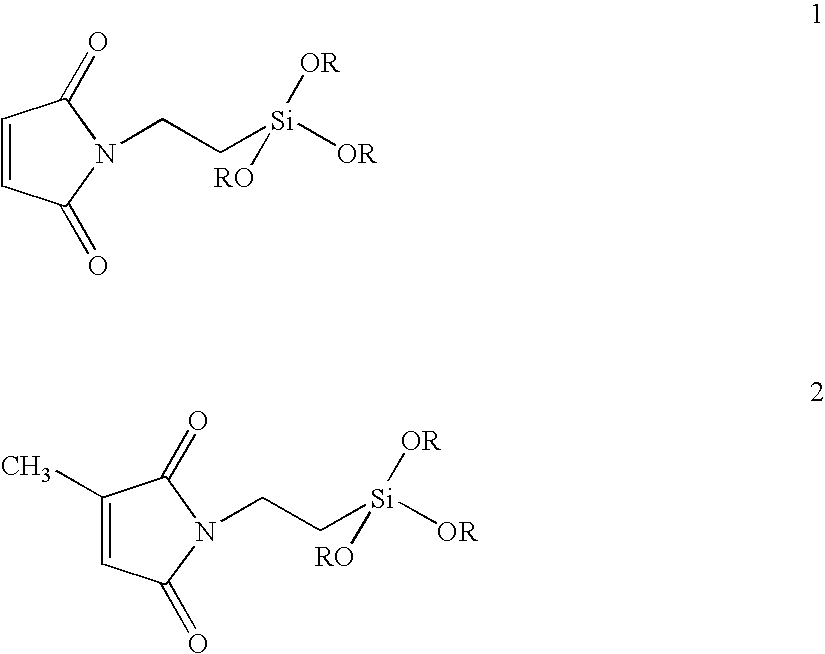

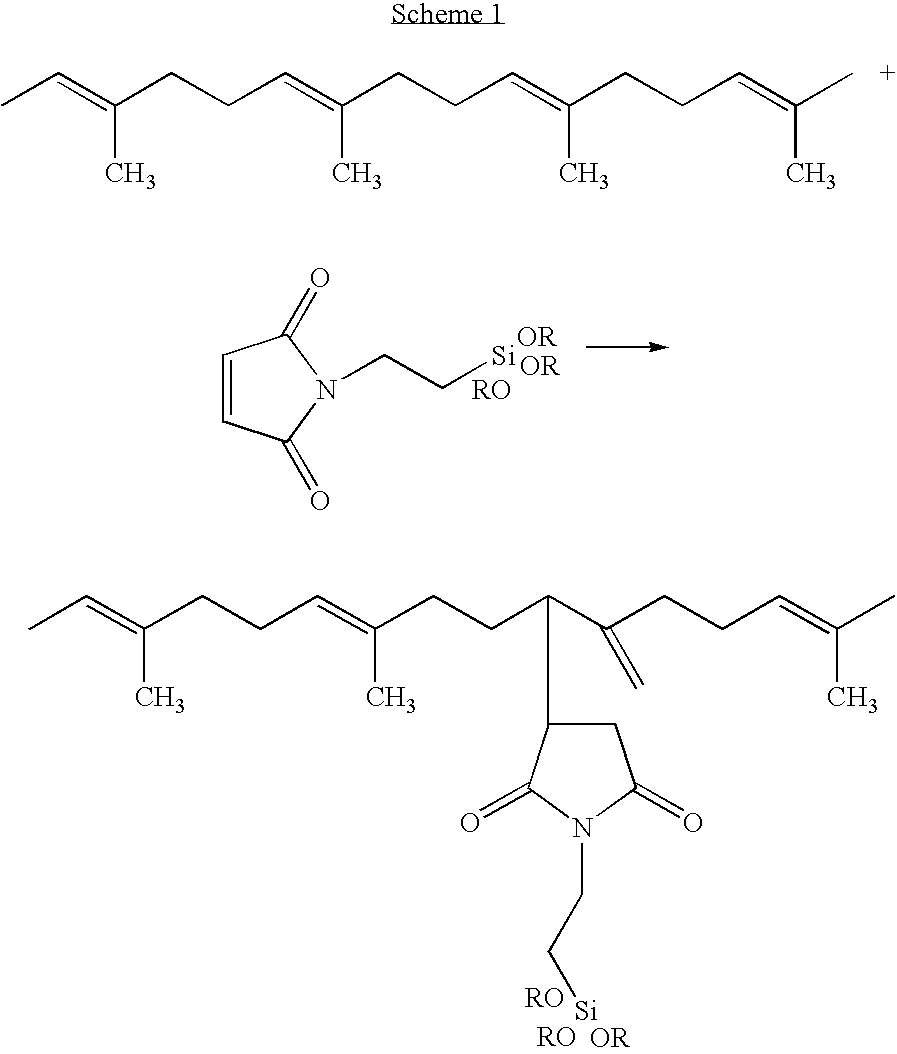

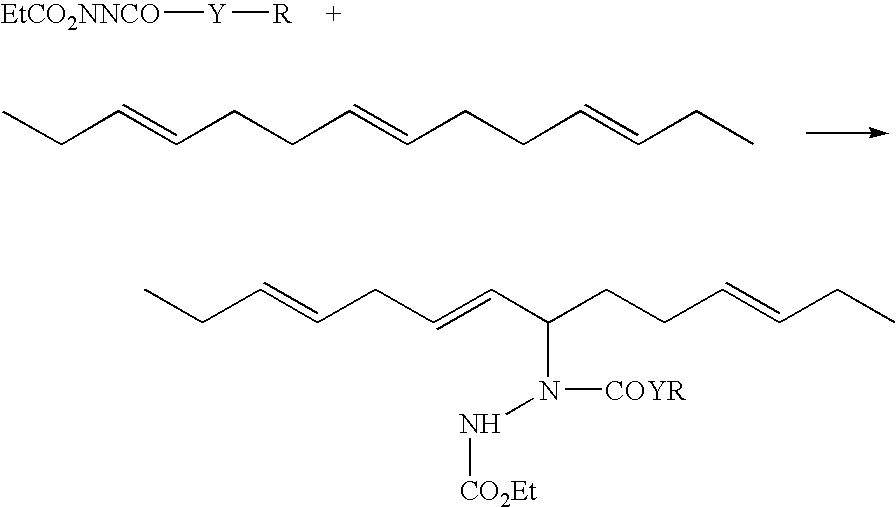

The invention provides vulcanizable rubber compound having improved tensile mechanical and dynamic viscoelastic properties. The compounds are formed by mixing an elastomer, containing unsaturated carbon-carbon bonds in its molecular structure, with a reinforcing inorganic filler silica in the presence of an alkyl alkoxysilane and a non-sulfur coupling agent that binds to the rubber backbone with an “ene” linkage or a 1,3 dipolar addition linkage. In particular, the coupling agent and the alkyl alkoxysilane are present in the compound in a weight ratio of about 0.0001:1 to about 1:1.

Owner:BRIDGESTONE CORP

Pigmented inks and dispersants used therewith

Pigmented inks are disclosed comprising an aqueous medium, a pigment, a dispersant, and a humectant. Inks are disclosed where the humectant is a sulfonated polyethylene oxide which provides long decap times and fast drying of the printed image. Inks are further disclosed where the dispersant is an alkyl(sulfophenoxy)benzenesulfonic acid or its salt. Such dispersants reduce the agglomeration of pigment particles and reduce or eliminate the deposition of foreign substances on heater elements during the jetting process. A variety of pigments, dispersants, humectants, and aqueous media can be used. Combinations of a sulfonated polyethylene oxide humectant and an alkyl(sulfophenoxy)benzenesulfonic acid (salt) dispersant provide inks with good stability, few kogation problems, long decap times and relatively fast drying times.

Owner:3M INNOVATIVE PROPERTIES CO

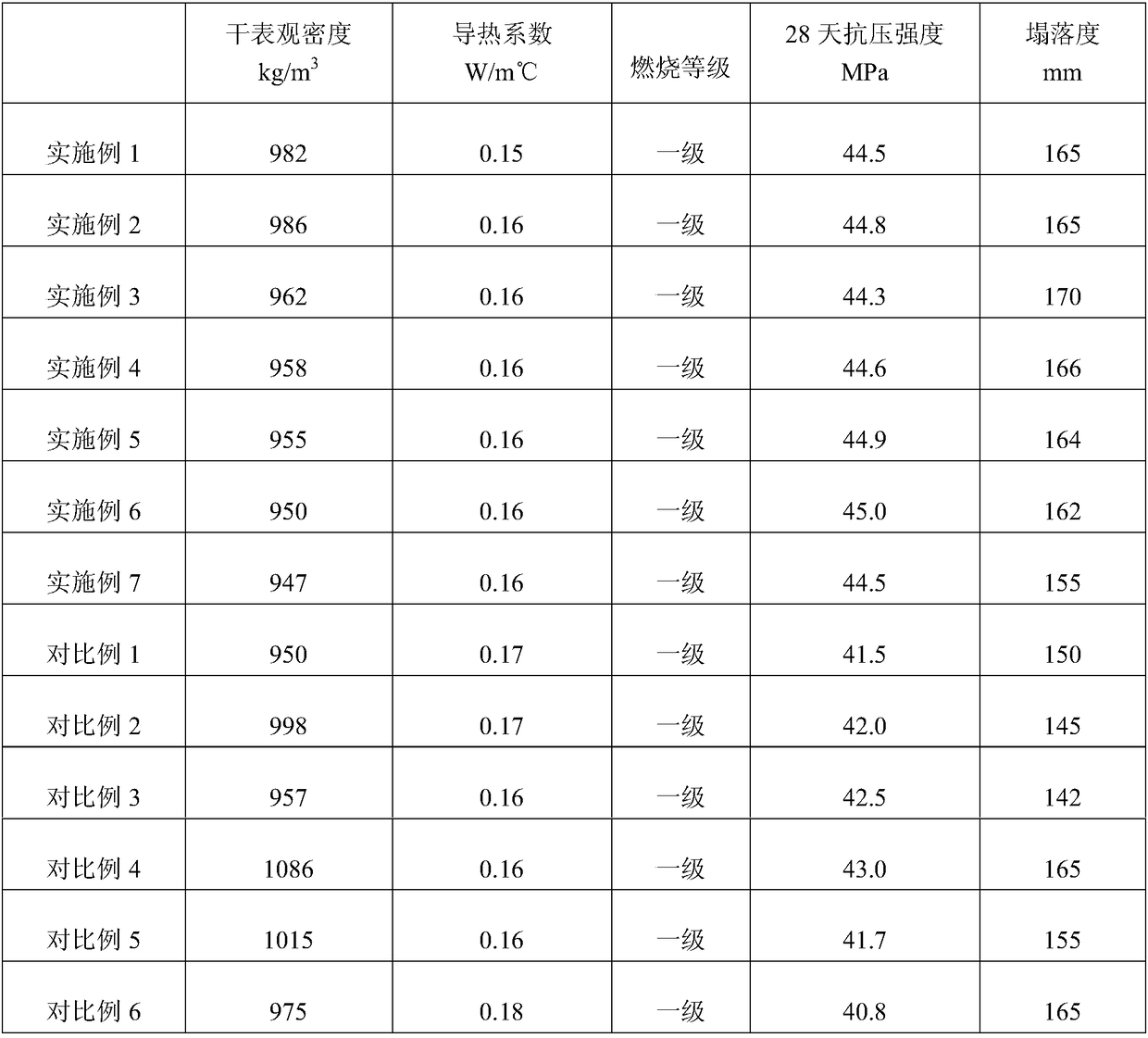

High-strength lightweight aggregate concrete and preparation method thereof

The invention provides high-strength lightweight aggregate concrete. The concrete comprises the following raw materials in parts by weight: 350 to 550 parts of cementing material, 450 to 600 parts oflightweight fine aggregate, 500 to 650 parts of lightweight coarse aggregate, 5 to 7 parts of an additive, and 150 to 170 parts of water. The lightweight fine aggregate comprises 60 to 80 percent of fine aggregate ceramsite in mass percent, and 20 to 40 percent of active construction waste powder in mass percent; the lightweight coarse aggregate comprises the following components in mass percent:50 to 75 percent of coarse aggregate ceramsite, 10 to 30 percent of stone gangue, 10 to 20 percent of ceramic waste residue, and 3 to 8 percent of expanded graphite. The concrete reasonably utilizes the stone gangue, construction waste, urban sludge and ceramic waste residue into a gel material and aggregate, not only improves the mechanical strength and stability of the concrete, but also provides a novel approach for the reuse of solid waste, and is beneficial to energy saving and environmental pressure relieving.

Owner:GUANGXI XUTENG INDUSTRIAL GROUP CO LTD

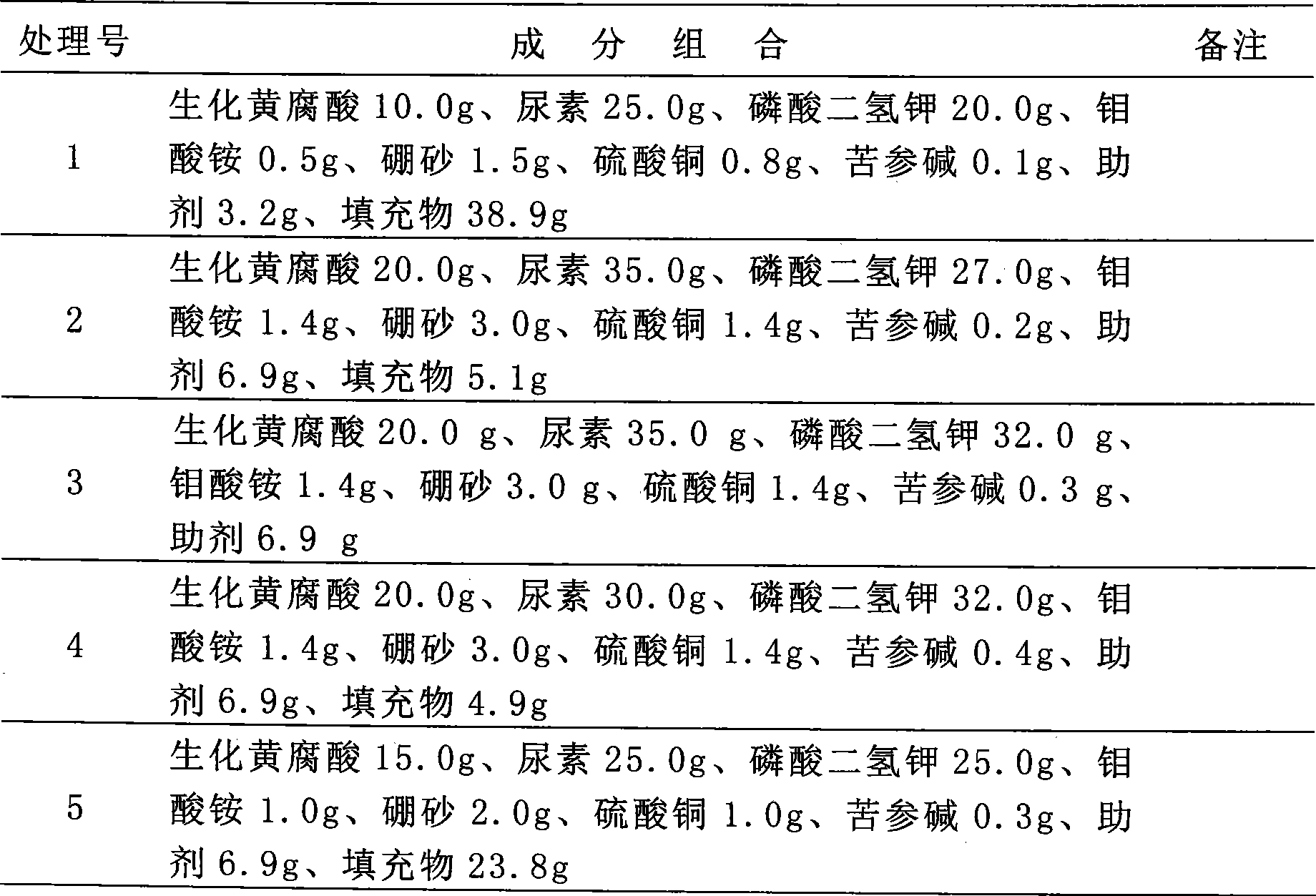

Novel non-pollution foliar medical fertilizer and preparation thereof

InactiveCN101503323APromote absorptionImprove fertilizer efficiencyAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersSocial benefitsFilling materials

The invention discloses a novel nuisanceless foliage fertilizer which is characterized in that every 100 parts by weight of the novel nuisanceless foliage fertilizer comprises the components according to the parts by weight: 10.0-30.0 parts of biochemical fulvic acid, 25.0-40.0 parts of urea, 20.0-35.0 parts of monopotassium phosphate, 0.5-2.0 parts of ammonium molybdate, 1.5-4.0 parts of borax, 0.8-2.0 parts of bluestone, 0.1-0.5 part of matrine, 3.2-7.5 parts of auxiliary agent and the rest of filling material. A method for preparing the novel nuisanceless foliage fertilizer comprises: all the components are mixed according to the measurement, fully stirred by a stirrer and ground, and packed according to the measurement. The foliage fertilizer has multiple effects of promoting the growing development of crops, increasing both production and income, improving the quality, increasing nutrient utilization rate, controlling pests, no pollution and the like, and is especially suitable for the production of nuisanceless agricultural products. The foliage fertilizer has remarkable application effect, simple manufacturing technique, great market potential, obvious economic and social benefits and very wide application prospect.

Owner:TAIAN ACAD OF AGRI SCI

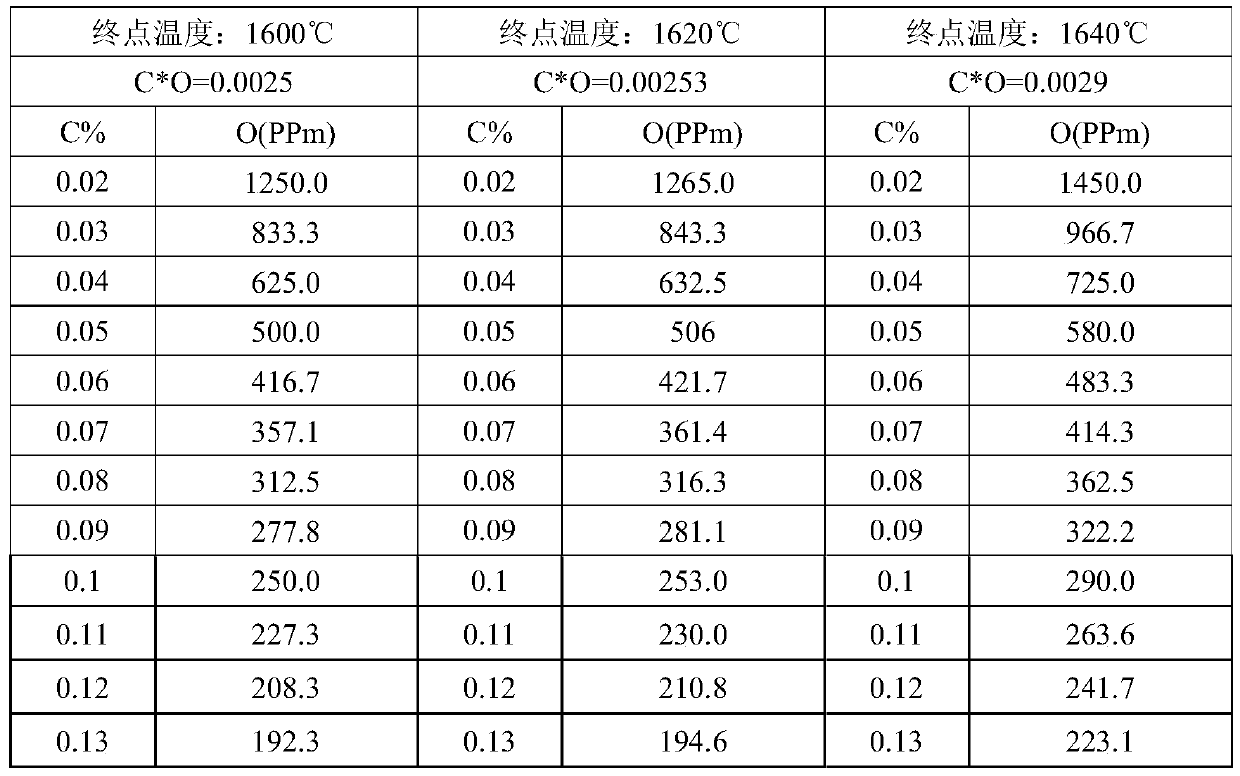

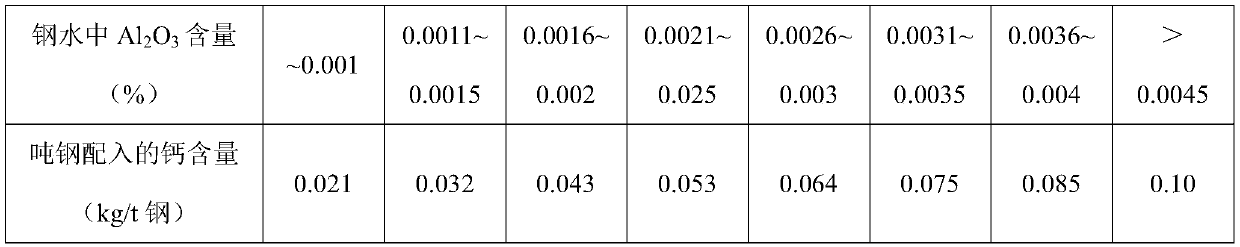

Method for reducing flocculating flows of low silicon aluminum killed steel

ActiveCN102534118AImprove equipment productivity and product qualityEliminate pouring accidentsDeoxidizationTundish

The invention provides a method for reducing flocculating flows of low silicon aluminum killed steel. The method comprises the following steps of: covering a ladle by using lime after the slagging-off of molten steel; before the primary sampling of a ladle furnace (LF), adding a proper amount of fluorite, a proper amount of bauxite and a proper amount of lime, and stirring the mixture by adopting strong argon, and after the primary sampling, adding passivated aluminum powder for deoxidization, heating and slagging the mixture, supplementing the lime and keeping the temperature of the molten steel; performing regulation by adopting an aluminum wire according to the weight of Als in a primary sample, and stirring the mixture by adopting the strong argon; after wire feeding, stirring the mixture by adopting weak argon, and controlling the proportion of [Ca] to the [Als] in the steel; controlling the argon blowing amount of an upper nozzle of a tundish, and keeping the molten steel pouring liquid level of the tundish to be more than or equal to 500mm; and finishing weak argon blowing over the ladle in front of a machine halfway through the pouring of the ladle. By the method, the flocculating flow phenomena of the molten steel can be effectively controlled, and are reduced from 11 to 18 per pouring to 0 to 1 per pouring to realize no flocculating flow in the continuous pouring of more than 15 ladles of the low silicon aluminum killed steel, the productivity of equipment is greatly improved, the quality of the product is greatly improved, and pouring interrupt accidents can be reduced.

Owner:ANGANG STEEL CO LTD

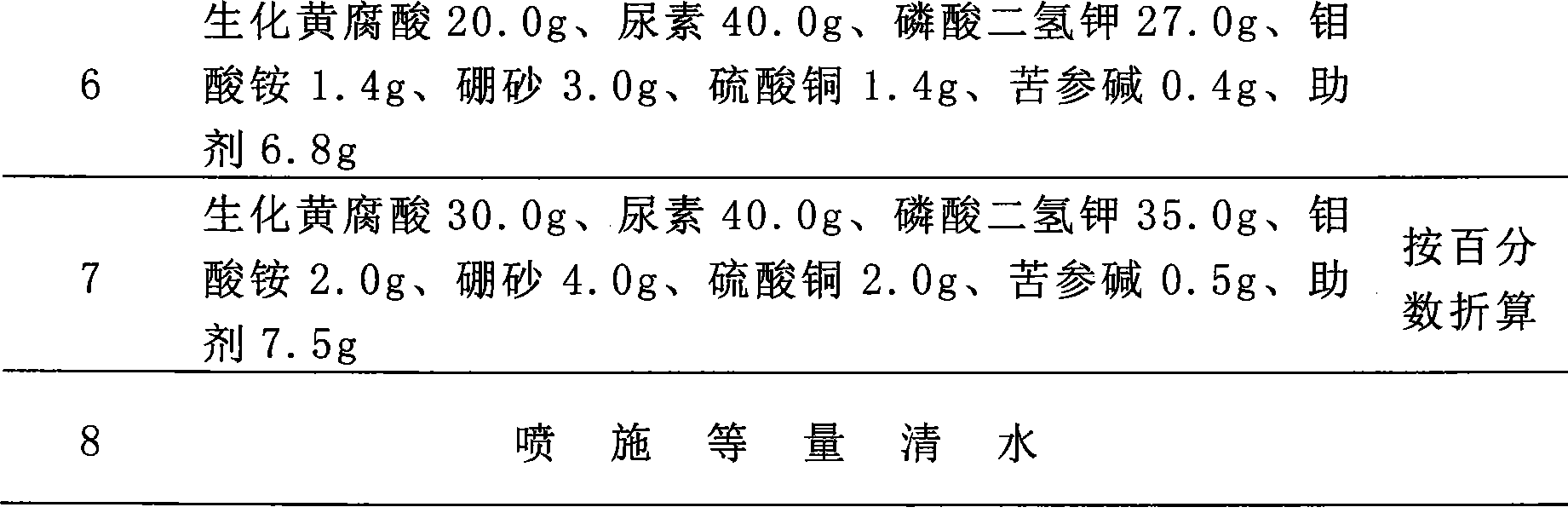

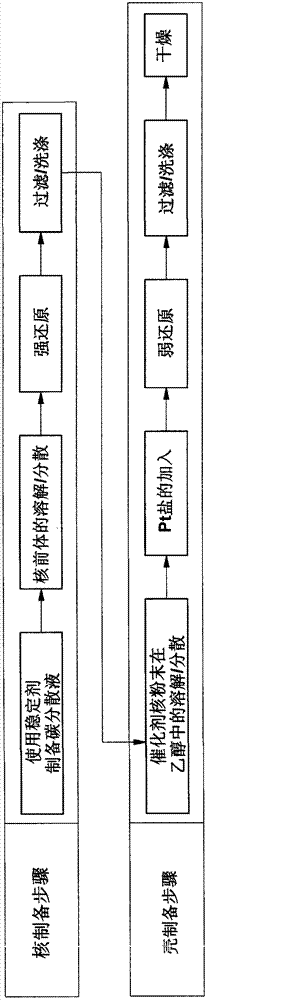

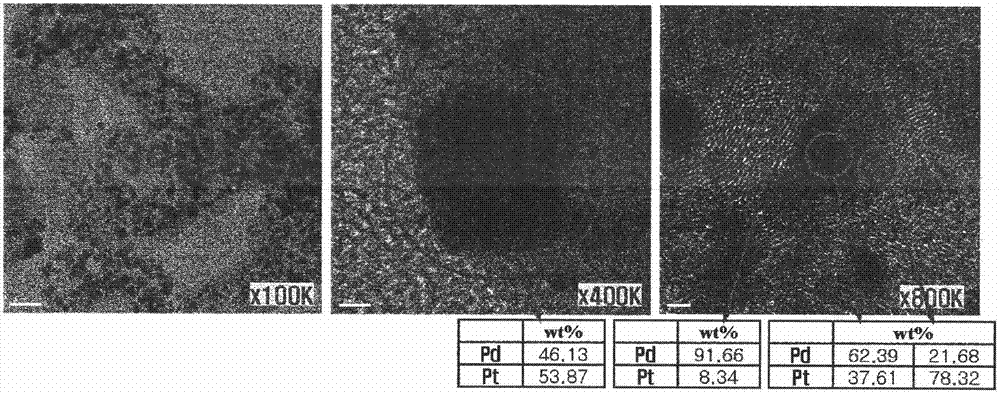

Method for manufacturing core-shell type supported catalysts and core-shell type supported catalysts formed thereby

InactiveCN103157465AEasy loadingShorten flocculation timeCell electrodesMicroballoon preparationAlloySolvent

A method for manufacturing a core-shell type supported catalyst, wherein alloy particles having a core-shell structure with a different interior and exterior are supported on a complex carbon support. The method includes: 1) dissolving and dispersing a carbon support in a solvent using a stabilizer; 2) dissolving a core precursor in the solution, and adding a strong reducing agent to reduce and support a transition metal of the core precursor on a surface of the carbon support; 3) filtering and washing the carbon support on which the transition metal is supported; 4) re-dispersing the filtered and washed carbon support in a shell precursor aqueous solution; and 5) adding a weak reducing agent to the solution of step 4) at 60-80 DEG C. so that metal ions of a shell precursor are selectively reduced and deposited on the transition metal.

Owner:HYUNDAI MOTOR CO LTD +1

LF treatment method for producing low-carbon low-silicon low-manganese steel

The invention relates to the field of medium and thin slab continuous casting, and particularly relates to an LF treatment method for producing low-carbon low-silicon low-manganese steel, which comprises melted iron pretreatment and converter smelting, and is characterized by directly entering an LF furnace for refining after tapping of converter smelting, upgrading molten steel in the LF furnace through persistent argon blowing decarburization and then directly beginning continuous casting. Compared with the prior art, the method has the benefits of lowering the cost for producing the steel; compared with an RH-LF duplex process, the production cost is lowered by 37.5 yuan / ton; and compared with an RH straight-up manner, the number of production tanks is increased to 12 from 7 every cast, and the impurity removal defect rate of the steel plate is reduced; and therefore, the eddying flow phenomenon when a medium and thin slab casting machine is used for producing the steel is reduced.

Owner:ANGANG STEEL CO LTD

Anti-flocculant coating composition

An aqueous composition containing pigment and an acrylic polymer and having reduced flocculation of pigment particles.

Owner:ROHM & HAAS CO

Preparation process of red date condensed juice high in cAMP content

The invention discloses a preparation process of red date condensed juice high in cAMP content. The preparation process includes the following steps of firstly, conducting separating, washing and smashing; secondly, conducting hot water extraction; thirdly, conducting cooling and heat preservation enzymic method oriented conversion; fourthly, adding composite enzyme preparations; fifthly, inactivating enzymes; sixthly, conducting centrifugation; seventhly, conducting filtration; eighthly, conducting concentration and pasteurization; ninthly, conducting filling. Compared with the prior art, the preparation process has the advantages that the process is simple, the production period is shortened, and the energy loss is reduced; extraction is conducted after smashing is conducted, and therefore extraction of nutritional ingredients in red dates can be improved; by means of the extraction and enzymolysis combined method, the juice yield is greatly improved, the processing time is greatly shortened, and the cyclic adenosine monophosphate content in red date juice is improved; date peel is utilized, and the cAMP content is improved; preparations of pectinase, cellulose and protease are used in a composite mode, and the hydrolysis capacity of enzymic preparations is improved; the step-by-step enzymolysis and extraction process is adopted, and interference between related enzyme preparations is avoided.

Owner:河北九维生物科技开发有限公司

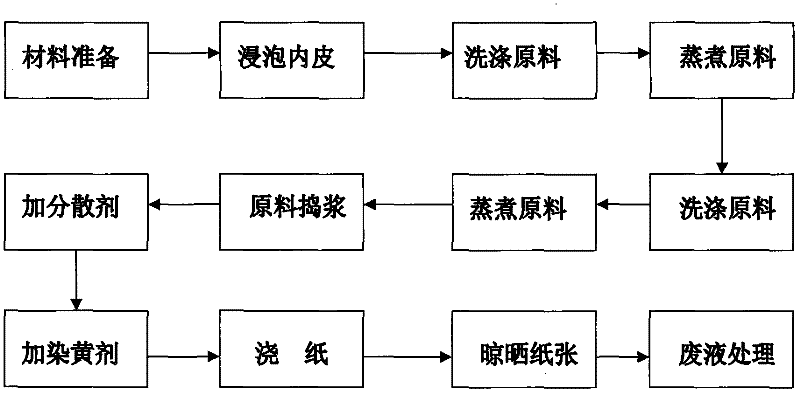

Method for making Tibetan paper by hand

InactiveCN102242520AMaintain essential featuresReduce serious damagePulping with inorganic basesPaper-making machinesHandwritingThymelaeaceae

The invention discloses a method for making Tibetan paper by hand, relates to a papermaking technique, and in particular relates to the method for making the Tibetan paper by hand. The method provided by the invention is used for solving the problems that in the existing method for making the Tibetan paper by hand, the output is limited, the vegetation ecology is damaged, the quality of paper is low, the environment is polluted, and the like. The method comprises the following steps: cooking endothelium of thymelaeaceae wikstroemia stem and endothelium of stellera chamaejasme L. as raw materials; adding in a defined amount of potassium hydroxide in the cooking process; adding a defined amount of cactus juice as a dispersing intensifier into paper pulp; eliminating whiteness of the paper pulp with a defined amount of Coptis chinensis extract liquid according to the dyeing requirement; and discharging the waste liquid generated in the processes of raw material cooking and rinsing after being subject to flue gas treatment. The method provided by the invention retains the characteristics of the raw materials and processes of traditional Tibetan paper. The method for making Tibetan paper by hand is environment-friendly. The acquired Tibetan paper is excellent in uniformity, is mothproof and mildew-proof, can be stored for a long term and is flexible and folding-resisting. The appearance of the acquired Tibetan paper is laden with history. The Tibetan paper acquired by using the method can be used as a high-rank material for government document making, various classic Confucian texts, literature masterpiece printing, and Tibetan cultural handwriting.

Owner:YUNNAN UNIV

Self-adhesion modified asphalt waterproofing coil coating material, preparation method thereof and passive special self-adhesion asphalt waterproofing coil for buildings

ActiveCN110746930AImprove compactnessExtend your lifeNon-macromolecular adhesive additivesRoof covering using flexible materialsBituminous waterproofingPhosphoric acid

The invention discloses a self-adhesion modified asphalt waterproofing coil coating material, a preparation method thereof and a passive special self-adhesion asphalt waterproofing coil for buildings.The raw materials for preparing the self-adhesion modified asphalt waterproofing coil coating material include the following components: mixed asphalt, polyethylene wax, a stabilizer, a linear SBS modifier, a powder SBR modifier, tackifying resin and inorganic filler, wherein the mixed asphalt is a mixture of petroleum asphalt and softening oil, and the stabilizer is a mixture of polyphosphoric acid and a phosphotriester. The self-adhesion asphalt waterproofing coil has a longitudinal-transverse tensile value of >= 1000 N and elongation of >= 2%, and the modified asphalt is special-made modified asphalt, and is characterized by good compactness and high temperature resistance; and compared with ordinary self-adhesion modified asphalt, the modified asphalt is delicate, and has no bubbles and resistance to a high temperature of 100 DEG C.

Owner:四川东方雨虹建筑材料有限公司

RH (relative humidity) treatment method for low silicon-aluminum killed steel

The invention relates to the technical field of continuous casting refining treatment, and in particular relates to an RH (relative humidity) treatment method for low silicon-aluminum killed steel. The method is characterized in that the method is suitable for <C> greater than or equal to 0.010% and less than or equal to 0.05%, <Si> greater than or equal to 0.03% and less than or equal to 0.05%, and argon-blown silicon less than or equal to 0.008% after discharge of steel from a converter, SiO2 oxidized by low carbon ferrosilicon and Al2O3 in molten steel are reacted through rimmed steel by RH so as to produce deoxidized product aluminum silicate, and fine Al2O3 inclusion adhere to the aluminum silicate in floating upward process, so that the purpose of purifying the molten steel is achieved. Compared with the prior art, the method has the beneficial effects of meeting the requirement of upper limit of 0.03% of the end product silicon of low silicon-aluminum killed steel, reducing the phenomenon of flocculation caused by producing RH low silicon-aluminum killed steel through a middle sheet billet chamber machine, and lowering the inclusion rate of a steel board, and the cold rolling inclusion rate of defect is lowered to 0.26% from 0.46%.

Owner:ANGANG STEEL CO LTD

Bio-Energy Reactor

InactiveUS20110308962A1Reduce flocculationReduce heat buildupCellsPhotography auxillary processesElectrolysisLiquid medium

A system includes an ionic exchange conduit through which a flow of photosynthetic biomass is drawn capturing an electrical charge which is used to alternately power a photonic activated reservoir housing a living photosynthetic biomass suspended in a flowing liquid medium which self generates an electrical charge as it migrates towards and through a cathode separated from an anode by a membrane. Upon electrical transfer through the circuit an electrolysis process begins and releases hydrogen and oxygen into enclosed atmosphere chambers where these separated gases can be captured for use in a fuel cell.

Owner:ENNESYS

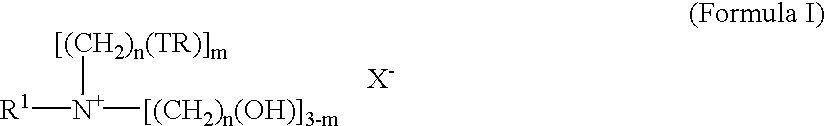

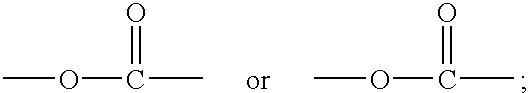

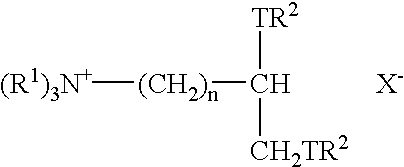

Fabric conditioning compositions

InactiveUS20030114339A1Small sizeReduce flocculationCationic surface-active compoundsOrganic detergent compounding agentsPolymer chemistrySilicone

A fabric conditioning composition comprises: (a) from about 7.5 to 80% by weight of an ester-linked quaternary ammonium fabric softening material comprising comprising at least one mono-ester linked component and at least one tri-ester linked component; (b) 0.9% to 15% by weight of a fatty complexing agent; (c) an emulsified silicone wherein the weight ratio of the monoester linked component of compound (a) to compound (c) is from 5:1 to 1:5 and the emulsifier for the silicone comprises a nonionic compound.

Owner:HENKEL KGAA

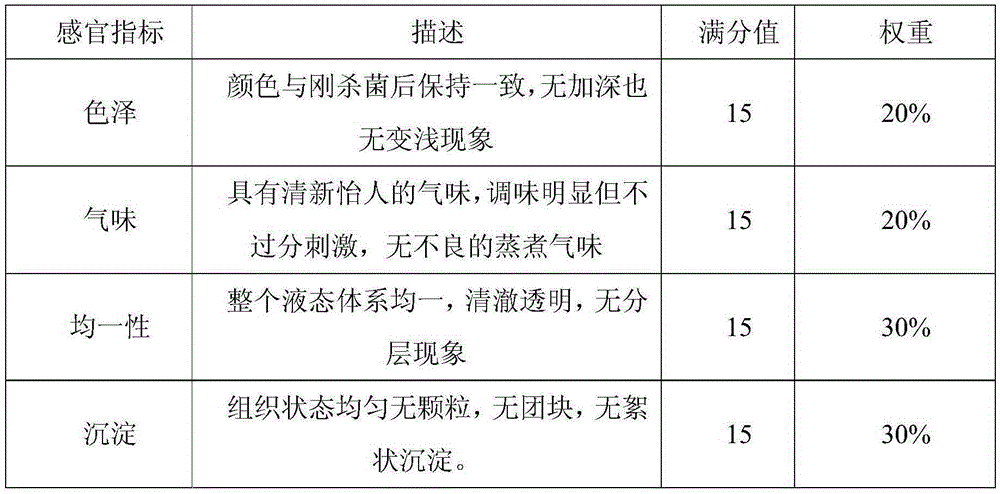

Series Clinacanthus nutans functional beverage and preparation method thereof

ActiveCN105341570APrevent dental cariesFragrant smellNatural extract food ingredientsFood ingredient functionsSolubilityVitamin C

The invention relates to a series Clinacanthus nutans functional beverage and a preparation method thereof, belongs to the technical field of food processing, and aims to solve the problems of flocculation precipitation of the Clinacanthus nutans functional beverage, color changes of tea soup and bad smell of the tea soup. The series Clinacanthus nutans functional beverage disclosed by the invention comprises Clinacanthus nutans aqueous extract enzymatic hydrolysate, vitamin C and varied minerals, and plant water solubility extracts or active substances can also be added. The preparation method comprises the following steps of firstly, preparing Clinacanthus nutans powder, compounding a Clinacanthus nutans aqueous solution, adding beta-cyclodextrin, adjusting the pH of the systems, then performing enzymolysis treatment, then adding various active substances, performing homogenizing treatment, and then performing disinfection so as to obtain the series Clinacanthus nutans functional beverage. The prepared series Clinacanthus nutans functional beverage disclosed by the invention can still keep clear and transparent after being preserved for 9 months at normal atmospheric temperature after disinfection, the smell has delicate fragrance, and the series Clinacanthus nutans functional beverage can have the effects of regulating the balance of body fluid and improving hypoxia resistance.

Owner:HARBIN INST OF TECH

Production method for producing low-carbon low-silicon and aluminum-containing steel through short process

The invention belongs to the field of metallurgy processes and particularly relates to a p roduction method for producing low-carbon low-silicon and aluminum-containing steel through a short process. The low-carbon low-silicon and aluminum-containing steel is composed of, by weight, 0.04-0.06% of C, 0-0.03% of Si, 0.15-0.25% of Mn, 0-0.02% of P, 0-0.015% of S, 0.015%-0.050% of Als and the balance Fe and inevitable impurities. An LF link is omitted, the problem of silicon reversion caused by LF process treatment for reducing slag is solved under the condition that the purity of molten steel is not influenced, so that the target rate of Si content in the low-carbon low-silicon and aluminum-containing steel is increased, and the product yield is increased; and through CAS station strong deoxidation, the molten steel is completely deoxidized in short time, the molten steel castability is improved, sprue flocculating flow is reduced, and mass stable continuous casting production of the low-carbon low-silicon and aluminum-containing steel is achieved.

Owner:SHANDONG IRON & STEEL CO LTD

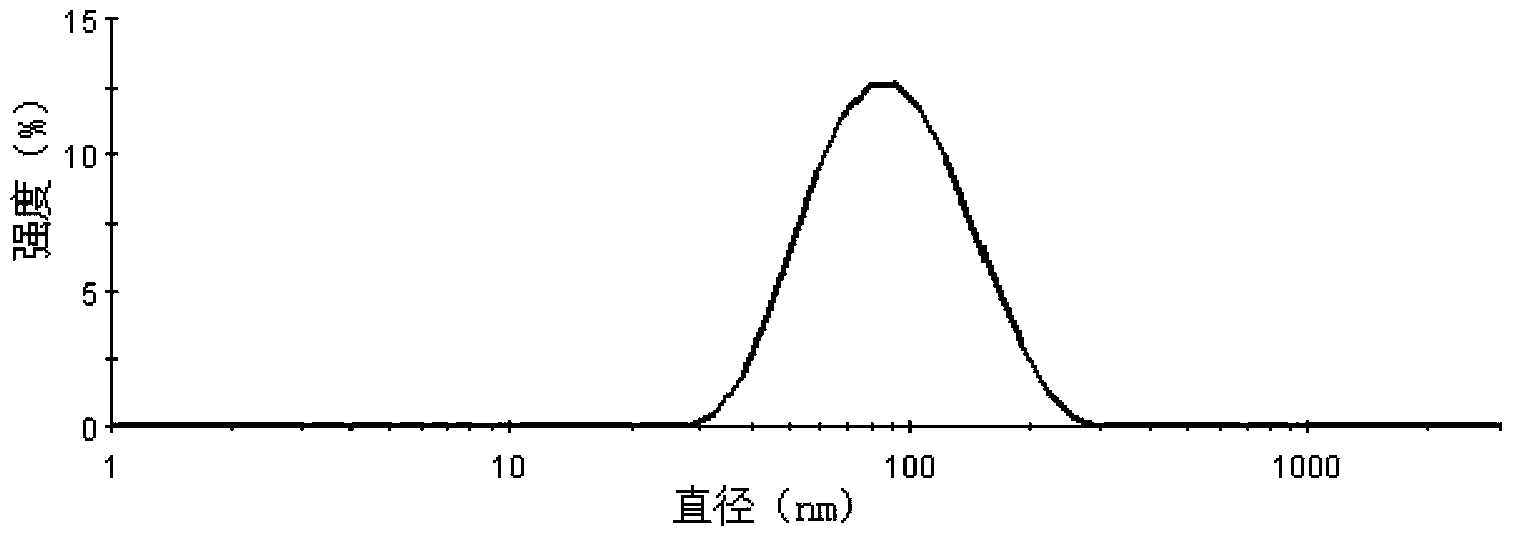

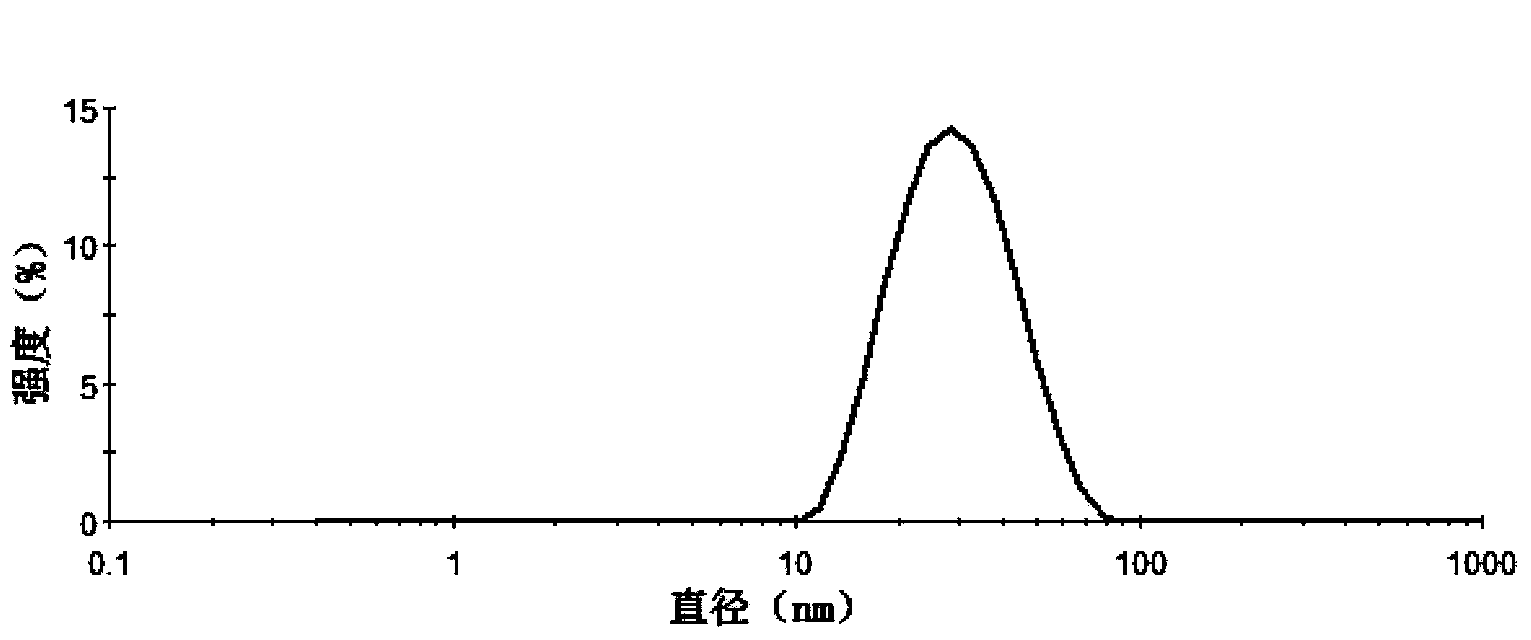

Docetaxel nanometer micelle, and preparation method and application thereof

ActiveCN104224710AImprove stabilityLong validity periodOrganic active ingredientsPharmaceutical non-active ingredientsSolubilitySide effect

The invention discloses a docetaxel nanometer micelle, a preparation method and application of the micelle to prepare medicines for treating tumor or drug-resistant tumor. The docetaxel nanometer micelle comprises 1 part by weight of docetaxel, 10-100 parts by weight of a carrier material and 0-10 parts of oil, wherein the average particle size of the docetaxel nanometer micelle is 10-200 nm. According to the preparation, the water solubility of docetaxel is substantially improved, the stability of the preparation is improved, the cycling time of docetaxel in blood is prolonged, the toxic and side effects of conventional preparations are reduced, docetaxel nanometer micelle can be driven to be targeted to tumor tissue through EPR effect, so that the anti-tumor curative effect of docetaxel is improved, and the docetaxel nanometer micelle overcomes the multidrug resistance of tumor.

Owner:SHANGHAI INST OF MATERIA MEDICA CHINESE ACAD OF SCI

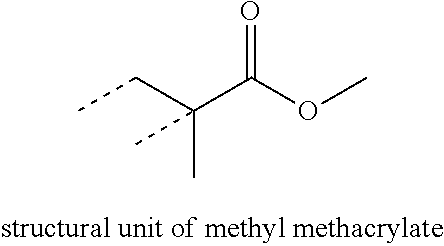

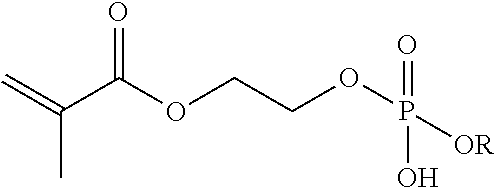

Bimorphological latex

The present invention relates to a composition comprising a bimorphological aqueous dispersion of first and second polymer particles, wherein the first polymer particles comprise a shell and a phosphorus acid functionalized protuberating core, and the second polymer particles do not comprise a protuberating core. The composition is useful for pigmented coatings formulations.

Owner:ROHM & HAAS CO

Aluminum-free titanium-containing steel anti-flocculation-flow operation method

The invention relates to an operation method of an aluminum-free titanium-containing steel anti-flocculation-flow operation method comprising the steps that: (1) after converter tapping, slagging is carried out, and molten steel is added into a lime cover tank; (2) fluorite, bauxite and lime are added, and stirring is carried out; (3) silicon-calcium-barium powder is added; (4) when slag is formed, rest lime is supplemented; during an LF furnace final-stage, slag thickening lime is added; (5) a titanium component is regulated and qualified in one time in an early-stage; (6) other components are refined, and it is required that regulation should be successful within a maximum of twice; (7) LF furnace treatment final-stage weak stirring and argon bottom blowing are carried out; (8) a soft sealing ring is adopted at a long nozzle before a continuous casting machine; (9) middle-ladle upper nozzle argon blowing is carried out; (10) middle-ladle molten steel casting level is stabilized; (11) middle-ladle level covering effect is ensured; and (12) large-pot weak argon blowing is carried out before the machine. Compared with prior art, the method provided by the invention has the advantages that: molten steel flocculation phenomenon is effectively reduced; square billet or slab continuous-casting no-flocculation-flow production is realized; production stability is ensured; production capacity and product quality are improved; and more economic benefit is provided for enterprises.

Owner:ANGANG STEEL CO LTD

Method for treating rutile titanium dioxide waste water

ActiveCN104108814AImprove recycling efficiencySignificant economic and environmental benefitsFerroso-ferric oxidesMultistage water/sewage treatmentEnvironmental chemistryPolyacrylamide

The invention discloses a method for treating rutile titanium dioxide waste water. The method comprises the following three steps of: (1) mixing acid waste water and alkaline waste water, stirring, then naturally depositing to obtain a supernatant and bottom deposits, and controlling mixing temperature to 50-60 DEG C, wherein the pH value of a solution is 7-8 after mixing; (2) adding polyacrylamide to the supernatant obtained in the step (1) according to the concentration ratio of 5-10ppm, stirring, and depositing; (3) carrying out aeration, filter pressing and drying on the lower deposits obtained in the step (1) to obtain iron oxide black, wherein filter liquor obtained through the filter pressing can be directly discharged. The method disclosed by the invention can be used for recovering insoluble titanium from the rutile titanium dioxide waste water as much as possible and reducing the discharge amount of the rutile titanium dioxide waste water, thereby recycling the water resources and further creating great economic benefit and environmental protection benefit to enterprises.

Owner:SICHUAN LOMON TITANIUM IND CO LTD

Rubber compositions containing non-sulfur silica coupling agents bound to diene rubbers

ActiveUS8329297B2Facilitate binding of silicaImprove suppression propertiesPigmenting treatmentPneumatic tyre reinforcementsElastomerDynamic viscoelasticity

The invention provides vulcanizable rubber compound having improved tensile mechanical and dynamic viscoelastic properties. The compounds are formed by mixing an elastomer, containing unsaturated carbon-carbon bonds in its molecular structure, with a reinforcing inorganic filler silica in the presence of an alkyl alkoxysilane and a non-sulfur coupling agent that binds to the rubber backbone with an “ene” linkage or a 1,3 dipolar addition linkage. In particular, the coupling agent and the alkyl alkoxysilane are present in the compound in a weight ratio of about 0.0001:1 to about 1:1.

Owner:BRIDGESTONE CORP

Method for preparing small-fraction filling composite masterbatch through semi-open type superheated steam spray-drying method

The invention provides a method for preparing small-fraction filling composite masterbatch through a semi-open type superheated steam spray-drying method. The technological method is used for preparing rubber nanocomposites through wet mixing and is less in energy consumption, safe and simple in technology. Rubber latex is selected and used for being mixed with filler slurry, a certain quantity of rubber auxiliary is added and stirred to be uniform, an obtained mixture is dried through a semi-open type superheated steam spray tower at a certain feed rate, the nano composite rubber masterbatch is prepared and collected and passes through a sieve plate, and blocks are formed after rolling is conducted. The method is simple in technology, complete in reaction, safe, free of hidden dangers, less in energy consumption and capable of reducing cost; human factors are few, continuous production can be achieved, the product quality is stable, industrial research is easy, and green and environmental protection is achieved. By means of the rubber masterbatch produced through the method, inorganic filler can be uniformly dispersed in a rubber matrix in a nano-scaled mode, and the rubber masterbatch can be applied to the fields such as saloon car tread rubber and engineering tread rubber.

Owner:BEIJING UNIV OF CHEM TECH

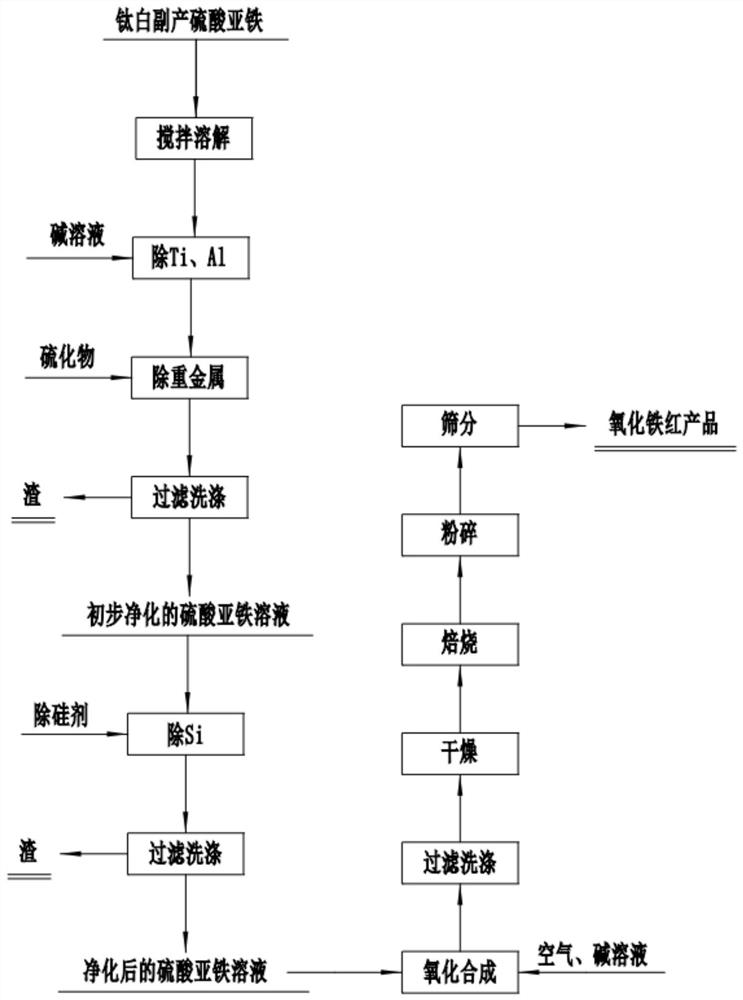

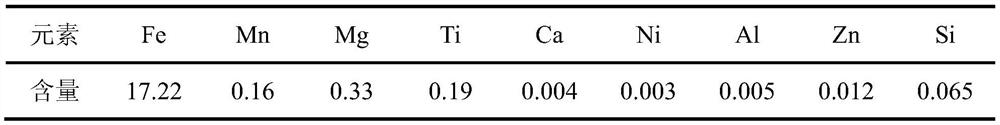

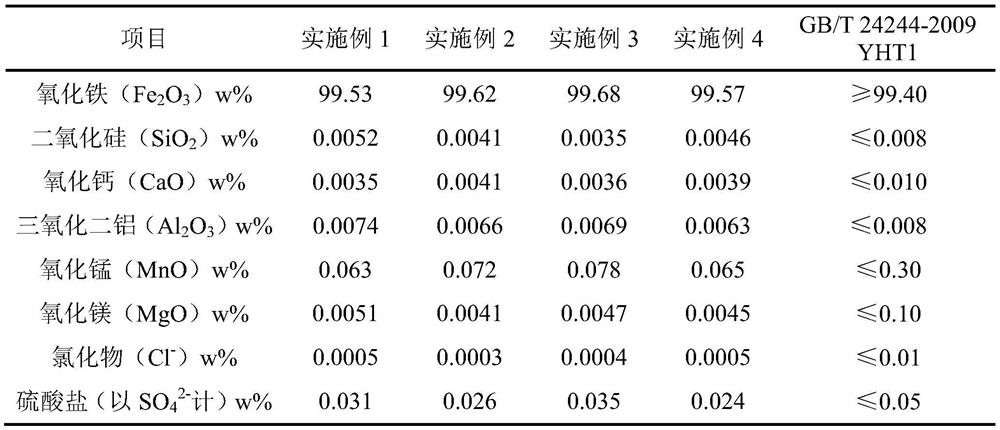

Method for preparing iron oxide red by utilizing titanium dioxide byproduct ferrous sulfate, product and application of product

ActiveCN111634952AReduce flocculationAvoid hydrolysisInorganic material magnetismFerric oxidesIron sulfateGuar gum

The invention discloses a method for preparing iron oxide red from a titanium dioxide byproduct ferrous sulfate, a product and application of the product, and belongs to the technical field of magnetic materials. The method comprises the following steps: S101, purification and impurity removal; S102, oxidation synthesis; and S103, roasting, crushing and screening, wherein a silicon removal agent adopted for purification and impurity removal is a compound of polyferric sulfate, cationic guar gum and sodium alginate. According to the invention, by reasonably matching a plurality of inorganic andorganic high-molecular polymers, the coagulating sedimentation effect, the electric neutralization capability and the bridge frame adsorption effect of the silicon removal agent are fully exerted, the silicon impurity in ferrous sulfate is effectively removed, the feeding speed of a ferrous sulfate solution and an alkaline solution is accurately controlled in the oxidation synthesis process, hydrated iron oxide precipitate which is good in consistency, easy to filter and wash and high in activity is obtained, and an iron oxide red product high in purity and good in performance is successfullyprepared by further setting a reasonable roasting system.

Owner:SINOSTEEL NANJING NEW MATERIALS RES INST CO LTD +1

Treatment method for electroplating sludge

InactiveCN108383343ARealize resource utilizationReduce resource utilizationSludge treatment by de-watering/drying/thickeningWater treatment compoundsSlagSludge

The invention provides a treatment method for electroplating sludge. The method comprises the following steps: (1) adding a composite additive into the electroplating sludge in a mass ratio of 100 to(5-7), mixing uniformly, then putting the mixture in an ultraviolet irradiation condition, and stirring and processing for 1-1.5h at a revolving speed of 110-120r / min; (2) adding coke powder into themixture obtained in step (1), maintaining the added amount of the coke powder to be 20% of the mass of the mixture, mixing uniformly, then performing filter pressing treatment, collecting mud cakes, and meanwhile, discharging filtrate subjected to purification treatment; (3) smashing the mud cakes collected in step (2), drying the smashed mud cakes until the moisture content is less than or equalto 8%, keeping the smashed mud cakes in a condition that the temperature is 1,100-1,200 DEG C so as to perform smelting treatment, enabling exhaust gas, which is generated through smelting, to be subjected to purification treatment, then discharging the exhaust gas, and refining and separating materials subjected to smelting to obtain melted slag and metal alloy.

Owner:重庆康达实业有限公司

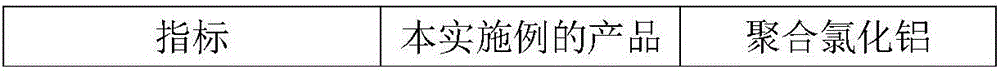

Preparation method of high-stability and polymeric-form polyaluminum chloride

ActiveCN110745852AReduce flocculationImprove stabilityNature of treatment waterAluminium chloridesGel preparationAluminium chloride

The invention discloses a preparation method of high-stability and polymeric-form polyaluminum chloride. The gel preparation process of polyaluminum chloride is combined with the polymerization reaction of an organic monomer to make aluminum ions react with the organic monomer in order to wrap the aluminum ions and stabilize the point position, so PAC has a good stability, and the aluminum form isnot substantially changed within 2 years, thereby the validity period of the product is prolonged, the product can be stored for 2 years, the treatment effect is stable, and the problem of poor stability of an existing liquid PAC product is solved. The method has the advantages of simple preparation process, easiness in operation, wide sources of raw materials, and mild preparation conditions, and the product has the characteristics of high purity, high Alb content, short reaction time and good treatment effect, and has the advantages of low dosage, high COD and turbidity removal rate, high stability and low residual aluminum content when applied to the treatment process of coal chemical industry wastewater.

Owner:NANJING UNIV OF TECH

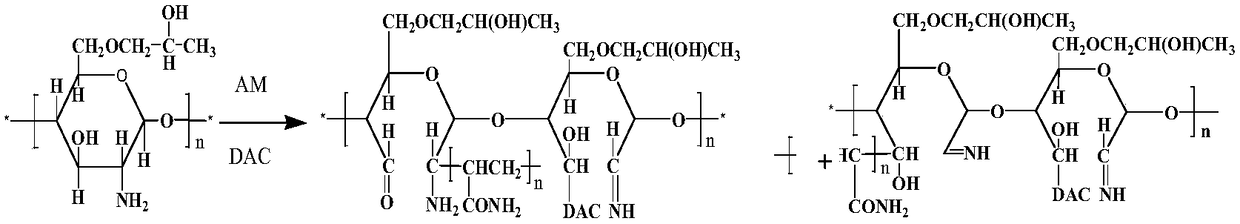

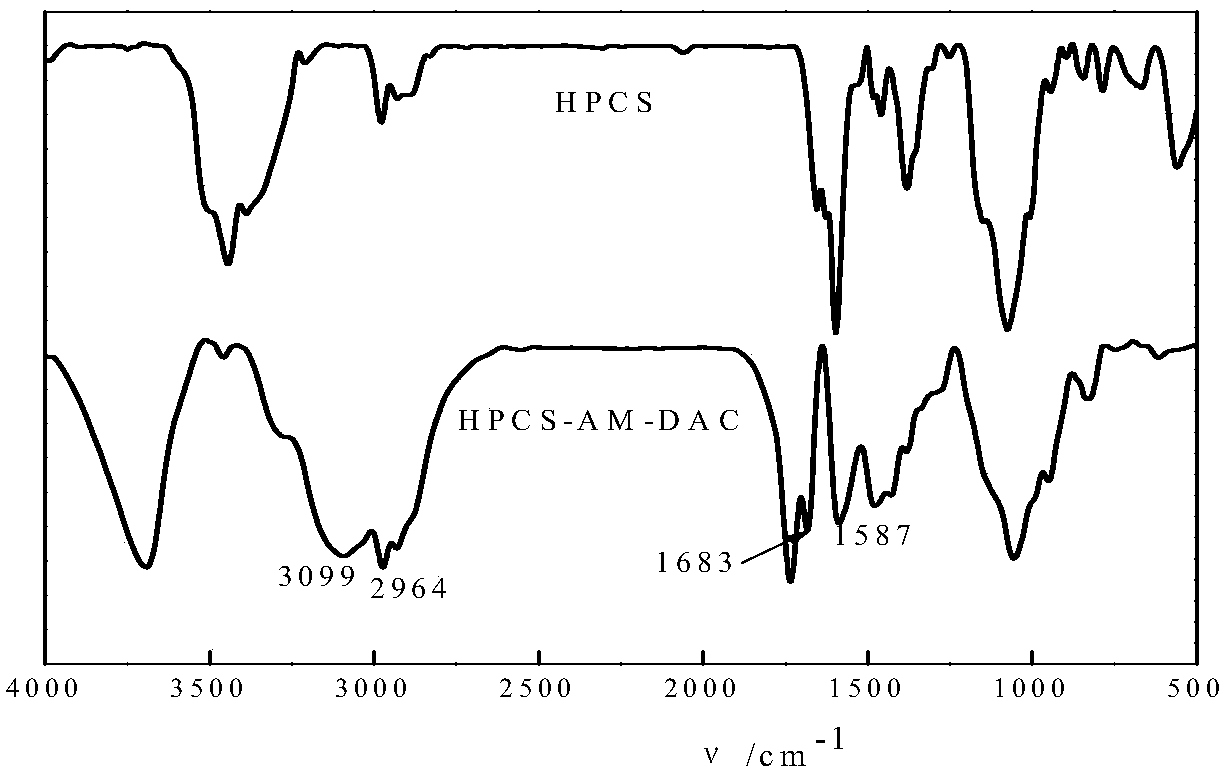

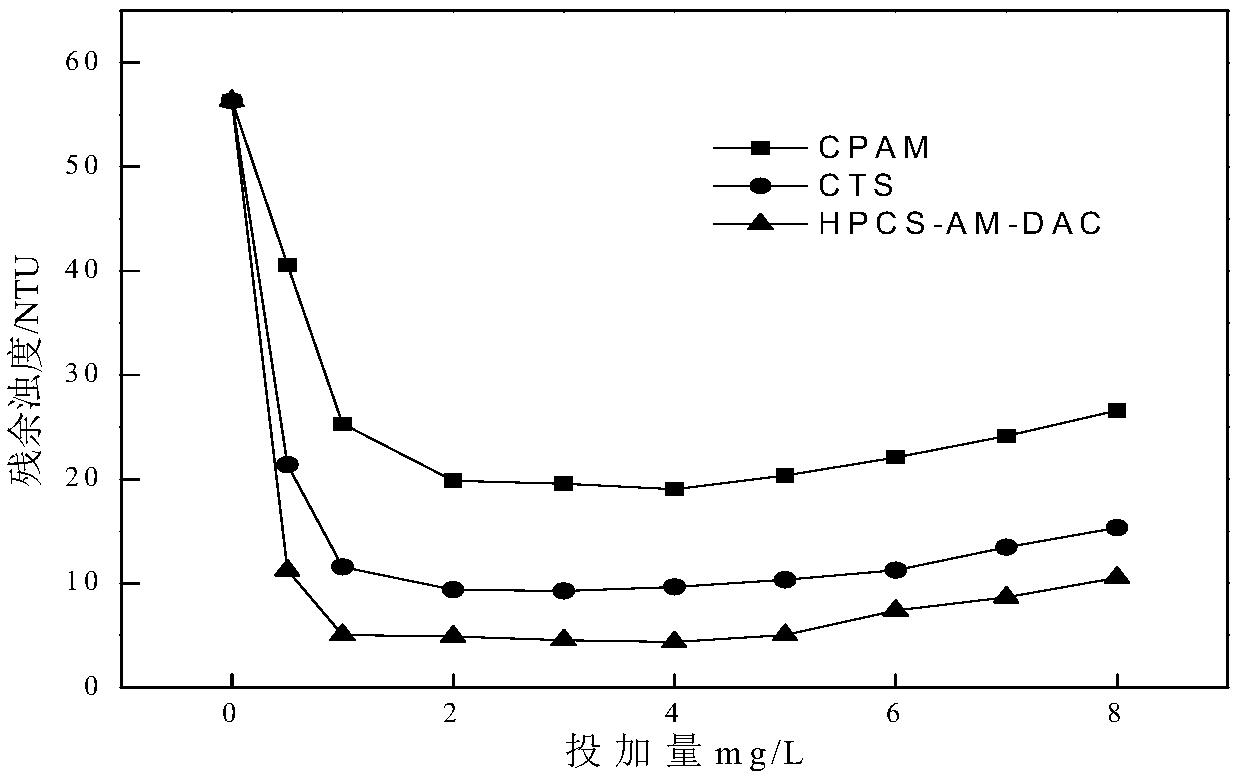

Preparation method of cationic high-molecular polymer

ActiveCN108299598ALow flocculation effectGood flocculation performanceWater/sewage treatment by flocculation/precipitationChemistryCeric ammonium nitrate

The invention relates to a preparation method of a cationic high-molecular polymer. The method comprises the steps of dividing acrylamide into two parts, and separately adding the two parts of acrylamide into water so as to obtain a first acrylamide water solution and a second acrylamide water solution; adding hydroxypropyl chitosan into a three-necked flask filled with distilled water, stirring to enable hydroxypropyl chitosan to be dissolved, removing oxygen and then heating up to 50-80 DEG C, then adding a ceric ammonium nitrate water solution, initiating a reaction for 20min, and then dropwise adding a mixture of an acryloyloxyethyltrimethyl ammonium chloride water solution and the first acrylamide water solution; after the dropwise addition is finished, dropwise adding the second acrylamide water solution, and the continuously carrying out a reaction for 4h; after the reaction is finished, treating to obtain the cationic high-molecular polymer. The prepared cationic high-molecularpolymer is high in density of positive charges, large in relative molecular mass and simple in aftertreatment; the product has good flocculating performance.

Owner:SHAANXI UNIV OF SCI & TECH

Method for preventing flocculation flow of small square billet medium-carbon high-silicon low-manganese steel

ActiveCN111041367AReduce flocculationIncrease the number of continuous pouring furnacesManufacturing convertersFlocculationSlag

The invention provides a method for preventing the flocculation flow of small square billet medium-carbon high-silicon low-manganese steel. Compared with the prior art, the method has the advantages that in order to improve the castability of the medium-carbon high-silicon steel, an end-point oxygen content and early-stage rapid slagging are controlled by optimizing end-point carbon and slag charge ratio of converter tapping, in a LF furnace process, large slag amount and high alkalinity are adopted to facilitate the deoxidation and desulfurization process, then a ladle argon blowing process is reasonably controlled, the argon blowing strength is properly set, the argon blowing time is properly prolonged, the floating and removal of oxide, sulfide and other inclusions in steel can be promoted, and the continuous casting nodulation can be obviously reduced through measures such as continuous casting process protection casting. Meanwhile, the molten steel casting temperature is properlyincreased, and the flocculation flow blockage phenomenon of a continuous casting intrusive water nozzle can be effectively avoided. By means of the method, the flocculation flow phenomenon of a smallsquare billet in the medium-carbon high-silicon steel PSB830 pouring process is reduced, and the multi-furnace stable continuous pouring and batch production are achieved.

Owner:WUHU XINXING DUCTILE IRON PIPES

Synthetic method of polyaluminum ferric chloride

The invention discloses a synthetic method of polyaluminum ferric chloride. The synthetic method comprises the following steps: firstly adjusting the content of Fe<2+> in iron-containing waste hydrochloric acid to be 7.8-8.2wt% and the content of HCl to be 9.0-9.2wt%; then adding a sodium nitrite solution, introducing nitrogen and reacting to obtain an iron trichloride liquid; then adding aluminium slag, aluminium-containing waste hydrochloric acid and hydrochloric acid according to a mass ratio of the iron trichloride liquid to the aluminium slag to aluminium-containing waste hydrochloric acid to hydrochloric acid being (6.9-7.0) to 1 to (3-3.2) to (4.1-4.3) and introducing steam to carry out heating reaction; then adding calcium aluminate powder and water, reacting and carrying out cooling and solid-liquid separation, thus obtaining the finished product polyaluminum ferric chloride. Aluminium-containing waste hydrochloric acid, the aluminium slag and iron-containing waste hydrochloric acid are comprehensively utilized and are converted to a water purifier with high added value. The synthetic method has the beneficial effects that the whole reaction only needs 4-6 hours; the equipment and the process are simple and convenient and feasible; the equipment investment is low; the synthetic method is simple to operate and is suitable for large-scale industrial production.

Owner:徐州美利圆环保科技有限公司

Concrete admixture prepared by using alkali paper making liquid waste

InactiveCN101659528AReduce tendency to aggregateReduce flocculationSolid waste managementLiquid wasteFrost

The invention relates to a concrete admixture for buildings. The concrete admixture is prepared by using alkali paper pulp liquid wastes as raw materials, adding rosins to react for 20-80min at 100-180 DEG C to obtain a product, and carrying out spray drying on the product to obtain a powder product. The product is applied to the concrete, reduces the water consumption and greatly improves the frost resistance of the concrete due to the air entrained property under the condition of ensuring the strength of the concrete. The invention can not only reduce the environmental pollution produced bypaper mills, but also provide inexpensive admixtures with excellent quality for the cement and concrete industries, thereby being a good strategy to protect environment and turn waste into wealth.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Flocculating agent for printing and dyeing wastewater treatment and application of flocculating agent

PendingCN109336238AElectricity is good, The effect of bridging is goodWater treatment parameter controlWater treatment compoundsFlocculationCrosslinked chitosan

The invention provides a flocculating agent for printing and dyeing wastewater treatment and an application of the flocculating agent, and relates to the technical field of wastewater treatment. The flocculating agent is prepared from components in parts by weight as follows: 50-70 parts of glutaraldehyde crosslinked chitosan, 25-35 parts of an inorganic flocculant, 3-15 parts of a plant extract flocculant and 3-7 parts of a collagen polypeptide based surfactant. Glutaraldehyde crosslinked chitosan has a quite good synthetic function with the inorganic flocculant, the plant extract flocculantand the collagen polypeptide based surfactant, so that the obtained flocculating agent has an excellent flocculation effect and has excellent COD removal rate and color removal rate.

Owner:方期洲

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com