Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

109results about How to "Not burned" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

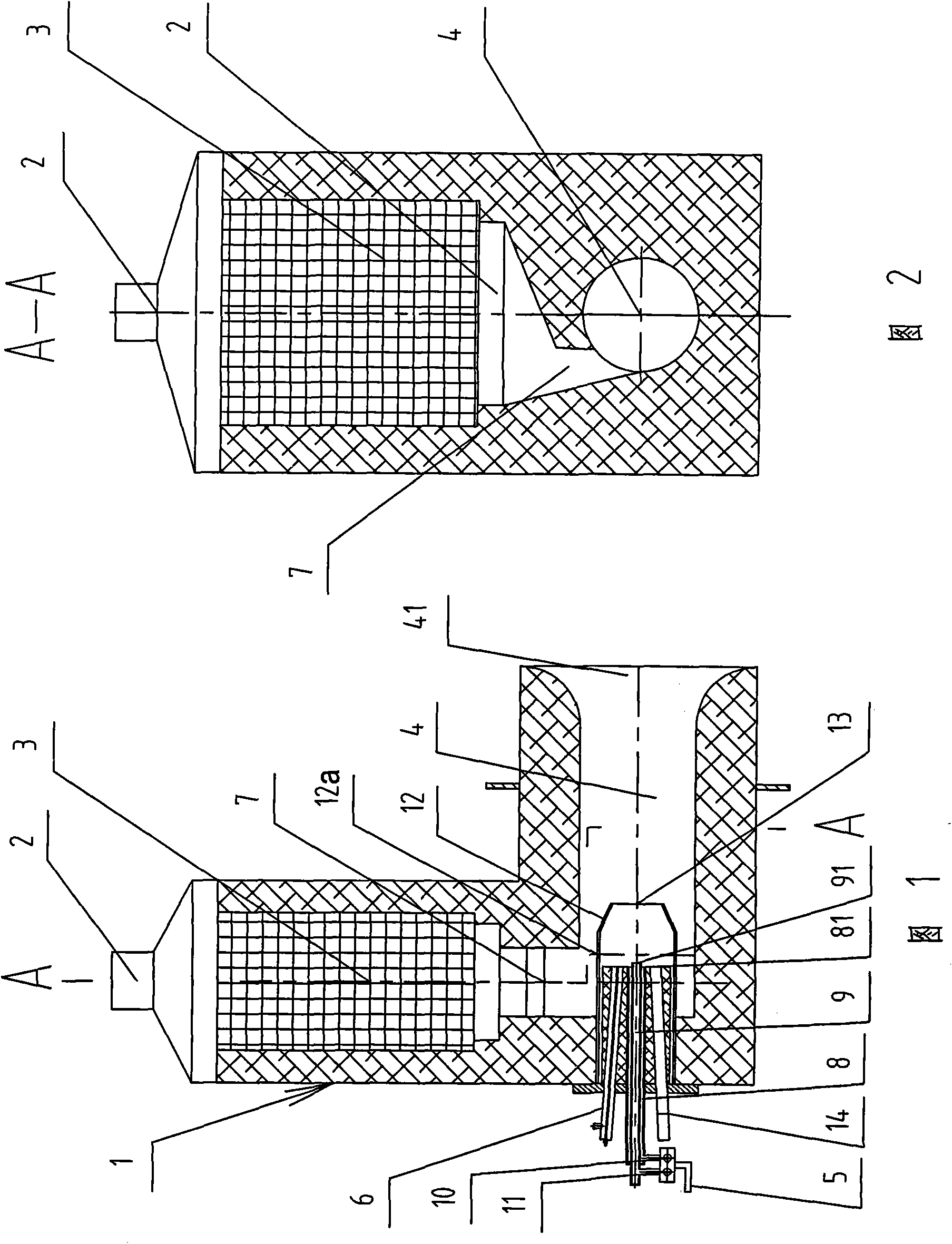

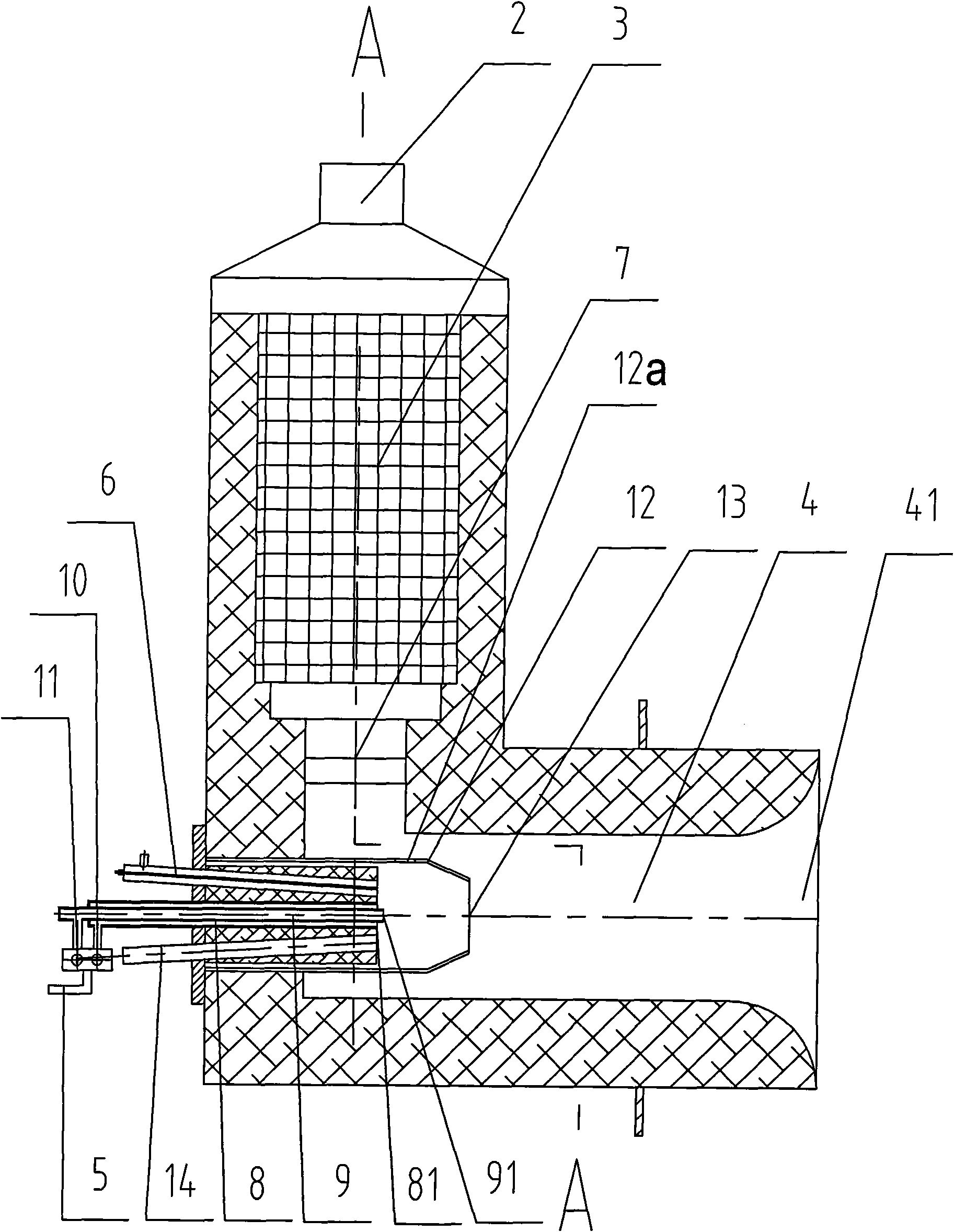

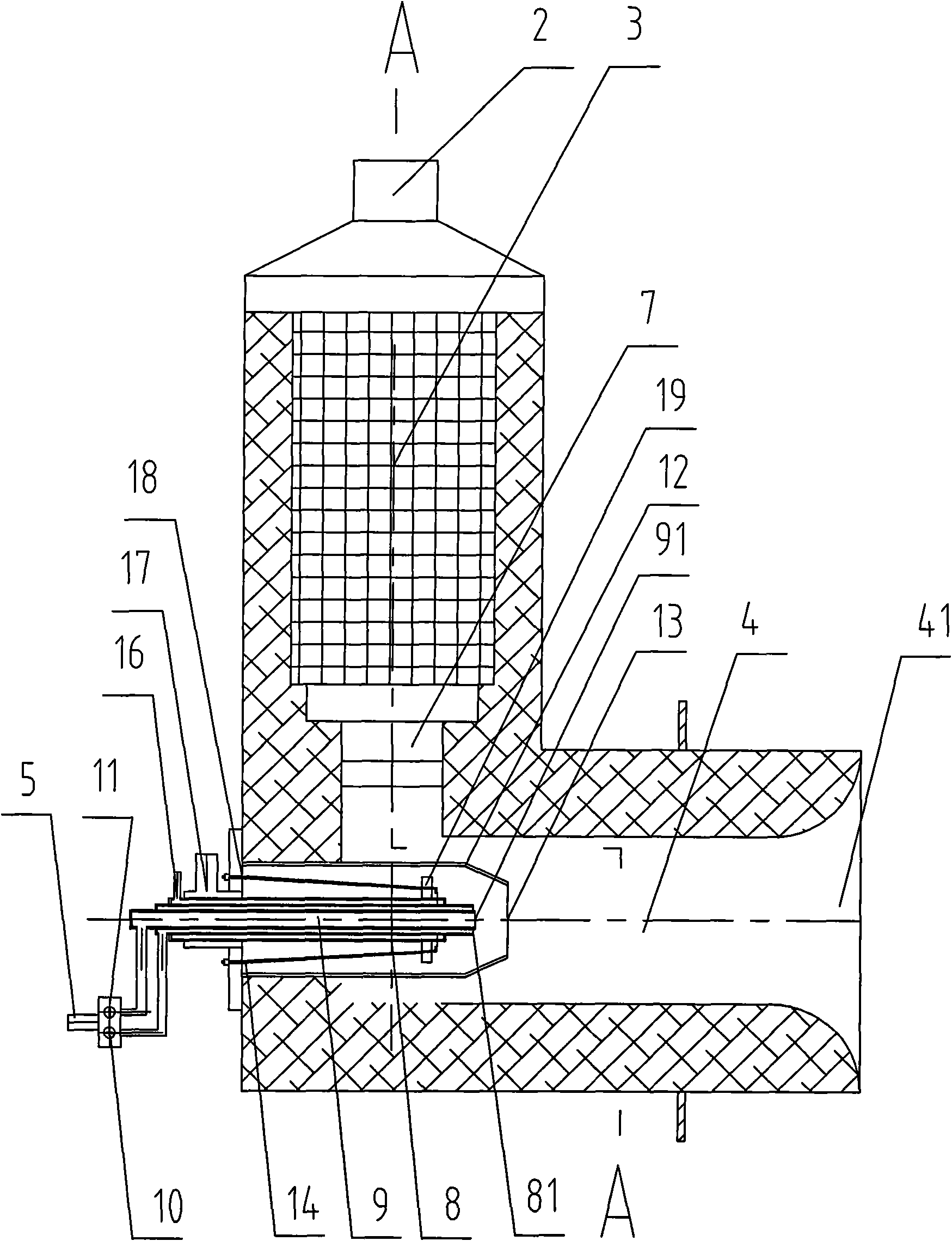

Flameless combustion heat accumulating type flat flame combustion nozzle

ActiveCN101639218AGood energy saving effectImprove energy efficiencyElectric spark ignitersIndirect carbon-dioxide mitigationGas pipelineHigh energy

The invention discloses a flameless combustion heat accumulating type flat flame combustion nozzle. A combustion nozzle body is internally provided with an air or smoke gas passage, a porous heat accumulator, a combustion cavity, a gas pipeline and an ignition device, wherein the tail end of the air or smoke gas passage is provided with a tangential air inlet duct positioned along the tangential direction of the circumferential combustion cavity, and the air or smoke gas passage is connected with the combustion cavity through the tangential air inlet duct; the tail end of the gas pipeline is provided with a flame combustion gas pipe and a flameless combustion gas pipe which are parallel and respectively controlled by a flame combustion control valve and a flameless combustion control valve, and the aperture of a flameless combustion gas spray orifice positioned on the tail end of the flameless combustion gas pipe is smaller than that of a flame combustion gas spray orifice positioned on the tail end of the flame combustion gas pipe. The flameless combustion heat accumulating type flat flame combustion nozzle has high energy utilization efficiency and good furnace temperature uniformity and can greatly reduce the discharge amount of NOX; fuel is sprayed at high speed through the necking spray orifice, thereby effectively controlling the flame temperature and being beneficial tothe sufficient combustion of the fuel; and in addition, the flame sprays into a furnace cavity with a very short spraying distance so as not to spray to parts inside the furnace cavity.

Owner:CHONGQING AOKEQI TECH

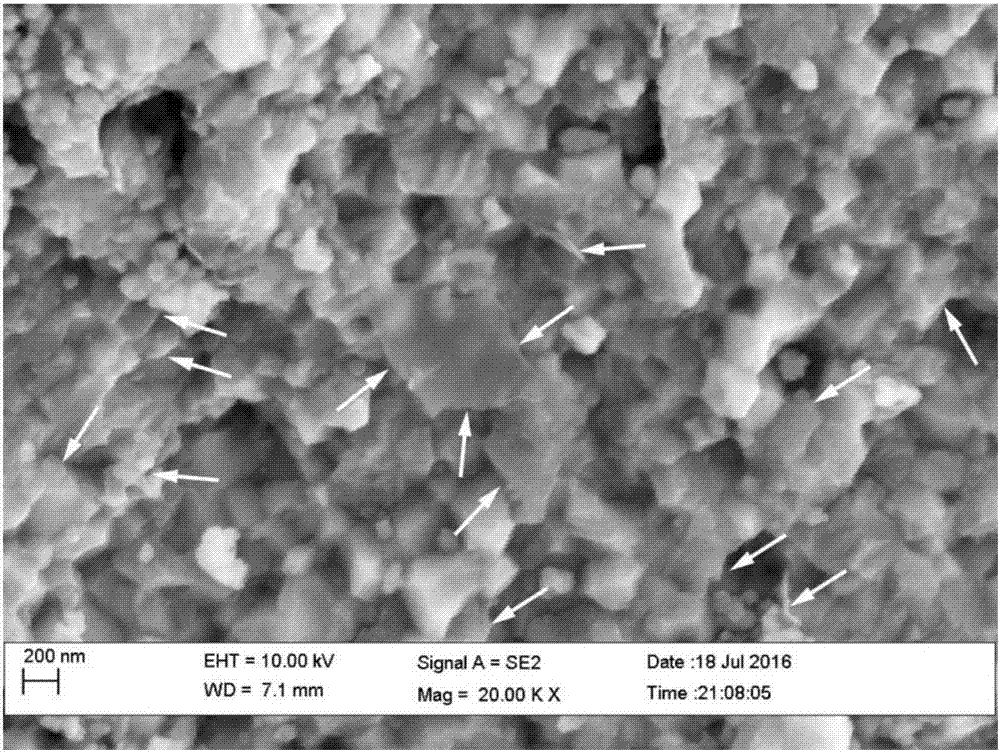

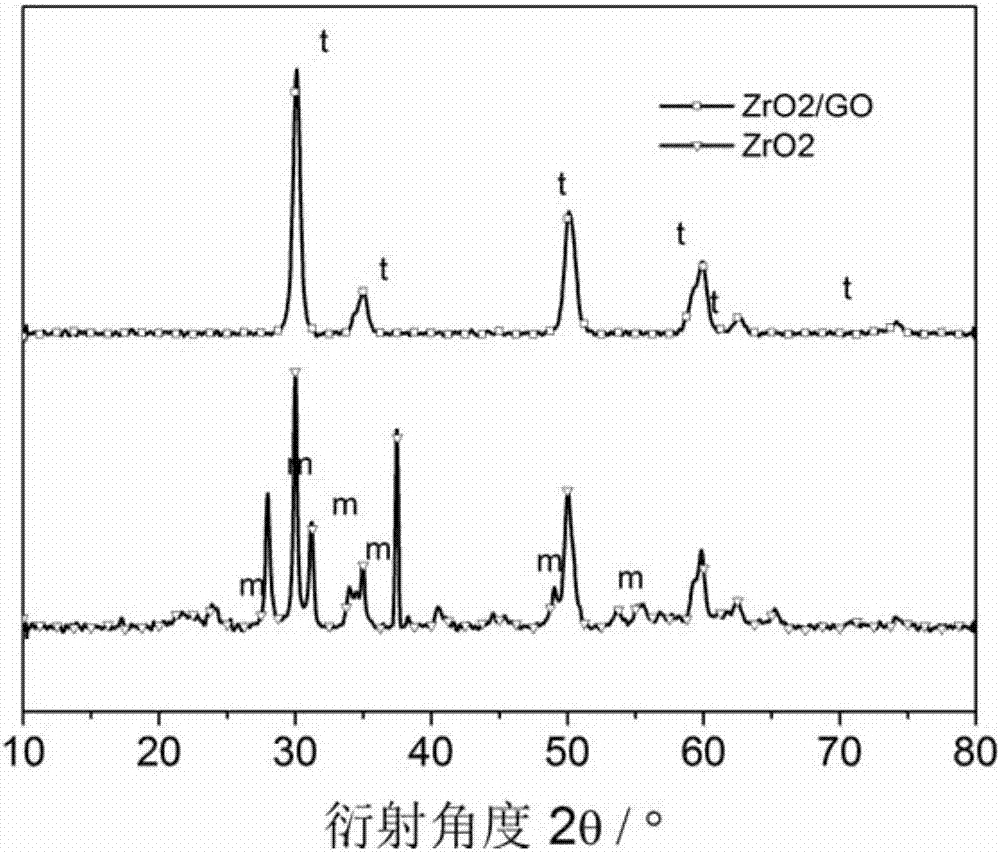

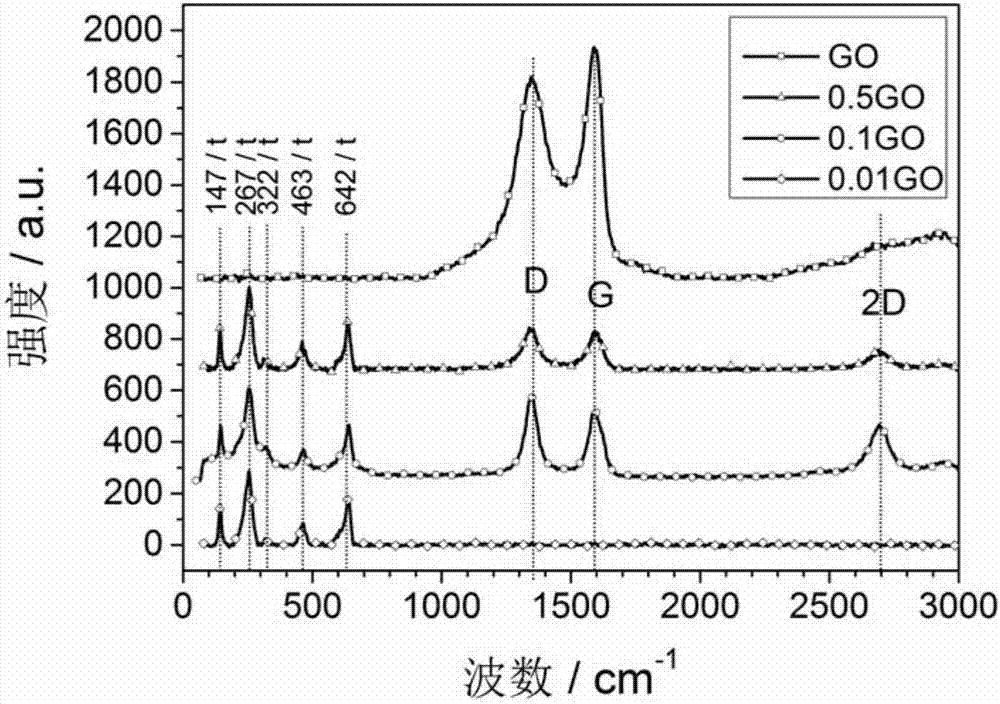

Graphene-zirconium oxide compound material and preparation method of same

The invention discloses a graphene-zirconium oxide compound material and a preparation method of same. The compound powder is prepared with zirconium oxide granulation powder and graphene oxide as raw materials, wherein the zirconium oxide granulation powder accounts for 99.5-99.99% of the total weight of the two components, and the graphene oxide accounts for 0.01-0.5% of the total weight of the two components. The preparation method includes the steps of: 1) dispersing and mixing the raw materials; and 2) sintering the mixture powder. In the method, the character that the graphene oxide can be reduced to form graphene at high temperature is fully considered, and meanwhile, under a high-pressure and high-vacuum atmosphere in the sintering environment, the graphene oxide is reduced in the zirconium oxide substrate in situ. The method has simple operation steps and high production efficiency and improves mechanical performances of zirconium oxide ceramic.

Owner:SOUTH CHINA UNIV OF TECH

Method for improving converted current switching capability of ultra-high voltage alternating current open isolating switch

ActiveCN101969006ANot burnedNot damaged by minor burnsHigh-tension/heavy-dress switchesAir-break switchesUltra high voltageEngineering

The invention belongs to the technical field of ultra-high voltage power transmission, in particular to a method for improving the converted current switching capability of an ultra-high voltage open alternating current isolating switch. Auxiliary circuits are added on a main contact to switch converted current, and isolating switches are used to guide the operation of electric poles, so that the converted current switching capability of the isolating switches can be greatly improved, and the use requirements for connecting the isolating switches in parallel can be met. Thus, by using the method, the converted current switching capability is greatly improved, the requirements for connecting the isolating switches in parallel are easily met, the influence of electric arcs is almost completely eliminated, the operation and the control of the isolating switches are greatly simplified, the cost is lowered and the reliability is improved.

Owner:CHINA ELECTRIC POWER RES INST +1

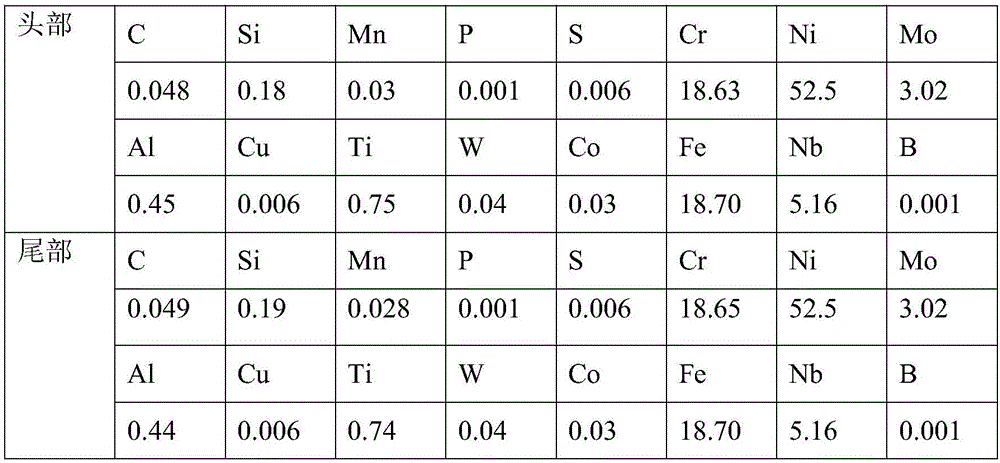

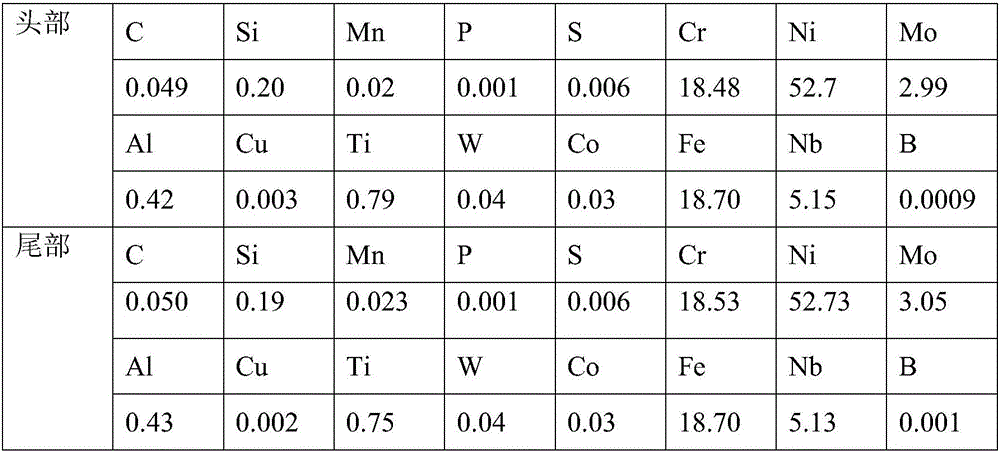

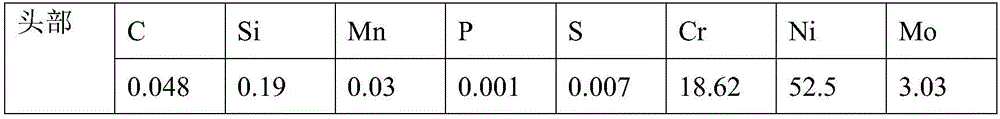

GH4169 alloy steel electroslag remelting refining slag and method for performing electroslag re-melting on GH4169 alloy steel

The invention provides GH4169 alloy steel electroslag remelting refining slag and a method for performing electroslag remelting on GH4169 alloy steel. The GH4169 alloy steel electroslag remelting refining slag comprises the following components in parts by weight: 60-70 parts of CaF2, 15-20 parts of Al2O3, 5-15 parts of CaO, 3-6 parts of MgO and 4-8 parts of TiO2. The method comprises: baking the remelting refining slag, taking the GH4169 alloy steel as a consumable electrode, assembling an electroslag remelting furnace, adding the baked remelting refining slag, aluminum powder and ferrotitanium powder into a crystallizer, turning on power for arc starting so as to establish a slag bath, and then performing remelting smelting on the consumable electrode under the protection of an inert gas. The refining slag provided by the invention has the characteristics of low melting point, low viscosity, high specific resistance, and relatively low air permeability in a high-temperature liquid state, and by adopting the refining slag, less aluminum and titanium elements during remelting of a GH4169 alloy can be over-burnt, so that the obtained steel ingots have bright and clean surfaces and also have qualified and uniform components.

Owner:宝武特冶航研科技有限公司

Smelting method for medium-strength and high-ductility ductile cast iron

The invention relates to a smelting method for medium-strength and high-ductility ductile cast iron. Ductile cast iron castings are manufactured through feeding and smelting, constituent fine adjusting, molten iron pre-treating, molten iron refining, spheroidizing and casting forming. The smelting method has the advantages that pig iron is added finally in the feeding process, and burning loss of crystalline cores in molten iron can be prevented; carbon and silicon carbide are added simultaneously in the pre-treating process, 1 / 3 of the molten iron needs to be poured out from a furnace, the liquid level of the molten iron left in the furnace can be located below an induction coil of the electric furnace, the stirring strength is improved when the molten iron is heated, and therefore the molten iron can fully absorb the carbon and the silicon carbide, and the pre-treating effect is guaranteed; the secondary inoculation treatment process is adopted for the inoculation treatment, inoculants are added into balling tundishes when the weight of balled output iron accounts for 1 / 3 of the weight of output iron, and therefore inoculation of the molten iron is fully guaranteed, the strength of the manufactured ductile cast iron can reach the medium strength, and the ductility is high.

Owner:江苏力源金河铸造有限公司

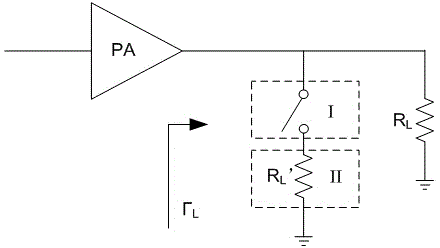

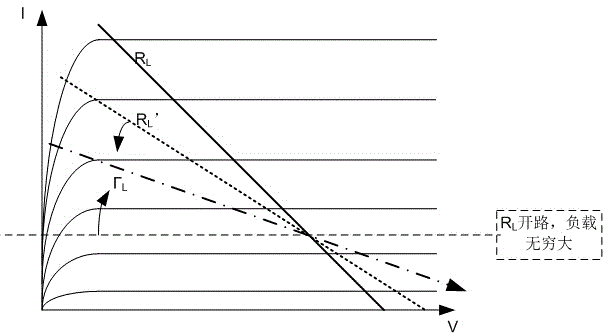

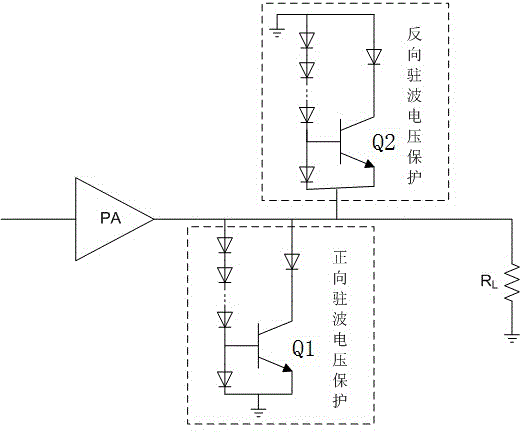

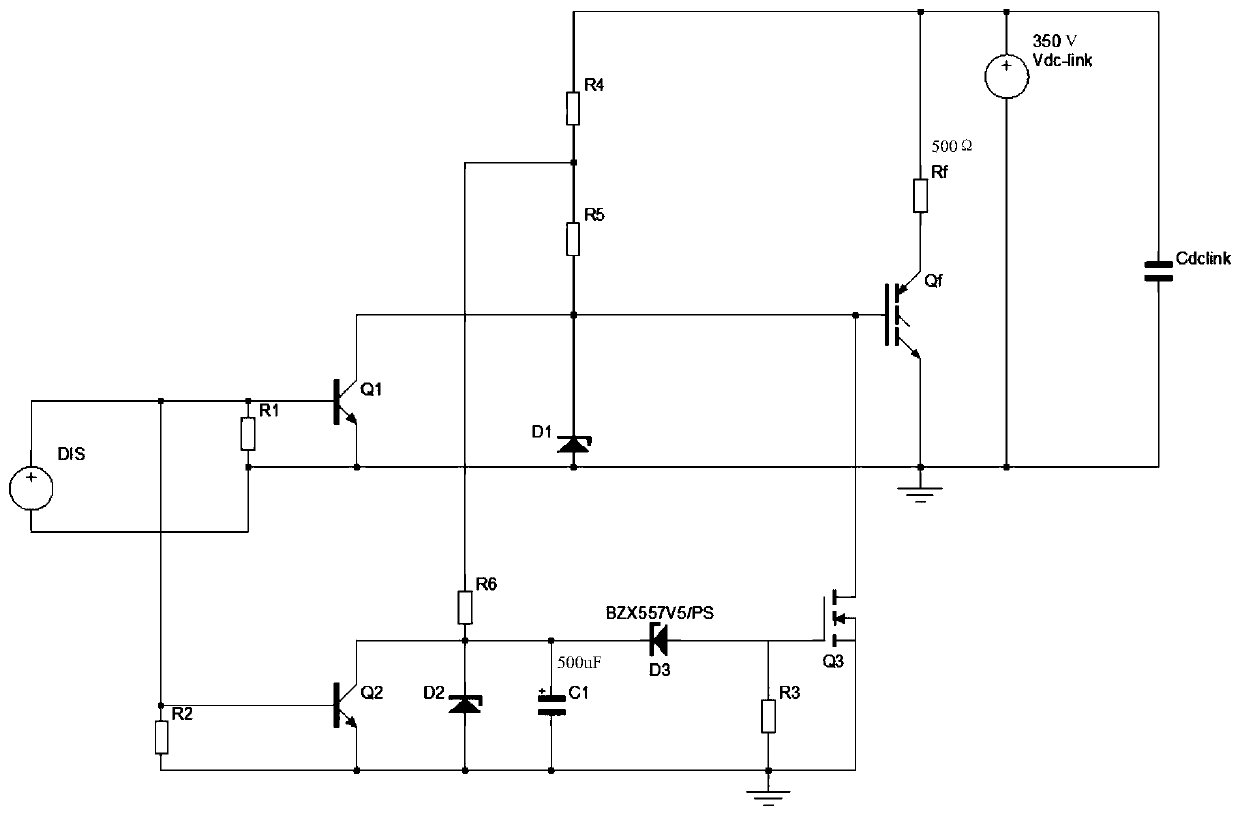

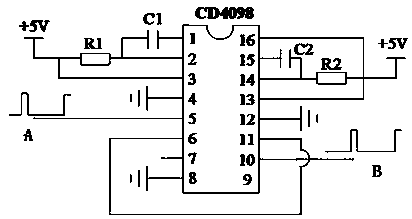

Standing wave voltage protection circuit for amplifier protection

InactiveCN104579191ANot burnedSimple structureAmplifier protection circuit arrangementsAudio power amplifierRadio frequency energy

The invention discloses a standing wave voltage protection circuit for an amplifier protection, the load matched with an power amplifier is connected with the output end of the power amplifier, the standing wave voltage protection circuit is connected between the power amplifier and the load, the standing wave voltage protection circuit comprises a standing wave ratio detection circuit and a tapping passage orderly connected, one end of the standing wave ratio detection circuit is connected with the output end of the power amplifier while the other end of the standing wave ratio detection circuit is connected with the tapping passage, the other end of the tapping passage is connected to the ground. The standing wave voltage protection circuit for the amplifier protection offers the transmission passage for the radio frequency energy through the tapping passage while the load is not matched and the supplying side output is open or short-circuited and the amplifier can be protected away from burn. The standing wave voltage protection circuit for the amplifier protection has integration outside the blade, the structure is simple, and the standing wave voltage protection circuit for the amplifier protection can be conveniently connected between the power amplifier output port and the load or the antenna.

Owner:SUZHOU INNOTION TECH

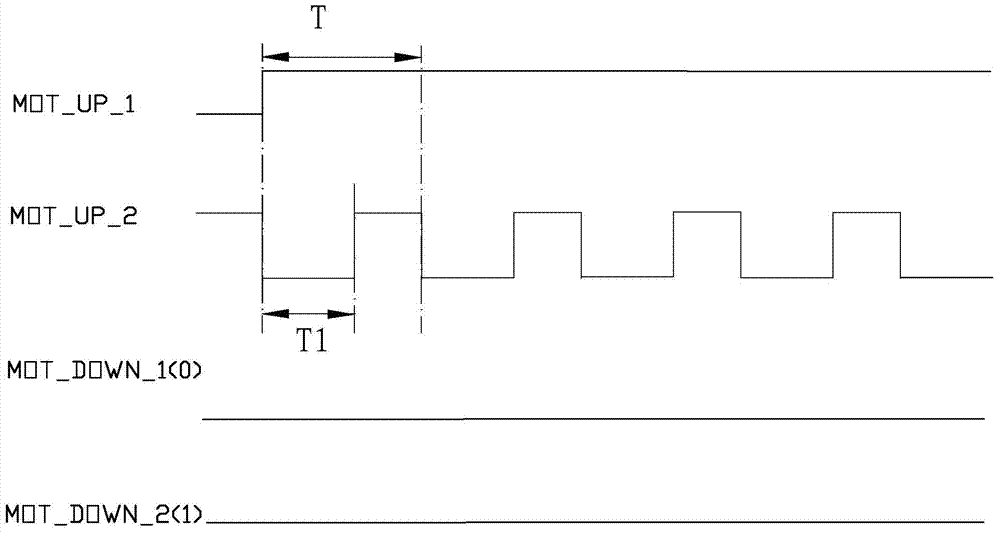

Method for controlling speed of motor

ActiveCN103501144AConsistent speedSlow downField or armature current controlAutomatic controlReducer

The invention discloses a method for controlling the speed of a motor. The motor comprises a direct current motor, a gear speed reducer, a control module and a rotating speed detecting module, wherein the gear speed reducer is used for conducting speed reducing on output of the direct current motor, the control module controls the direct current motor to operate, and the rotating speed detecting module is used for detecting the operating speed of the direct current motor. The method is characterized by including the following steps that the rotating speed detecting module detects the real-time operating speed of the direct current motor; the control module automatically controls the direct current motor to operate according to signals detected by the rotating speed detecting module, the direct current motor is maintained at constant preset speed which does not change along with the load after the speed of the direct current motor is reduced through the gear speed reducer, and the preset speed is smaller than the operating speed of the motor when the motor is unloaded at nominal voltage. When the direct current motor is a curtain motor, the preset speed is smaller than the operating speed of the curtain motor when the curtain motor is at nominal load, and the curtain motor is maintained at preset speed in a PWM speed regulating mode. When the direct current motor is a direct current tubular motor, the preset speed is smaller than the uplink speed of the direct current tubular motor when the direct current tubular motor is at nominal load.

Owner:NINGBO DOOYA MECHANIC & ELECTRONICS TECH

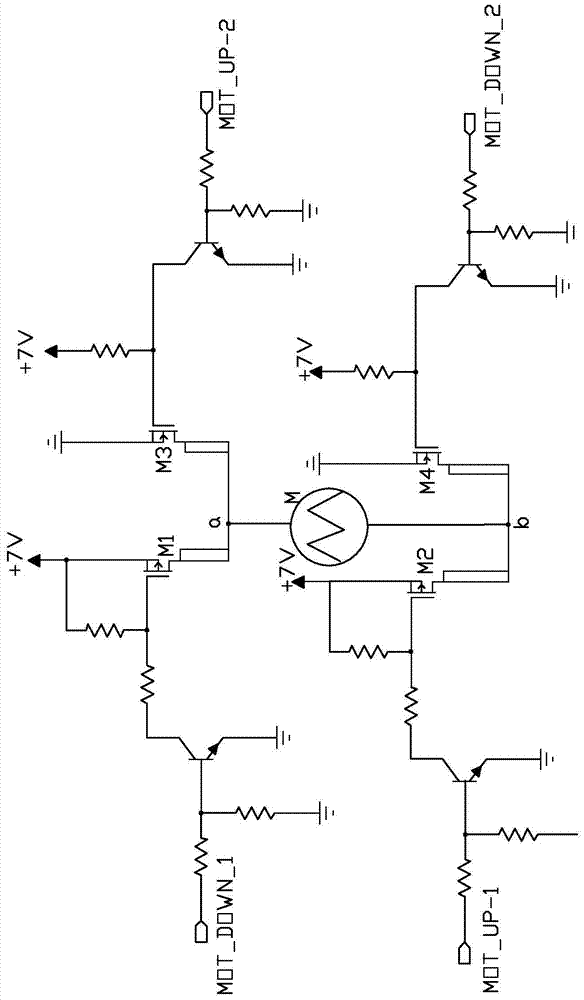

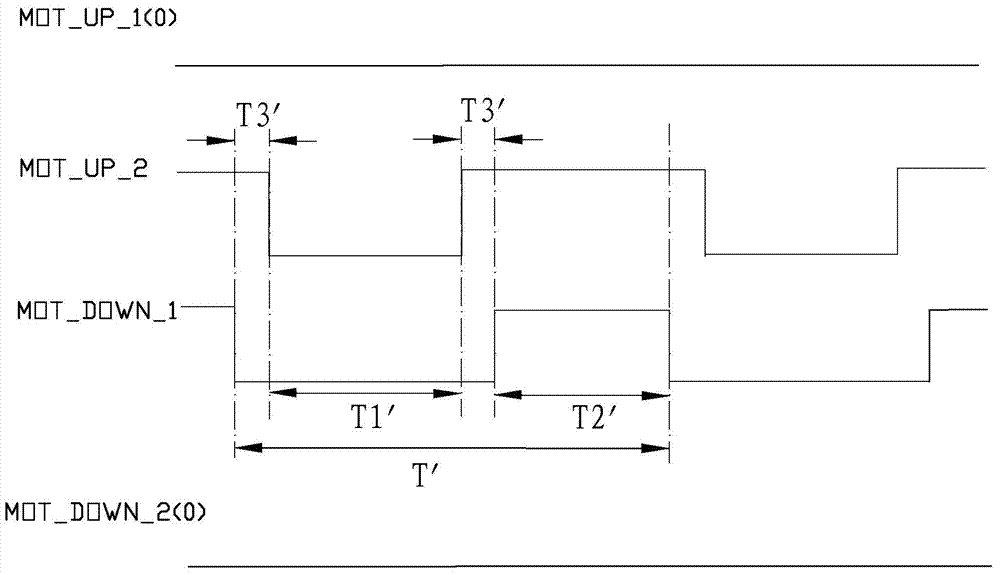

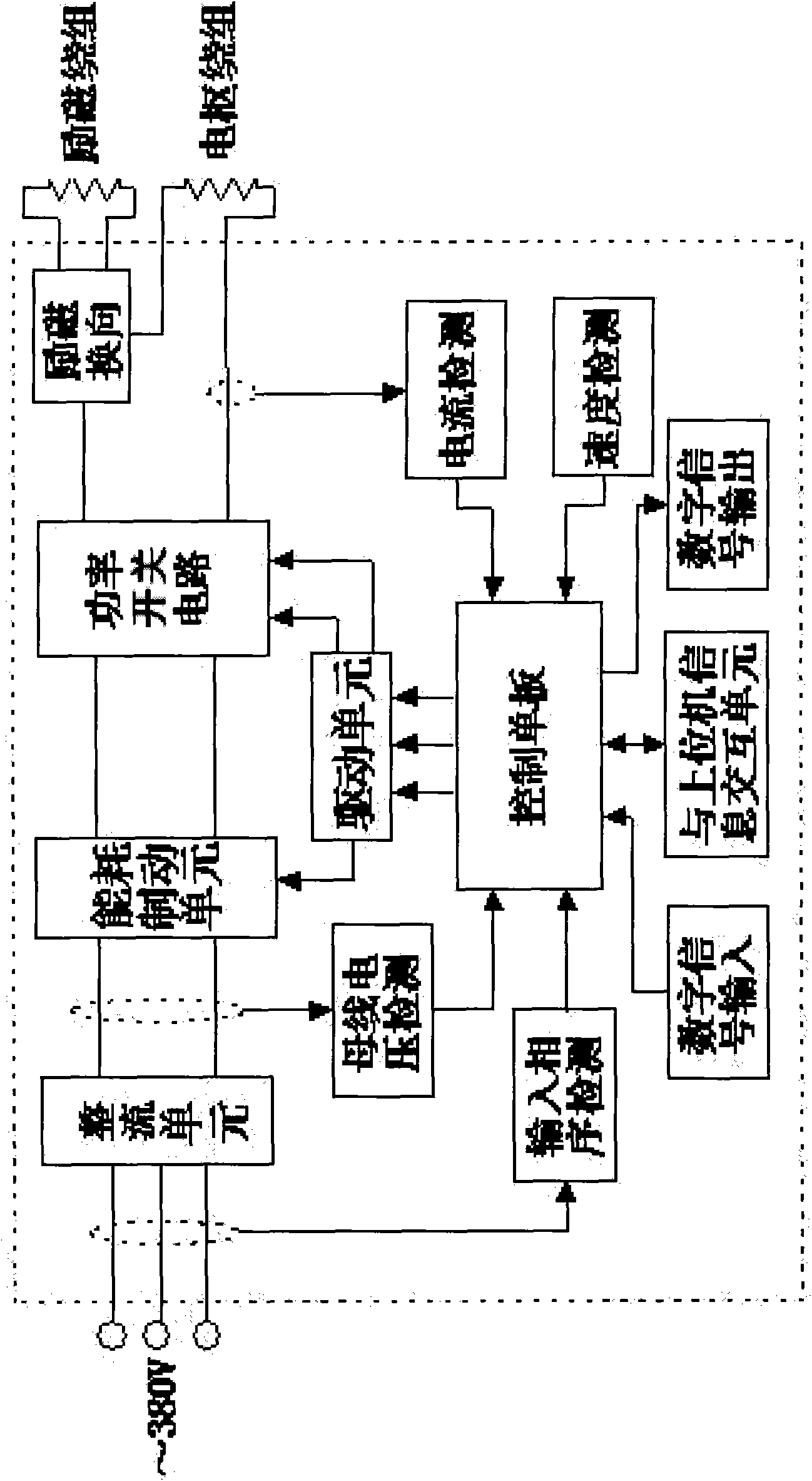

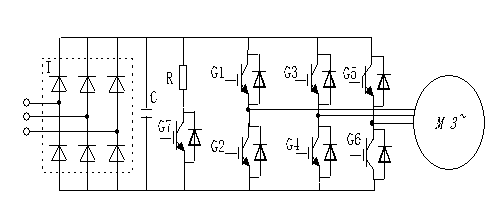

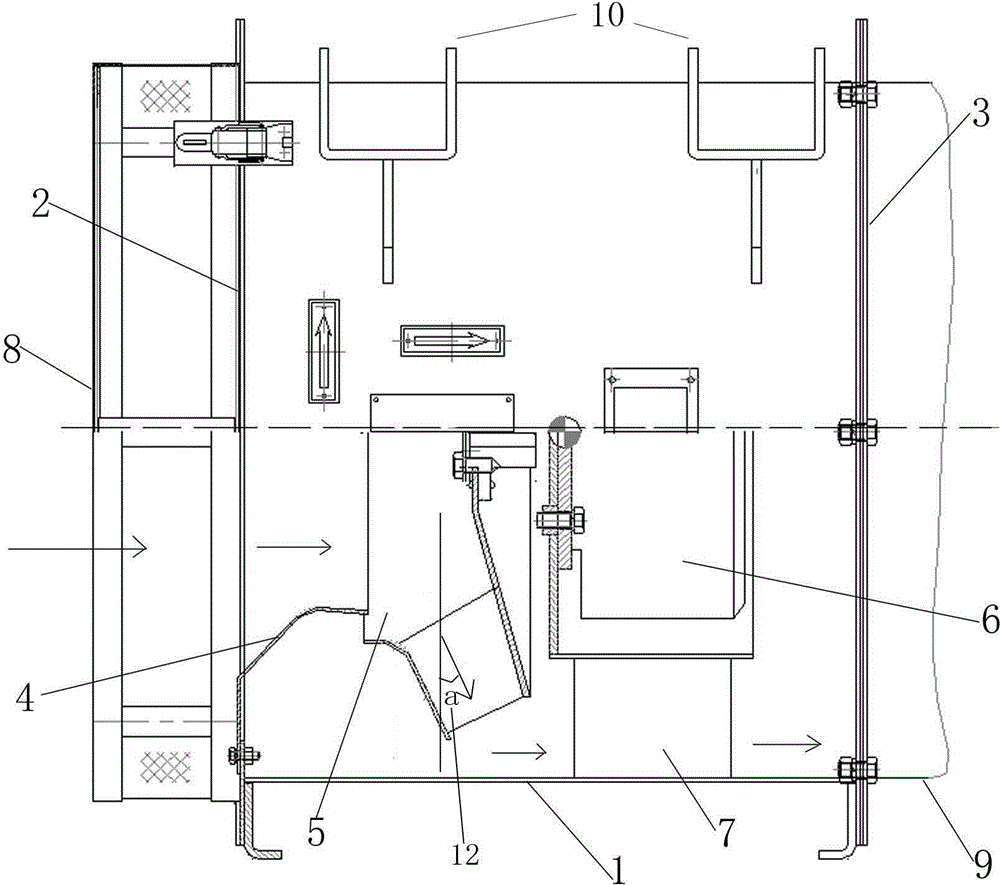

Drive device of series DC machine for pitch control system

ActiveCN101860311AImprove device reliabilitySimple circuitDC motor speed/torque controlEmergency protective circuit arrangementsCurrent limitingPitch control

The invention provides a drive device of a series DC machine for a pitch control system, which comprises a power loop part and a control loop part, wherein the power loop part comprises a rectifying unit, an energy consuming unit, a power switching circuit, an excitation reversing device, an alternating current input phase sequence detection unit, a busbar voltage and output current detection unit and the like, wherein the control loop part comprises an analogue signal sampling unit, a digital signal input acquiring unit, a speed signal acquiring unit, a digital signal outputting unit, an upper computer information interacting unit and the like. The circuit design is suitable for low-speed torque frequent starting of the series DC machine for the pitch control system and has characteristics of rapid response, current-limiting protection and flexible reversion. The drive device has perfect function and high reliability.

Owner:苏州新能健电气有限公司

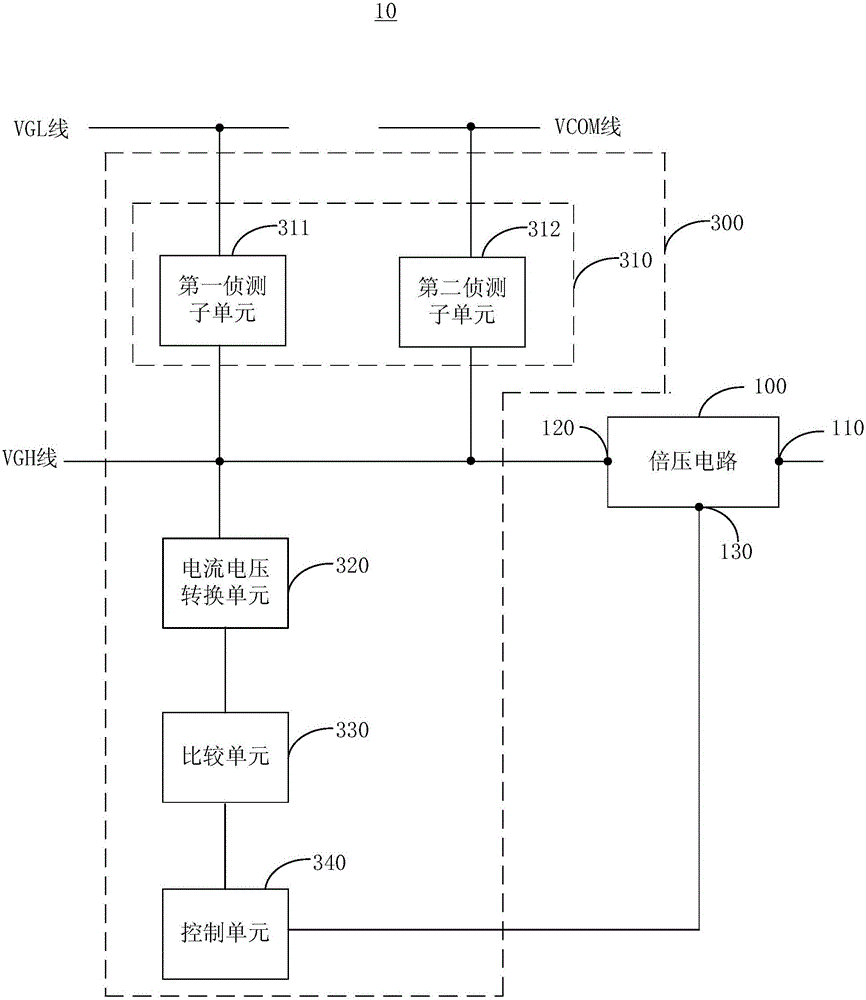

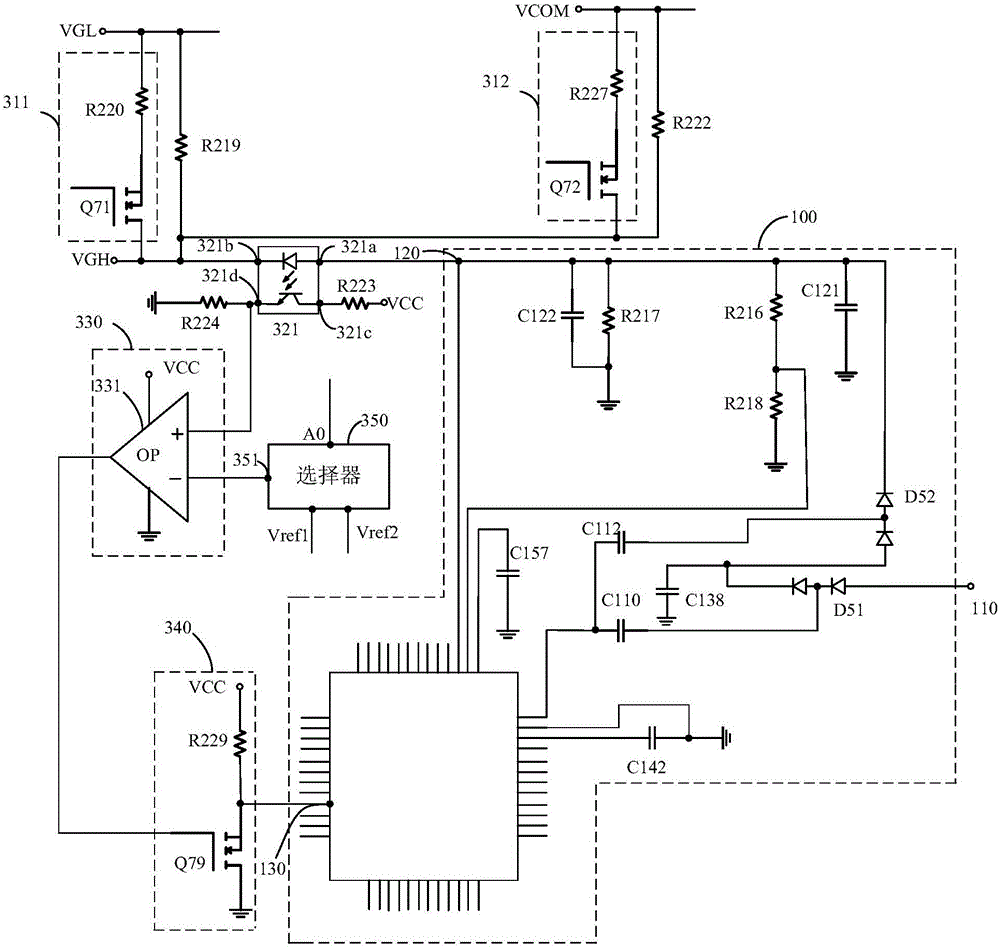

Direct-current voltage switching circuit and liquid crystal display device

ActiveCN105788560ANot burnedStatic indicating devicesDc-dc conversionLiquid-crystal displayControl signal

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Intelligent power distributing and saving device

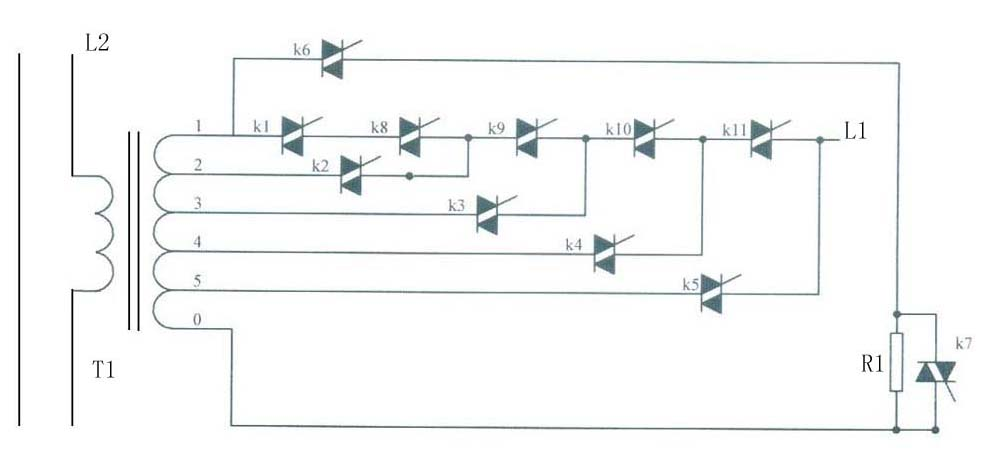

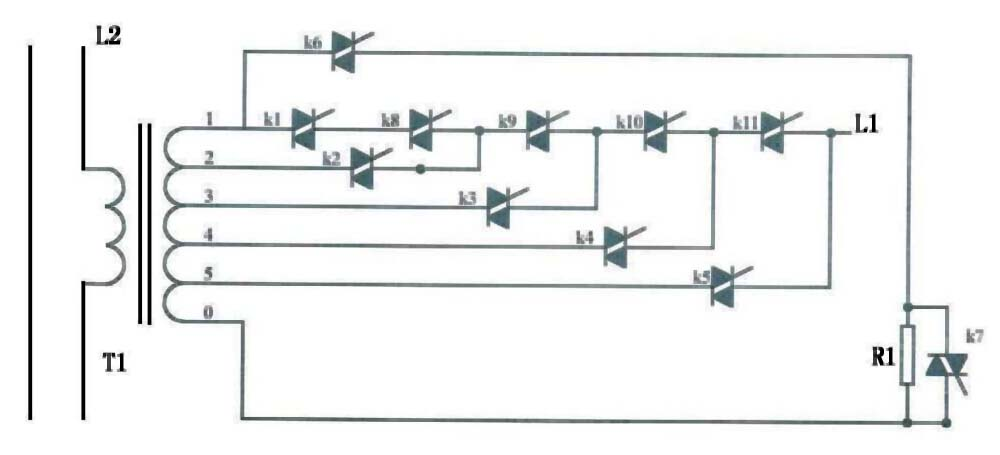

ActiveCN101841296ANot burnedLow costEmergency protective circuit arrangementsConversion without intermediate conversion to dcElectricityElectrical resistance and conductance

The invention relates to an intelligent power distributing and saving device, which comprises a transformer arranged in a shell, wherein the primary coil of the transformer is provided with 4 to 8 wiring terminals, contactless switch parts electrically connected with the wiring terminals and detecting and triggering units for controlling the on and off of the switch parts; and inductive energy release resistors and first release switches are arranged between the wiring terminals on two ends of the primary coil of the transformer. The release resistors and the release switches, which are arranged on the primary coil of the device, can protect the transformer from being burnt down and cause little increase in cost.

Owner:LIAONING ZHIYUAN ENERGY SAVING TECH

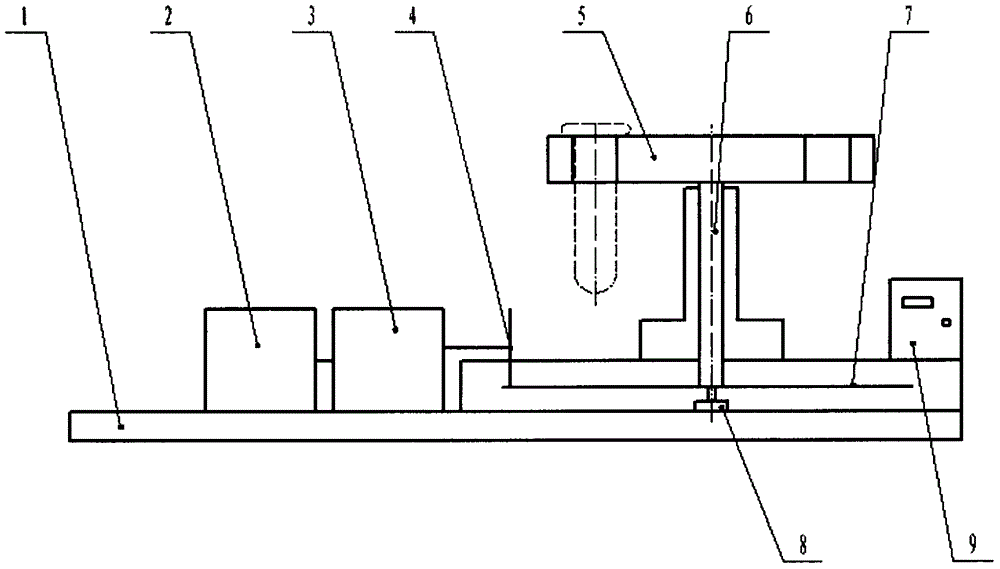

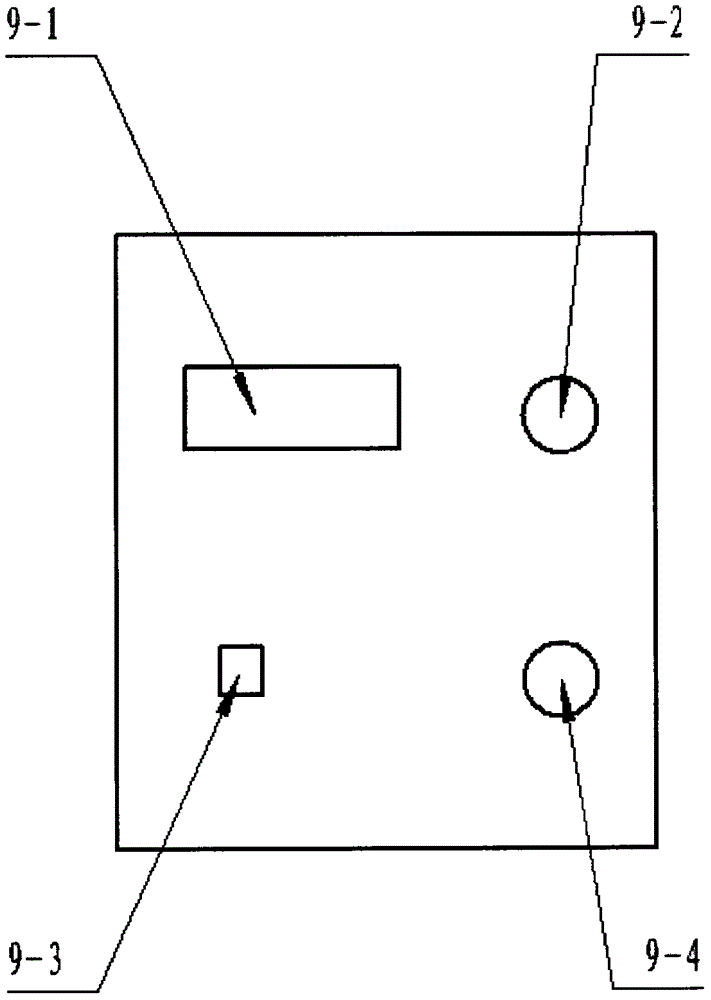

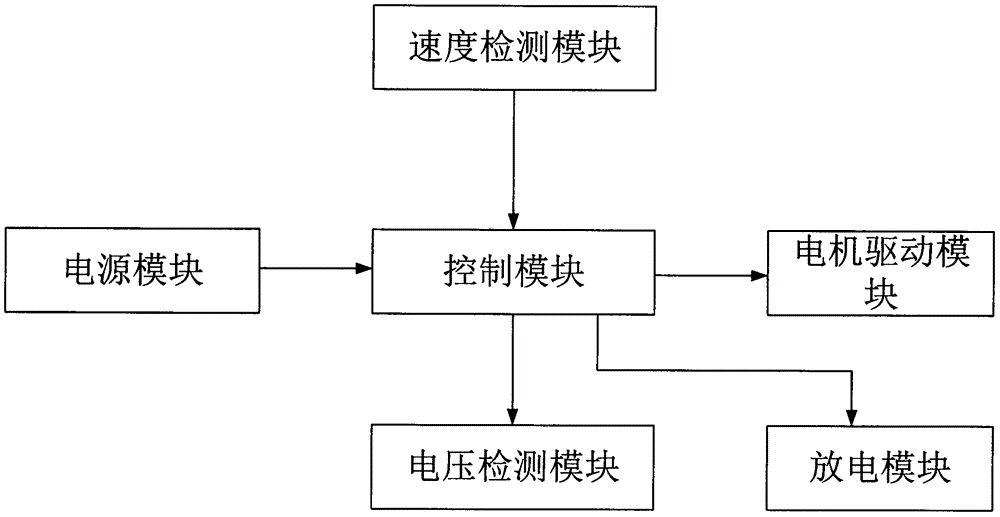

Automatic blood mixing shaking device for clinical laboratory

InactiveCN105675376AAvoid breakingEasy to usePreparing sample for investigationField or armature current controlComputer moduleEngineering

The invention relates to an automatic blood mixing device for laboratory. The front end of the base is provided with a motor, the output end of the motor is connected with the input end of a gearbox, and a small bevel gear is arranged on the output shaft of the gearbox. The small bevel gear Fit together with the large bevel gear, the large bevel gear is connected with the rotating platform through the connecting rod, the bottom end of the connecting rod is provided with a rotary encoder, and the control device is provided at the rear end of the base; the control device communicates with the motor and speed changer through the data line The boxes are connected together, and the output end of the rotary encoder is connected with the control device. The motor is a DC motor, and the rotary encoder includes a speed detection module for detecting the running speed of the DC motor. Balance detection system. The control device includes a control module operated by a DC motor, and the blood automatic mixing device for laboratory can save manpower to mix, save manpower, and improve work efficiency.

Owner:崔海涛

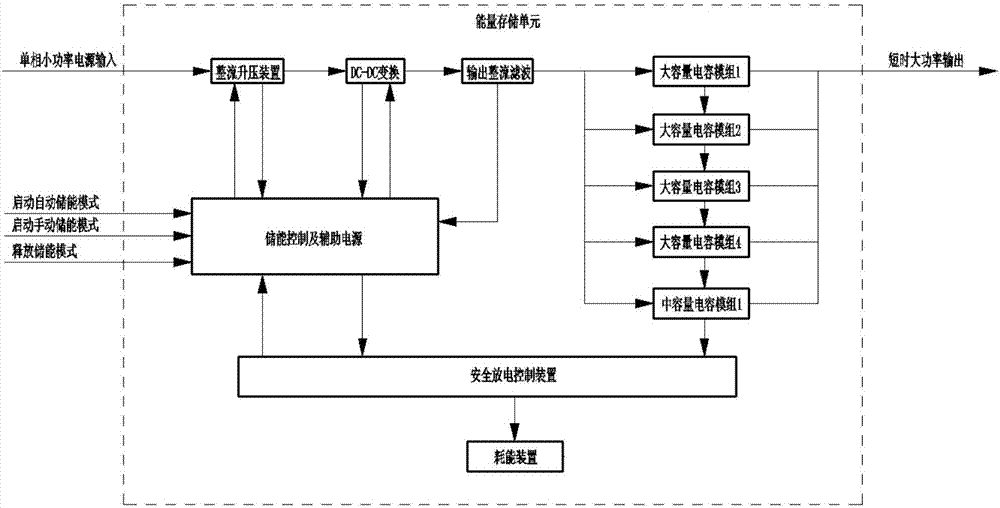

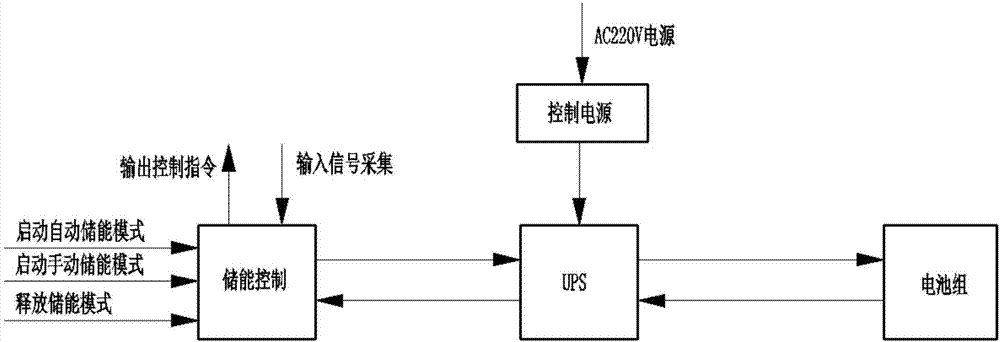

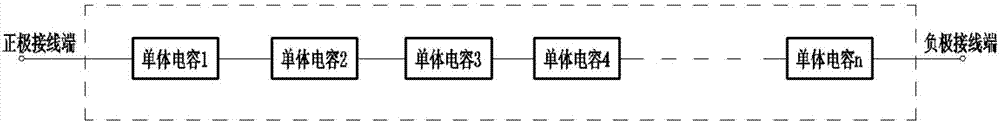

Energy storage unit for supplying short-time high-power supply and method

ActiveCN107196419AHigh energy storage densityFast energy storageElectrical storage systemBatteries circuit arrangementsCapacitanceHigh energy

The invention discloses an energy storage unit for supplying short-time high-power supply and a method. The input of a single-phase low-power power supply (alternating current or direct current, not greater than 6KW) passes through a rectifying and voltage-boosting apparatus, a DC-DC conversion module and an output rectifying and filtering module to transmit electric charges to a high-capacity energy storage which consists of multiple high-capacity capacitor modules and a medium-capacity capacitor module; and the process is completed within a few hundred seconds. After the high-capacity energy storage completes energy storage, single-phase short-time high-power output can be provided for the outside, so that the power supply requirement of a motor direct drive type operating mechanism can be satisfied; the energy storage unit has the advantages of modular structure, high energy storage density, high energy storage speed, diversified working patterns, safety and reliability in use, light weight, convenience in energy storage expansion and the like; the problem of dependence of short-time operation of high-capacity equipment on the conventional high-capacity power supply can be solved; and in addition, long-distance and large-section conductor power transmission can be avoided, the cost is lowered, and the adaptivity and mobility of the short-time high-power equipment are improved.

Owner:西安西电高压开关操动机构有限责任公司 +1

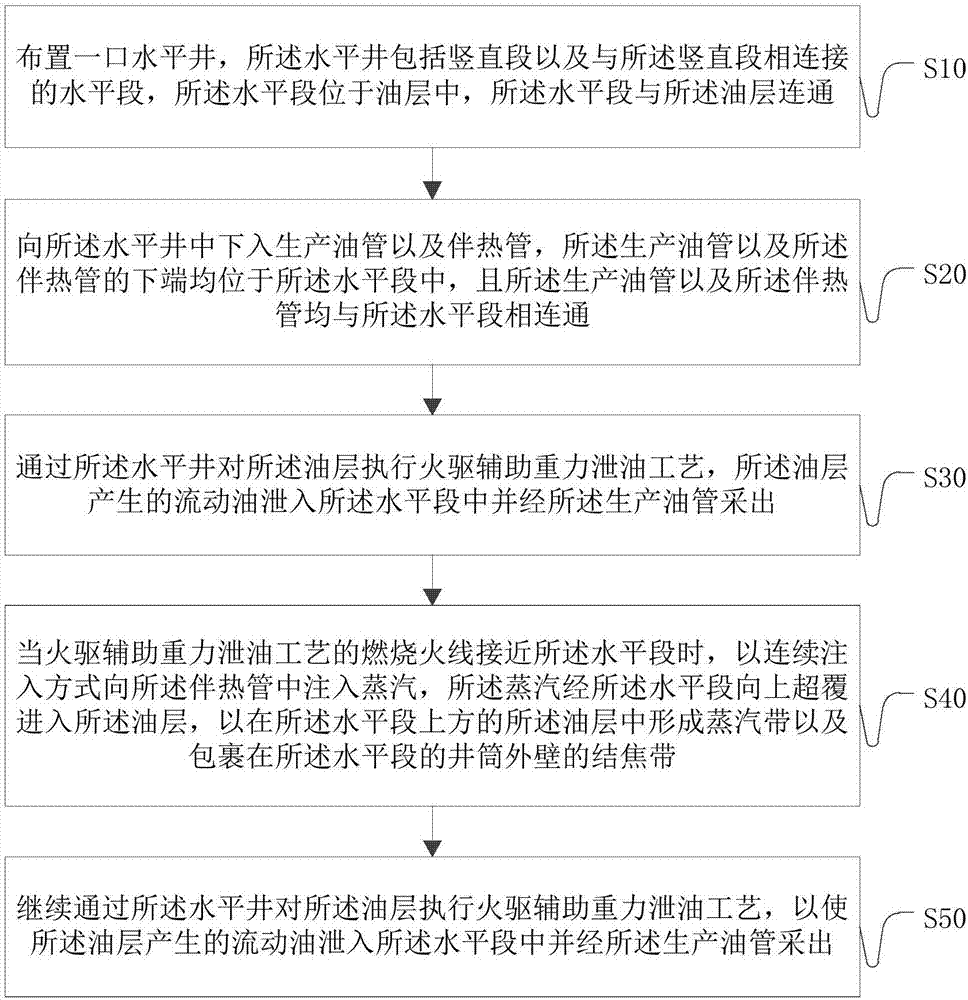

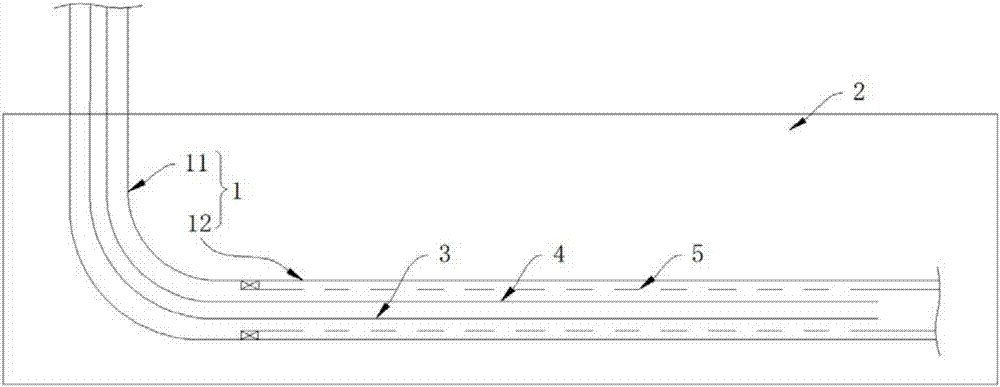

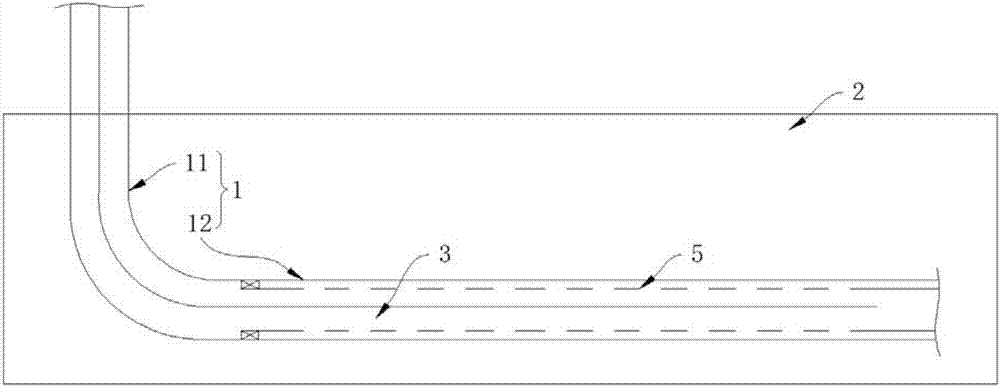

Method and device for improving fireflooding auxiliary gravity oil-drainage exploiting effect

The invention provides a method and device for improving the fireflooding auxiliary gravity oil-drainage exploiting effect. The device for improving the fireflooding auxiliary gravity oil-drainage exploiting effect comprises a horizontal well, a production oil pipe and a tracing pipe, wherein the horizontal well comprises a vertical section and a horizontal section which is connected with the vertical section, the horizontal section is located in an oil layer and communicates with the oil layer, and the production oil pipe and the tracing pipe are arranged in the horizontal well. The lower ends of the production oil pipe and the tracing pipe are both located in the horizontal section, and the production oil pipe and the tracing pipe communicate with the horizontal section. According to the device for improving the fireflooding auxiliary gravity oil-drainage exploiting effect, fire wires can be prevented from breaking through and entering into the horizontal section, and the fireflooding auxiliary gravity oil-drainage exploiting effect can be improved.

Owner:PETROCHINA CO LTD

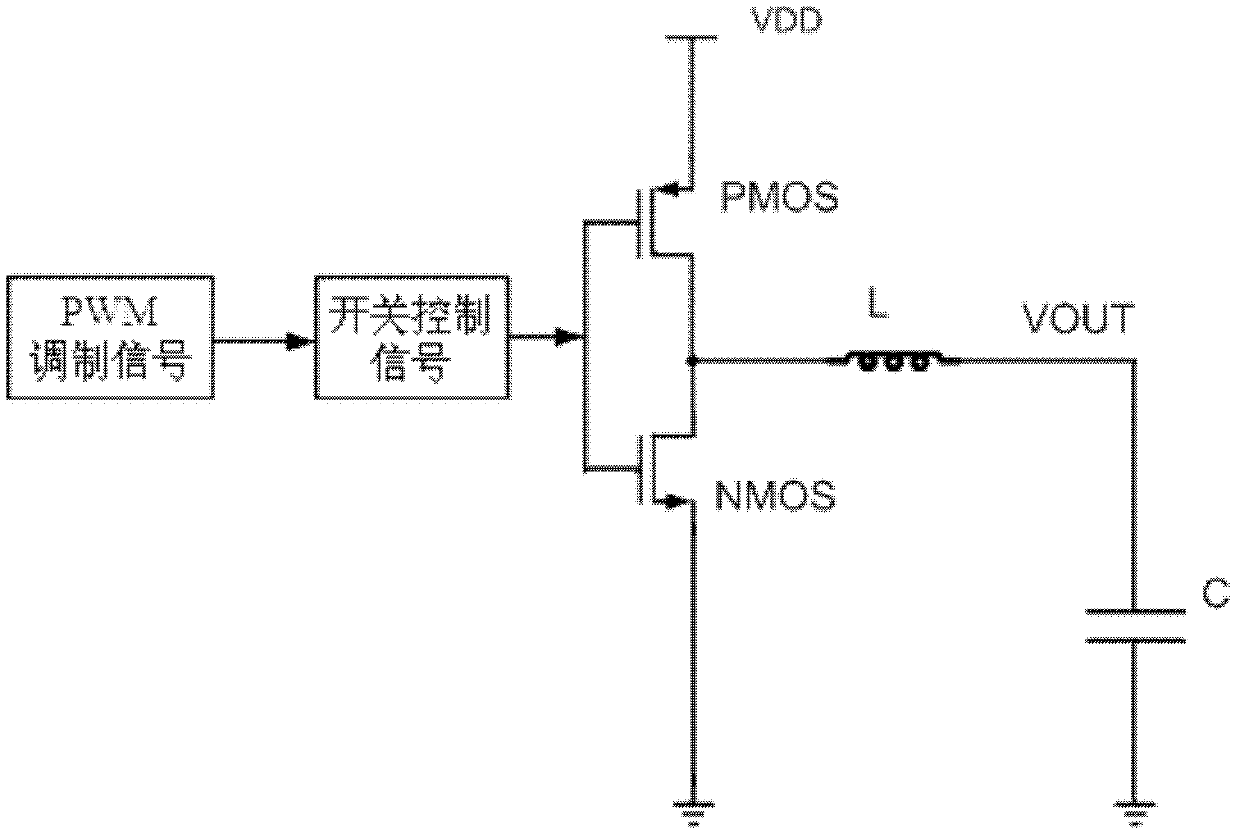

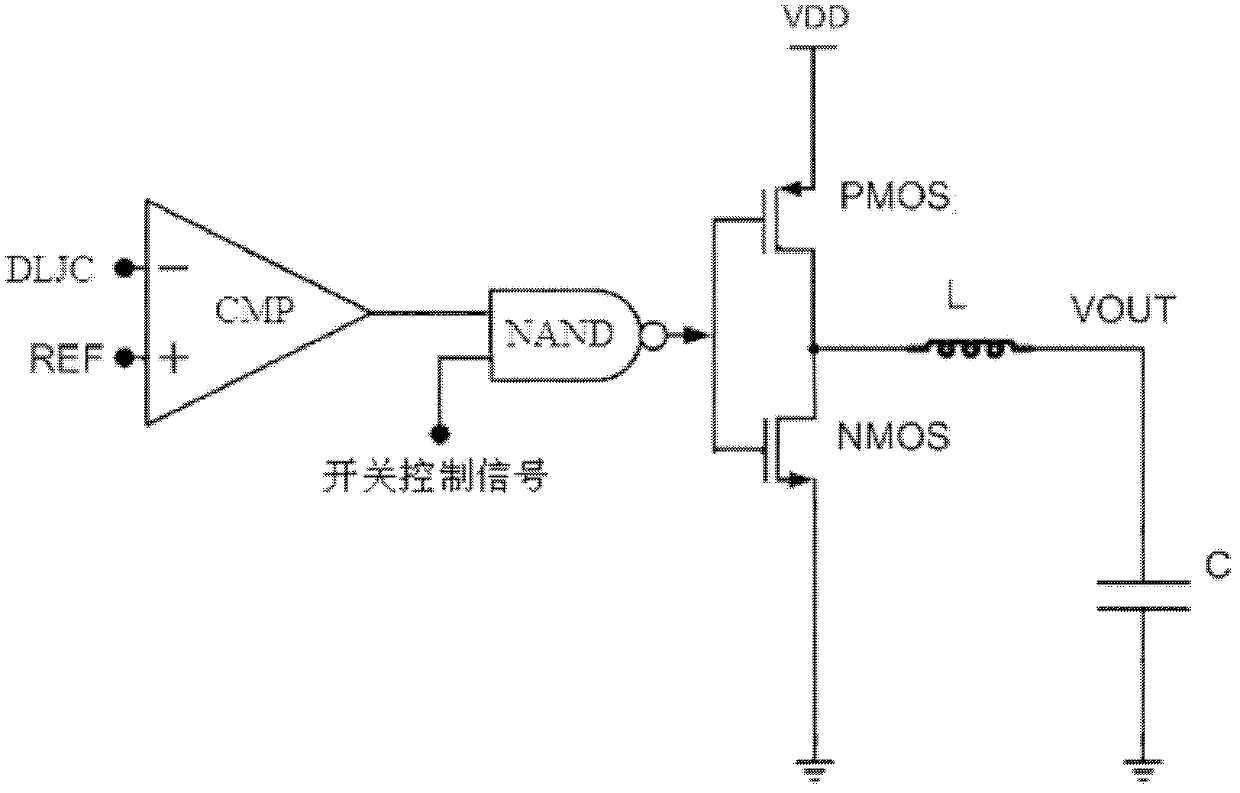

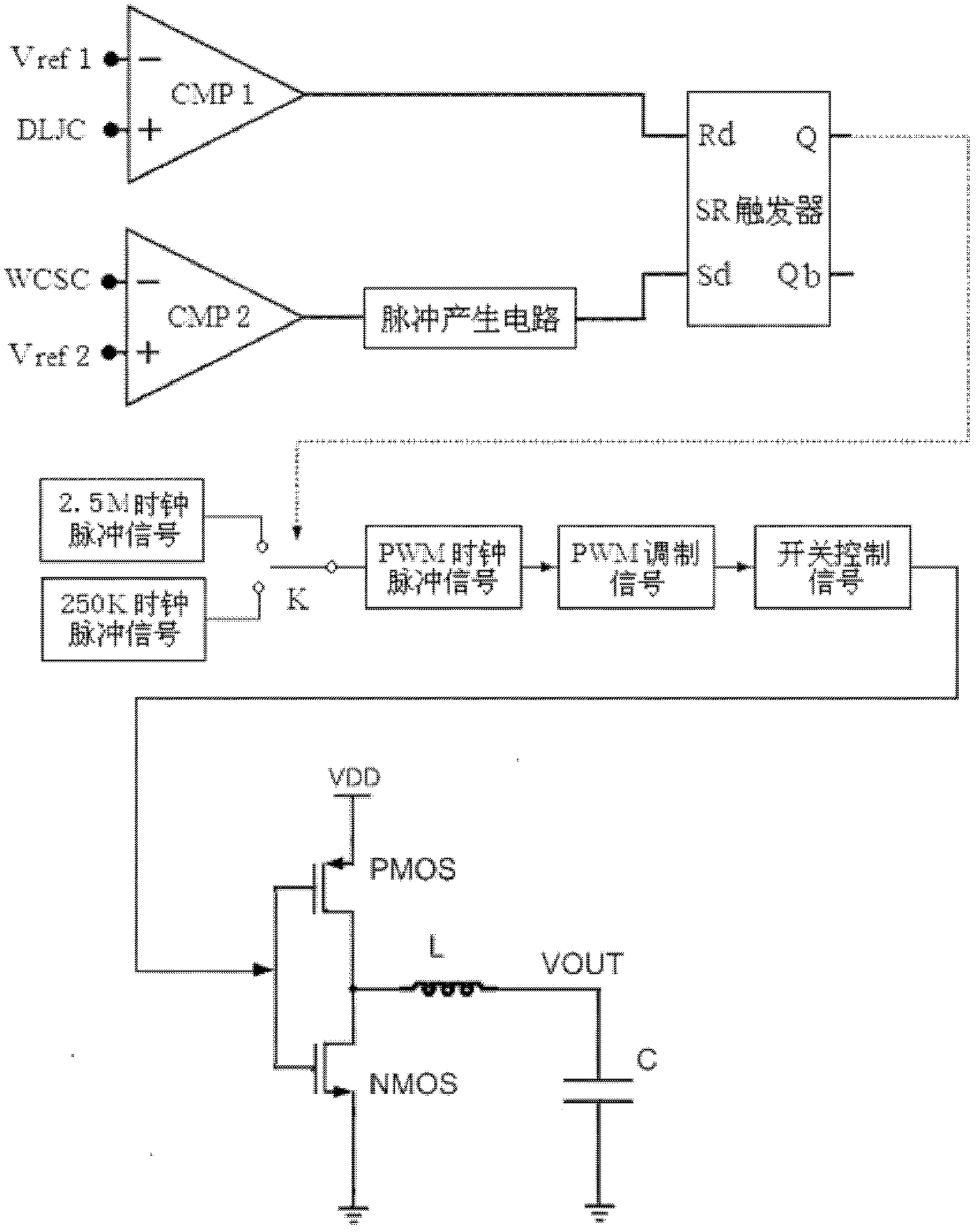

Over-current protection circuit for switch power supply

ActiveCN103311893ANot burnedShort on-timeArrangements responsive to excess currentComparatorSwitching power

The invention discloses an over-current protection circuit for a switch power supply. The over-current protection circuit comprises: a first comparator which is for comparing a current detection voltage of the switch power supply with a first reference voltage and outputting a high level or a low level based on the comparison result; a second comparator which is for comparing an error amplifier output voltage of the switch power supply with a second reference voltage and outputting a high level or a low level based on the comparison result; a pulse generation circuit which is for hopping a rising edge of an output signal of the second comparator into a short-pulse signal; and an SR trigger which is for controlling a frequency gating switch to gate a corresponding working frequency signal based on the output of the first comparator and the pulse generation circuit. With the over-current protection circuit, problem that switch power supply chips are burned out due to the over-current is prevented, reliability of the switch power supply is improved and a stable voltage output can be obtained.

Owner:SHANGHAI HUAHONG INTEGRATED CIRCUIT

High-abrasion-resisting diamond saw blade

InactiveCN108145793ANo shedding problemLow melting pointMetallic material coating processesCircular sawsBond interfaceHigh entropy alloys

The invention provides a high-abrasion-resisting diamond saw blade. Diamond single crystals are directly welded to a steel base, and main teeth and auxiliary teeth are formed. The situation of tool bit falling is avoided in the cutting process, and materials with iron nails can be cut. Due to the fact that no tool bit is additionally arranged, the problem of tool bit falling is completely avoidedin the cutting process, and the high-abrasion-resisting diamond saw blade is safe and reliable. Silver-copper-based welding powder is low in melting temperature and good in mobility. The alloy belongsto high-plasticity alloy, and due to the slow cooling process after welding, stress is fully released, and fracturing is avoided. Due to the fact that titanium and chromium are added, a film of TiC and CrC can be formed on the surface of the diamond at high temperature, and the diamond is protected from burning loss at high temperature. A thin layer of (FexCry)C can be formed on the bonding interface of chromium and the steel base, enough holding force is formed on diamond particles through the alloy bonding strength of the diamond tool bit and the steel base, and therefore the diamond cannotfall off in the cutting work. The outer surface of the diamond tool bit is coated with a layer of high-entropy alloy coating through a laser cladding method, and the abrasion resisting performance ofthe saw blade is effectively improved.

Owner:JIANGSU YOUHE TOOLS CO LTD

Electric automobile and discharge protection circuit thereof

The invention discloses an electric automobile and a discharge protection circuit thereof. The circuit comprises a discharge branch and a time delay switch, wherein the discharge branch is connected in parallel with a direct current bus power supply of the electric automobile, the discharge branch comprises a discharge resistor and a discharge switch which are connected in series, and the discharge switch is conducted when the direct current bus power supply releases voltage, and when the discharge switch is switched on, the direct current bus power supply and the ground form a loop through the discharge resistor and the discharge switch; and the time delay switch is connected with the discharge switch, and the time delay switch is used for turning off the discharge switch when the discharge switch is continuously turned on for more than a preset delay time. Even if the low voltage of the discharge control unit is powered down due to external reasons and the high voltage of the directcurrent bus battery is still continuous, the first switch included in the discharge branch can be turned off through the time delay switch, the first switch is prevented from continuously releasing the voltage of the high-voltage battery, long-time large-current operation is avoided, and the first switch is ensured not to be burnt out.

Owner:SHANGHAI ELECTRICGROUP CORP

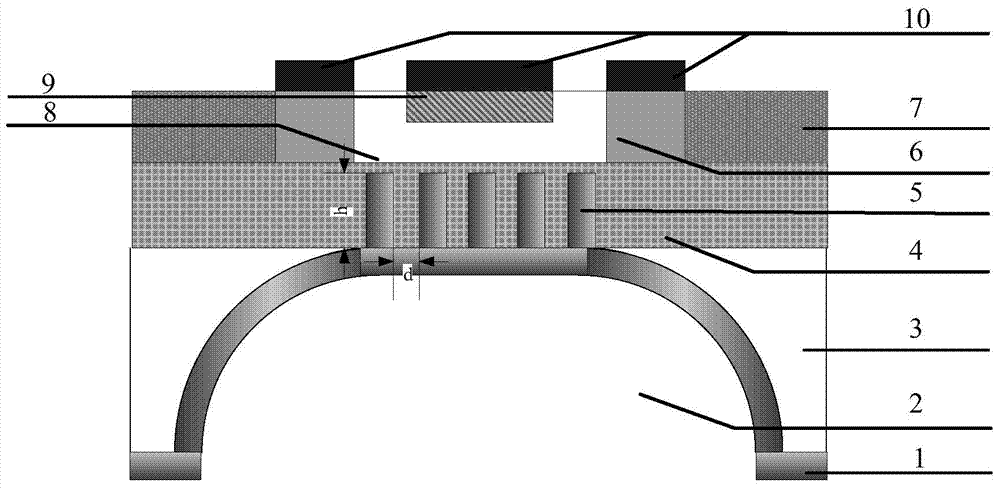

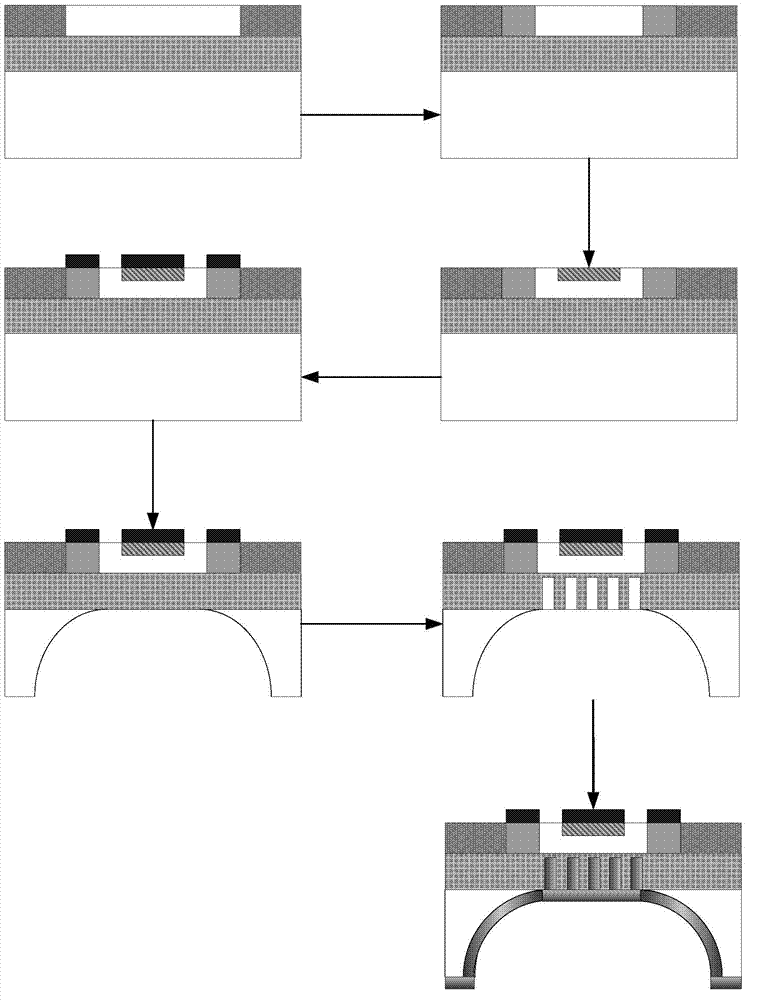

SOI CMOS technology-based radiation detector and preparation method thereof

ActiveCN103715293AInhibit the impact of performance parametersReduce volumeSemiconductor devicesIonSputter deposition

The invention provides an SOI CMOS technology-based radiation detector and a preparation method thereof. A Si film area, a source electrode or drain electrode injection area and a medium isolation area are arranged on an oxygen-buried oxidation layer in sequence from inside to outside, a body area injection area is embedded in the Si film area, and ohmic contact electrodes are arranged on the source electrode or drain electrode injection area and the body area injection area; and a Si substrate is arranged under the oxygen-buried oxidation layer, a groove with the bottom facing upwards is arranged on the Si substrate, a back gate electrode is arranged on the surface of the groove, and a back through hole metal filling area connected with the back gate electrode is arranged inside the oxygen-buried oxidation layer. The device has high radiation sensitivity, high induced charge capacity, low working gate voltage, and high reliability. The medium isolation area grows on a front side of a substrate; the source electrode or drain electrode injection area and the body area injection area are obtained by injecting ions; the ohmic contact electrodes are obtained by sputter deposition; and a detection window area and the back through hole area are etched on the reverse side of the substrate and are filled with metal. The method is simple in technology, good in repeatability, and low in cost, and is easy to be integrated with the manufacturing technology of an existing large scale integrated circuit.

Owner:NO 771 INST OF NO 9 RES INST CHINA AEROSPACE SCI & TECH

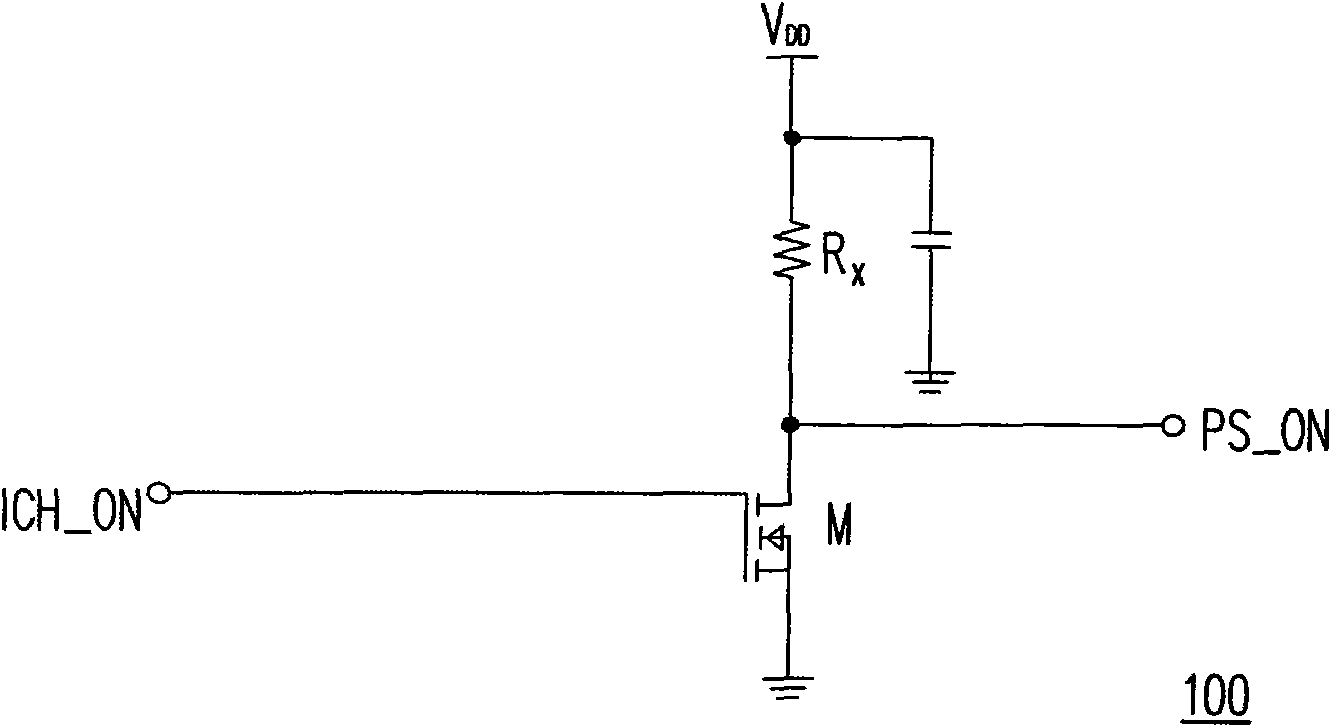

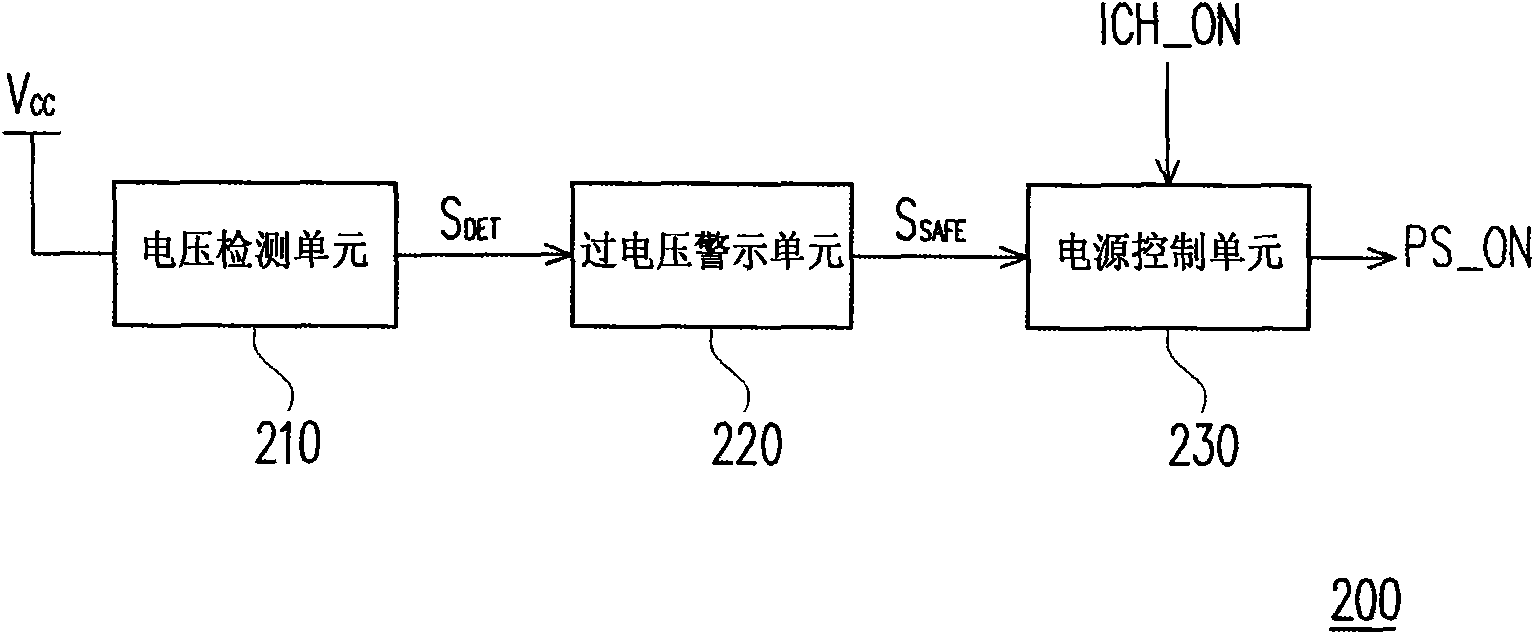

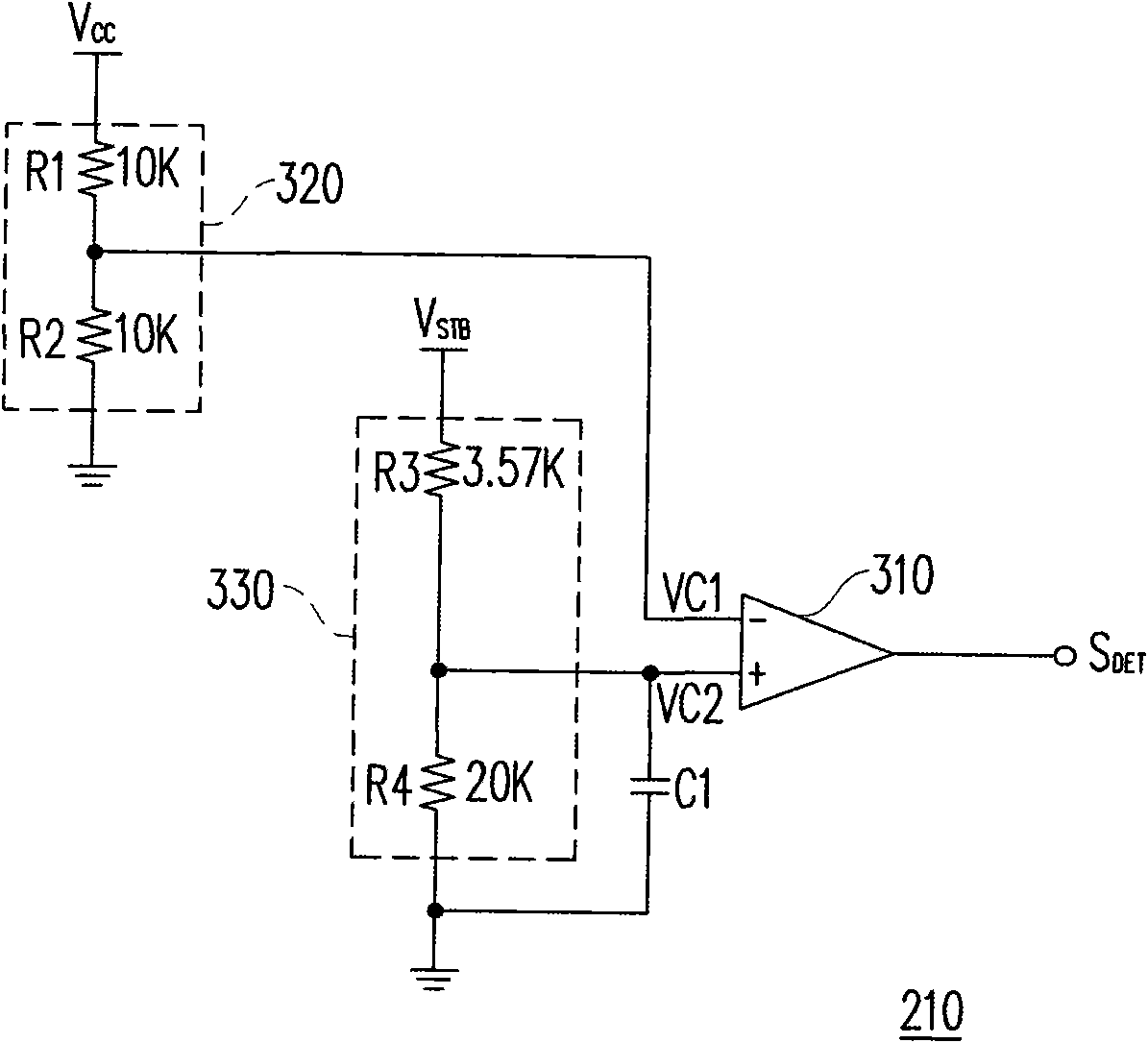

Over-voltage protection device

The invention relates to an over-voltage protection device which comprises a voltage detection unit, an over-voltage warning unit and a power control unit. When a system voltage is greater than a preset voltage, the voltage detection unit outputs a first logic or outputs a second logic; the over-voltage warning unit is coupled with the voltage detection unit and generates a voltage safety signal according to the output of the voltage detection unit; when the voltage detection unit outputs the first logic, the over-voltage warning unit carries out over-voltage warning; the power control unit is coupled with the over-voltage warning unit and receives a power driving signal; and when the voltage detection unit outputs the second logic and the power driving signal is enabled, the power control unit outputs a power enabling signal with a fourth logic according to the voltage safety signal so as to start a power supply, or the power control unit outputs a power enabling signal with a third logic so as to stop the power supply.

Owner:XINJIANG BAZHOU ELECTRIC POWER

Method for removing carbon in high-carbon copper-containing molten iron through injection of carbon dioxide

The invention provides a method for removing carbon in high-carbon copper-containing molten iron through injection of carbon dioxide and belongs to the field of metallurgy. The method comprises the following steps that firstly, the high-carbon copper-containing molten iron is guided into an induction furnace; secondly, carbon dioxide gas is injected into the high-carbon copper-containing molten iron, and stirring is conducted; thirdly, when the mass percent of the carbon in the high-carbon copper-containing molten iron is smaller than or equal to 0.2%, injection is stopped; and fourthly, carbon monoxide is post-processed to generate carbon dioxide, the carbon dioxide is recycled, and the copper-containing molten iron is separated from slag. According to the method, the injected carbon dioxide reacts with the carbon in the melt to generate carbon monoxide, after escaping, the carbon monoxide is combusted to regenerate the carbon dioxide, and the carbon dioxide returns to be used; and besides, the carbon dioxide is a weak-oxidation gas and cannot react with copper, and the carbon dioxide further has the dephosphorizing function and the desiliconization function. By the adoption of the method for removing the carbon in the high-carbon copper-containing molten iron through injection of the carbon dioxide, the technology is simple, a stirring system is additionally arranged in the induction furnace, energy is saved, environmental friendliness is achieved, the cost is low, the greenhouse gas is utilized, and therefore the high economic value and the good environmental protection function are achieved; and the purpose of removing the carbon is achieved, and the copper element in the high-carbon copper-containing molten iron can be protected against the burning loss.

Owner:NORTHEASTERN UNIV

Method and device for burning coal slime in circulating fluidized bed boiler

ActiveCN102032557AImprove combustion efficiencyNot burnedFluidized bed combustionApparatus for fluidised bed combustionCirculating fluidized bed boilerProcess engineering

The invention relates to a method and device for burning coal slime in a fluidized bed boiler. When the coal slime is burned in a medium and small-capacity circulating fluidized bed boiler, the way of feeding at the top of a furnace chamber is adopted; as the feeding point of the coal slime is near to the outlet of the furnace chamber, a large amount of the coal slime can fly out of the furnace chamber under the situation that the coal slime is not burned completely, and the burning efficiency is very low. The invention discloses the method for burning the coal slime in the circulating fluidized bed boiler, and the technical process of the method is as follows: sending the pasty coal slime into a dense phase region at the lower part of the furnace chamber of the circulating fluidized bed boiler, utilizing a device for burning the coal slime in the circulating fluidized bed boiler to smash the falling coal slime into small particles and disseminate the particles into the furnace chamber, mixing the coal slime with ascending smoke gas and recyclable materials, and then burning in the furnace chamber. The method and the device are used for burning the coal slime in the circulating fluidized bed boiler.

Owner:HARBIN BOILER

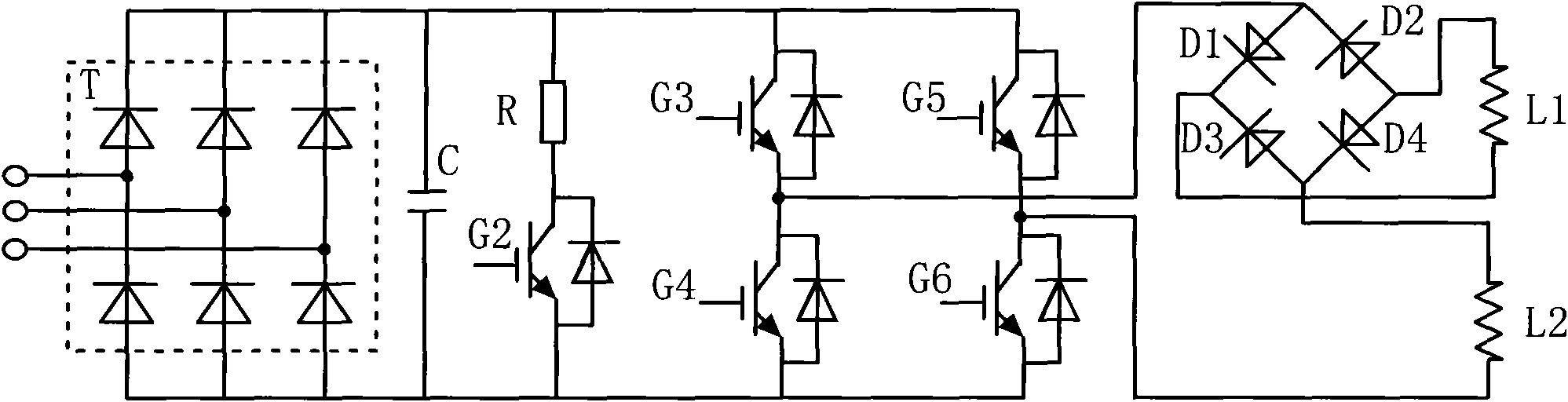

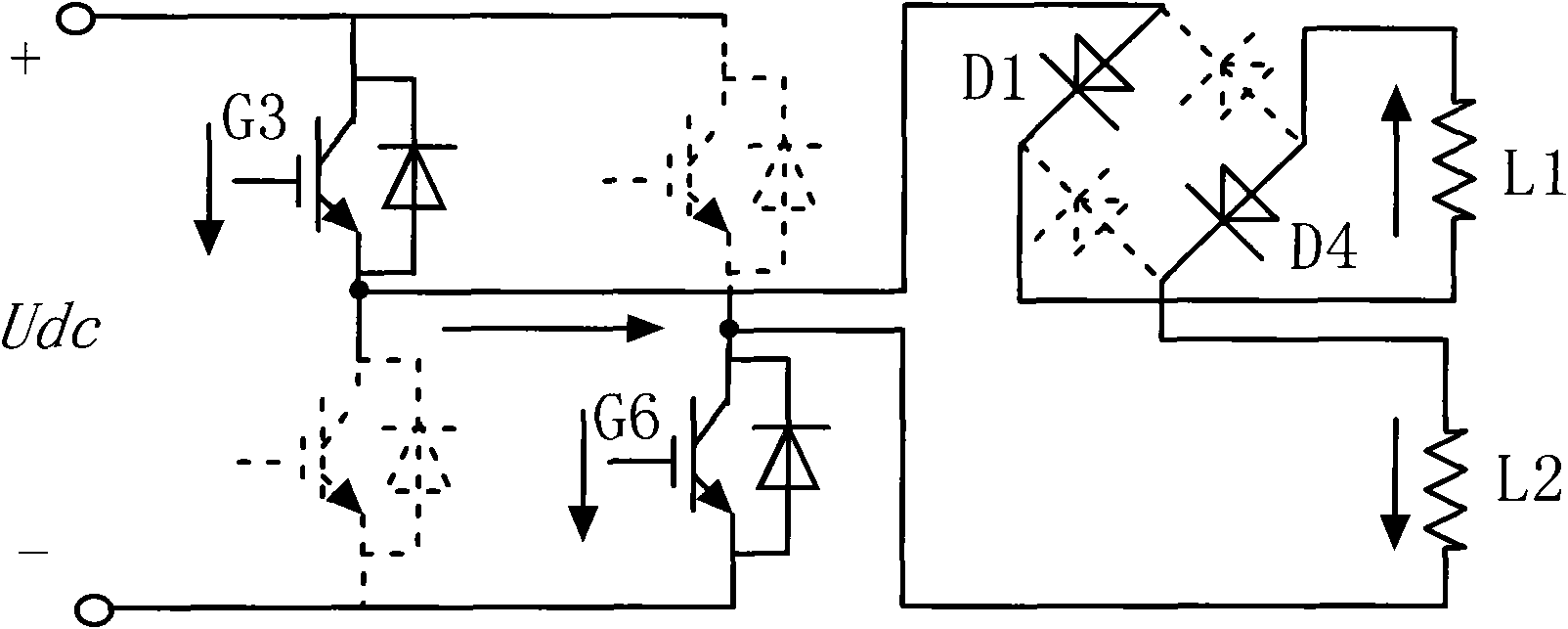

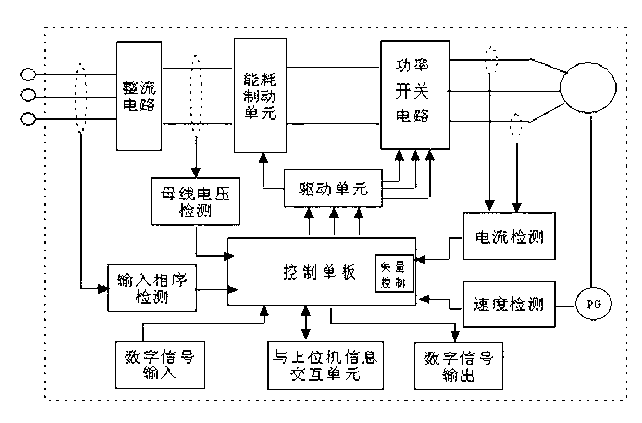

Vector control based driving device of alternating current motor for pitch control system

InactiveCN102832871AImprove reliabilityHigh control precisionVector control systemsSingle motor speed/torque controlAlternating currentDigital signal

The invention provides a vector control based driving device of an alternating current motor for pitch control. The driving device comprises a power loop part and a control loop part, wherein the power loop part comprises a rectifying unit, an energy consumption brake unit, a power switch circuit, an alternating current input phase sequence detection unit and a bus voltage and output current detection unit, the control loop part comprises an analog signal sampling unit, a digital signal input sampling circuit, a speed signal acquisition unit, a digital signal output unit and a unit for information interaction with an upper computer, etc. In control, a vector control technology is adopted. The vector control based driving device has a same good control effect as that of a direct current driver and is excellent in dynamic property and suitable for controlling an alternating motor for a high-power pitch control system. Compared with the direct current driver at the same power level, the vector control based driving device is low in cost and is improved in both control performance and reliability.

Owner:SUZHOU NENGJIAN ELECTRIC

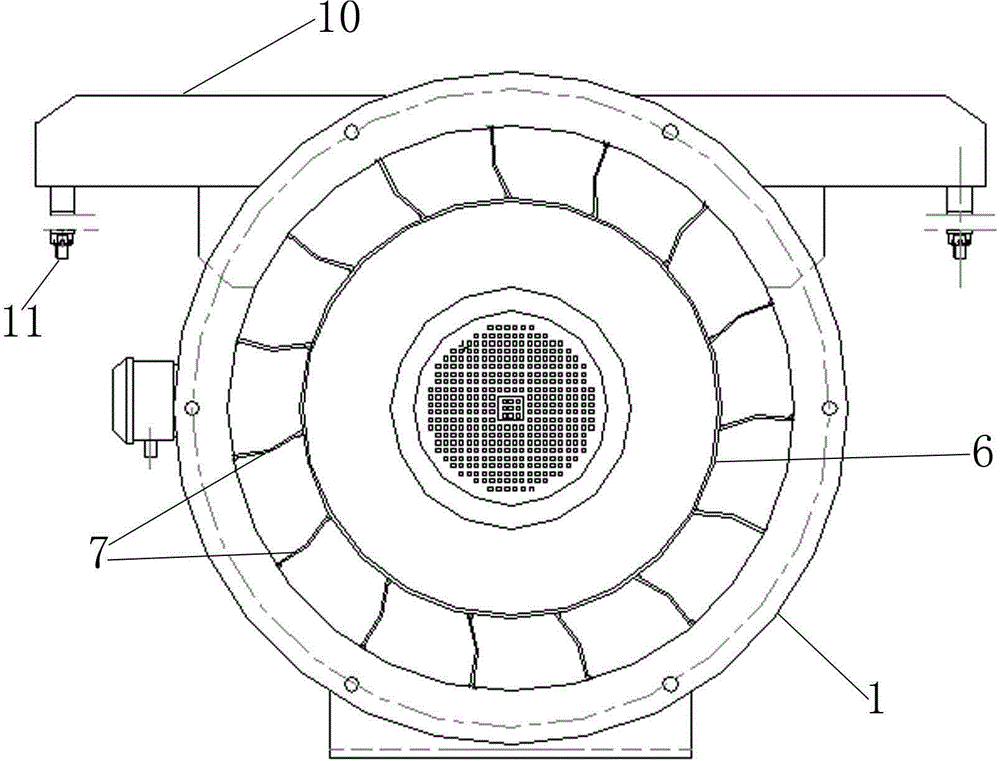

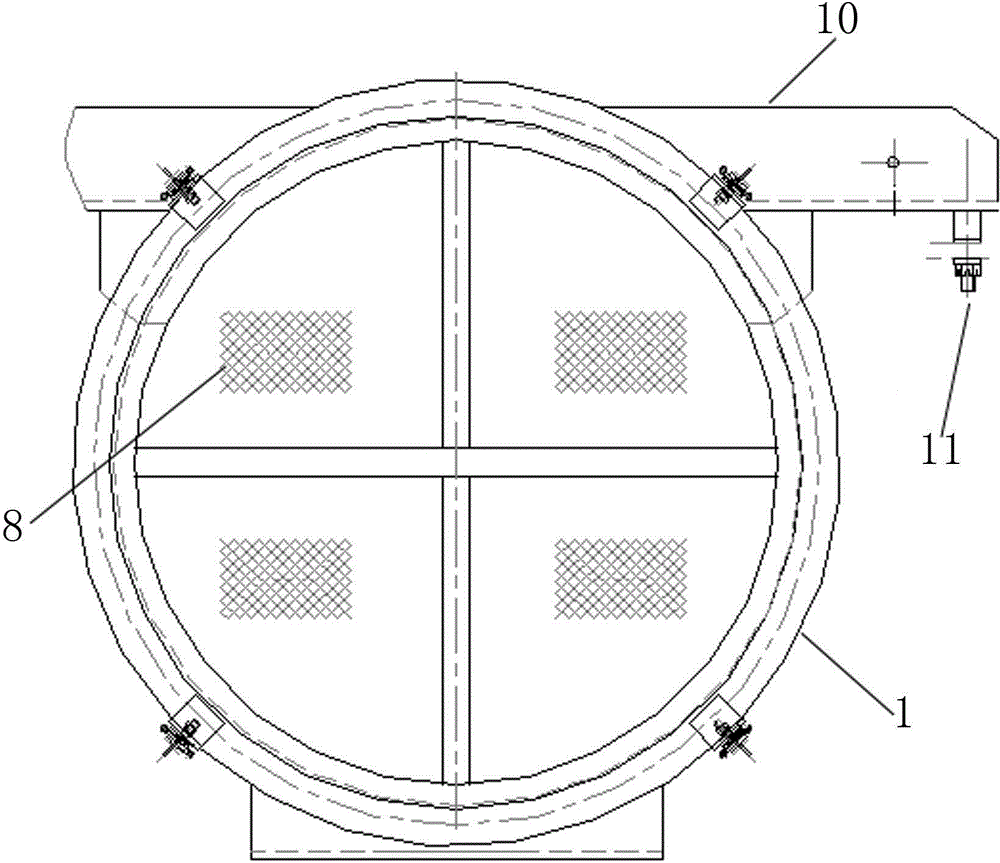

Inclined flow ventilator for subway locomotive filter reactor

InactiveCN103334940AImprove flow coefficientHigh pressure coefficientPump componentsPump installationsImpellerAir volume

The invention relates to a ventilator, in particular to an inclined flow ventilator for a subway locomotive filter reactor. By using the inclined flow ventilator, the technical problems that the air volume of the ventilator for the current subway locomotive filter reactor is not high, the air-out is not stable are solved. The inclined flow ventilator for the subway locomotive filter reactor comprises a barrel-shaped enclosure, wherein a guide cylinder, a centrifugal impeller and a motor driving the centrifugal impeller are arranged inside the enclosure in sequence; the rotating shaft of the centrifugal impeller is parallel with the axial direction of the enclosure; the projection of blades of the centrifugal impeller on a vertical plane on which the normal of the blades is vertical to the axial direction of the enclosure forms an included angle of 20-40 degrees with the vertical direction; the included angle faces to the air-out direction; the guide cylinder is in a structure contracting inwards; and the distance between the contracting end of the guide cylinder and the center axis of the enclosure is smaller than the spacing between the top ends of the blades of the centrifugal impeller and the central axis of the enclosure. Due to the combination of the centrifugal impeller and the axial flow enclosure, the air volume is high, the air-out is stable, and the filter reactor is guaranteed to work under normal temperature when a subway locomotive operates.

Owner:CRRC YONGJI ELECTRIC CO LTD

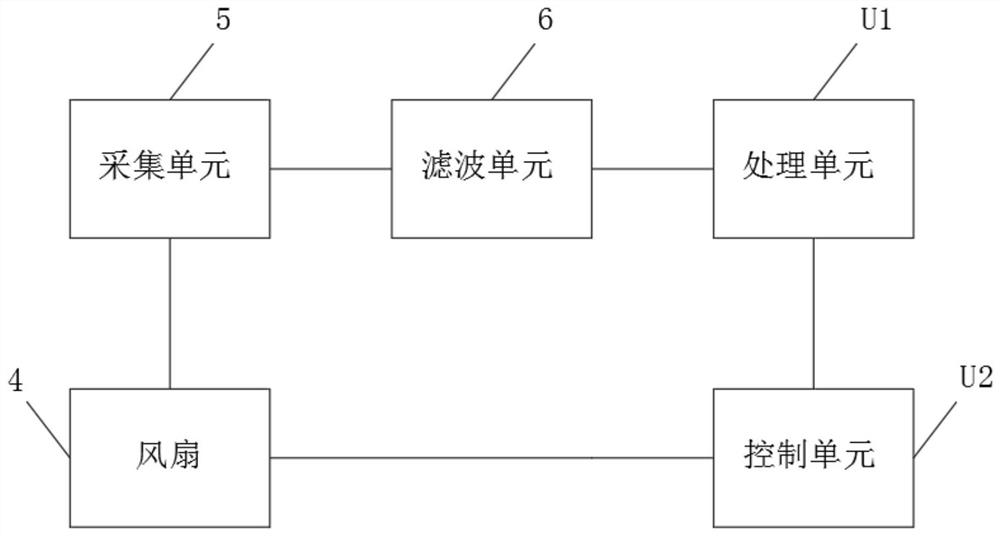

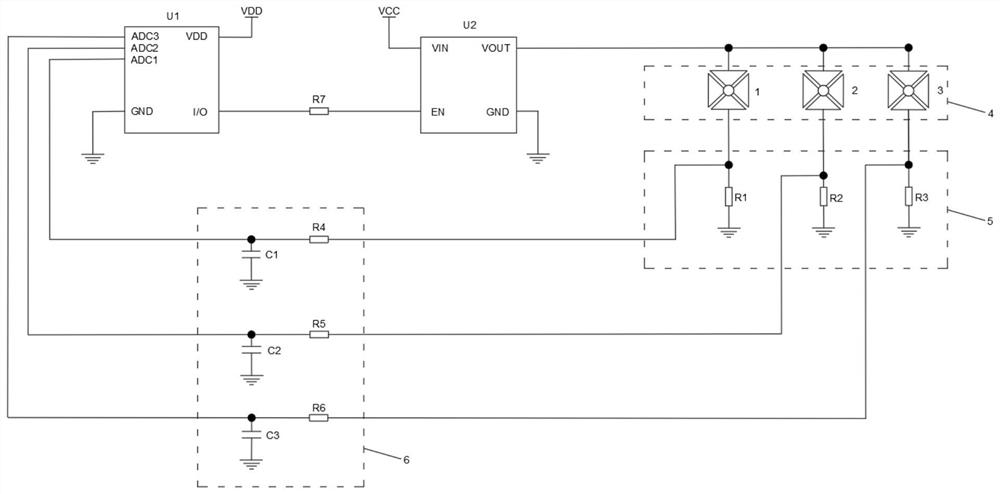

Ion fan protection circuit

PendingCN113225885AAvoid short circuitNot burnedArrangements responsive to excess currentElectrostatic chargesReference currentControl cell

The embodiment of the invention provides an ion fan protection circuit. The ion fan protection circuit comprises an acquisition unit, a filtering unit and a processing unit; the acquisition unit is connected with a fan group, acquires a current signal of the fan group and transmits the current signal to the filtering unit; the filtering unit is connected between the acquisition unit and the fan group, receives the current signal, filters the current signal and transmits the filtered current signal to the processing unit; and the processing unit is connected with the filtering unit and the control unit, receives the filtered current signal, and sends an enable signal to the control unit when the current value of the current signal exceeds a reference current value, so that the control unit stops supplying power to the fan group. The operation states of the multiple fans can be monitored in real time through the acquisition unit, the filtering unit and the processing unit, when any fan operates abnormally, the processing unit sends out an instruction in time to turn off the output of the control unit, short circuit of a circuit is avoided, and a host is protected from being burnt by current.

Owner:SHENZHEN BAIGUANG ELECTRONIC TECH CO LTD

Water cooling type sample bracket for high enthalpy airflow

ActiveCN109632866ANot burnedSafe and smooth connectionMaterial thermal analysisEngineeringTest requirements

The invention relates to a water cooling type sample bracket for a high enthalpy airflow. The water cooling type sample bracket for the high enthalpy airflow comprises a shell, a first closed part, asecond closed part, a support part and a bottom plate; the shell comprises an outer shell and an inner shell; the outer shell is provided with a first water inlet and a first water outlet; a hollow interlayer is between the outer shell and the inner shell; two ends of the hollow interlayer are closed; the hollow interlayer comprises a front area, a middle area and a rear area; the middle area is separated into an upper cavity and a lower cavity by two first stop parts arranged along the length direction of the shell; the front area forms an annular water cavity, and is communicated with the front ends of the upper cavity and the lower cavity; the rear end of the upper cavity is communicated with the rear area; and a sealing part is arranged between the rear end of the lower cavity and therear area, and used for sealing. The water cooling type sample bracket can be used for supporting a thermal protective material, so that ultra-long-time (greater than or equal to 2500 s) oxidation ablation behaviour research can be smoothly completed; and thus, the use performance test requirement of the thermal protective material of a hypersonic vehicle can be satisfied.

Owner:中国空气动力研究与发展中心超高速空气动力研究所

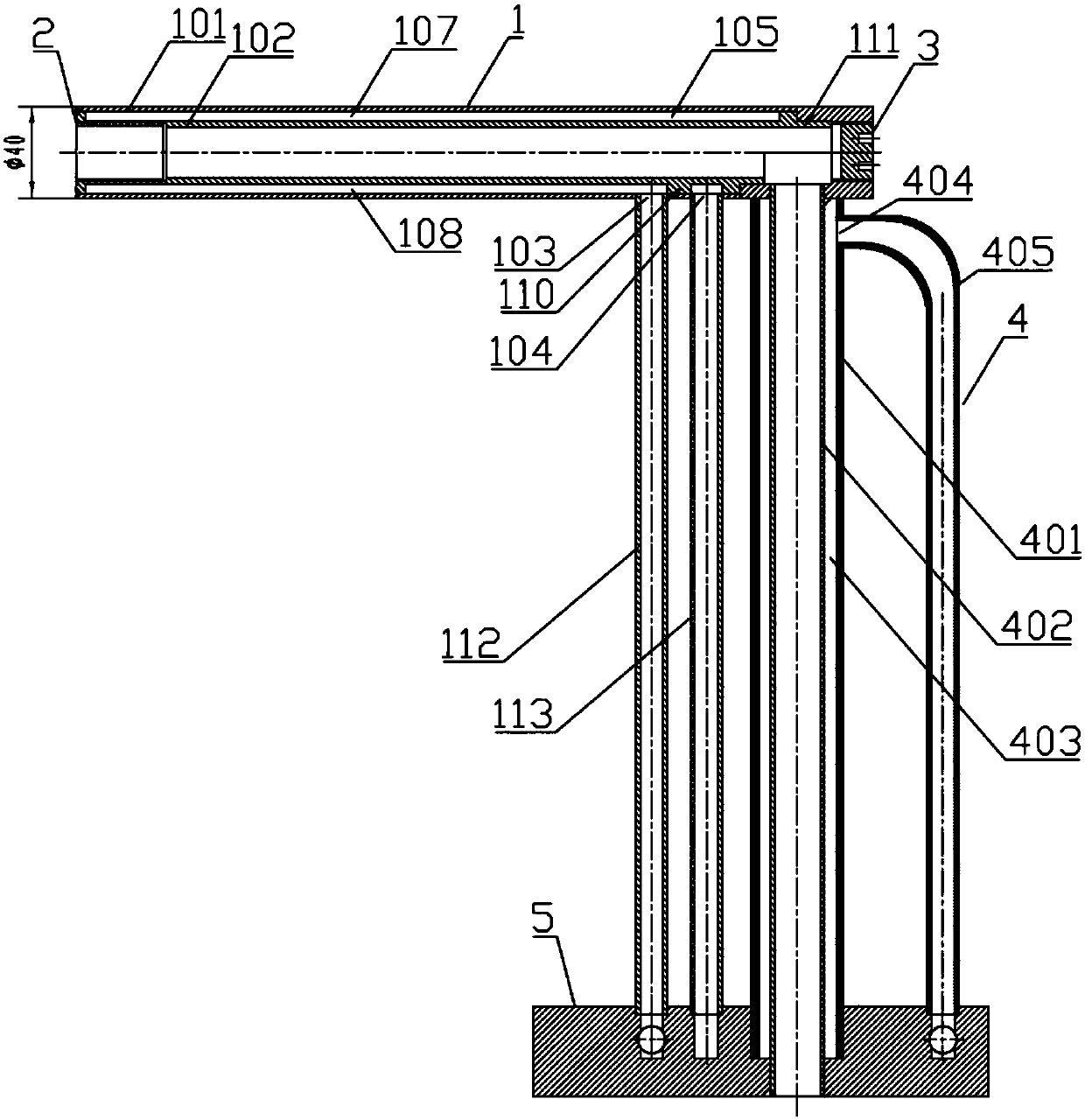

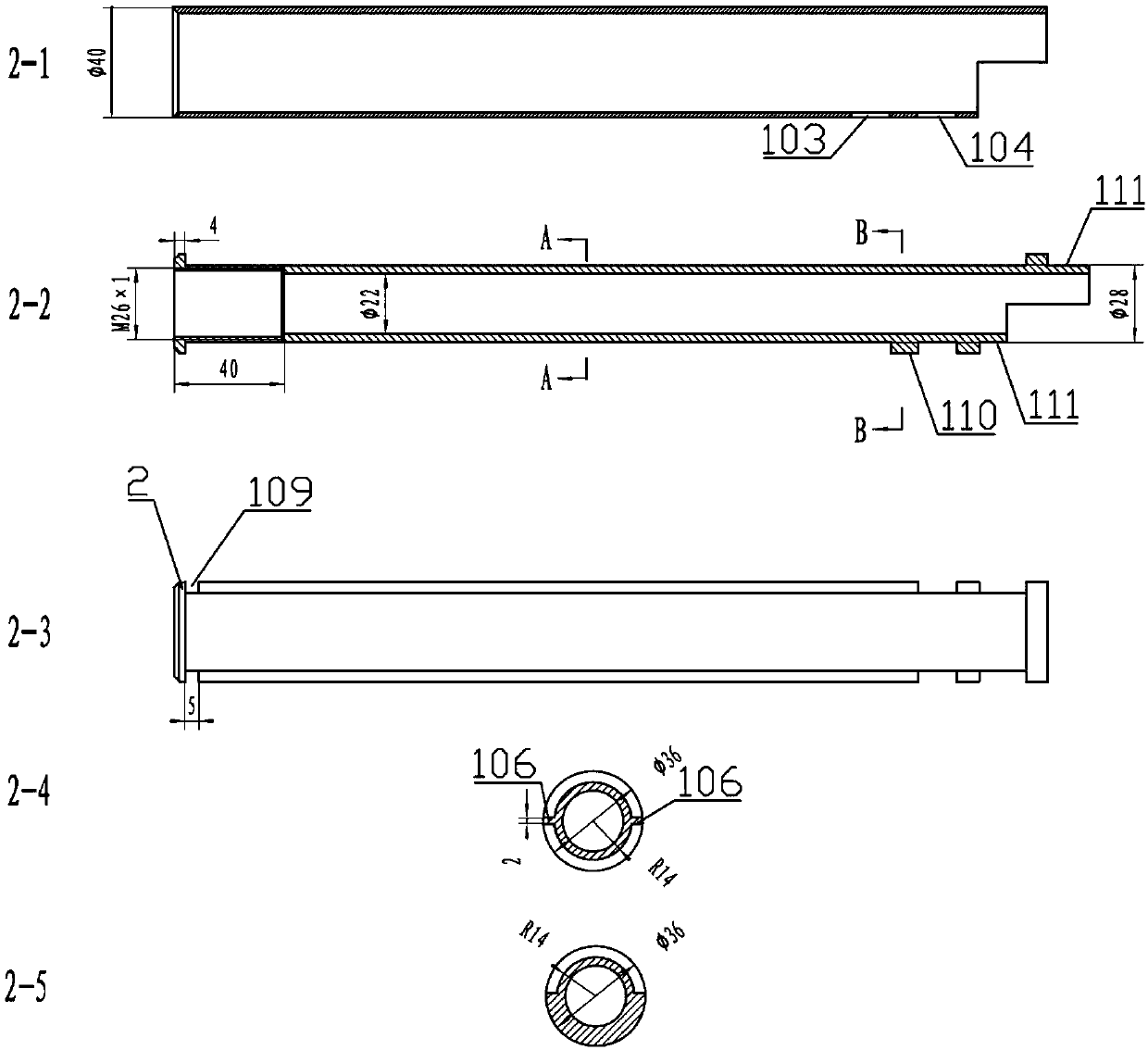

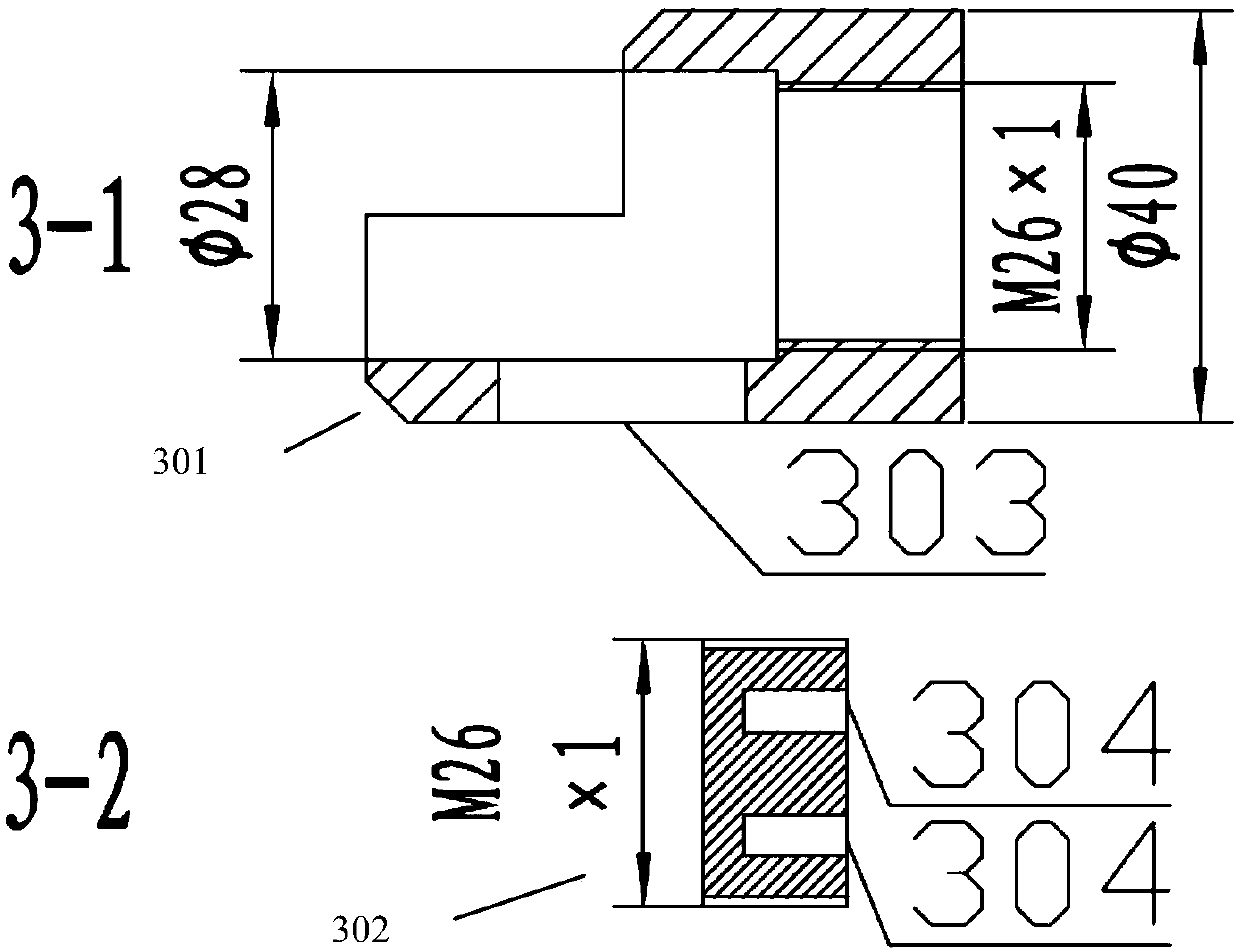

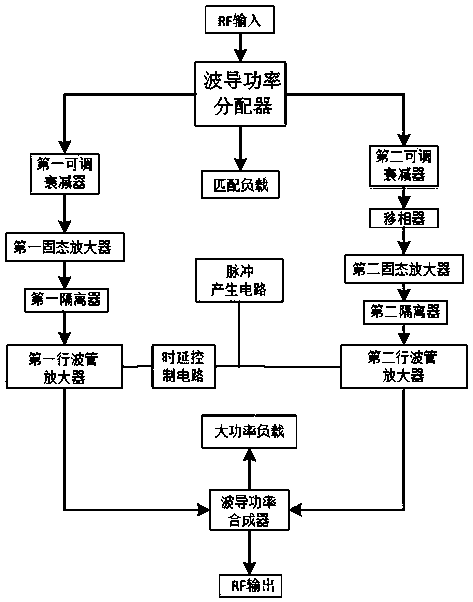

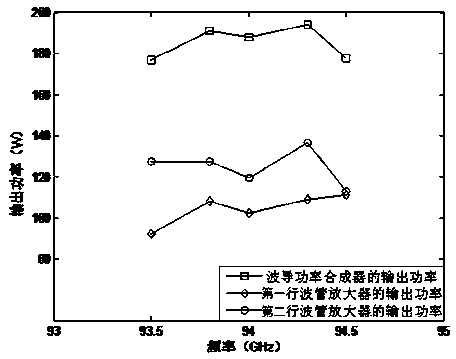

W-waveband pulse traveling-wave tube high-power combination system

InactiveCN103929158ARealization of high power synthesisNot burnedSingle output arrangementsPower combinerIsolator

The invention belongs to the technical field of millimeter waves and particularly relates to a W-waveband pulse traveling-wave tube high-power combination system. The system comprises a waveguide power divider, a first adjustable attenuator, a first solid-state amplifier, a first isolator, a first traveling-wave tube amplifier, a second adjustable attenuator, a phase shifter, a second solid-state amplifier, a second isolator, a second traveling-wave tube amplifier and a waveguide power combiner. According to the W-waveband pulse traveling-wave tube high-power combination system, high-power combination of a W-waveband two-way pulse traveling-wave tube is achieved technically, the two ways are respectively provided with an isolator, and therefore the solid-state amplifiers can be prevented from being burnt; the same signal source power is divided into two through the power divider with the output phase difference of 90 degrees, a 90-degree phase difference exists between the two ways to prevent mutual interference and self excitation of the two traveling-wave tube amplifiers, and a 90-degree phase difference exists between two inputs of the power combiner to guarantee effective combination of two ways of power.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

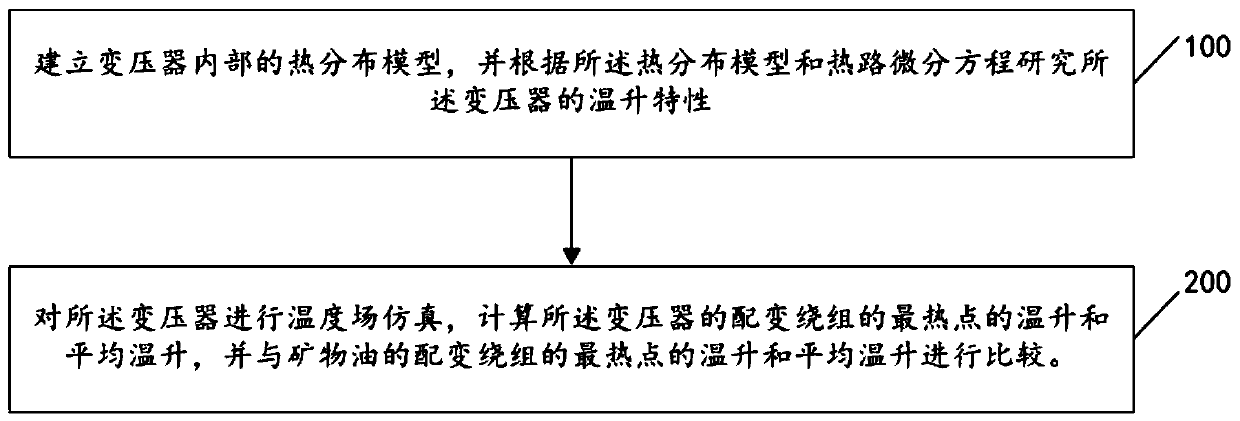

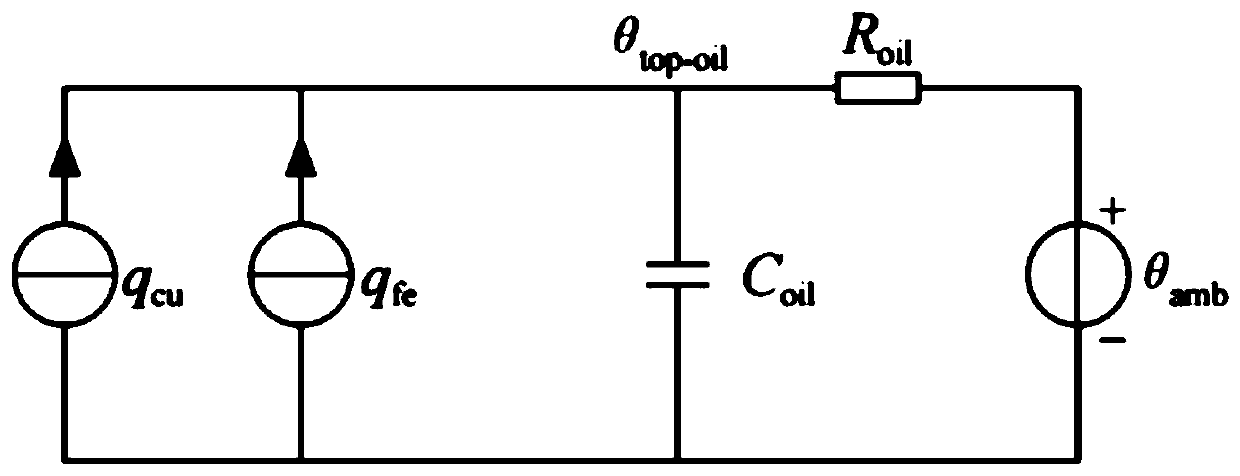

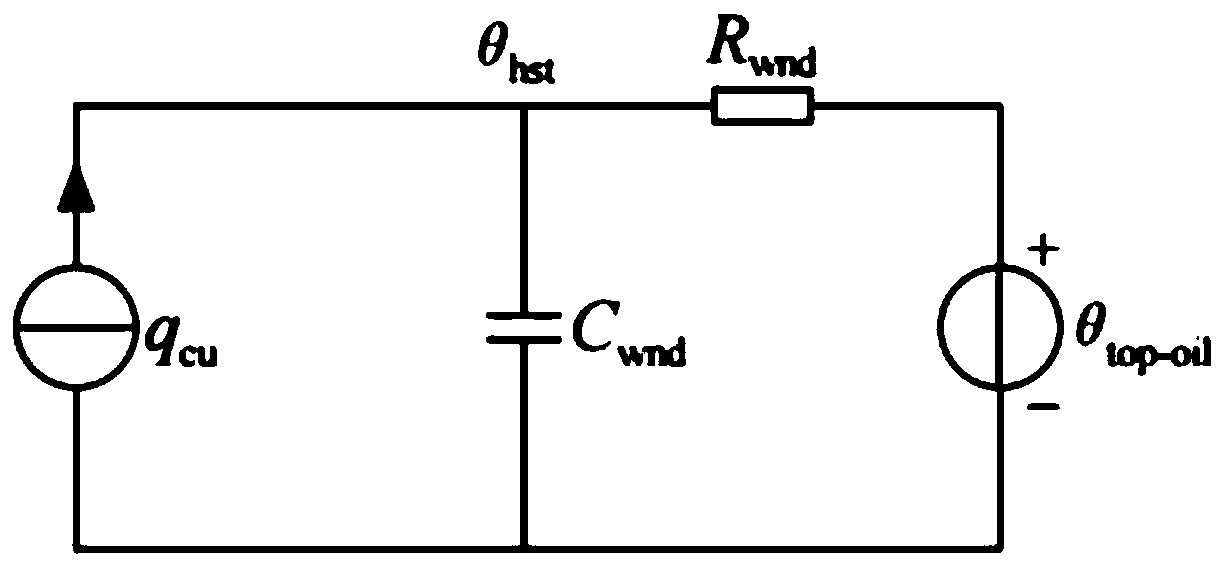

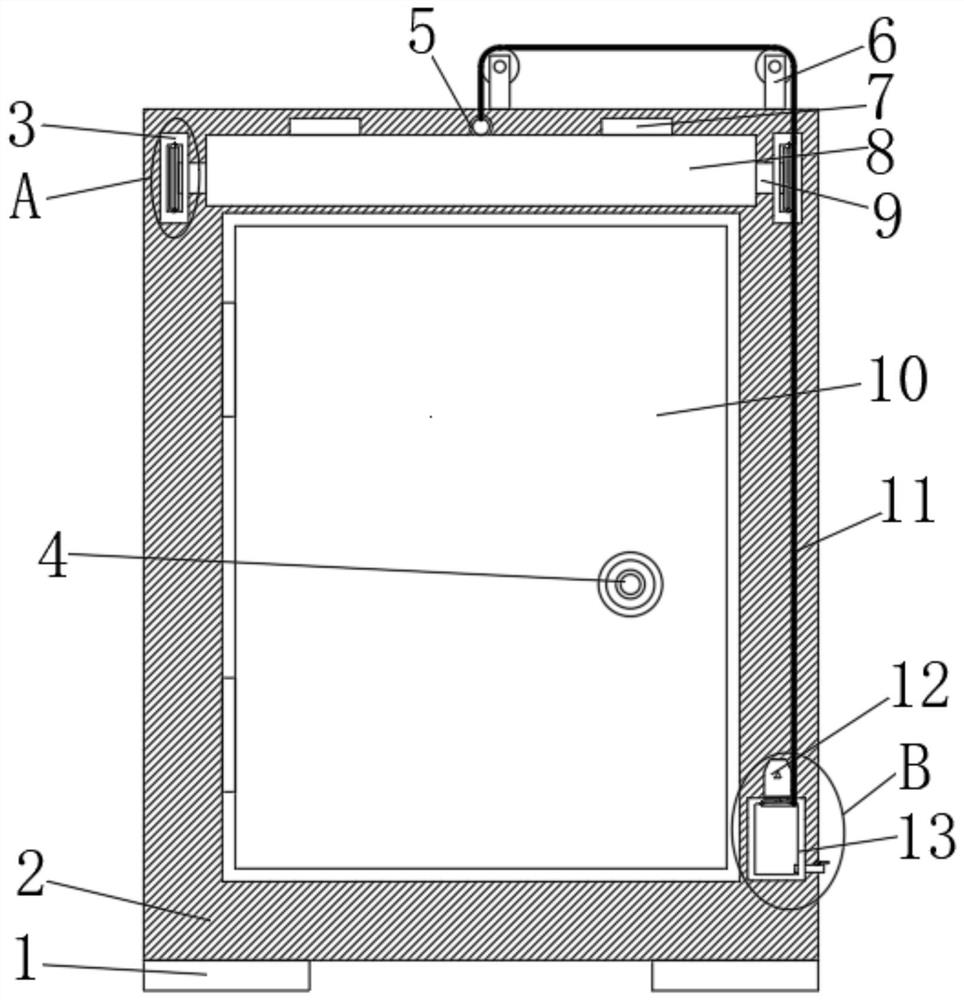

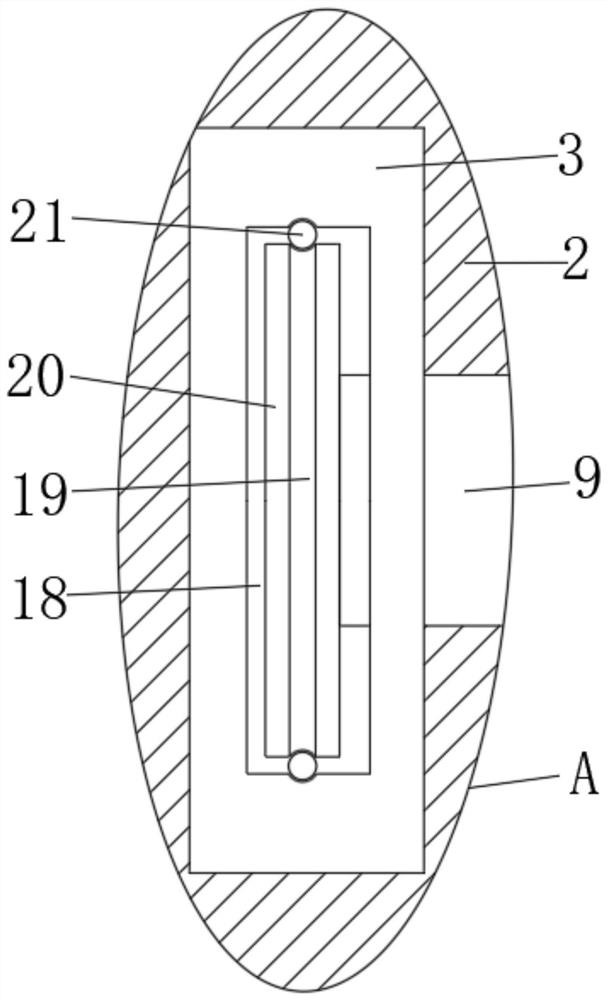

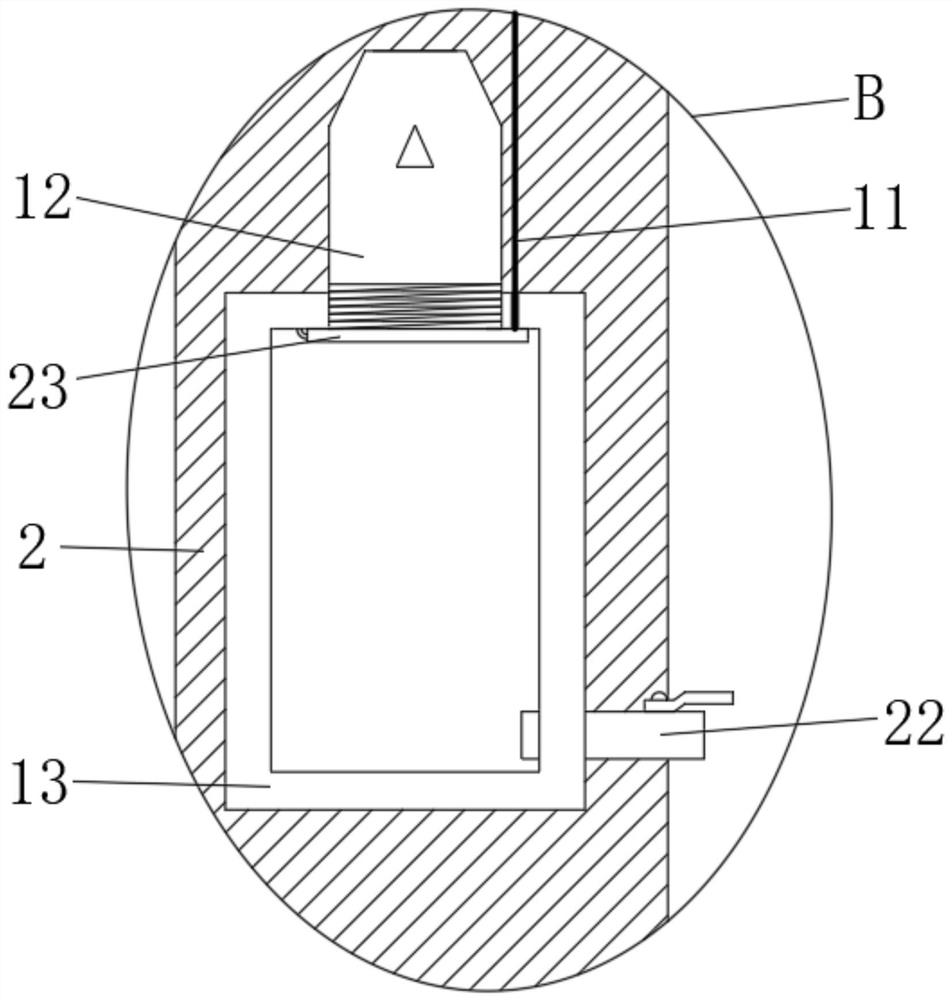

Dynamic protection constant value setting method and device, equipment and storage medium

PendingCN111398864ANot burnedThermometers using mean/integrated valuesElectric devicesPhysicsHeat distribution

The invention discloses a dynamic protection constant value setting method, device and equipment and a storage medium, and the method comprises the steps: building a heat distribution model in a transformer, and researching temperature rise characteristics of the transformer according to the heat distribution model and a thermal circuit differential equation; and performing temperature field simulation on the transformer, calculating the temperature rise and the average temperature rise of the hottest point of a distribution transformer winding of the transformer, and comparing the temperaturerise and the average temperature rise with the temperature rise and the average temperature rise of the hottest point of the distribution transformer winding of mineral oil. According to the application, the technical problems that an existing low-voltage main switch protection technology cannot effectively play the role of the high-overload-capacity distribution transformer when the rated current value is set, and the high-overload-capacity distribution transformer cannot bear the impact of long-time overload and is damaged if the set current value is too high are solved.

Owner:GUANGDONG UNIV OF TECH

Efficient storage medium and equipment for resource deployment in Internet of Things

The invention discloses an efficient storage medium and equipment for resource deployment in the Internet of Things. The efficient storage medium and equipment for resource deployment in the Internetof Things comprise a cabinet body, the cabinet body is rotatingly connected with a cabinet door, the side wall of the cabinet door is fixedly connected with a handle, the side wall of the cabinet bodyis fixedly connected with two fixed plates, each fixed plate is rotatingly connected with a rotating shaft, a fireproof blanket is arranged on the side walls of the rotating shafts in a winding mode,one end of the fireproof blanket is fixedly connected to the rotating shafts, the other end of the fireproof blanket is fixedly connected with two balancing weights, the other end of the fireproof blanket is fixedly connected with a pull ring, the pull ring is fixedly connected with a pull rope, the upper side of the cabinet body is fixedly connected with two sliding wheels, the pull rope sequentially penetrates through the two sliding wheels, and the side wall of the cabinet body is fixedly connected with a sound production device. The efficient storage medium and equipment for resource deployment in the Internet of Things are reasonable in design and ingenious in conception, a data storage cabinet can be protected from being burnt out in a fire disaster, the data safety is guaranteed, the practicability is high, and efficient storage medium and equipment for resource deployment in the Internet of Things are suitable for popularization.

Owner:华盈智优(常州)数据科技有限公司

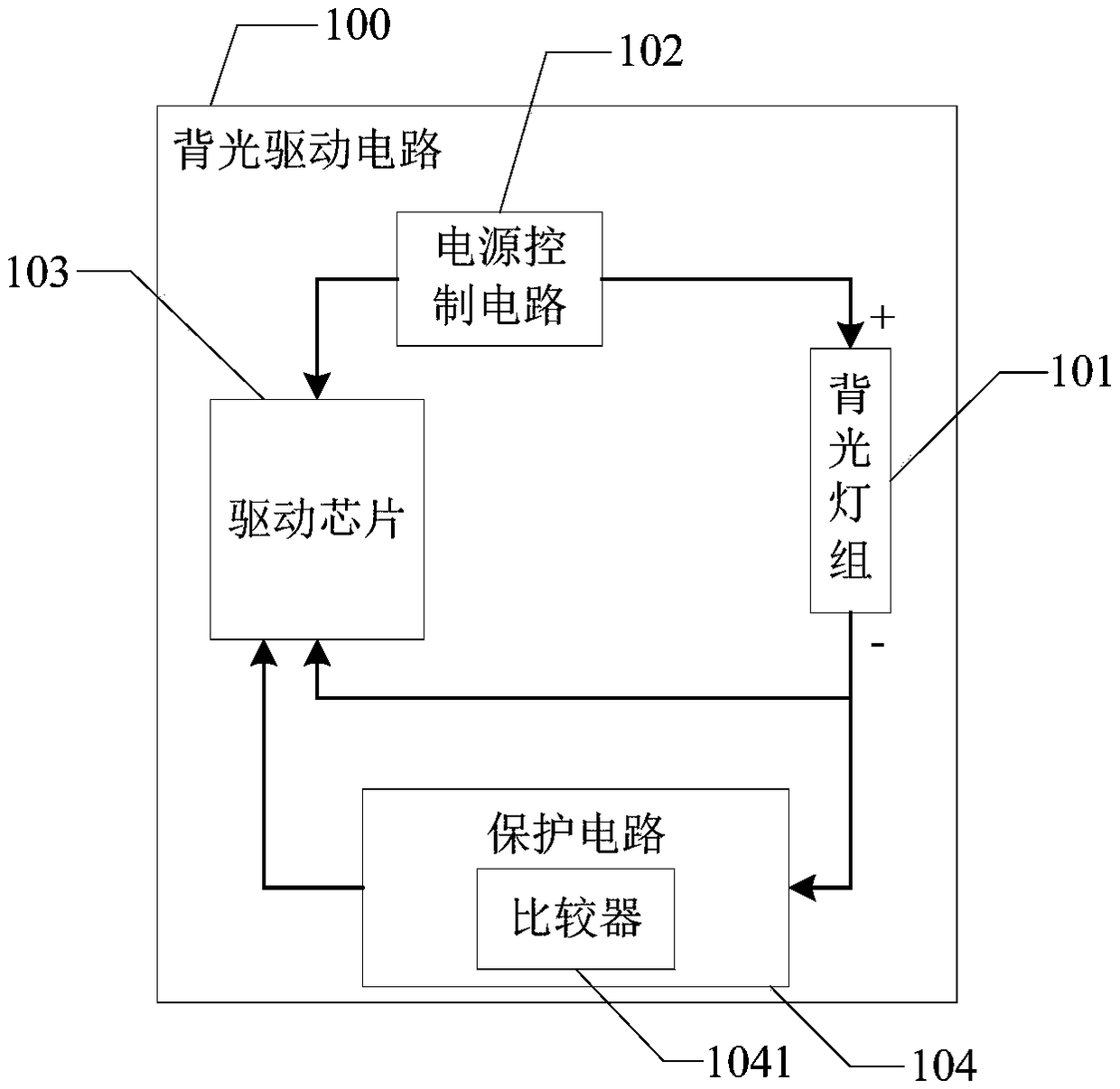

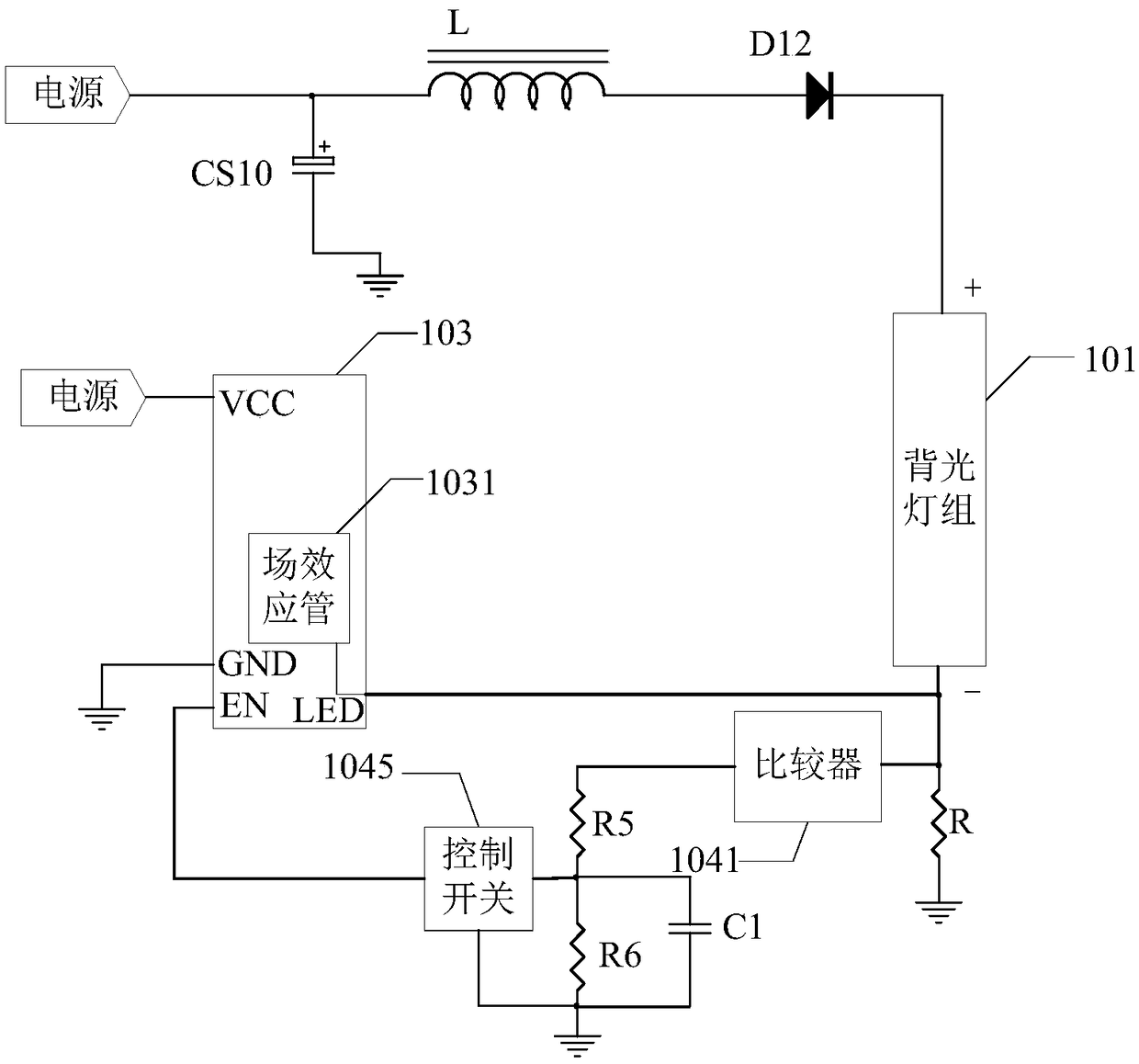

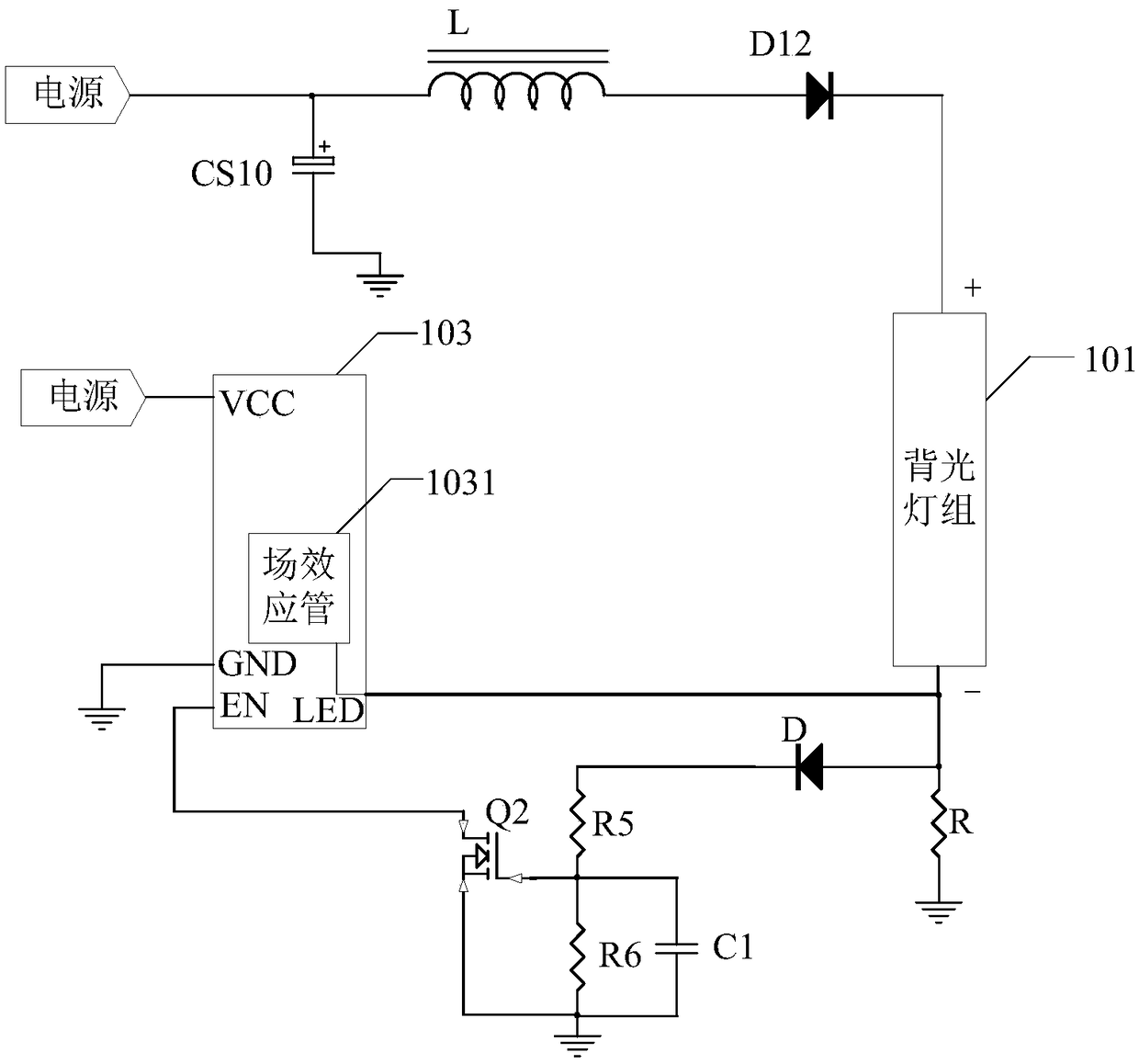

Backlight driving circuit, driving method and display device of display device

The embodiment of the present application provides a backlight driving circuit of a display device, a driving method and a display device. The backlight driving circuit comprises a backlight lamp group, a positive electrode of the backlight lamp group is connected with a power supply control circuit, and a negative electrode of the backlight lamp group is connected with a driving output terminal pin of a driving chip. A power control circuit connected with the backlight lamp group; a driving chip, wherein the driving output terminal pin of the lamp group of the driving chip is connected with the negative electrode of the backlight lamp group; the protection circuit comprises a comparator, an input end of the protection circuit is connected with a negative electrode of the backlight lamp group, an output end of the protection circuit is connected with an enabling end of the driving chip, and when the comparator judges the the circuit current is greater than a protection threshold value,the protection circuit controls the driving chip to stop working; by controlling the level signal at the enable terminal, the driver chip stops working, and the driver chip is protected from being burned when the backlight driver circuit is short-circuited or the current is too large.

Owner:HEFEI HUIKE JINYANG TECH

Generator rotor and production method thereof

InactiveCN101369752AHigh mechanical strengthFrictionlessWindings insulation shape/form/constructionApplying solid insulationStatorInsulation layer

An engine rotor includes a principal shaft, a rotor core, a coil and an insulating bracket cover; the rotor iron is mounted on the principal shaft, and is provided with a groove on the outer circumference surface; the coil is arranged in the groove of the rotor core; the insulating bracket cover is covered on two ends of the rotor core, and the insulating bracket cover is coated with high temperature resistant insulation layer outside. A method for manufacturing the same includes the steps of mounting the rotor core on the principal shaft firstly, then embedding the coil into the groove of the rotor core and linking the coil joints, banding the joints with insulating tapes well, casing the insulating bracket cover on the rotor core end section, and then coating the high temperature resistant insulation layer outside the insulating bracket cover, finally making the bracket cover and the coil end section to form one body by means of dipping paint and high-temperature bake. The structure of the invention intensify greatly the mechanical strength of the rotor coil end section, and the coil end section is not easy to disassemble to throw out the core groove, which ensures non friction between the rotor and the stator, and ensure the generator from being burned.

Owner:GUANGZHOU ENGGA GENERATORS

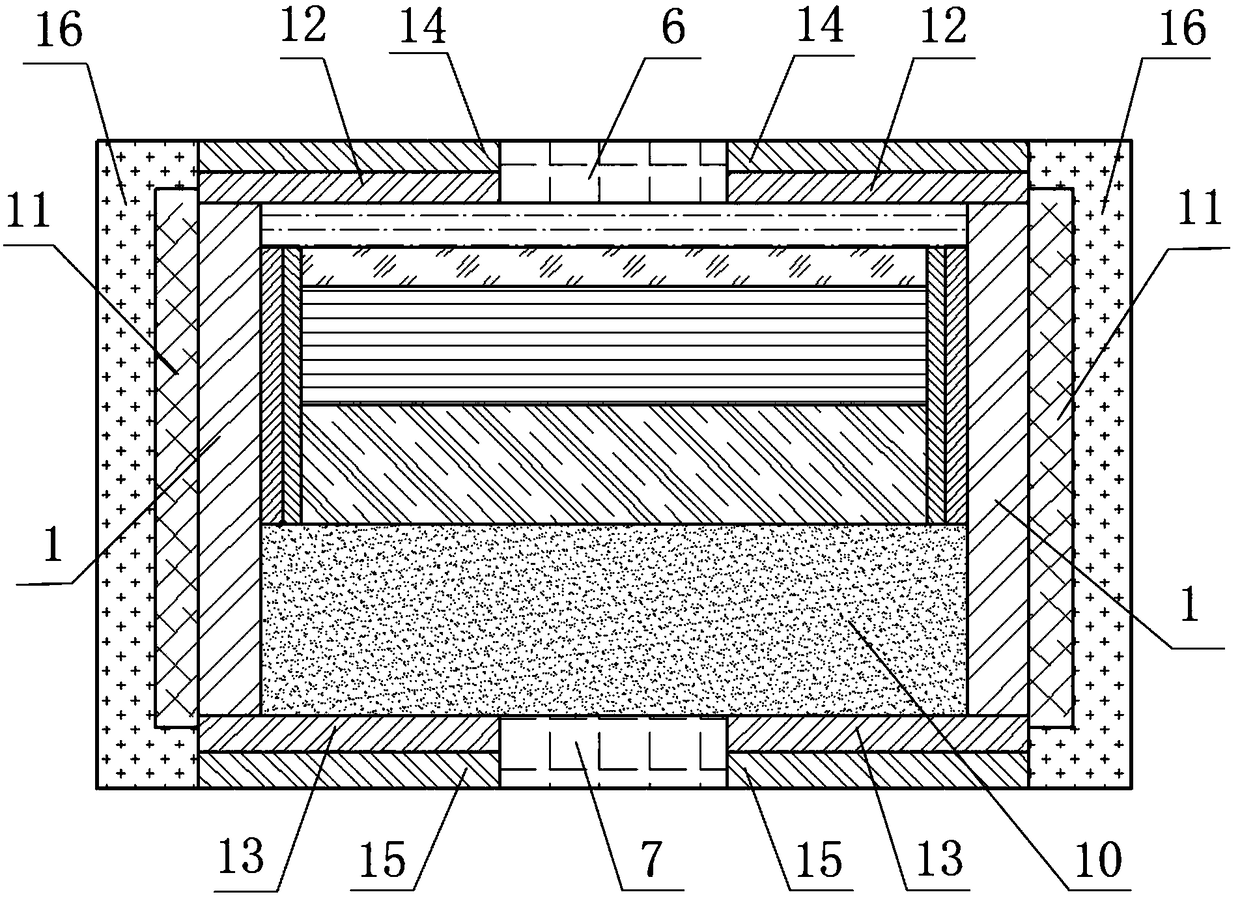

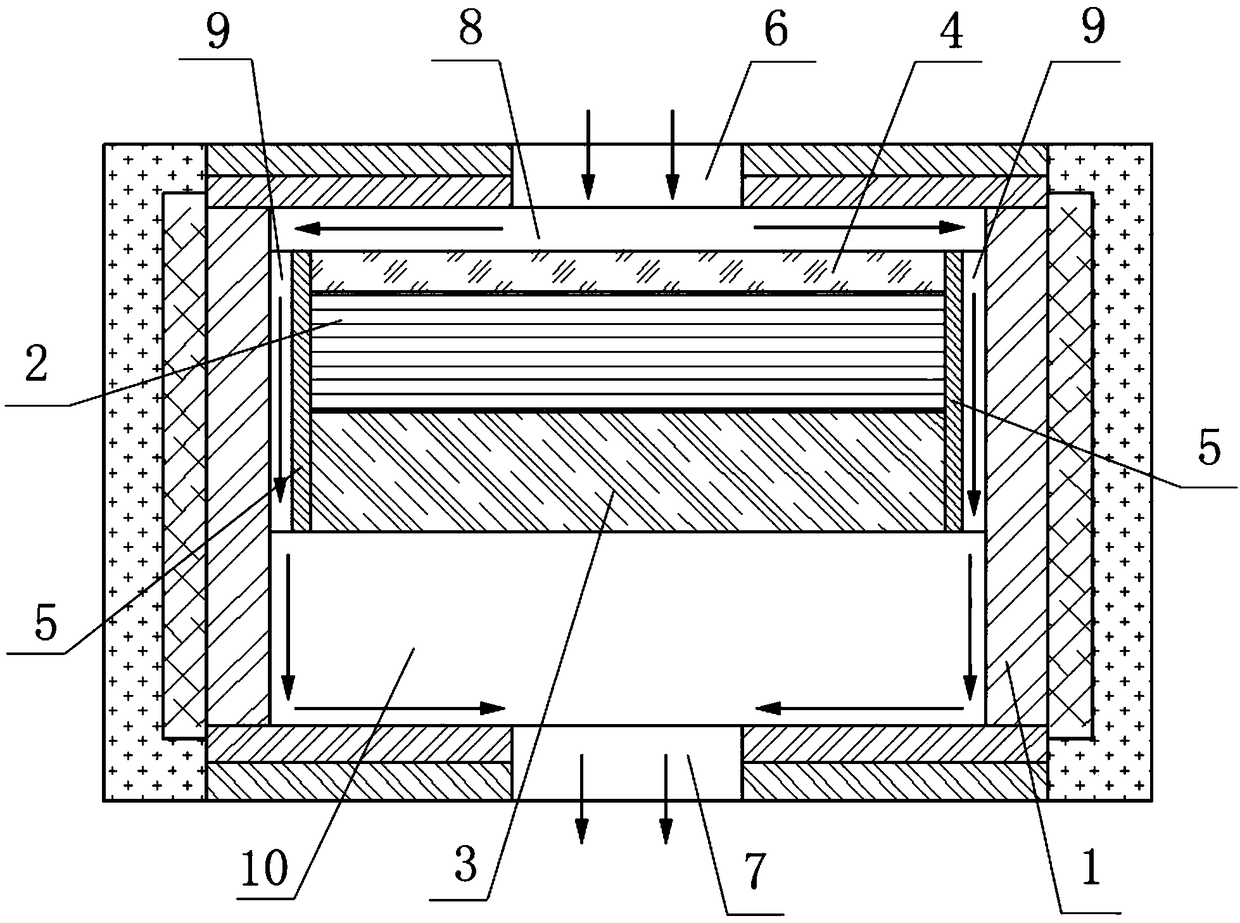

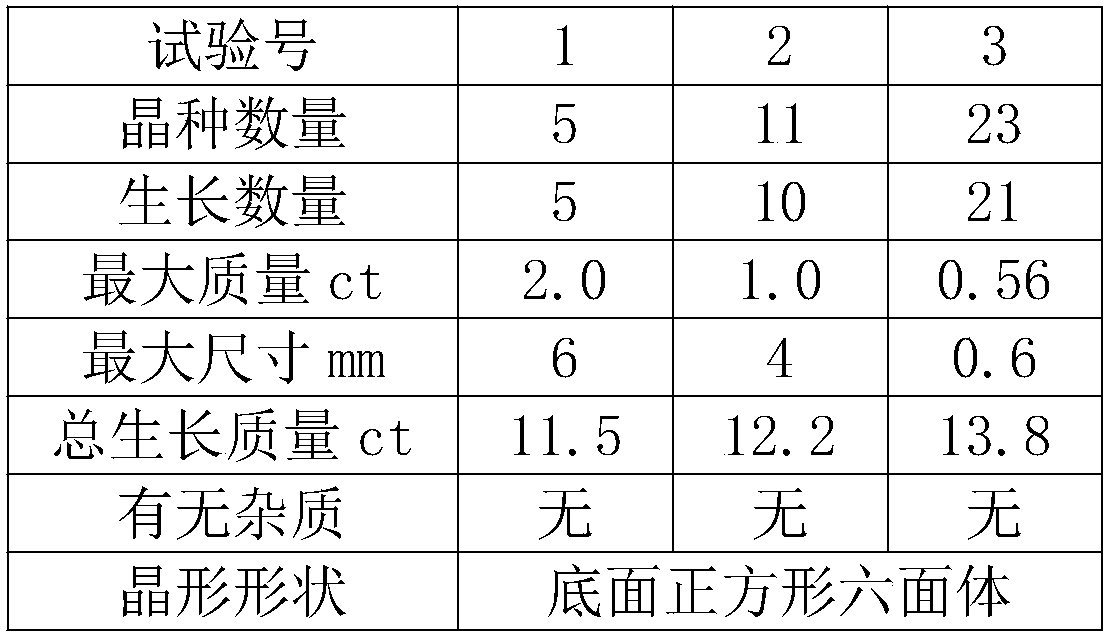

A thermal insulation material for synthesizing large-grain diamond

ActiveCN106552556BSimple componentsWide variety of sourcesUltra-high pressure processesAdamiteLarge particle

The invention discloses a heat preservation material for synthesis of large-particle diamond. The heat preservation material comprises, by weight, 50%-60% of first solid metal halide salt resistant to high temperature, 20%-33.3% of second solid metal halide salt resistant to high temperature, and 16.7%-25% of titanium dioxide. Compared with the prior art, the heat preservation material has the beneficial effects that components are simple and sources of raw materials are wide; and by arranging the heat preservation material in a diamond synthesis device, it is ensured that the synthesized large-particle diamond cannot be burnt while the synthesis temperature of the large-particle diamond is effectively ensured.

Owner:JIXI HAOSHI NEW ENERGY MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com