Method for controlling speed of motor

A technology of speed control and speed, which is applied in the field of controlling the speed of DC motors, can solve the problems that the speed cannot be reduced, the discharge energy is large, and the promotion and application of tubular motors are limited, so as to reduce the discharge energy, prolong the service life, and ensure the effect of not being burned

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

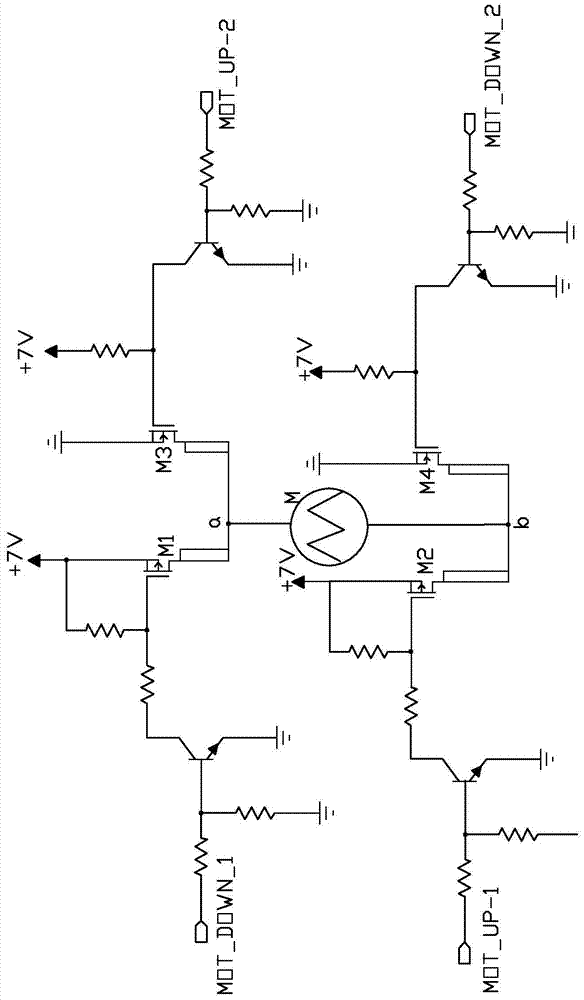

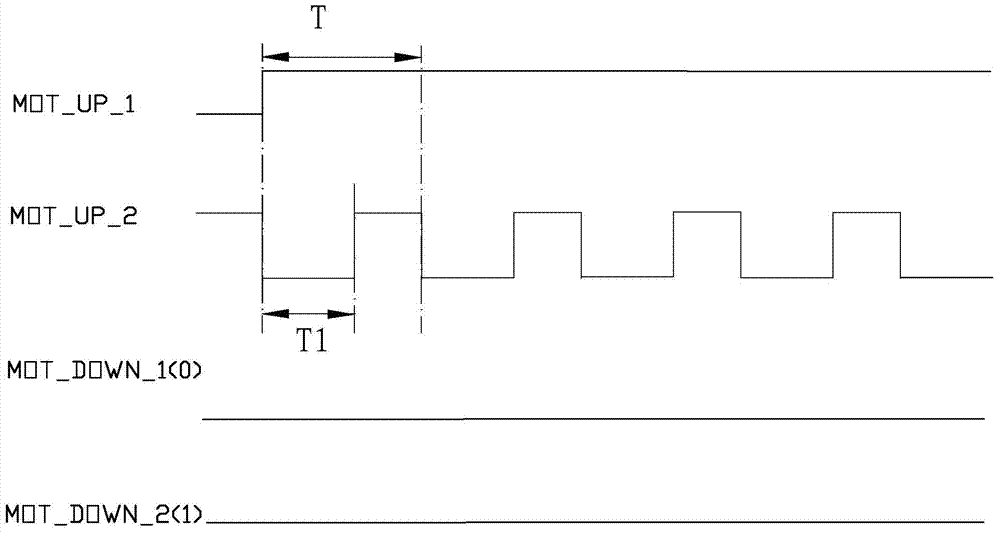

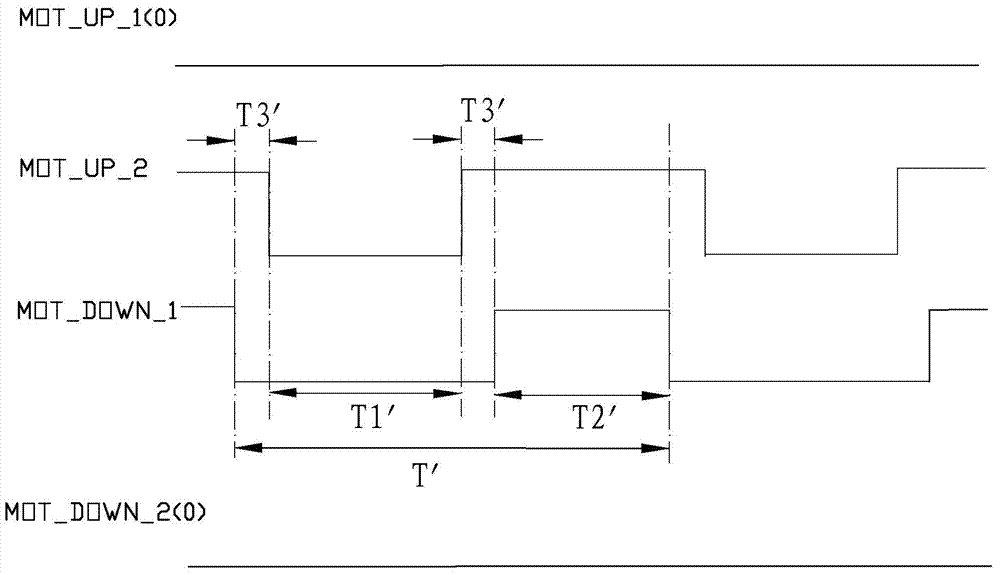

[0032] A speed control method for a direct current tubular motor, the direct current tubular motor is commonly used, including a direct current motor, a gear reduction box connected to the output shaft of the direct current motor to reduce the speed of the direct current motor, a control module for controlling the operation of the direct current motor, and The rotation speed detection module for detecting the rotation speed of the DC motor, in this embodiment, can use a Hall element for detection, and the above components are placed in the outer tube. The motor drive module used by the DC motor is an existing H-bridge drive circuit, such as figure 1shown. The H-bridge drive circuit includes an upper bridge arm and a lower bridge arm. The upper bridge arm includes a first P-type MOS transistor M1 and a second P-type MOS transistor M2. The lower bridge arm includes a first N-type MOS transistor M3 and a second N-type MOS transistor. Tube M4.

[0033] The source of the first P-...

Embodiment 2

[0047]A method for controlling the speed of a curtain opening and closing motor. The curtain opening and closing motor also includes a DC motor, a gear reduction box, a control module, a speed detection module, etc., and drives the curtain to open and close horizontally. The speed is lower than the running speed at no-load under the rated voltage. In order to make the curtain opening and closing motor run at a low noise and run at a constant speed under the no-load condition, its running speed is always controlled at a predetermined speed. Preferably, the The predetermined speed is lower than the operating speed at rated voltage with no load and rated load. The speed control of the opening and closing curtain motor can adopt the PWM speed regulation method when the tubular motor drives the load upward as mentioned above.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com