GH4169 alloy steel electroslag remelting refining slag and method for performing electroslag re-melting on GH4169 alloy steel

A GH4169, electroslag remelting technology, which is applied in the field of electrometallurgy and black metal materials, can solve the problems of weak removal of harmful elements and inclusions, easy burning, poor surface finish of steel ingots, etc., and achieves unstable oxidation The effect of low content of substances and variable price oxides, simple preparation process, and good market application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

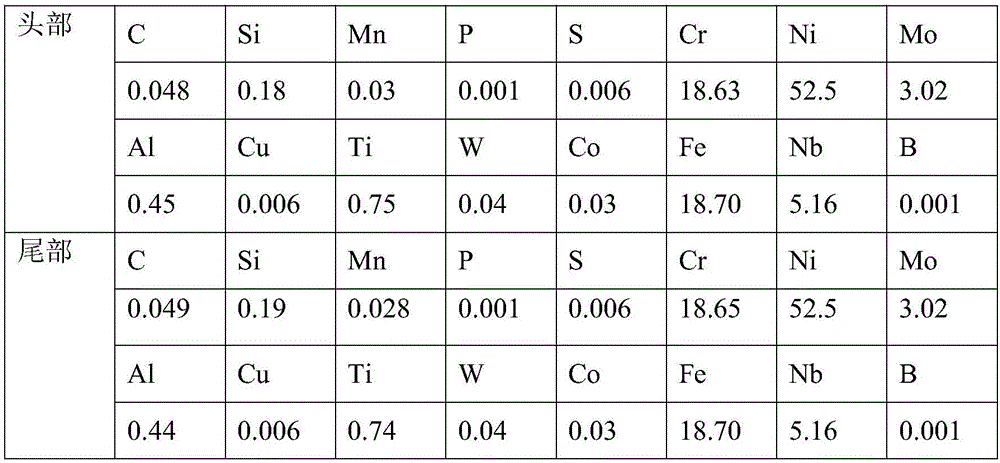

Embodiment 1

[0029] A GH4169 alloy steel electroslag remelting refining slag, comprising the following components by weight: 65 parts of CaF 2 , 15 Al 2 o 3 , 12 parts of CaO, 3 parts of MgO and 5 parts of TiO 2 .

[0030] The method for carrying out electroslag remelting of GH4169 alloy steel by using the above electroslag remelting refining slag comprises the following steps:

[0031] 1) Prepare the remelting refining slag according to the formula described in this example, and bake the remelting refining slag at 800° C. for 7 hours;

[0032] 2) Using GH4169 alloy steel as the consumable electrode, assemble the electroslag remelting furnace, add the remelting and refining slag baked in step 1) into the crystallizer of the electroslag remelting furnace, and add aluminum powder and Ferro-titanium powder, set voltage 58V, current 2500A to energize and start the arc, and set up a slag pool; wherein, the mass ratio of aluminum powder, ferro-titanium powder and the remelted refining slag i...

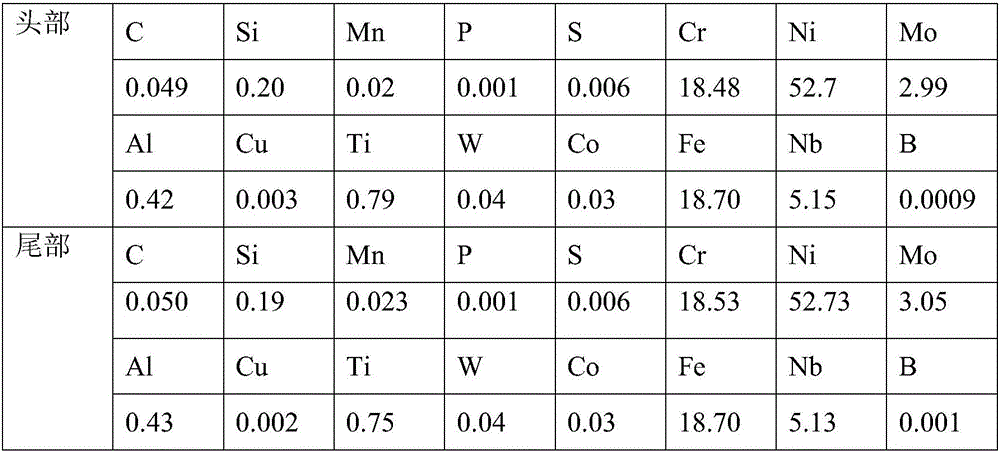

Embodiment 2

[0038] A GH4169 alloy steel electroslag remelting refining slag, comprising the following components by weight: 60 parts of CaF 2 , 20 Al 2 o 3 , 10 parts CaO, 5 parts MgO and 5 parts TiO 2 .

[0039] The method for carrying out electroslag remelting of GH4169 alloy steel by using the above electroslag remelting refining slag comprises the following steps:

[0040] 1) Prepare the remelting refining slag according to the formula described in this example, and bake the remelting refining slag at 750° C. for 9 hours;

[0041] 2) Using GH4169 alloy steel as the consumable electrode, assemble the electroslag remelting furnace, add the remelting and refining slag baked in step 1) into the crystallizer of the electroslag remelting furnace, and add aluminum powder and Ferro-titanium powder, set voltage 57V, current 2700A to energize and start the arc, and establish a slag pool; wherein, the mass ratio of aluminum powder, ferro-titanium powder and the remelted refining slag is 11:8...

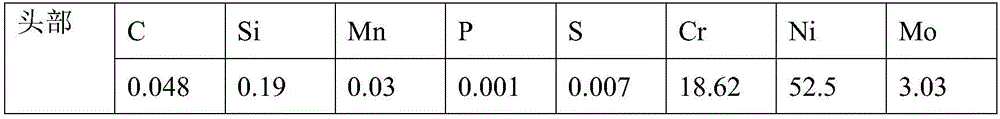

Embodiment 3

[0047] A GH4169 alloy steel electroslag remelting refining slag, comprising the following components by weight: 70 parts of CaF 2 , 15 Al 2 o 3 , 5 parts of CaO, 6 parts of MgO and 4 parts of TiO 2 .

[0048] The method for carrying out electroslag remelting of GH4169 alloy steel by using the above electroslag remelting refining slag comprises the following steps:

[0049] 1) Prepare the remelting refining slag according to the formula described in this example, and bake the remelting refining slag at 750° C. for 8 hours;

[0050] 2) Using GH4169 alloy steel as the consumable electrode, assemble the electroslag remelting furnace, add the remelting and refining slag baked in step 1) into the crystallizer of the electroslag remelting furnace, and add aluminum powder and Ferro-titanium powder, set voltage 55V, current 3000A to energize and start the arc, and establish a slag pool; wherein, the mass ratio of aluminum powder, ferro-titanium powder and the remelting refining sla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com