Non-contact mixed solid-liquid electrolyte lithium storage battery and preparation method thereof

A non-contact, lithium battery technology, applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, lithium batteries, etc., can solve problems such as short circuit and affect the safety performance of lithium batteries, so as to slow down the impact, improve electrical cycle performance, and excellent conductivity rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

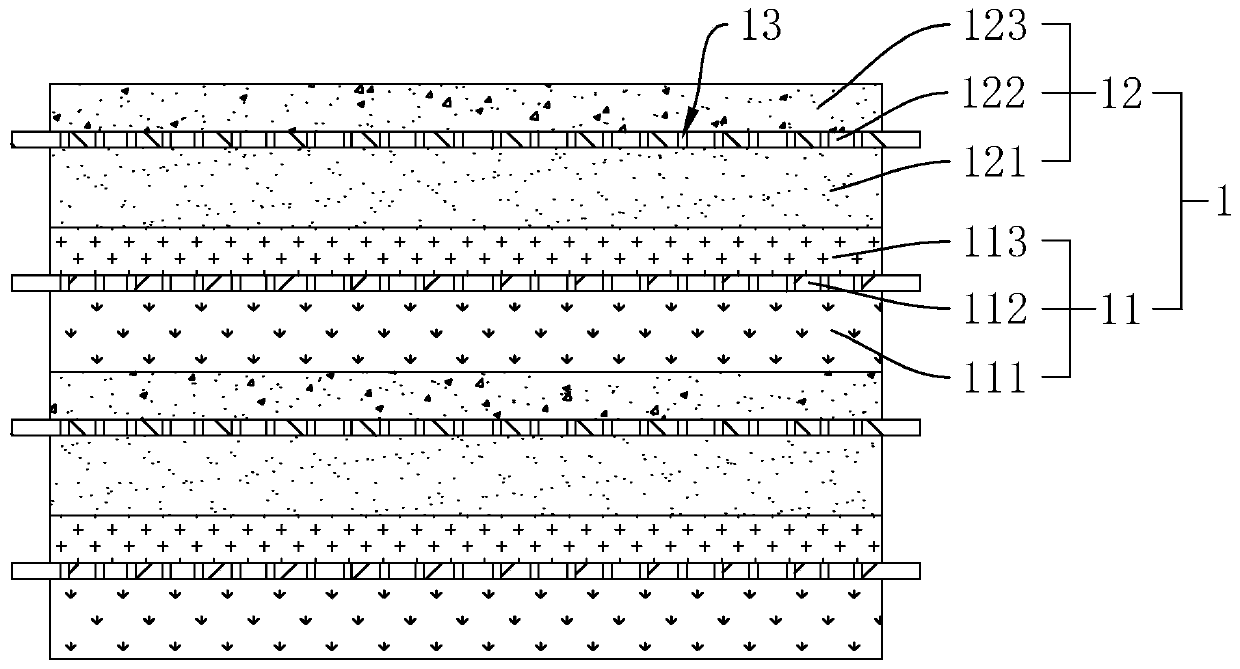

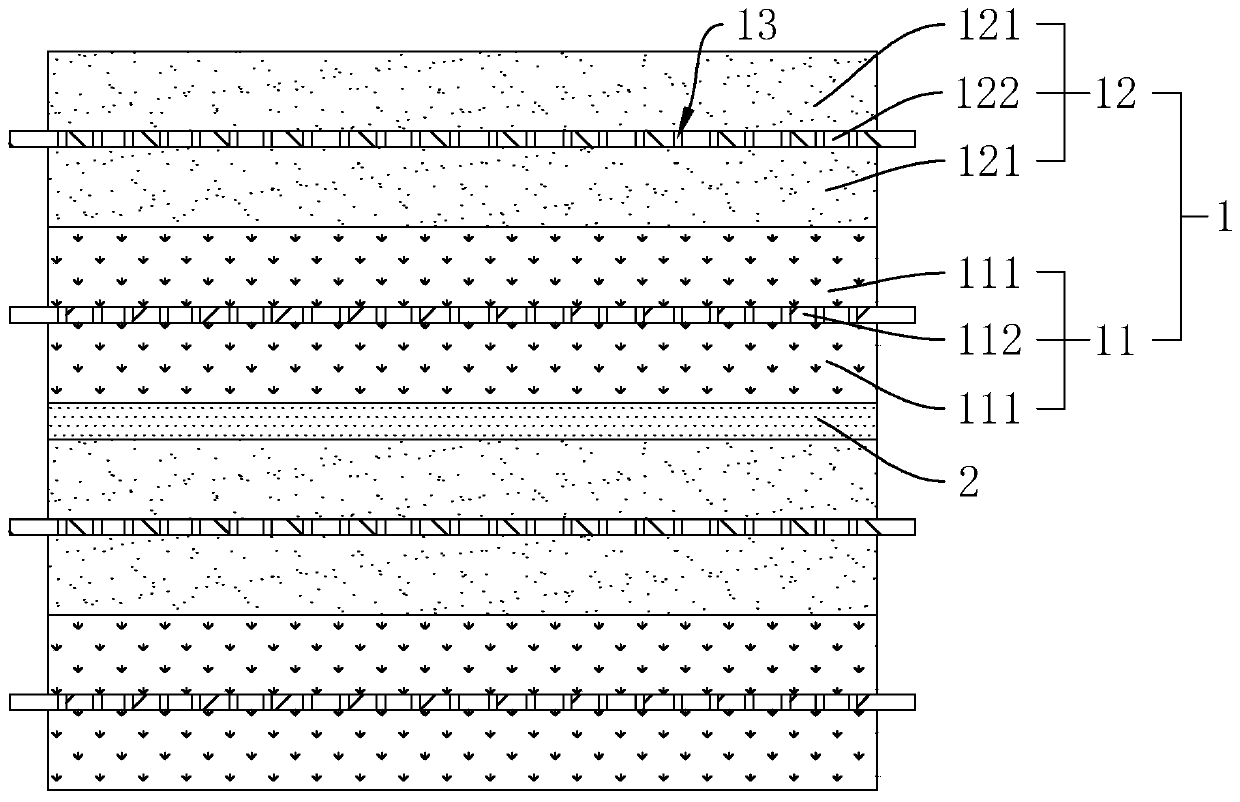

[0061] A method for preparing a non-contact mixed solid-liquid electrolyte lithium battery: comprising the following steps:

[0062] ①. Preparation of positive electrode structure:

[0063] a. Weigh LiCoO successively according to the weight ratio of 80:10:10 2 , carbon black and polyvinylidene fluoride, N-methylpyrrolidone was added and mixed uniformly to obtain a positive electrode active slurry with a solid content of 50% for forming the positive electrode active layer 111 .

[0064] b. Weigh LLTO, PEO and LiTFSI sequentially at a weight ratio of 5:5:10, add deionized water and mix evenly to obtain a positive electrode solid electrolyte slurry with a solid content of 60% for forming the positive electrode solid electrolyte layer 113 .

[0065] c. Take an 8 μm thick aluminum foil as the positive electrode current collector 112, wherein the area of the through hole 13 on the aluminum foil accounts for 12% of the total area, and coat the positive electrode active slurry pre...

Embodiment 2

[0077]In this embodiment, on the basis of the method in Embodiment 1, the following adjustments are made:

[0078] Positive electrode active slurry: Weigh iron phosphate, carbon black and polyvinylidene fluoride sequentially in a weight ratio of 90:5:5, add N-methylpyrrolidone and mix evenly, with a solid content of 30%.

[0079] Positive electrode solid electrolyte slurry: weigh LAGP, PAA and LiClO sequentially in a weight ratio of 50:25:10 4 , adding N,N-dimethylformamide and mixing evenly, the solid content is 20%.

[0080] Negative electrode active slurry: Weigh the silicon carbon material, acetylene black and sodium carboxymethyl cellulose sequentially in a weight ratio of 80:15:5, add deionized water and mix evenly, and the solid content is 30%.

[0081] Negative electrode solid electrolyte slurry: Weigh LAGP, PAA and LiClO sequentially in a weight ratio of 40:5:20 4 , adding N,N-dimethylformamide and mixing evenly, the solid content is 40%.

[0082] The liquid electr...

Embodiment 3

[0084] In this embodiment, on the basis of the method in embodiment 1, the following adjustments are made:

[0085] Positive electrode active slurry: Weigh LiNi sequentially according to the weight ratio of 85:10:5 0.6 co 0.2 mn 0.2 o 2 , carbon black and polyvinylidene fluoride, adding N-methylpyrrolidone and mixing evenly, the solid content is 80%.

[0086] Positive electrode solid electrolyte slurry: weigh LAGP, PMMA and LiBF sequentially in a weight ratio of 85:30:50 4 , add tetrahydrofuran and mix well, the solid content is 10%.

[0087] Negative electrode active slurry: Weigh lithium titanate, acetylene black and sodium carboxymethyl cellulose sequentially in a weight ratio of 90:5:5, add deionized water and mix evenly, with a solid content of 80%.

[0088] Negative electrode solid electrolyte slurry: Weigh LAGP, PMMA and LiBF sequentially in a weight ratio of 85:30:50 4 , add tetrahydrofuran and mix well, the solid content is 10%.

[0089] The liquid electrolyte ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Internal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com