A preparing method of a high-power high-energy density lithium ion battery

A lithium-ion battery, high energy density technology, used in the manufacture of electrolyte batteries, battery electrodes, secondary batteries, etc., can solve problems such as rate type energy difference, poor liquid absorption ability, etc. The effect of improving conductivity and rate capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

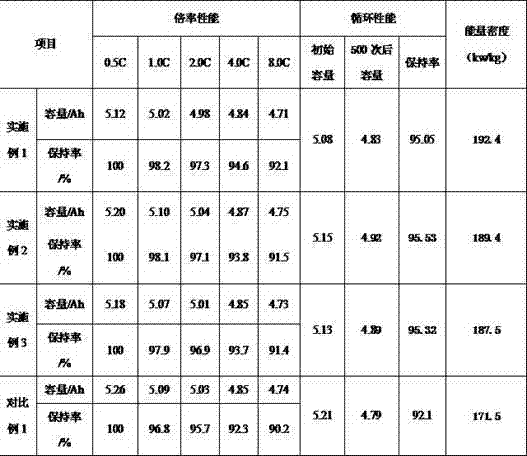

Embodiment 1

[0013] A method for preparing a lithium-ion battery with high power and high energy density, comprising the following steps:

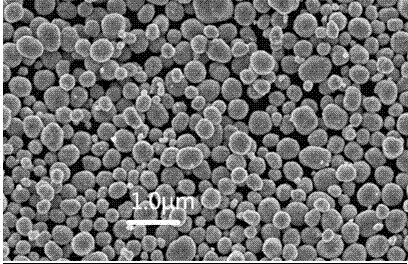

[0014] 1. Anode material: Weigh 30 grams of polystyrene with a particle size of 50nm and 100 grams of polystyrene with a particle size of 1.5 μm, add it to 1000 grams of double distilled water solvent and stir evenly, then add 26.2 grams (0.1mol) of NiSO 4 ·6H 2 O, 28.1 g (0.1 mol) C O SO 4 ·7H 2 O, 19.8 g (0.1 mol) MnCl 2 4H 2 O, 28.8 grams (0.3 mol) of ammonium carbonate, and then filter it to obtain an organic-inorganic structure composite material, then mix it with 7.2 grams (0.3 mol) of lithium hydroxide, and use 100 milliliters of tetrahydrofuran organic solvent to dissolve and remove the template, after filtering Get Li(Ni x co y mn 1-x-y )O 2 (Denoted as: NCM) material, then place the above-mentioned dry NCM material in the reactor, feed nitrogen into the reactor, and heat to make the temperature in the reactor reach 800 ° C, stop feed...

Embodiment 2

[0017] 1. Anode material: Weigh 10 grams of polystyrene with a particle size of 40nm and 40 grams of polystyrene with a particle size of 1.0 μm, add them to 1000 grams of ethanol solvent and stir evenly, then add 26.2 grams (0.1mol) of NiSO 4 ·6H 2 O, 28.1 g (0.1 mol) C O SO 4 ·7H 2 O, 19.8 g (0.1 mol) MnCl 2 4H 2 O, 6.0 grams (0.1mol) of urea, after which it was filtered to obtain an organic-inorganic structure composite material, then mixed with 7.4 grams (0.1mol) of lithium carbonate, and 200 milliliters of tetrahydrofuran organic solvent was used to dissolve and remove the template, and after filtration, Li (Ni x co y mn 1-x-y )O 2 (Denoted as: NCM) material, then place the above-mentioned dry NCM material in the reactor, feed nitrogen into the reactor, and heat to make the temperature in the reactor reach 500 ° C, stop feeding nitrogen, and then feed Pass acetylene and ammonia into the reactor, keep it at 8000°C for 60 minutes, and grow carbon nanotubes on the su...

Embodiment 3

[0020] 1. Positive electrode material: Weigh 10 grams of polystyrene with a particle size of 50 nm and 40 grams of polystyrene with a particle size of 2.0 μm, add them to 1000 grams of ethanol solvent and stir evenly, then add 26.2 grams (0.1mol) of NiSO 4 ·6H 2 O, 28.1 g (0.1 mol) C O SO 4 ·7H 2 O, 15.1 g (0.1 mol) MnSO 4 , 30.0 grams (0.5mol) of urea, and then filter it to obtain an organic-inorganic structure composite material, then mix it with lithium carbonate 37.0 grams (0.5mol), and use 400 milliliters of tetrahydrofuran organic solvent to dissolve and remove the template. After filtration, Li( Ni x co y mn 1-x-y )O 2 (Denoted as: NCM) material, then place the above-mentioned dry NCM material in the reactor, feed nitrogen into the reactor, and heat to make the temperature in the reactor reach 1000 ° C, stop feeding nitrogen, and then feed Pass acetylene and ammonia into the reactor, keep it at 1200°C for 20 minutes, and grow carbon nanotubes on the surface of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com