Inclined flow ventilator for subway locomotive filter reactor

A filter reactor and oblique flow technology, which is applied in the field of oblique flow fans for subway locomotive filter reactors, can solve the problems of insufficiently stable air output and insufficient air volume of the fan, and achieve stable air output and large air output Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

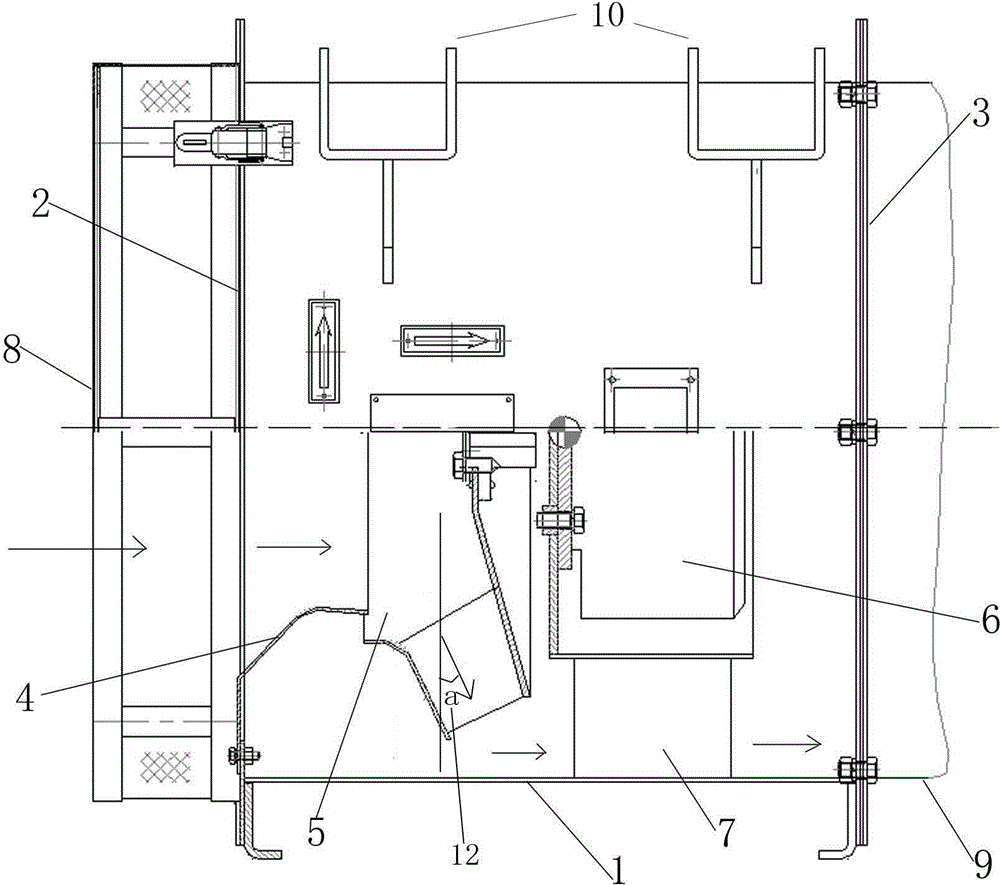

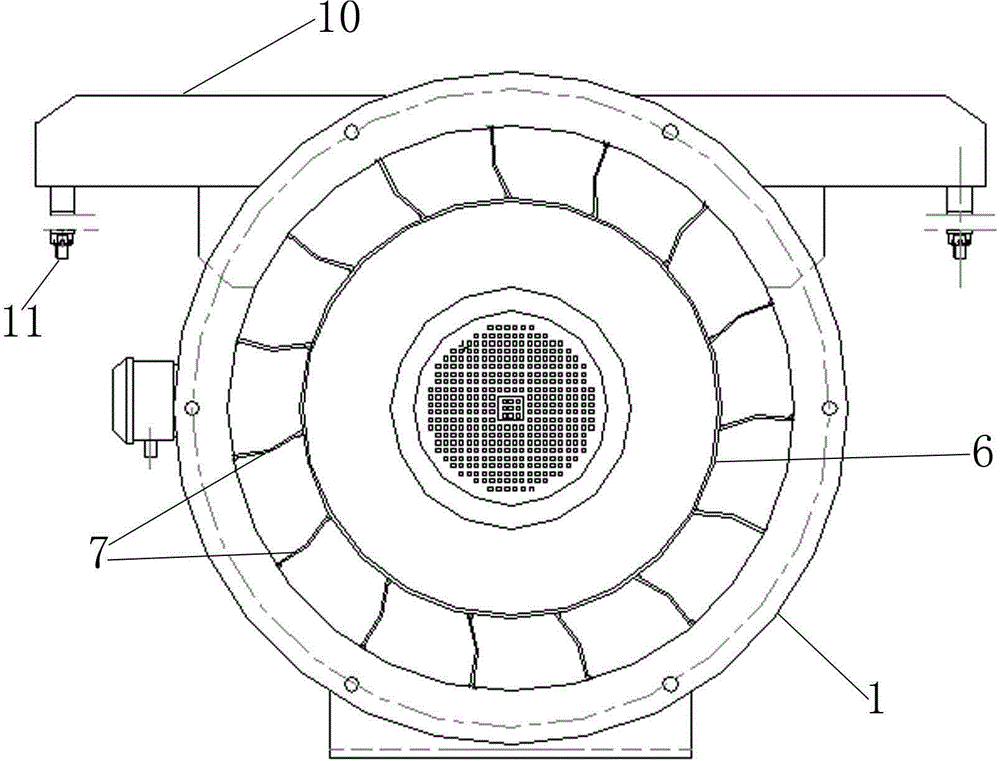

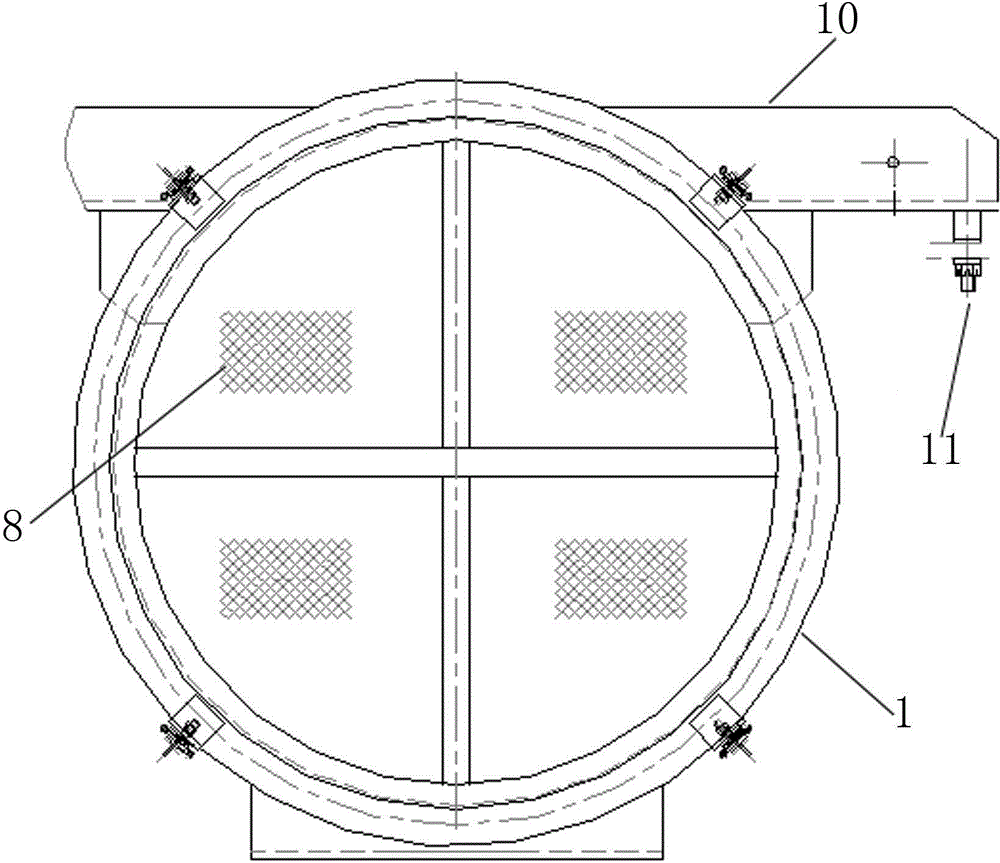

[0014] A kind of oblique flow fan for subway locomotive filter reactor, comprises the tubular casing 1 that is provided with air inlet and outlet; Said casing is provided with guiding tube 4, Centrifugal impeller 5 and the motor 6 driving the centrifugal impeller; the rotating shaft of the centrifugal impeller 5 is parallel to the axial direction of the casing 1, and the blades of the centrifugal impeller 5 are on a vertical plane whose normal line is perpendicular to the axial direction of the casing The included angle between the projection and the vertical direction is a12 and it faces the direction of the wind, and the included angle a12 is 20~40° (20°, 25°, 30°, 35°, 40° can be selected); the guide tube 4 has an inward closing structure, and the distance between the closed end and the central axis of the casing 1 is smaller than the distance between the top of the blade of the centrifugal impeller 5 and the central axis of the casing 1 .

[0015] The inner wall of the cas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com