Method of calculating centrifugal impeller pre-swirl entry enthalpy rise coefficient based on maximum flow coefficient

A centrifugal impeller, maximum flow technology, which is applied in the components, calculation, and electrical digital data processing of the pumping device for elastic fluid, which can solve the problem of large deviation, ignoring the influence of enthalpy coefficient, and ignoring any pre-precession. Gas and other problems, to achieve the effect of compact structure, accurate and fast calculation, and large flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example

[0069] This example demonstrates the method of calculating the enthalpy coefficient in combination with the design process of an industrial transonic centrifugal impeller, wherein It is calculated according to the Stodola formula, that is, formula (1). The enthalpy coefficient is calculated by the following 12 steps:

[0070] 1) Determine the design requirements of the centrifugal impeller: isentropic efficiency η = 0.87, total pressure ratio ε = 6, flow coefficient φ = 0.15

[0071] 2) given constant k=0.85, R=287, γ=1.4, beta 2 = 38, z = 13, σ = 1.07, α 1 =30deg

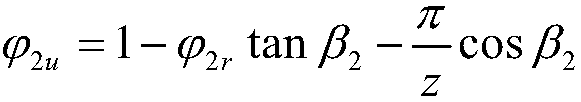

[0072] 3) Calculate according to formula (1)

[0073] 4) Assume that the initial enthalpy rise coefficient μ 0 =0.7

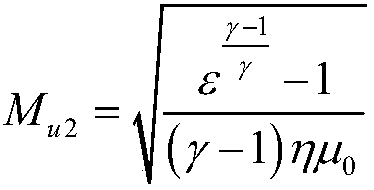

[0074] 5) Calculate the machine Mach number M according to formula (2) u2 =1.65659

[0075] 6) Assume initial M w1,0 =1.1

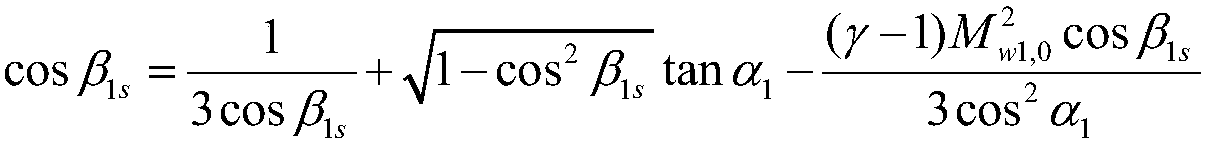

[0076] 7) Calculate β according to formula (3) 1s , the final result β 1s =45.33

[0077] 8) Calculate M according to formula (4) w1 , the final result M w1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com