Flood discharge structure adopting bottom hole and surface hole combined flood discharge and energy dissipation

A flood discharge structure and flood discharge technology, applied in marine engineering, construction, barrage/weir, etc., can solve the problems of water flow directly scouring the downstream river bank, the influence of the stability of the downstream bank slope, and low energy dissipation rate, so as to increase the energy dissipation rate and flow rate. The effect of coefficient, reduction of digging depth, reduction of impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

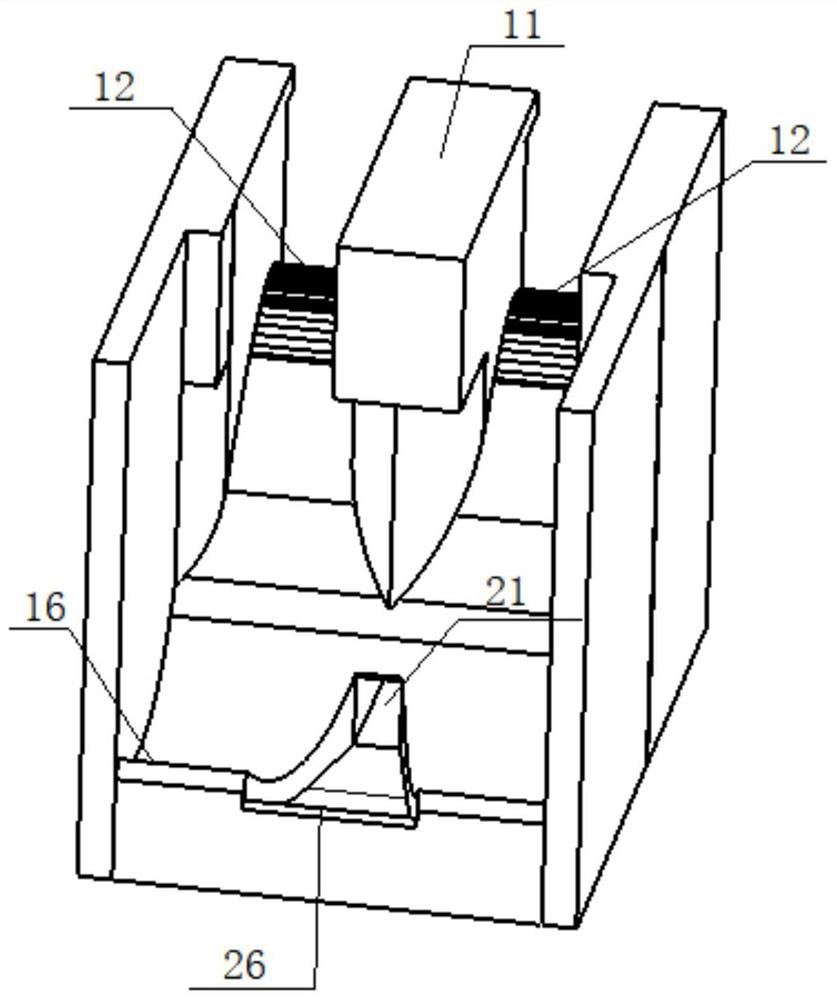

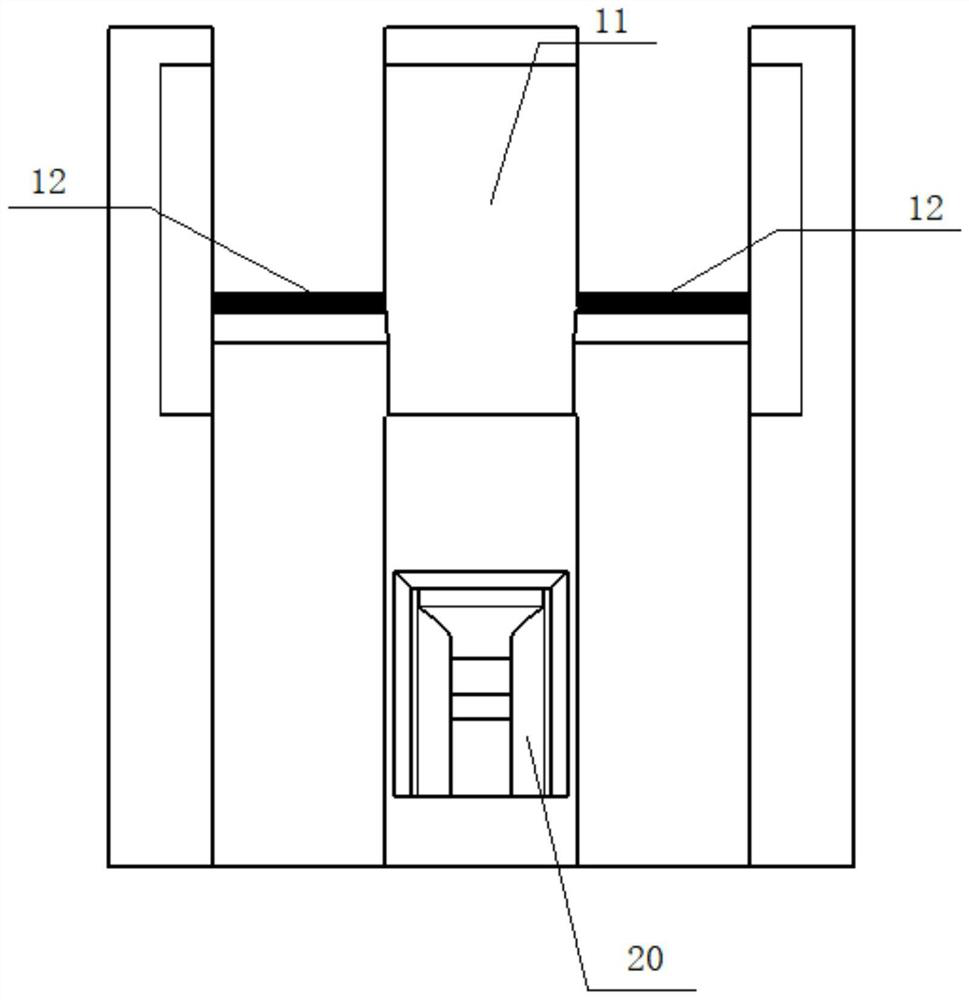

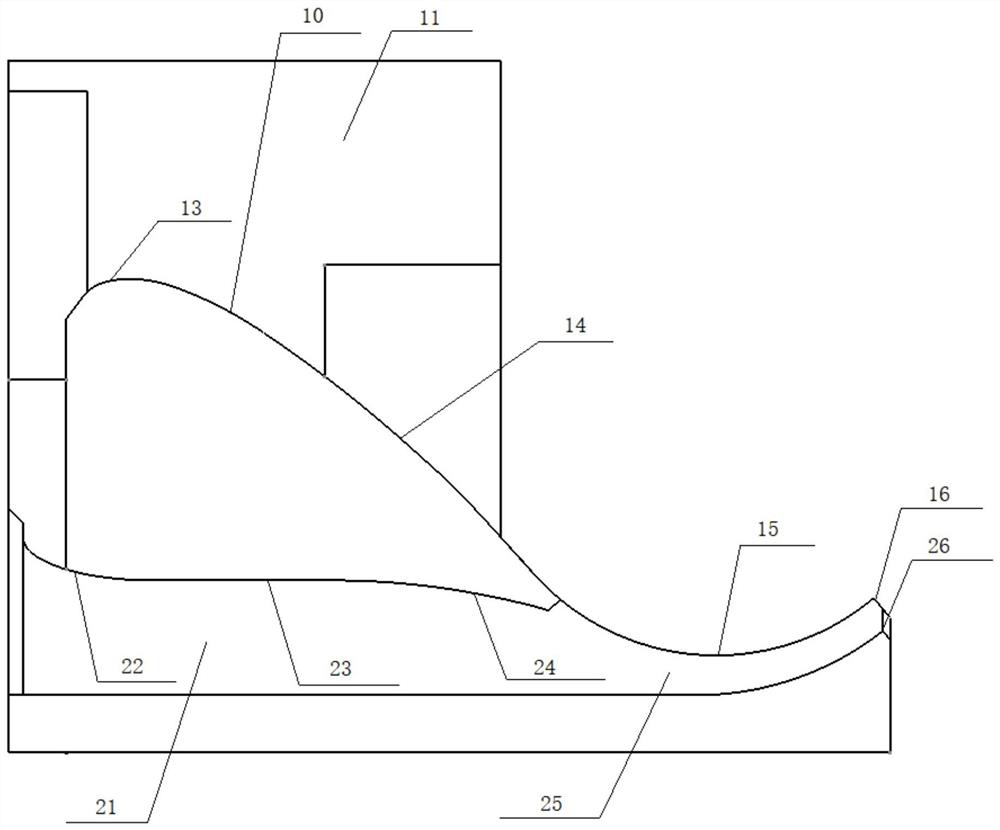

[0021] as attached Figures 1 to 3 As shown, this embodiment discloses a flood discharge building, which is used as a water conservancy and hydropower project for flood discharge and energy dissipation. It has a flood discharge structure that uses a combination of bottom holes and surface holes. The method improves the energy dissipation rate in the stilling pool, and can significantly reduce the scouring effect of the discharged water on the bank slope.

[0022] Specifically, such as figure 1 and 2 As shown, the flood discharge structure includes: a surface hole flood discharge unit 10 and a bottom hole flood discharge unit 20, which are arranged in sequence from top to bottom along the vertical direction of the flood discharge building, so that when the flood discharge flow is small, only the bottom hole is used for flood discharge. The un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com