Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

107results about How to "No thickness unevenness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

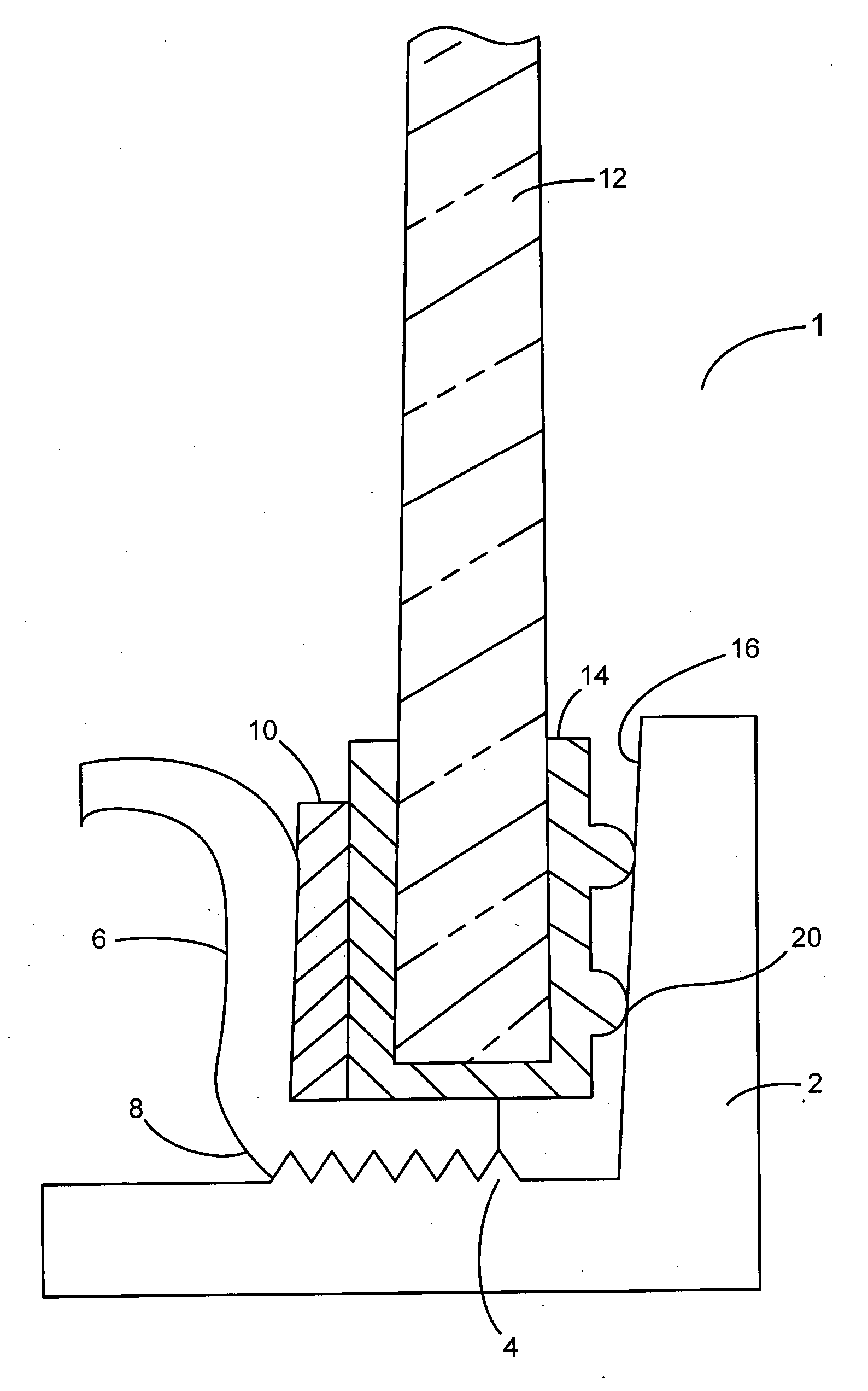

Artificial intervertebral disc having a slotted belleville washer force restoring element

InactiveUS6918934B2Avoid skewImprove securityJoint implantsSpinal implantsIntervertebral discVertebral bone

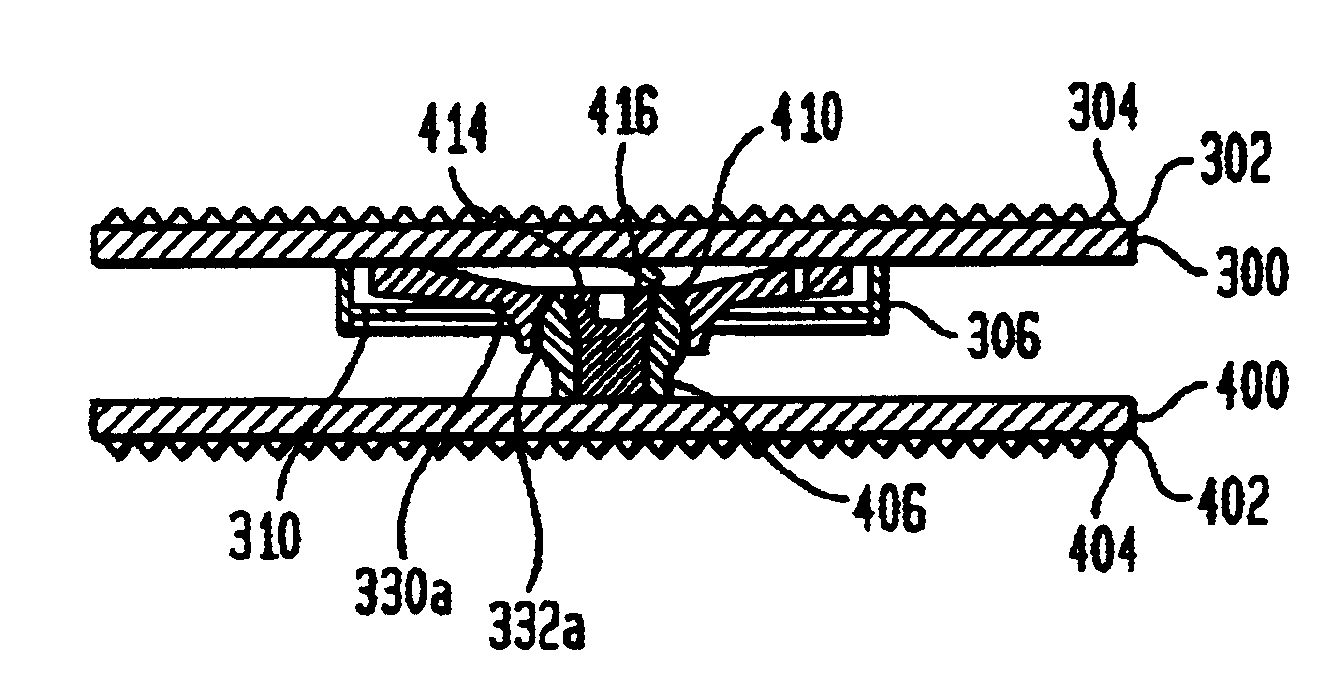

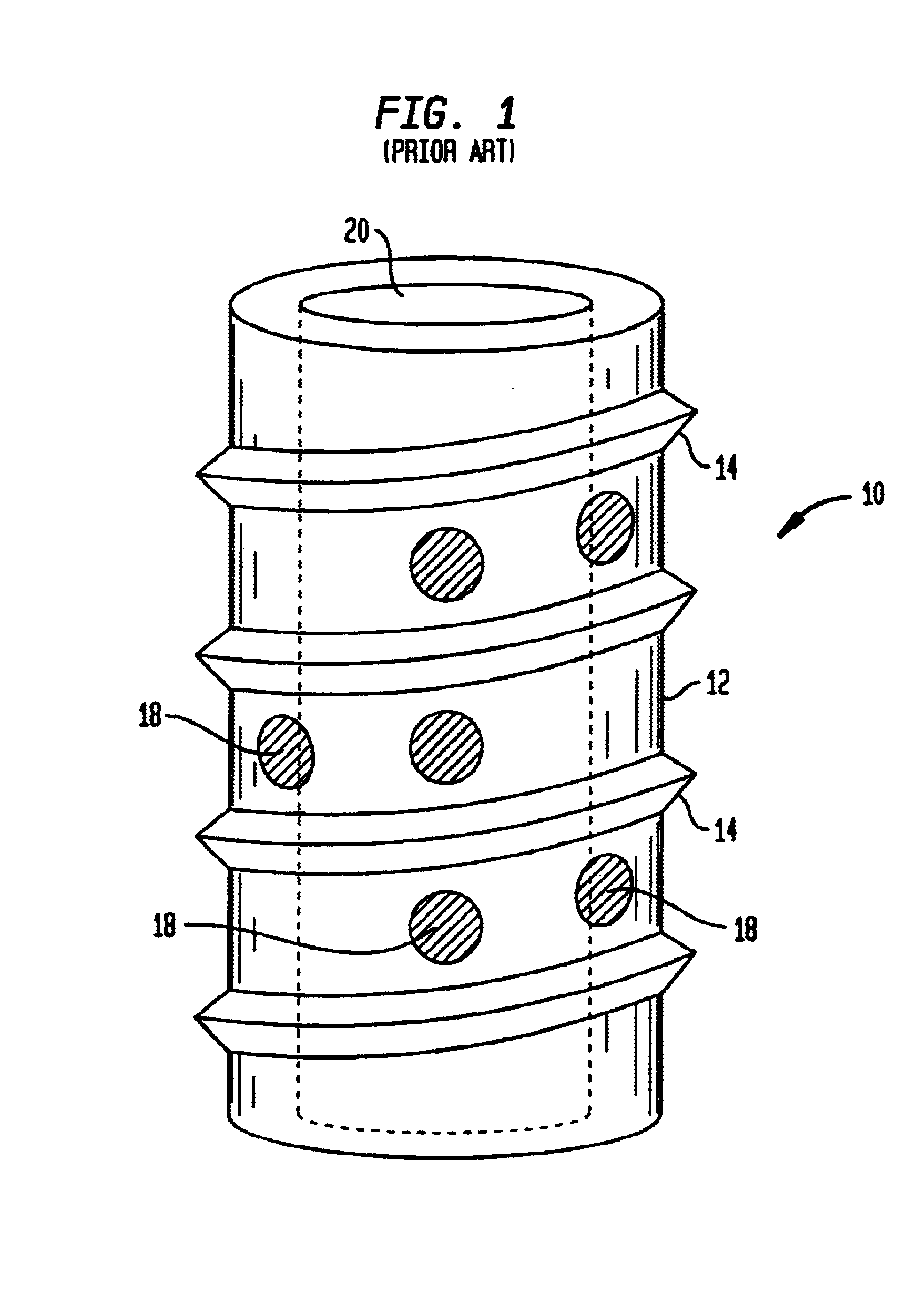

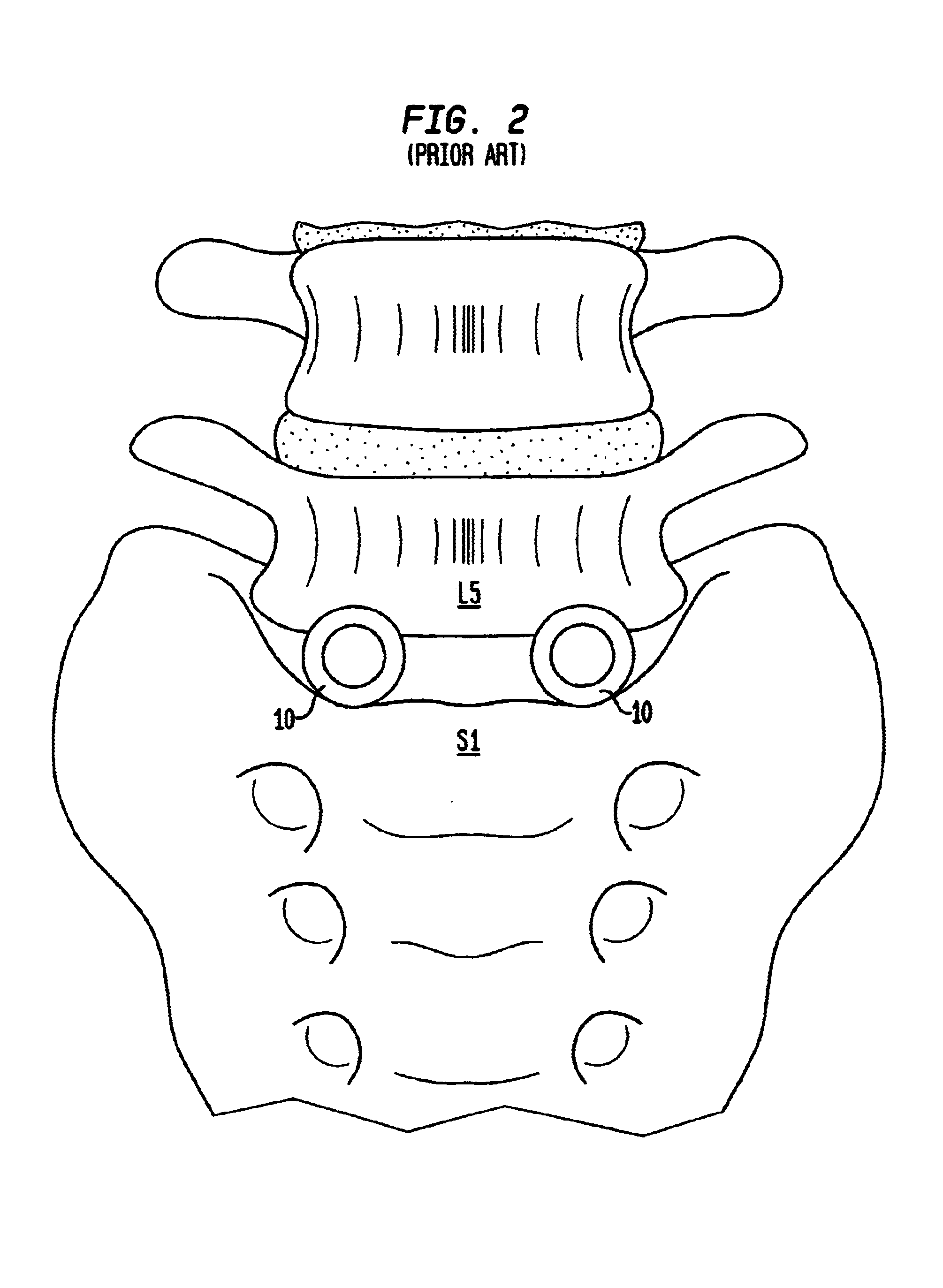

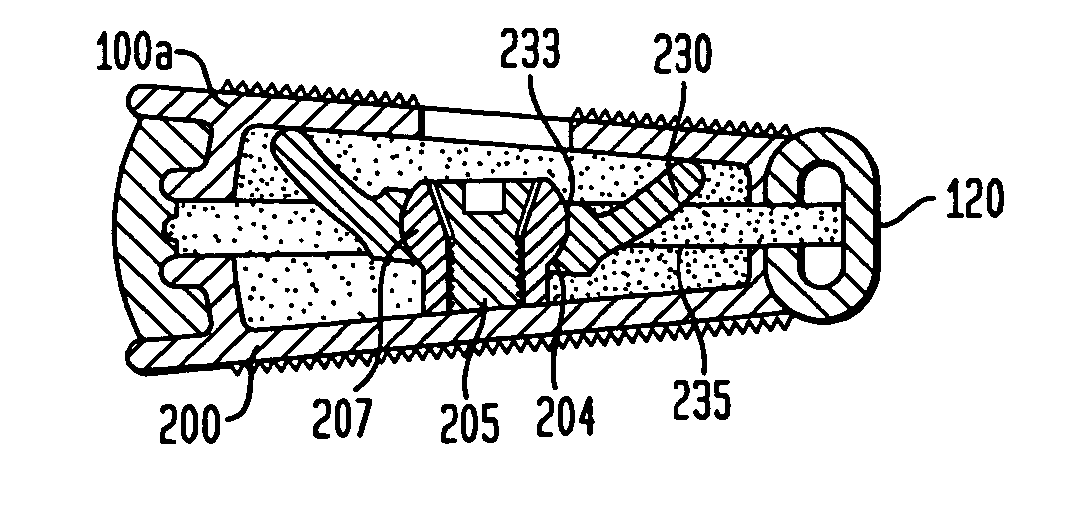

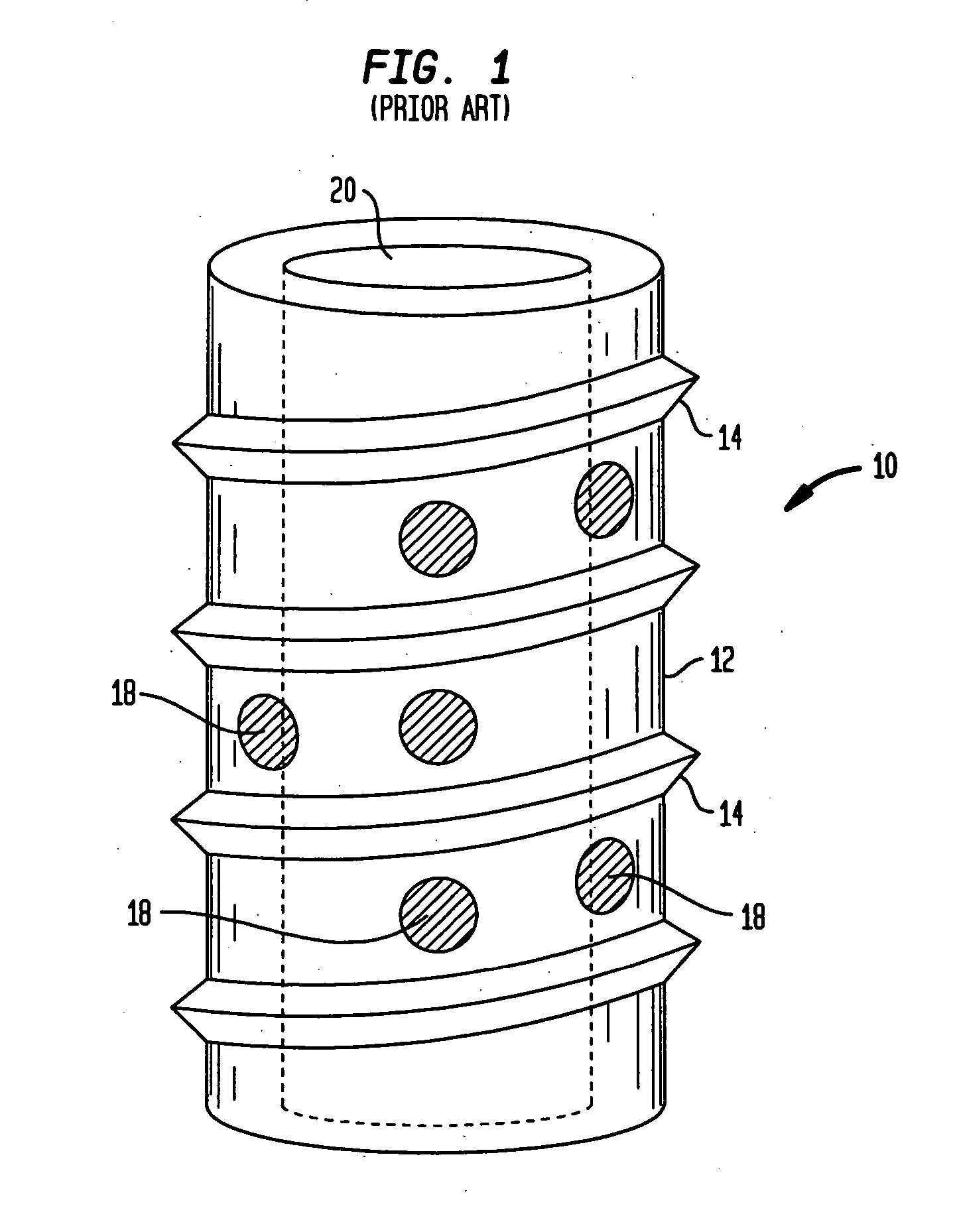

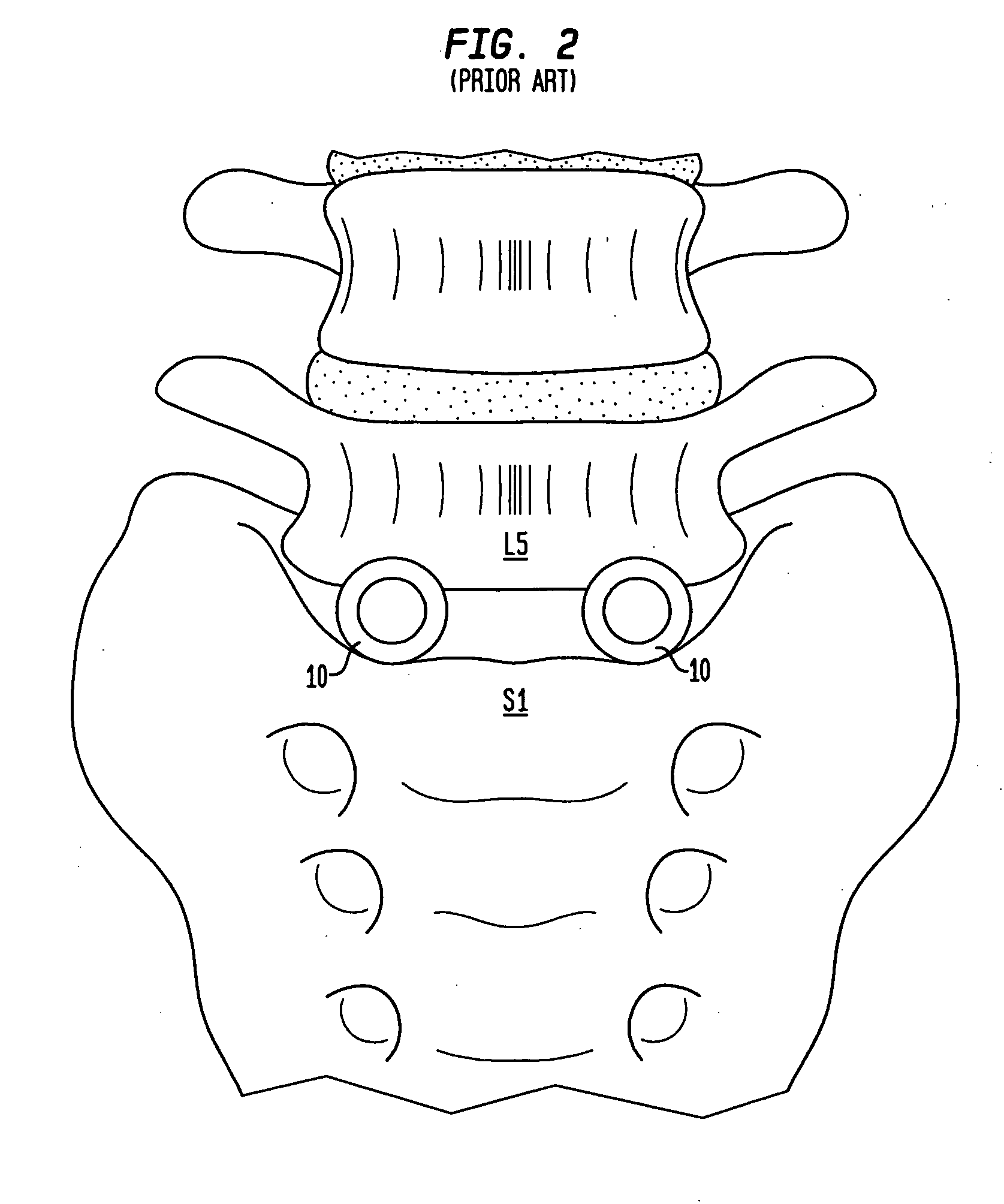

An artificial disc having a pair of opposing plates for seating against opposing vertebral bone surfaces, separated by at least one spring mechanism. The preferred spring mechanism is at least one spirally slotted belleville washer, and in some embodiments the belleville washer is also radially thinning or thickening. Various illustrated embodiments use two washers or one washer. For double washer embodiments, the wide ends of the washers seat against respective opposing plates, in some embodiments each being maintained thereagainst by a retaining wall and ring or a circular recess and retaining shield. For single washer embodiments, the narrow end of the washer can be modified to have a curvate socket for rotatably mounting onto a semispherical protuberance extending from one of the plates.

Owner:HOWMEDICA OSTEONICS CORP

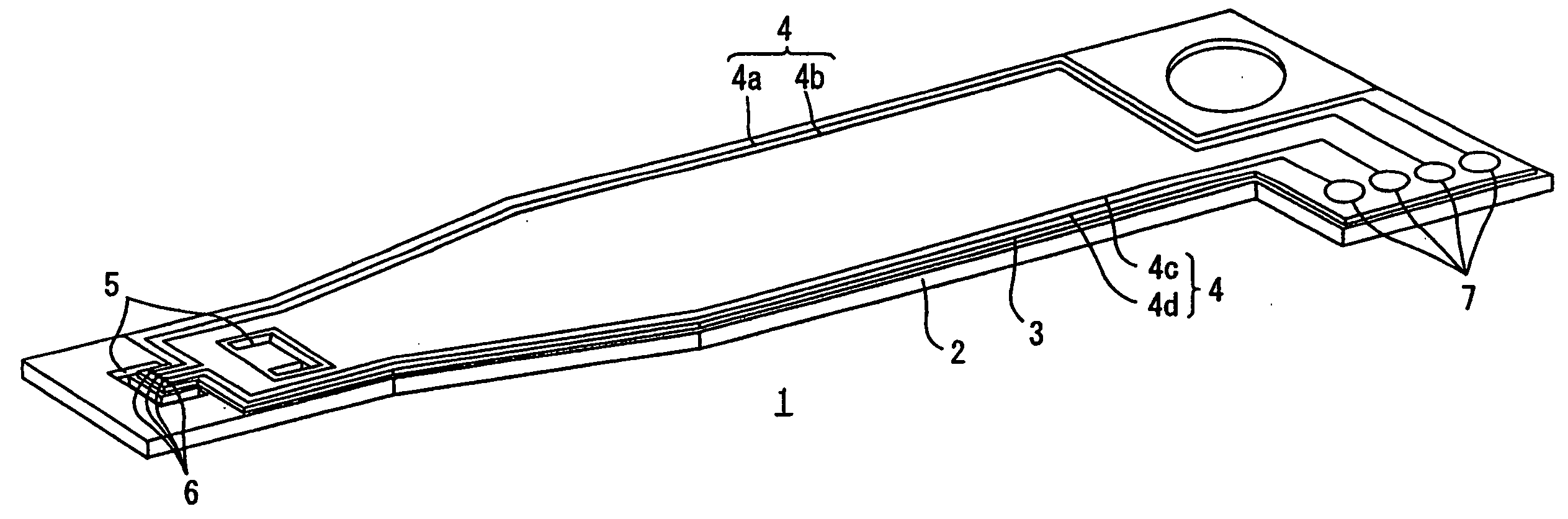

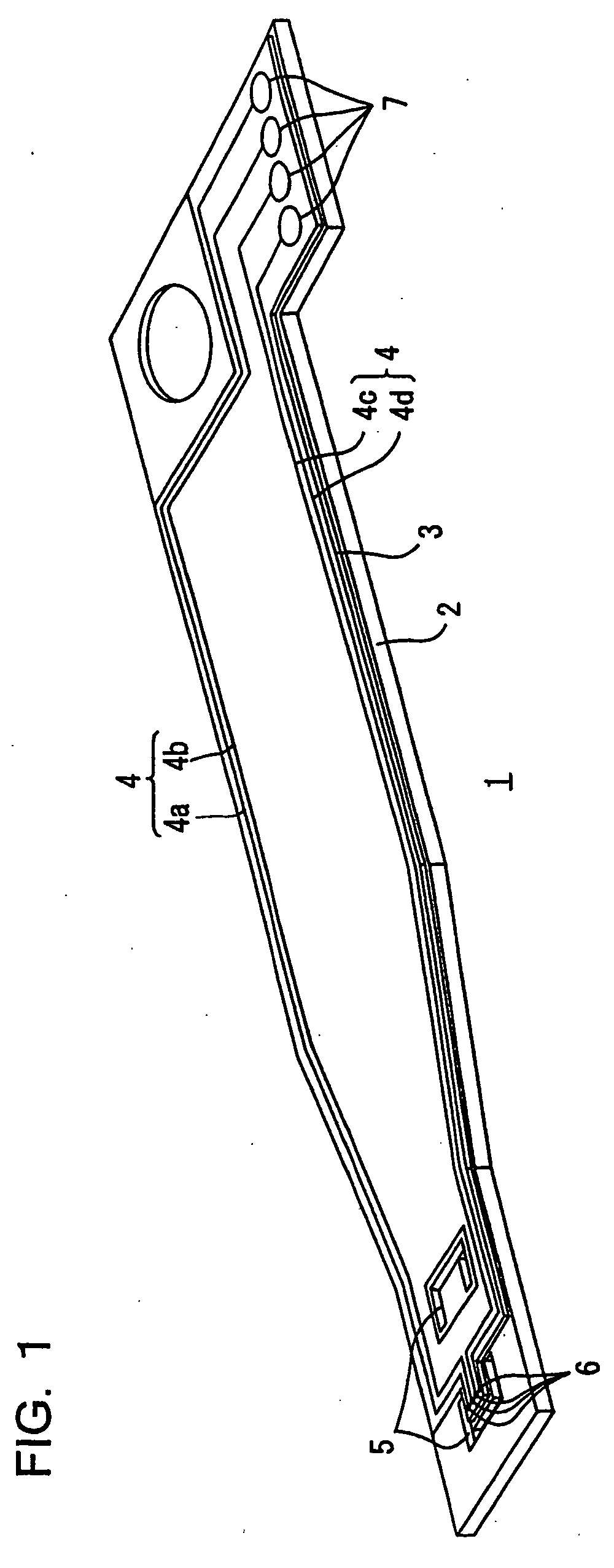

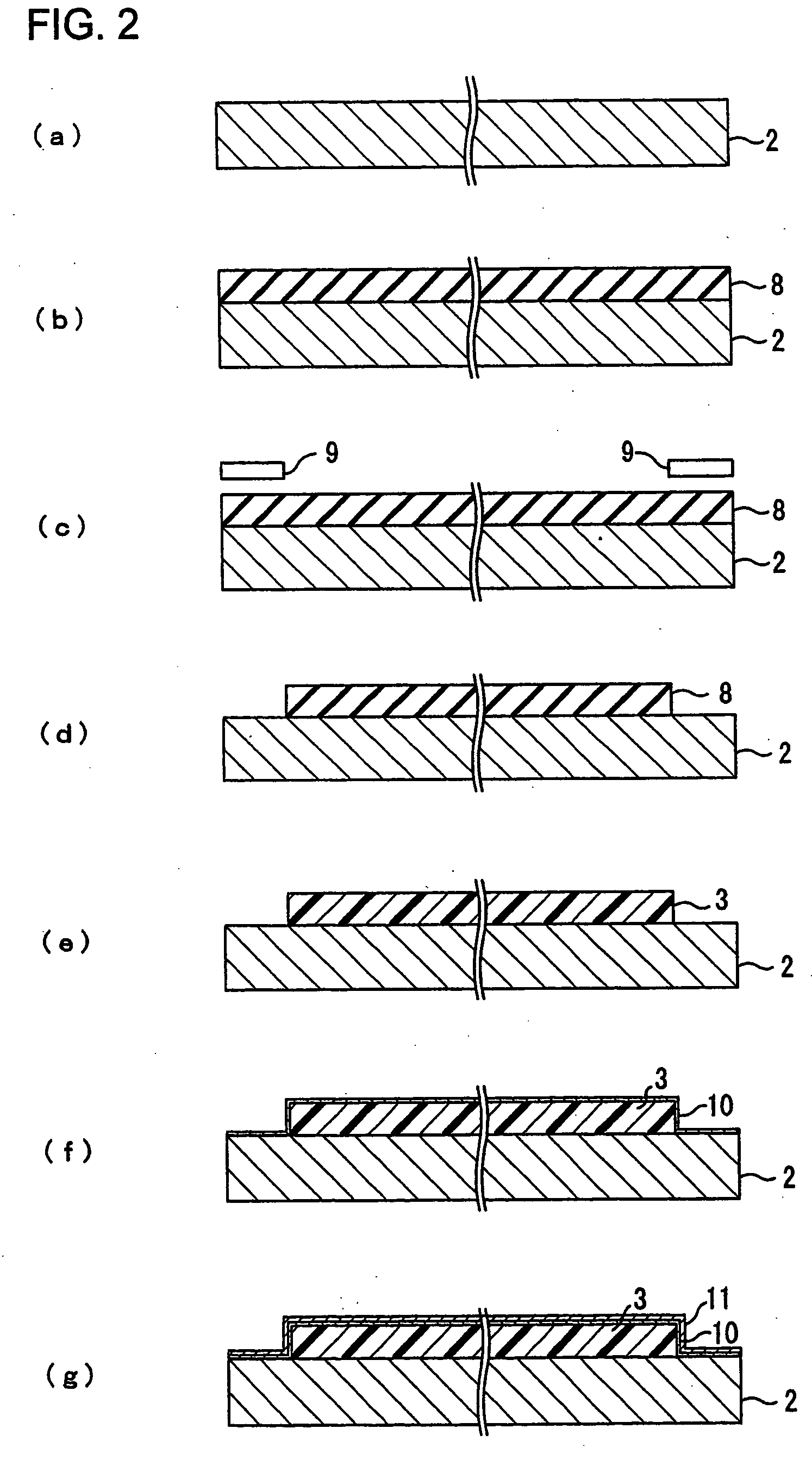

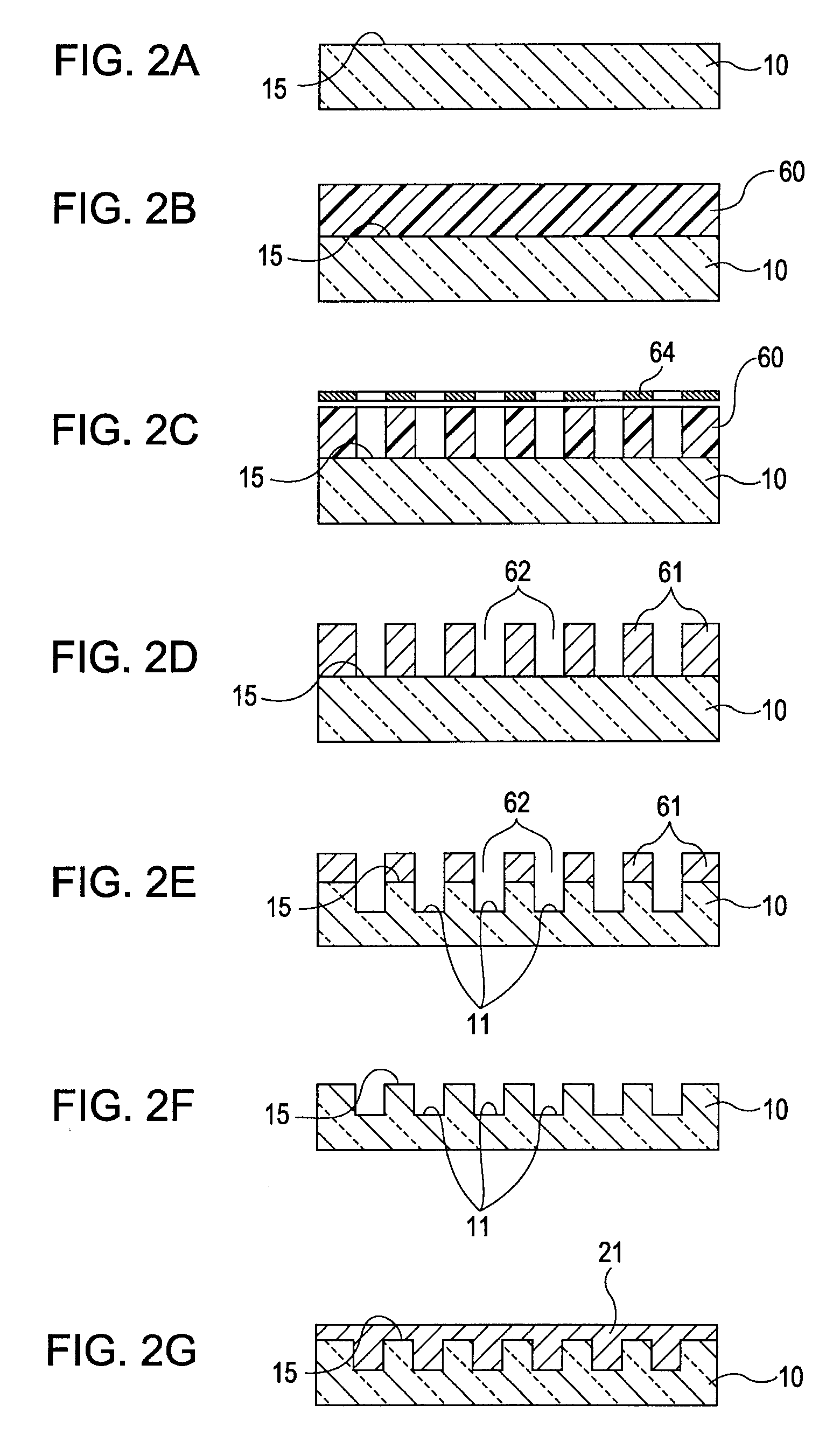

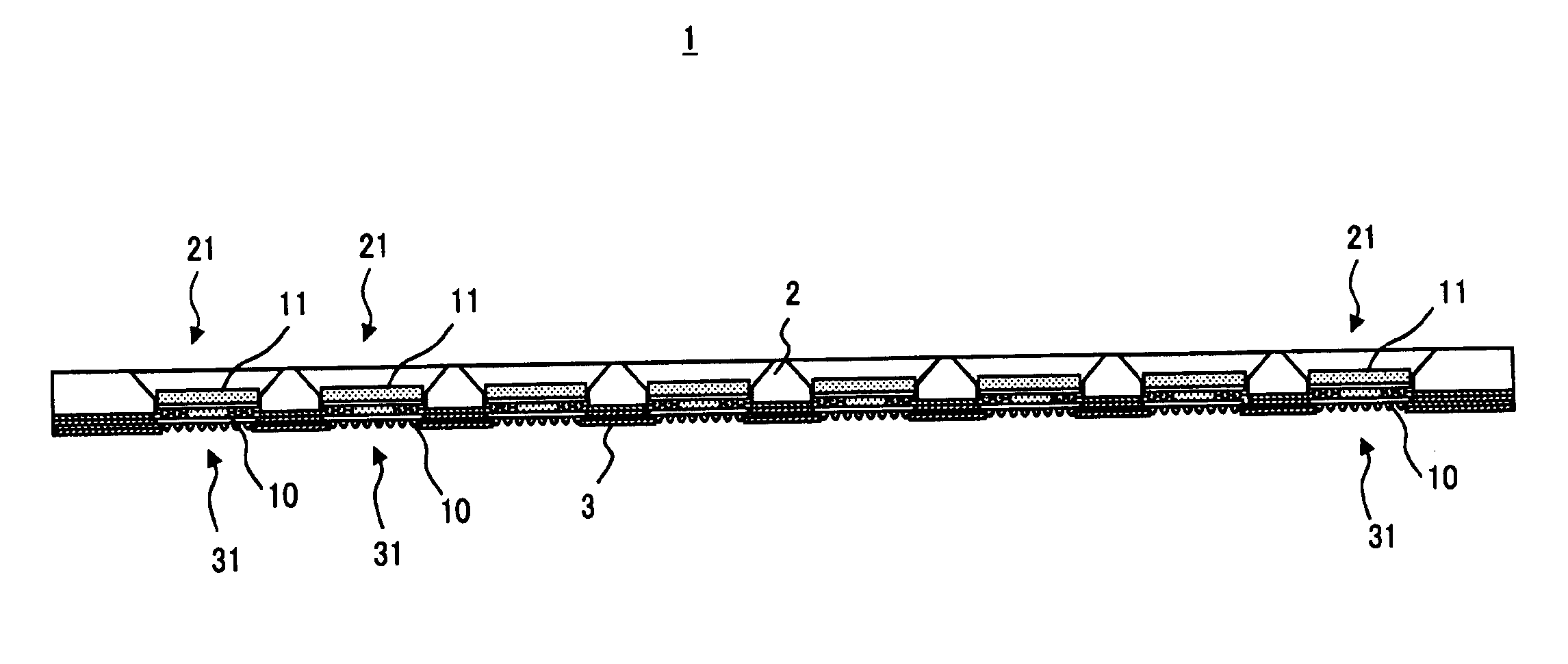

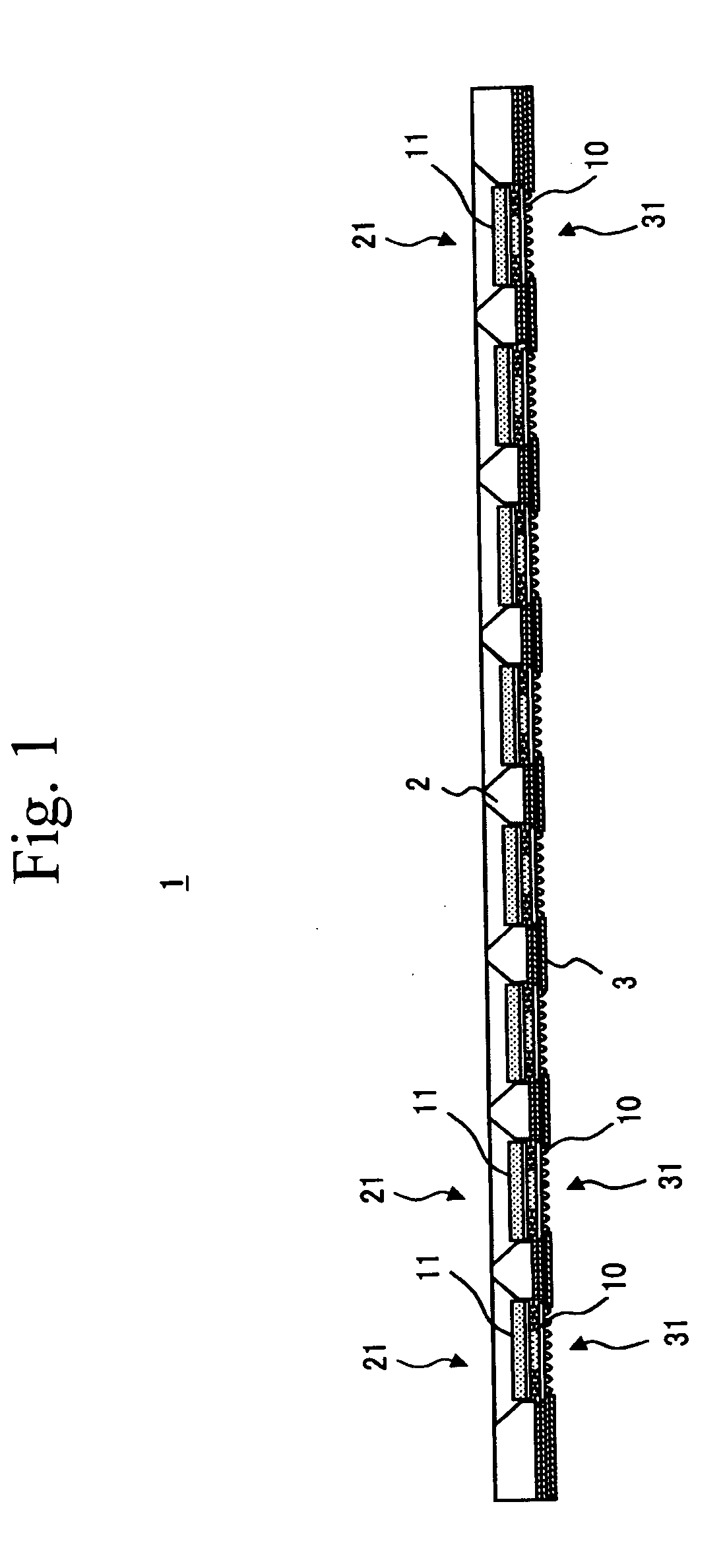

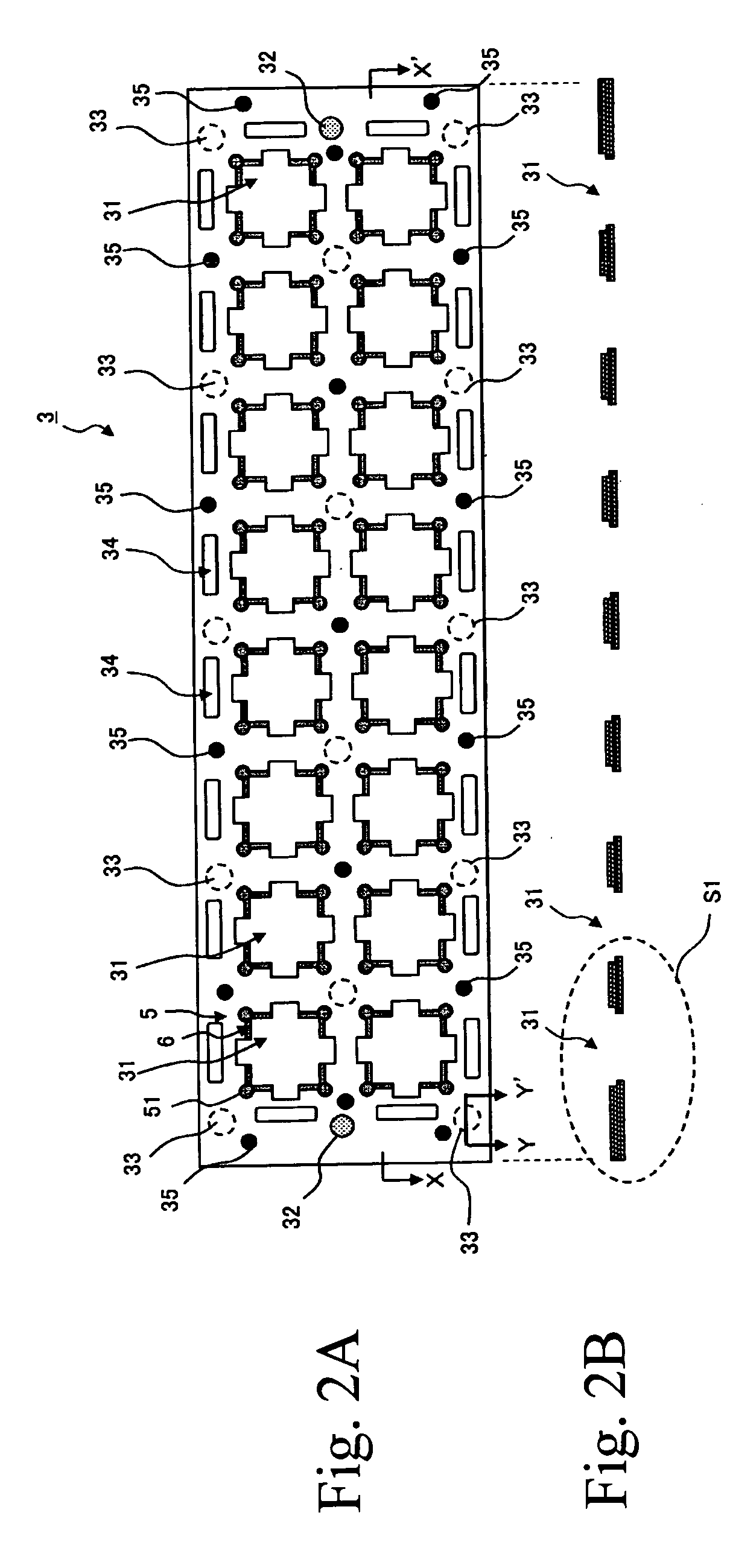

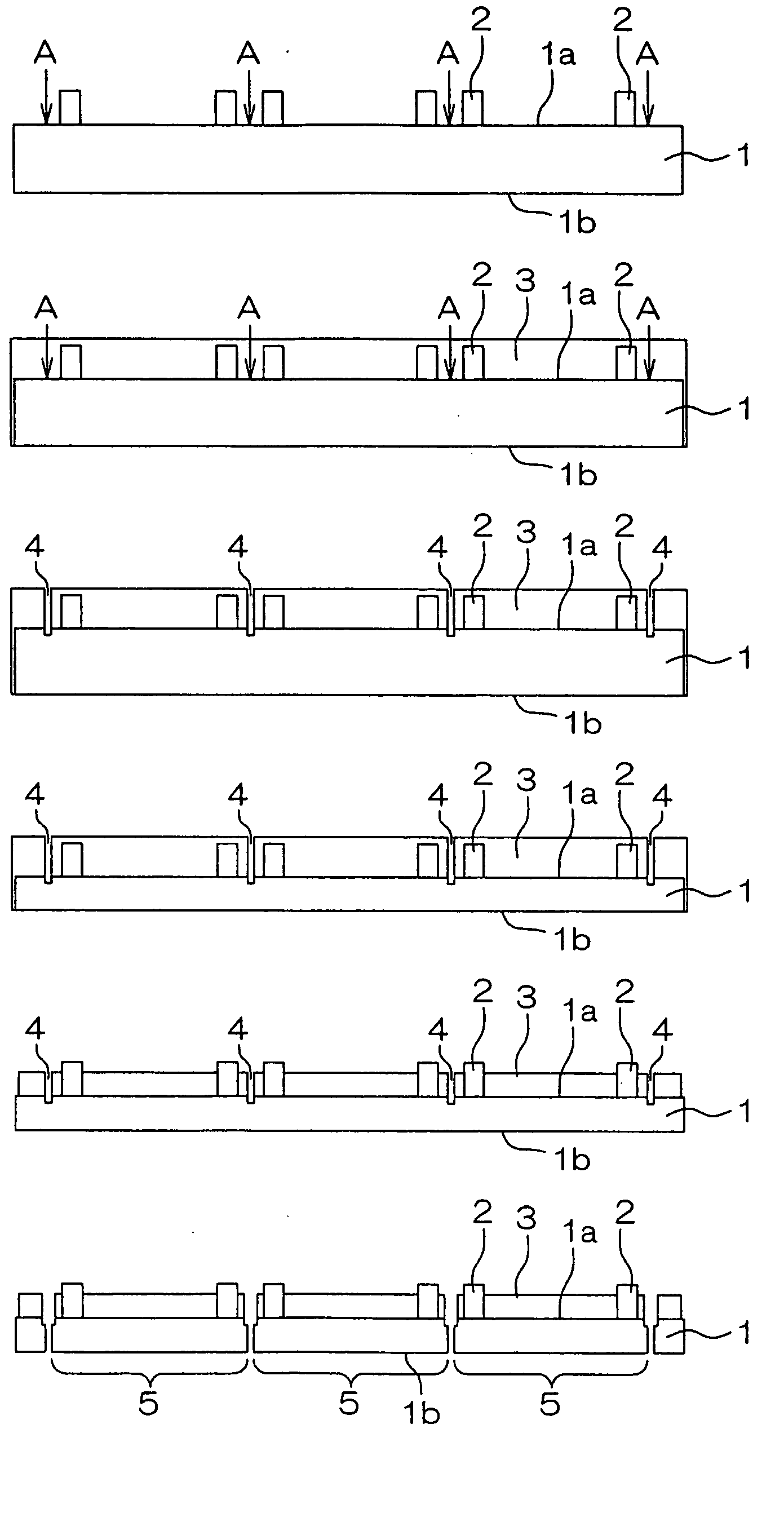

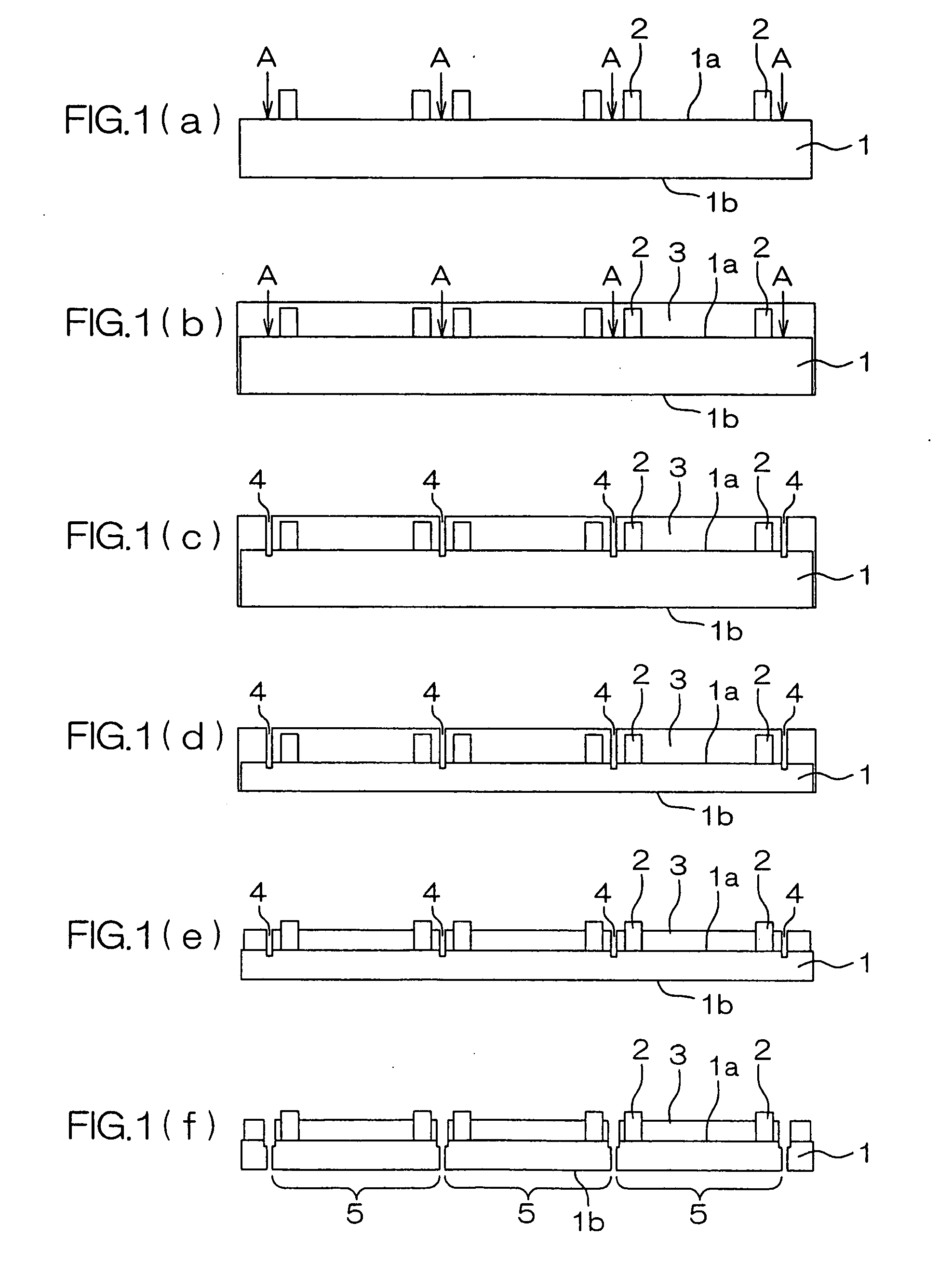

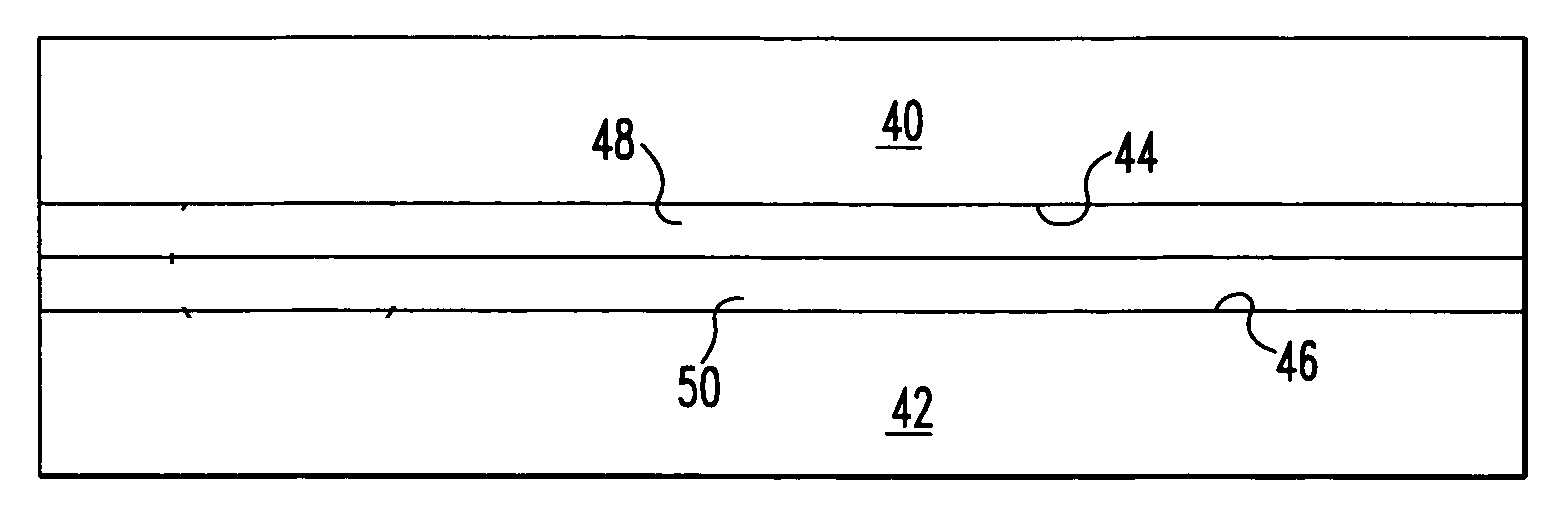

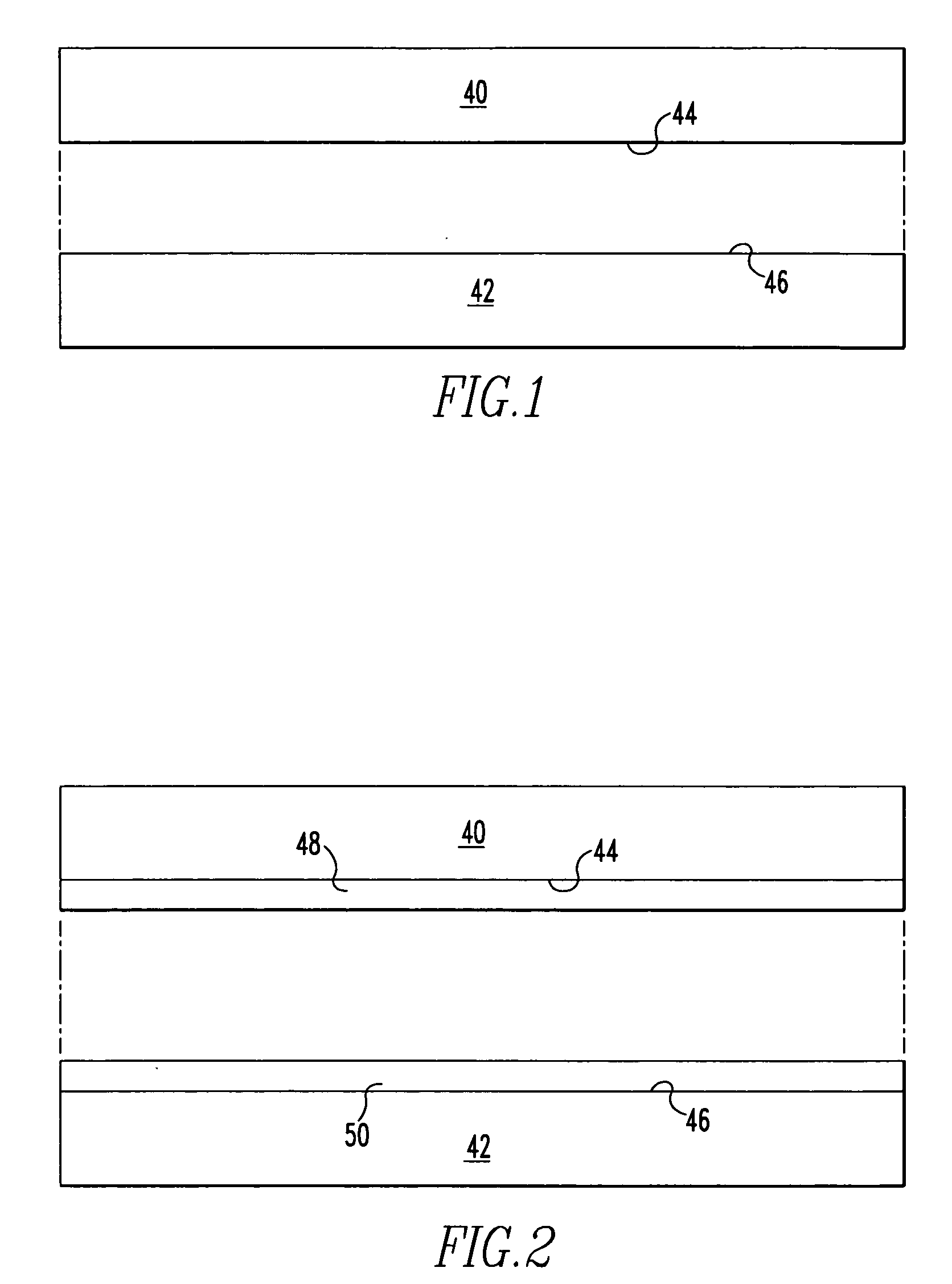

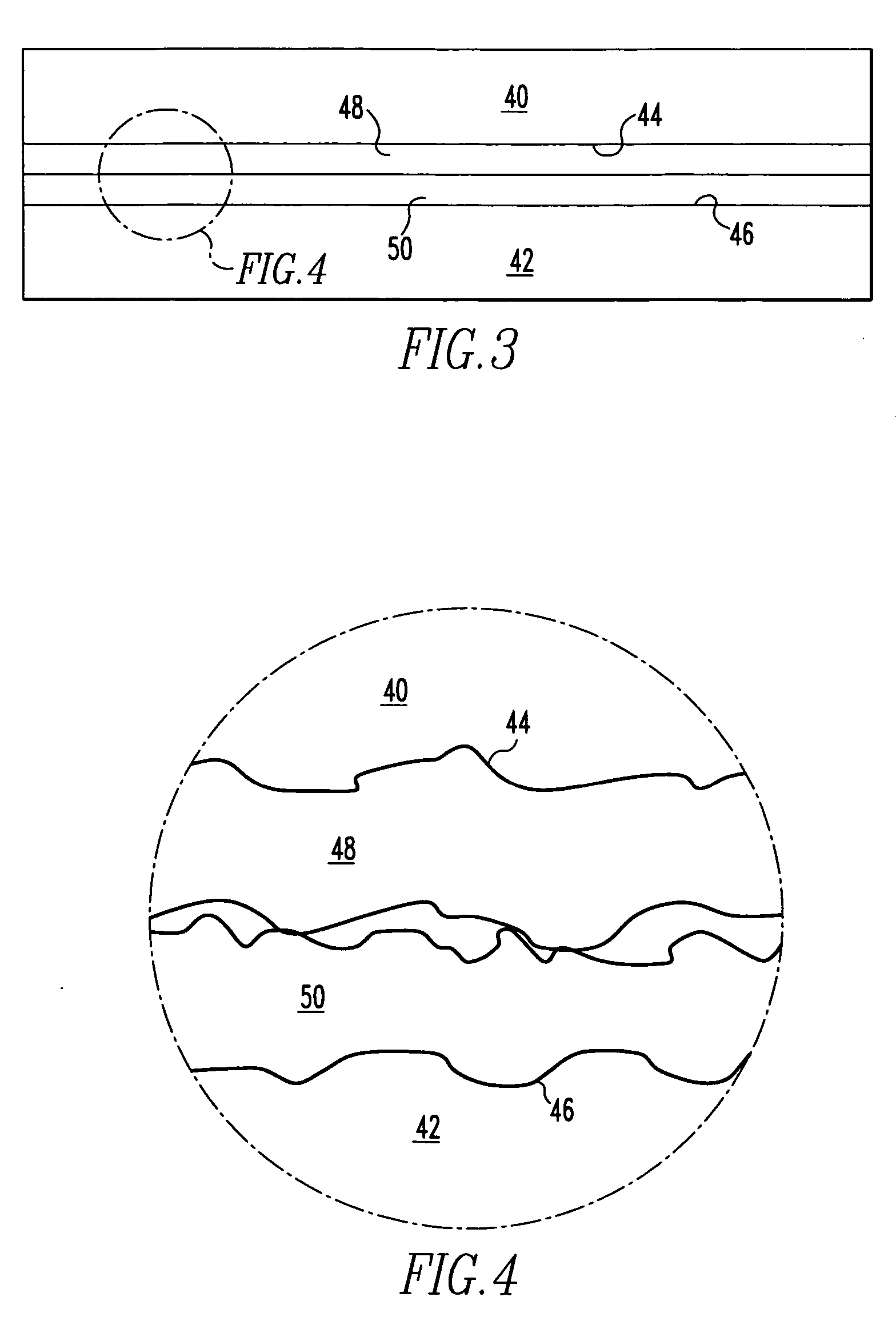

Production method of suspension board with circuit

InactiveUS20050186332A1Preventing deterioration of outward appearance and defectPrevent deterioration of outward appearance and defectFluid-dynamic spacing of headsRecord information storageResistElectrical conductor

In order to provide a new production method of a suspension board with circuit capable of preventing deterioration of the outward appearance and defects in products caused by a metal supporting layer, and further capable of forming an electroless nickel plating layer having an even thickness in a reliable manner, an insulating base layer is first formed on a supporting board, and a chromium thin film and a copper thin film are formed next sequentially on the surface of the supporting board exposed from the insulating base layer and on the entire surface of the insulating base layer. Subsequently, a plating resist is formed in a reversal pattern with respect to the wired circuit pattern on the surface of the copper thin film, and a conductor layer is formed on the surface of the copper thin film exposed from the plating resist by electrolytic plating. The plating resist is removed after an electroless nickel plating layer is formed on the conductor layer. Subsequently, the copper thin film and the chromium thin film are removed sequentially, and an insulating cover layer is formed next.

Owner:NITTO DENKO CORP

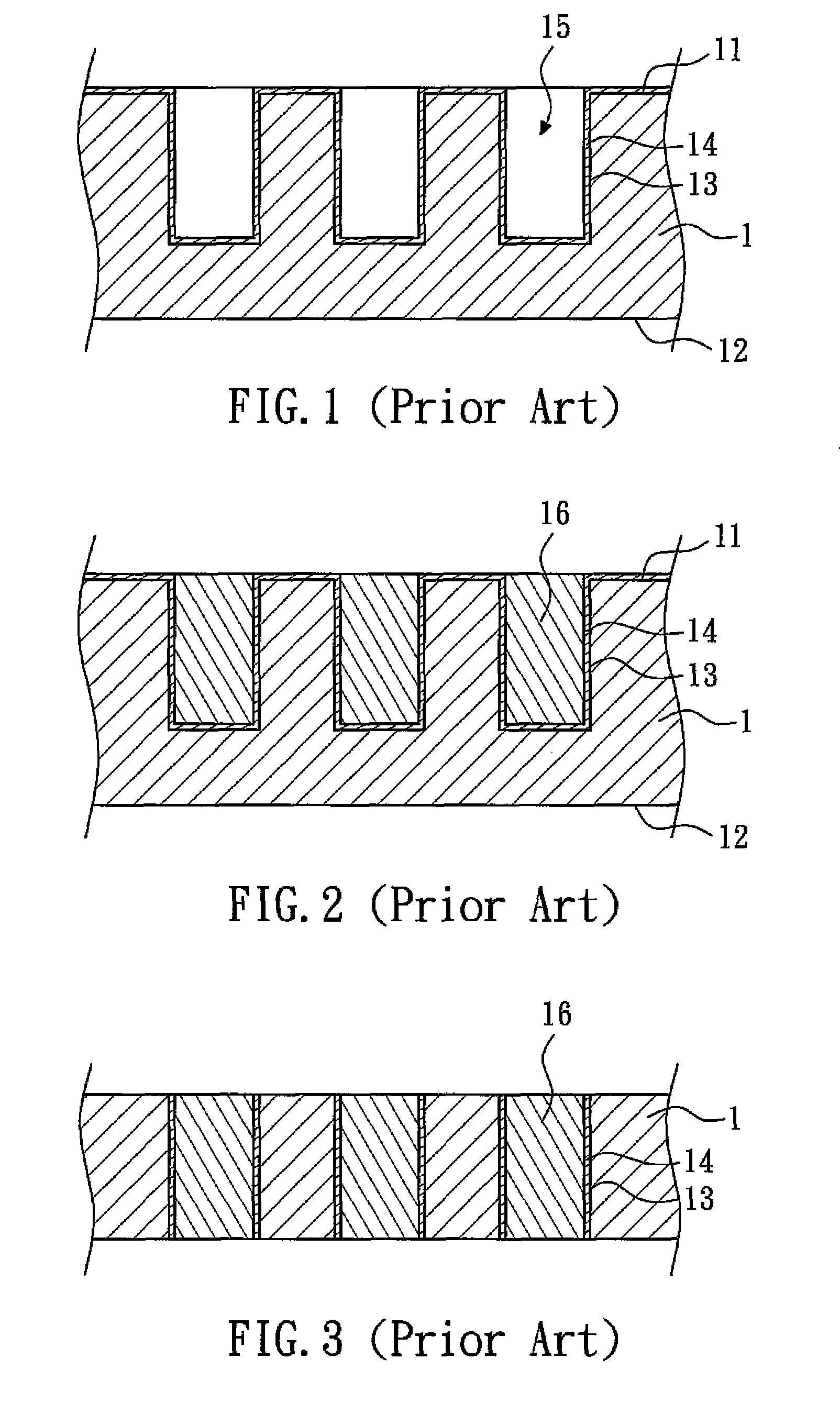

Wire grid type polarization element, manufacturing method thereof, liquid crystal device, and projection type display apparatus

InactiveUS20090027773A1High transmittanceHigh qualityOptical articlesPolarising elementsEngineeringLiquid crystal devices

There is provided a wire grid type polarization element equipped with a plurality of lines of metal grid on a translucent substrate. A plurality of lines of groove like concave portions are formed on the substrate, and the metal grid is embedded in the plurality of lines of groove like concave portions.

Owner:SEIKO EPSON CORP

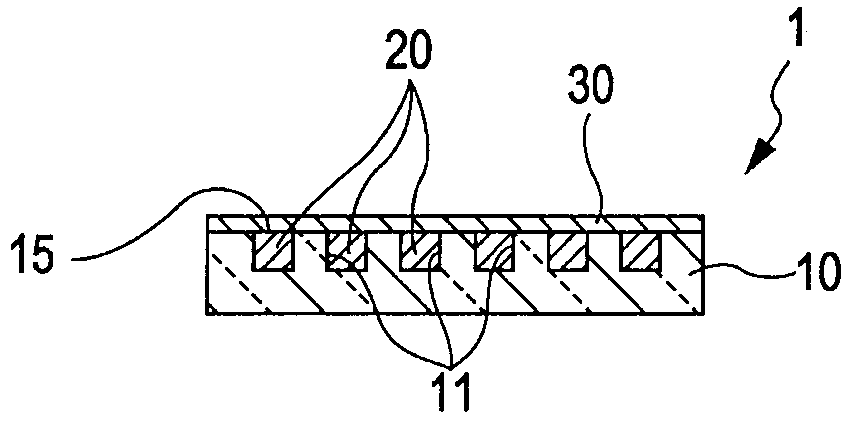

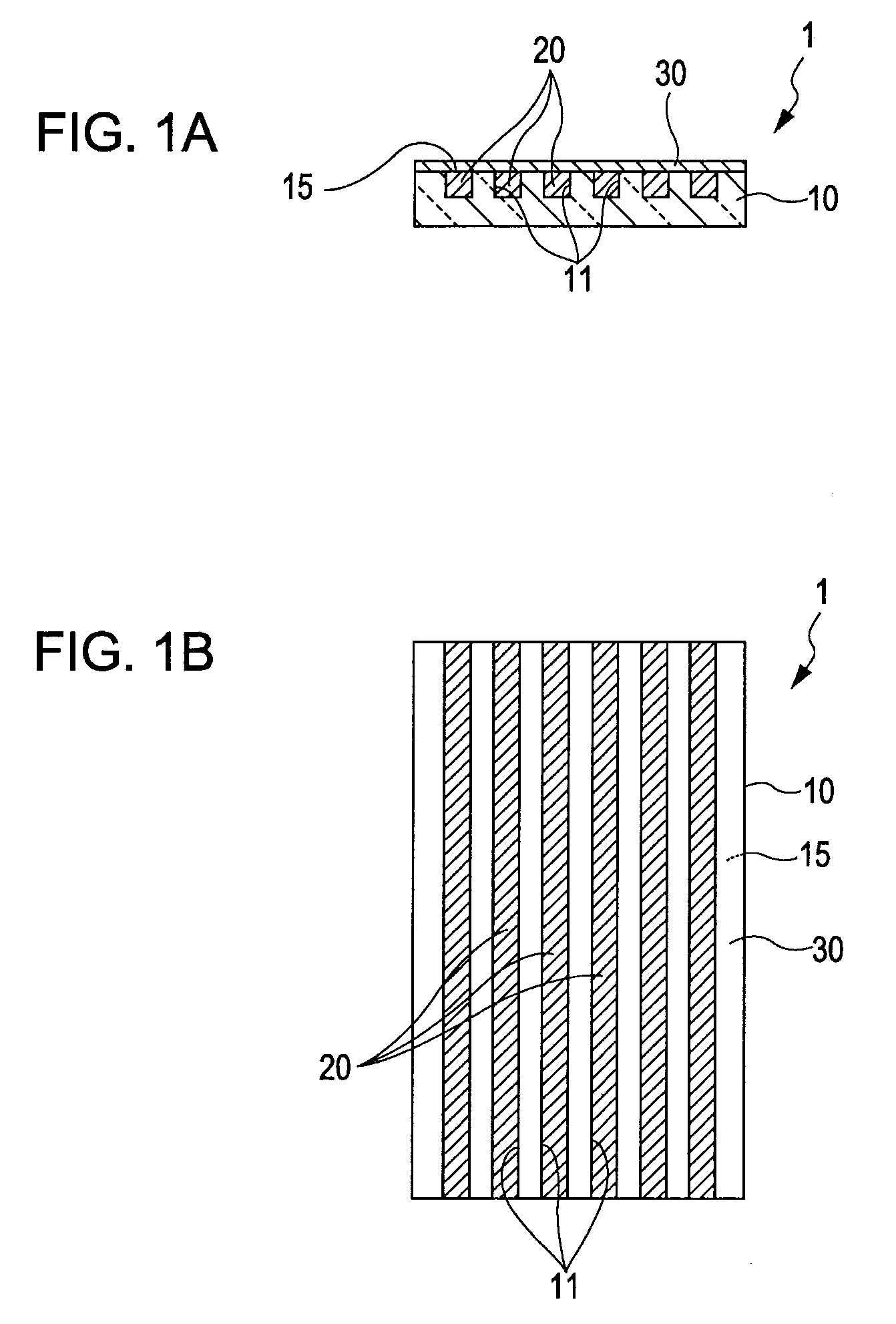

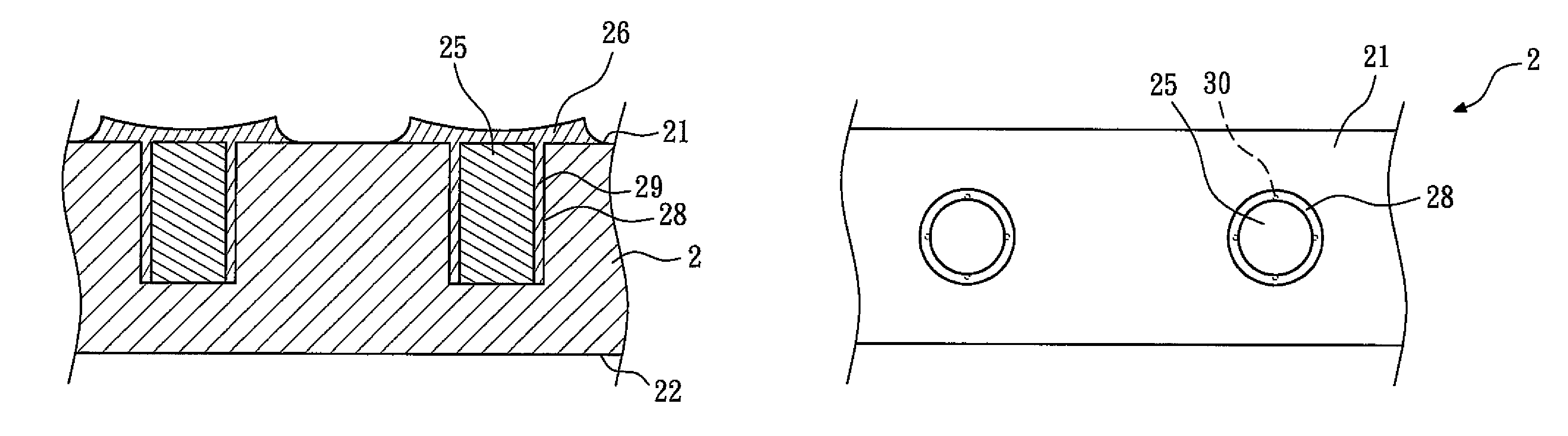

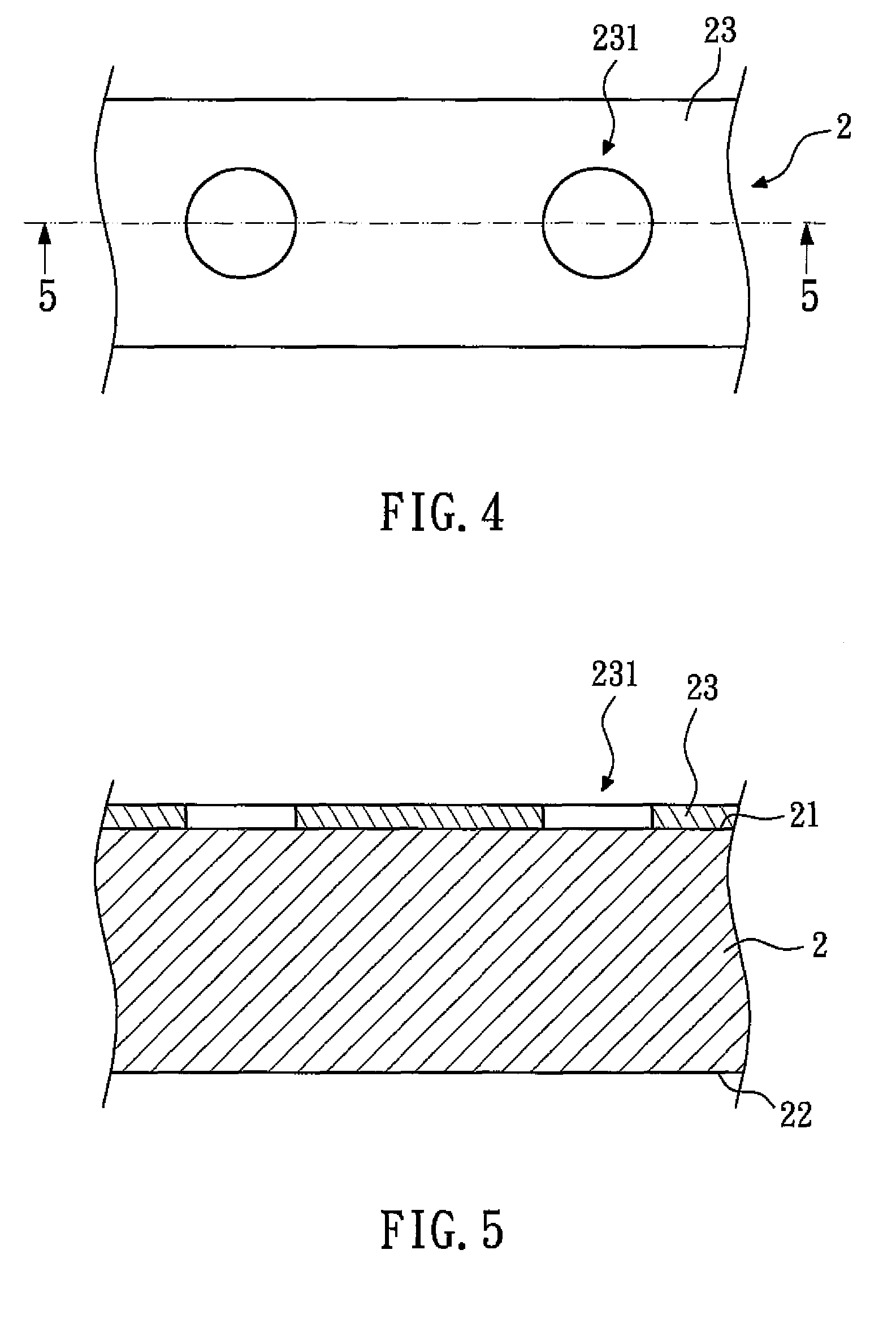

Method for forming vias in a substrate

ActiveUS7816265B2No thickness unevennessSemiconductor/solid-state device manufacturingOptoelectronicsMaterials science

A method for forming vias in a substrate, including the following steps: (a) providing a substrate having a first surface and a second surface; (b) forming a groove on the substrate; (c) filling the groove with a conductive metal; (d) removing part of the substrate which surrounds the conductive metal, wherein the conductive metal is maintained so as to form an accommodating space between the conductive metal and the substrate; (e) forming an insulating material in the accommodating space; and (f) removing part of the second surface of the substrate to expose the conductive metal and the insulating material. In this way, thicker insulating material can be formed in the accommodating space, and the thickness of the insulating material in the accommodating space is even.

Owner:ADVANCED SEMICON ENG INC

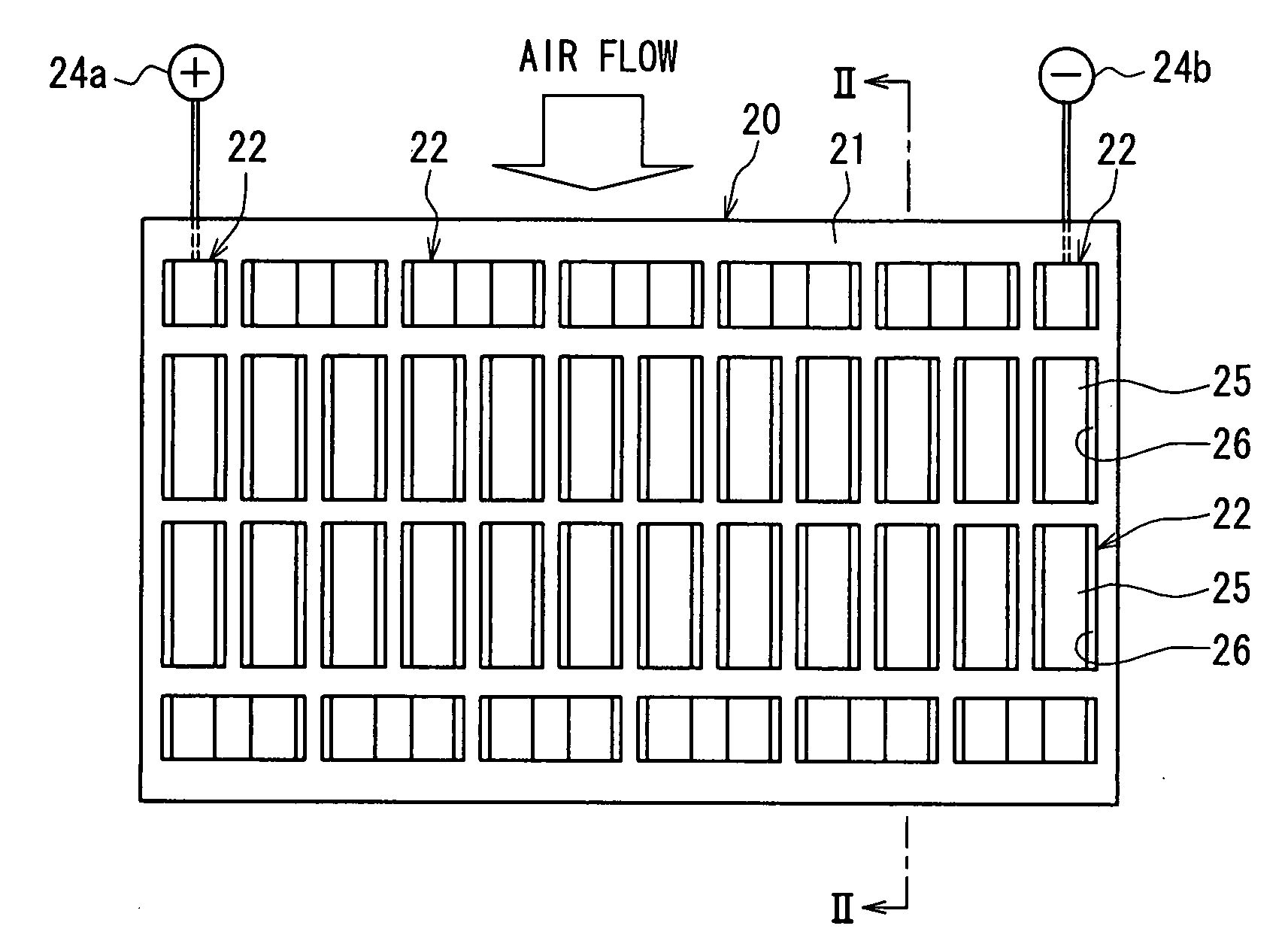

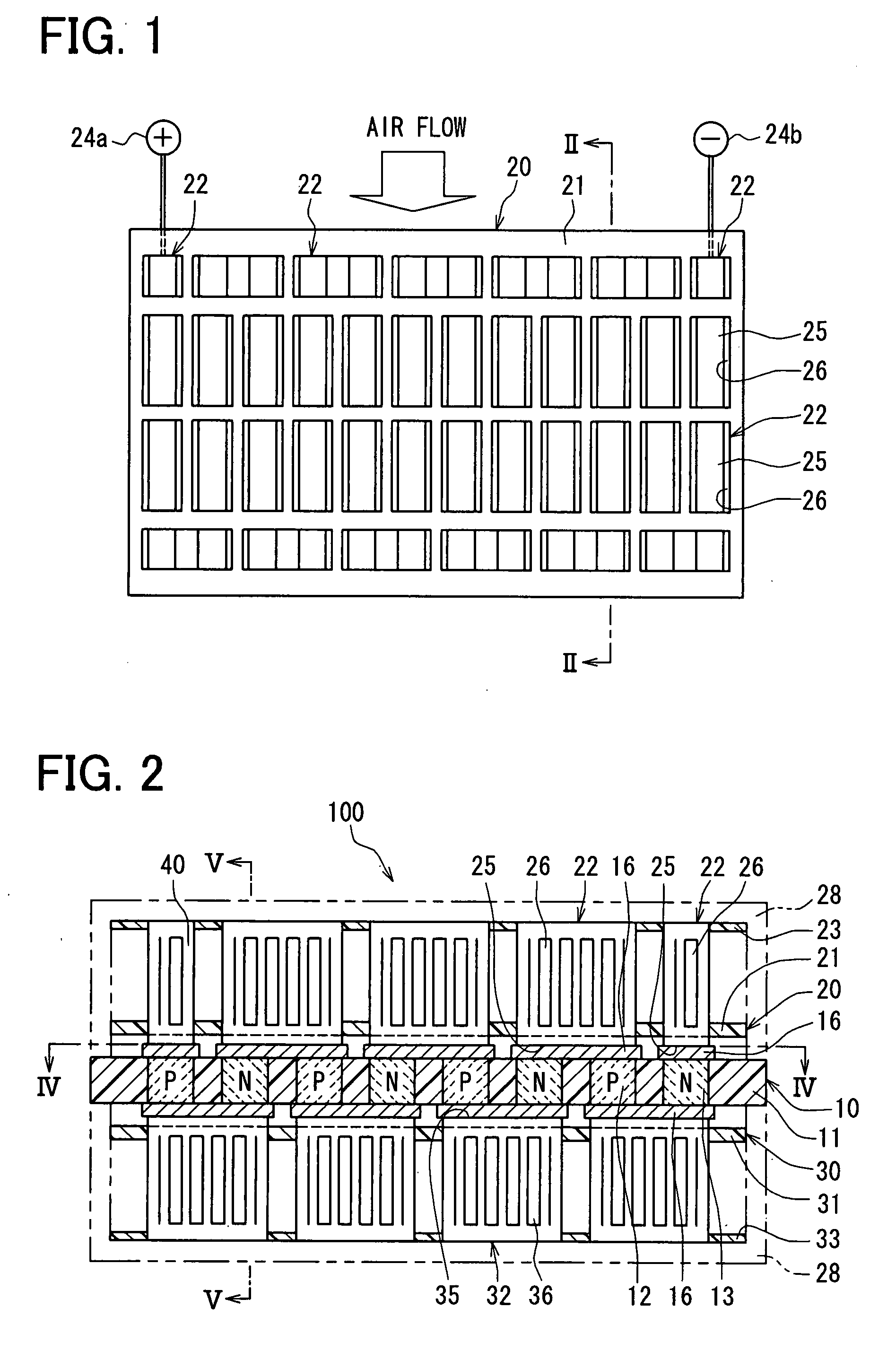

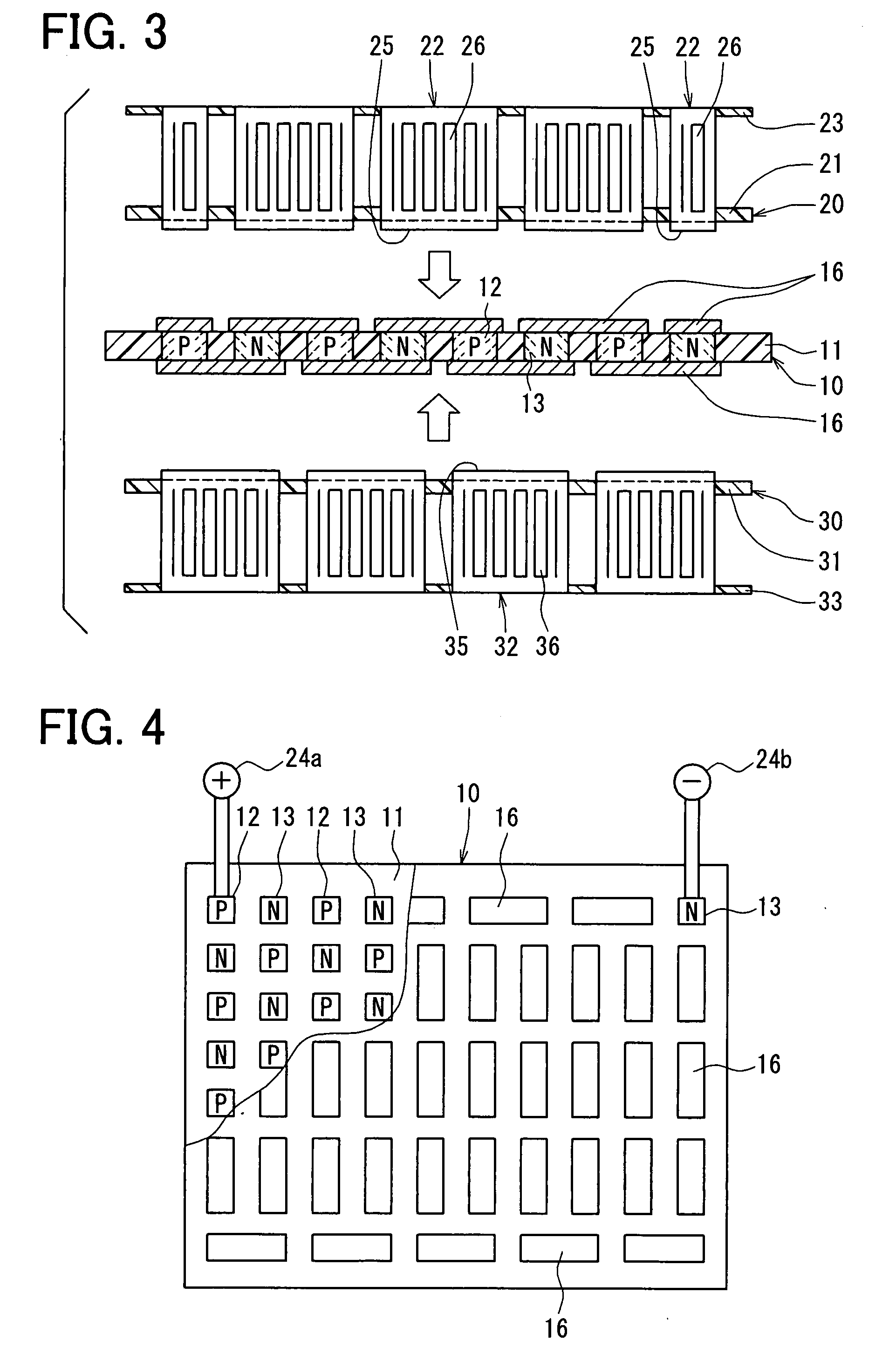

Thermoelectric conversion device and manufacture method of the same

InactiveUS20080000511A1Reduce deteriorationControl migrationThermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentCooking & bakingEngineering

A thermoelectric conversion device and a manufacture method for the thermoelectric conversion device are provided. The manufacture method includes a joining process for respectively joining heat exchanging members to thermoelectric-element pairs of an thermoelectric element module, an immersion process for immersing the thermoelectric element module and the heat exchanging members in an immersion sink where an melted insulating material is provided, and a baking process for baking an assembly of the thermoelectric element module and the heat exchanging members where the insulating material has been applied in the immersion process so that an insulating film is formed. Thus, an electrical insulation can be provided while a heat-exchanging capacity and an air-blowing capacity are maintained.

Owner:DENSO CORP

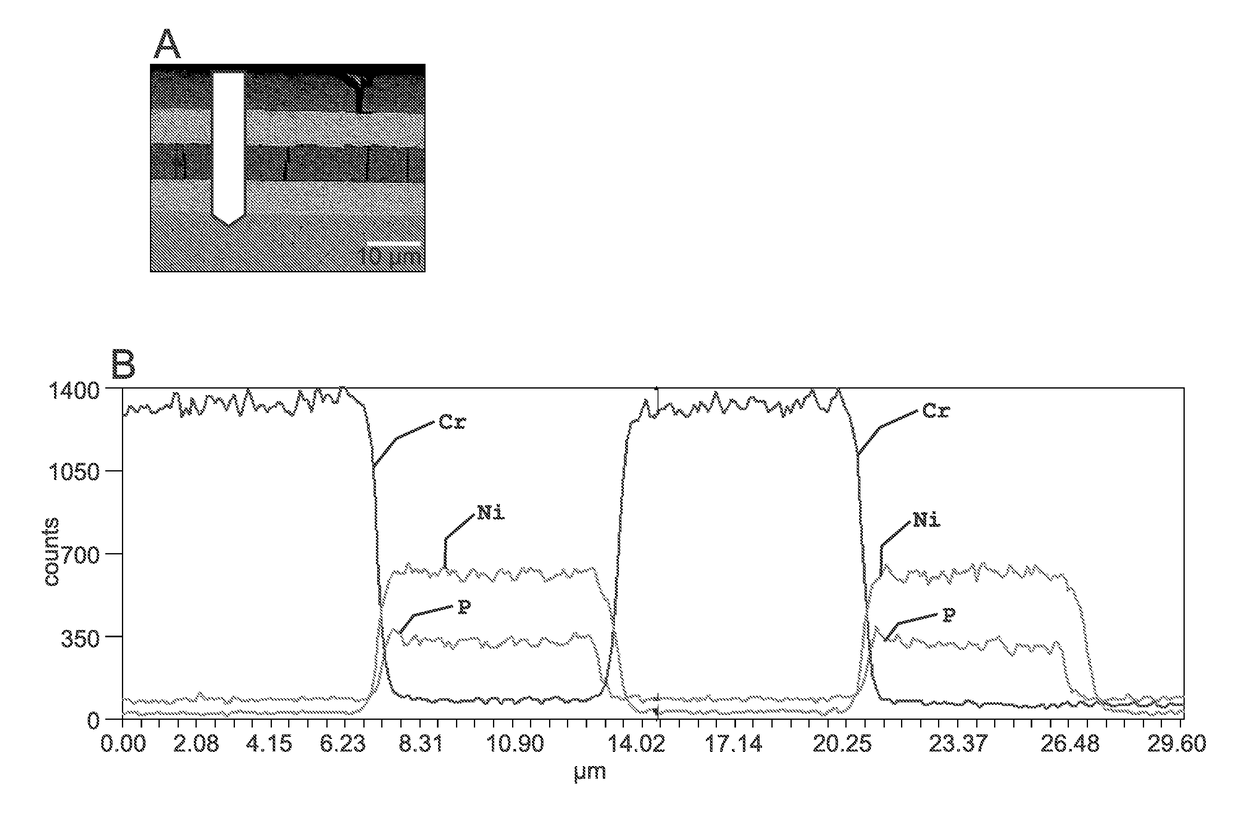

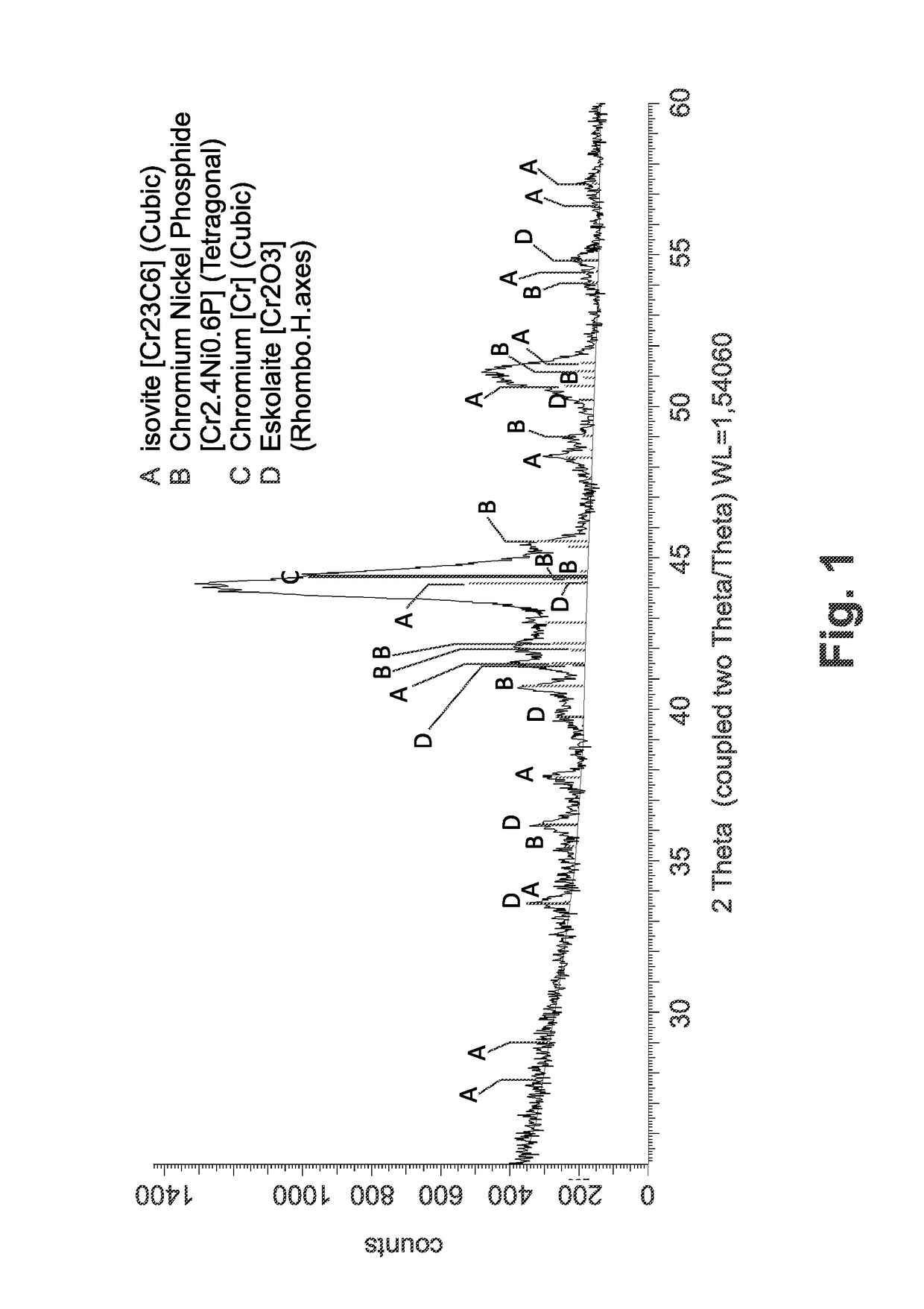

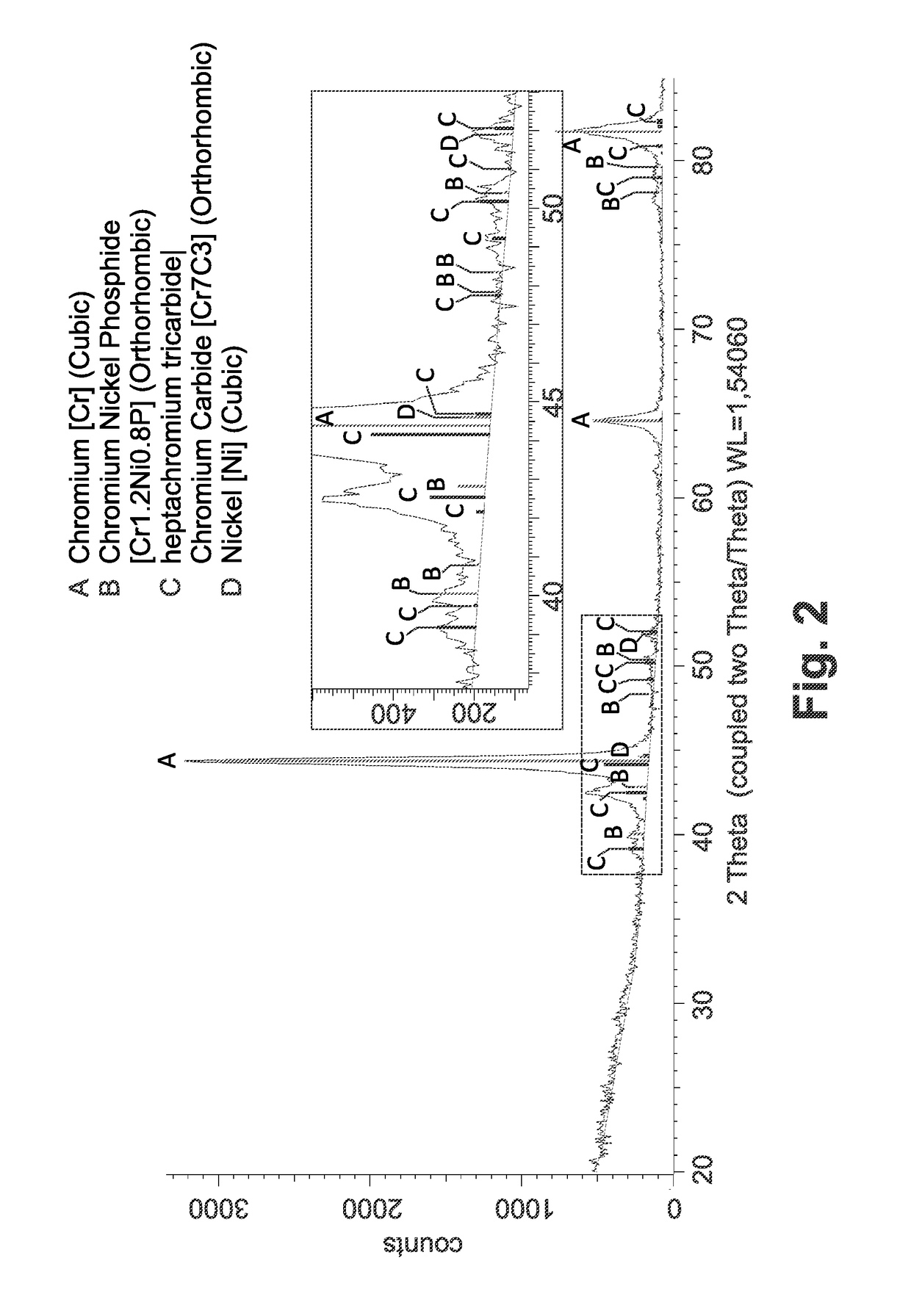

A chromium-containing coating, a method for its production and a coated object

ActiveUS20170159198A1High and adjustable hardnessImprove corrosion resistanceLiquid/solution decomposition chemical coatingSuperimposed coating processPhysical chemistryCrystallization

The invention relates to a chromium-based coating comprising at least one layer rich in crystalline phase or phases of nickel (Ni) and / or Ni compounds, and at least one layer rich in crystal-line phase or phases of chromium (Cr) and / or Cr compounds, Cr being electroplated from a trivalent chromium bath. The coating is characterized in that the it further comprises one or more crystalline phases of chromium-nickel-phosphorus (CrNiP), which CrNiP phase has been produced by heat treating a coating comprising at least one layer of nickel-phosphorus (NiP) and at least one layer of Cr. The invention also relates to a method for producing a chromiumbased coating and to a coated object.

Owner:SAVROC

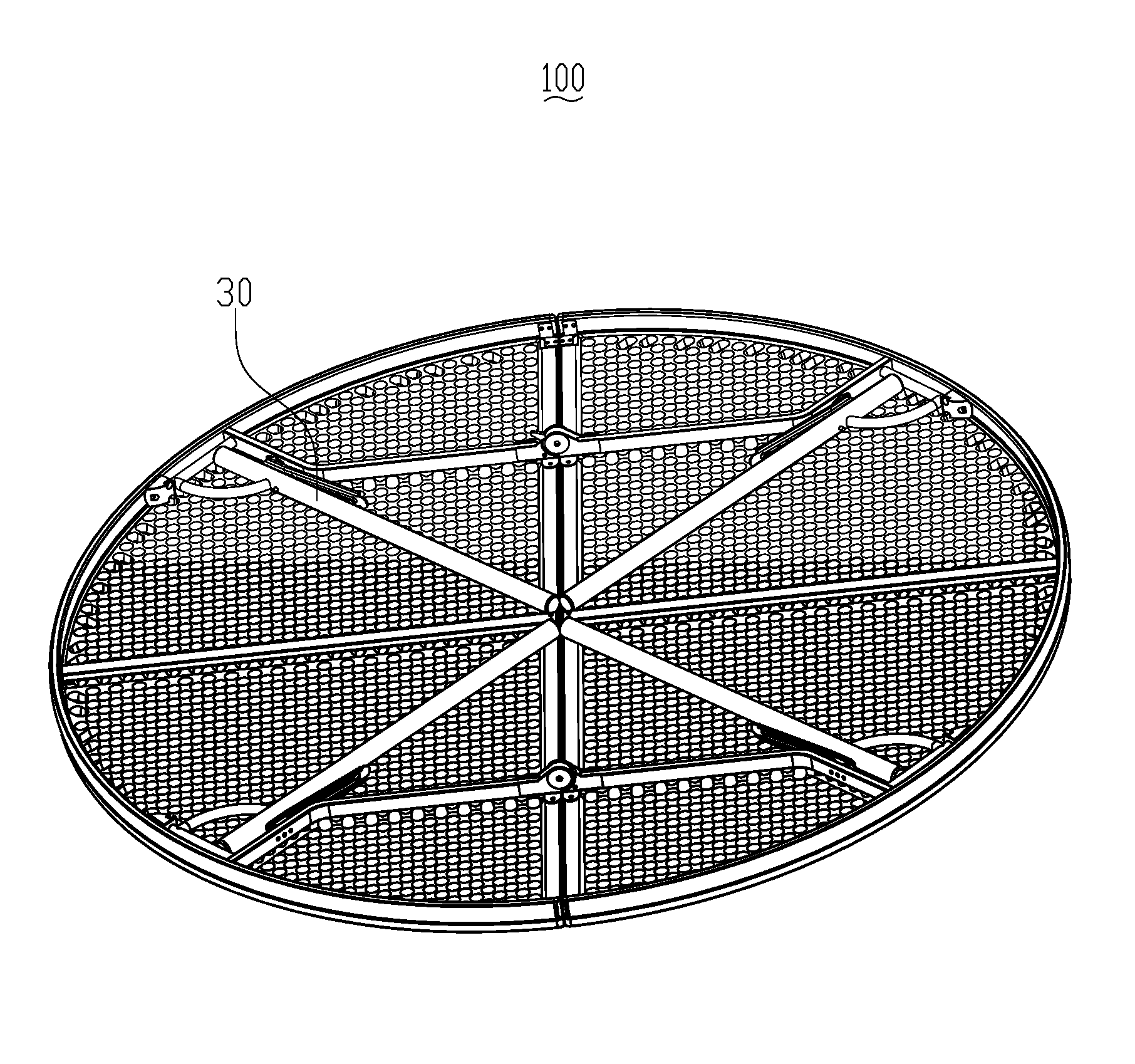

Folding round table

ActiveUS9504314B2Maximally lengthenReduce spacingFoldable tablesStowable tablesRound tableEngineering

Owner:NEW TEC INTEGRATION (XIAMEN) CO LTD

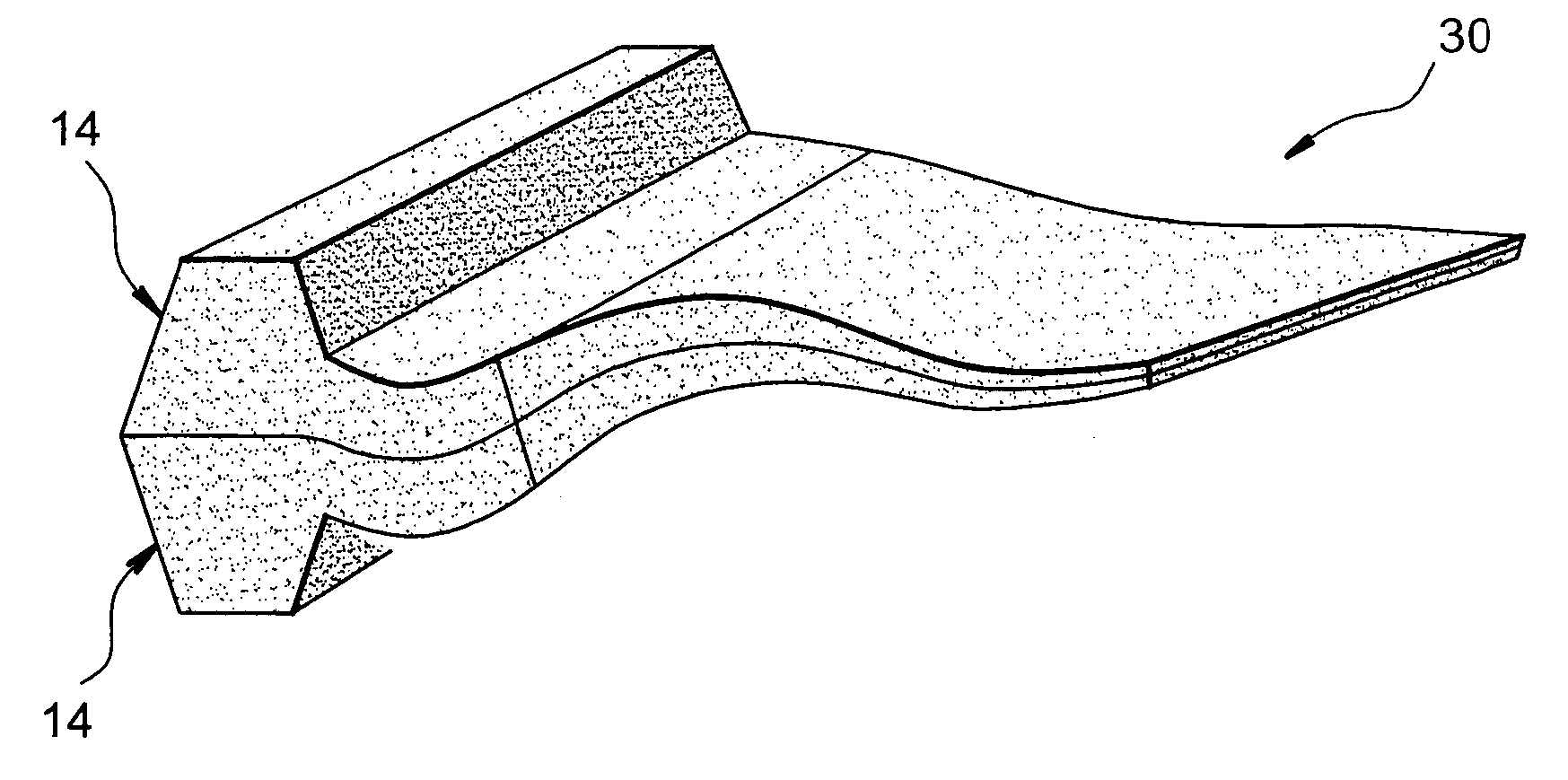

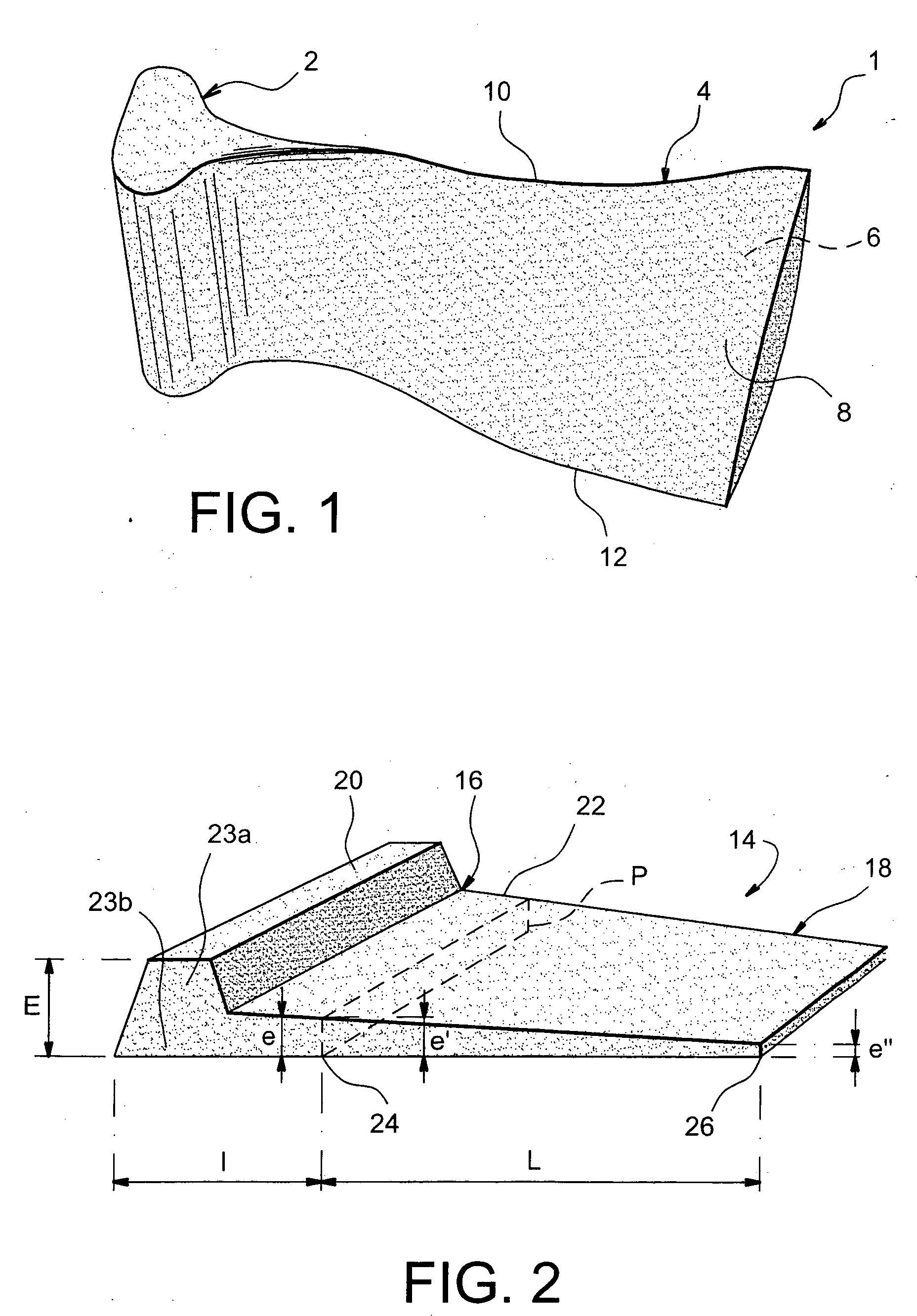

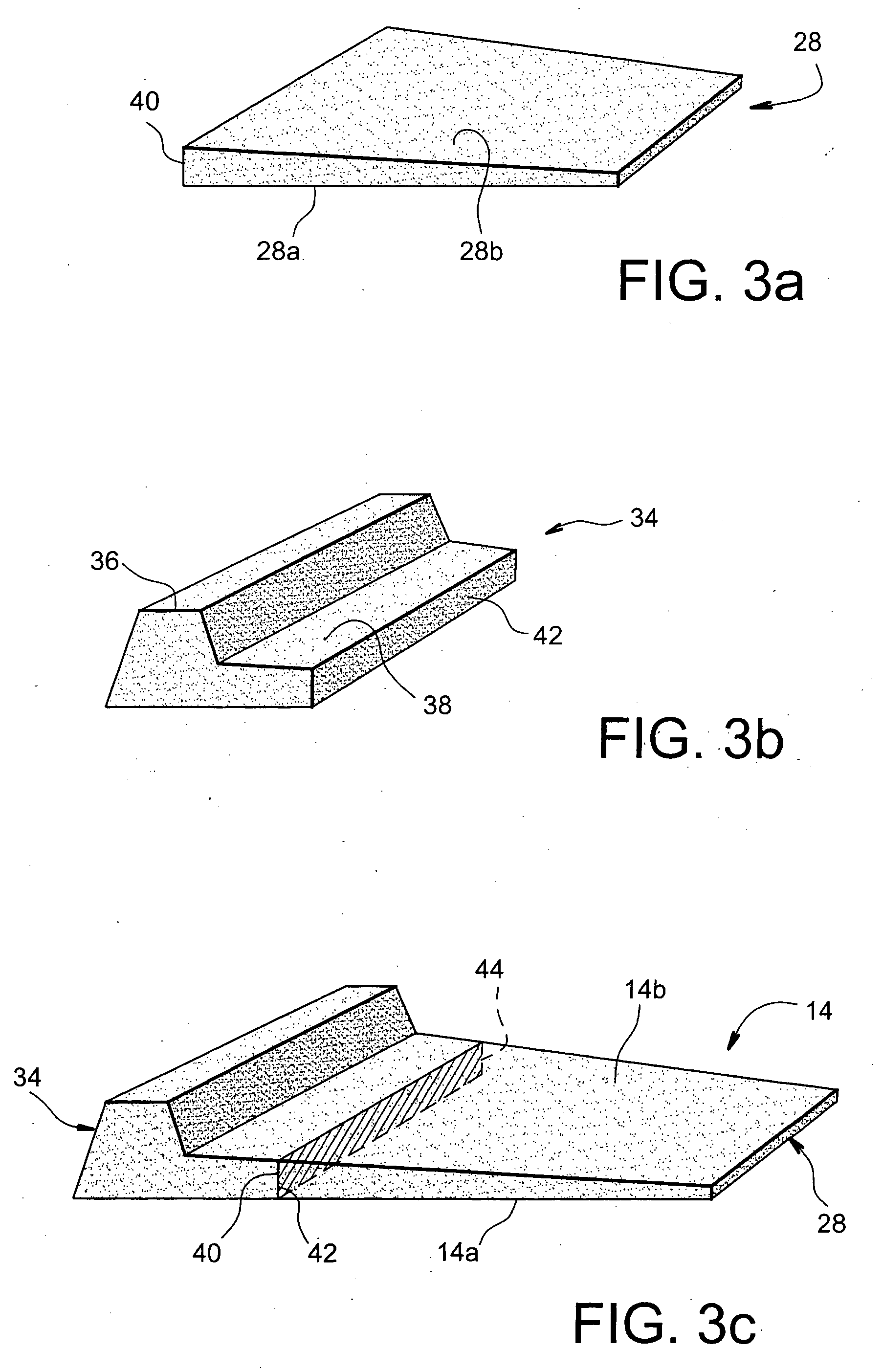

Method of manufacturing a hollow blade for a turbine engine

ActiveUS20050005445A1Reduce manufacturing costNo thickness unevennessTurbinesPump componentsTurbineRazor Blade

The invention relates to a method of manufacturing a hollow blade for turbine engine comprising a foot and a rotor blade, the method comprising a production stage of two external parts (14) as well as an assembling stage via diffusion bonding of these two external parts so as to obtain a blade preform. According to the invention, the production stage of the two external parts comprises, for each of these parts, the following operations: the making via forging of a primary element (28) constituting at least a rotor blade part of the external part; the making via forging of at least a secondary element (34) intended to form at least partially a foot part of the external part; and the assembling of each secondary element (34) onto the primary element so as to obtain the external part.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

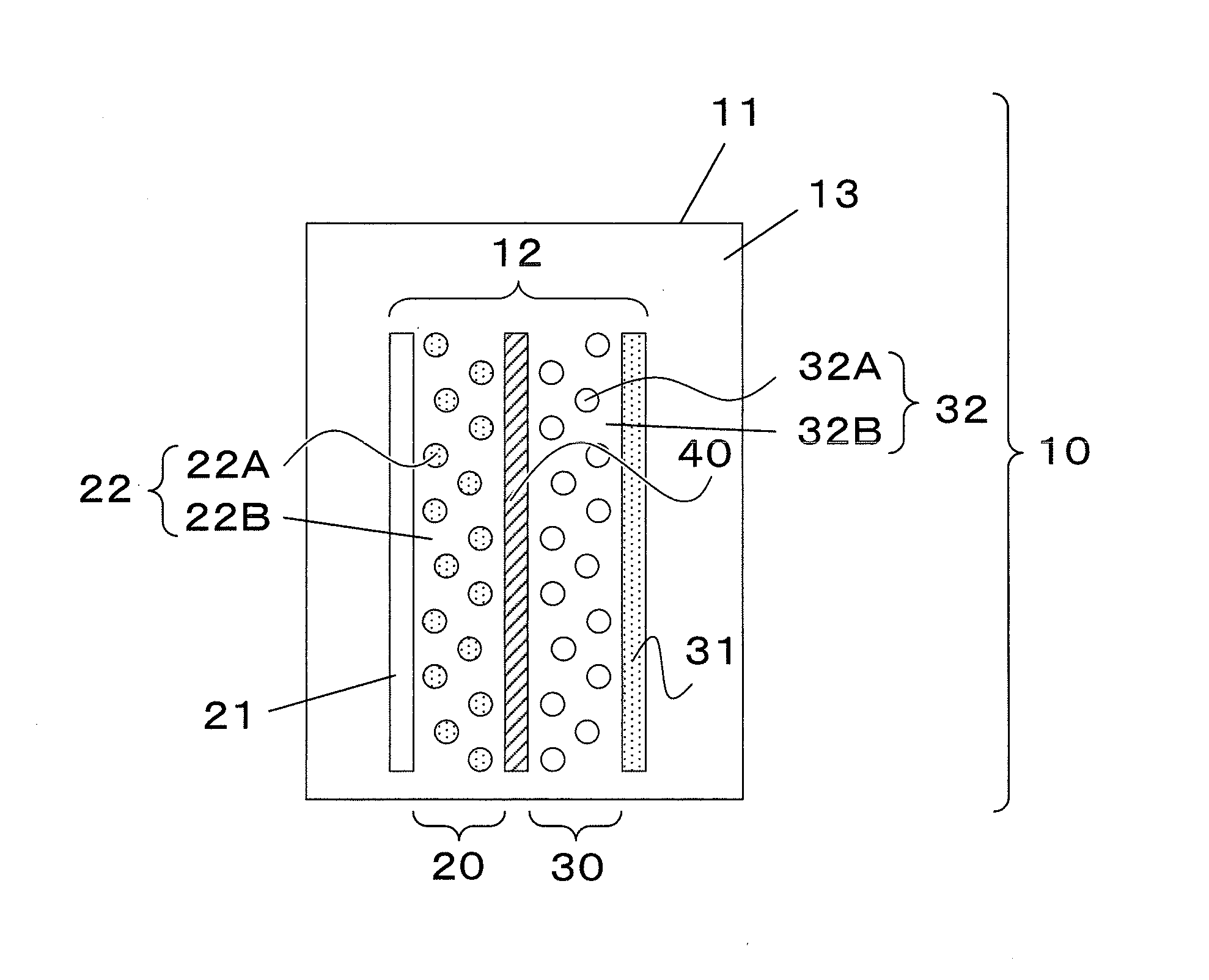

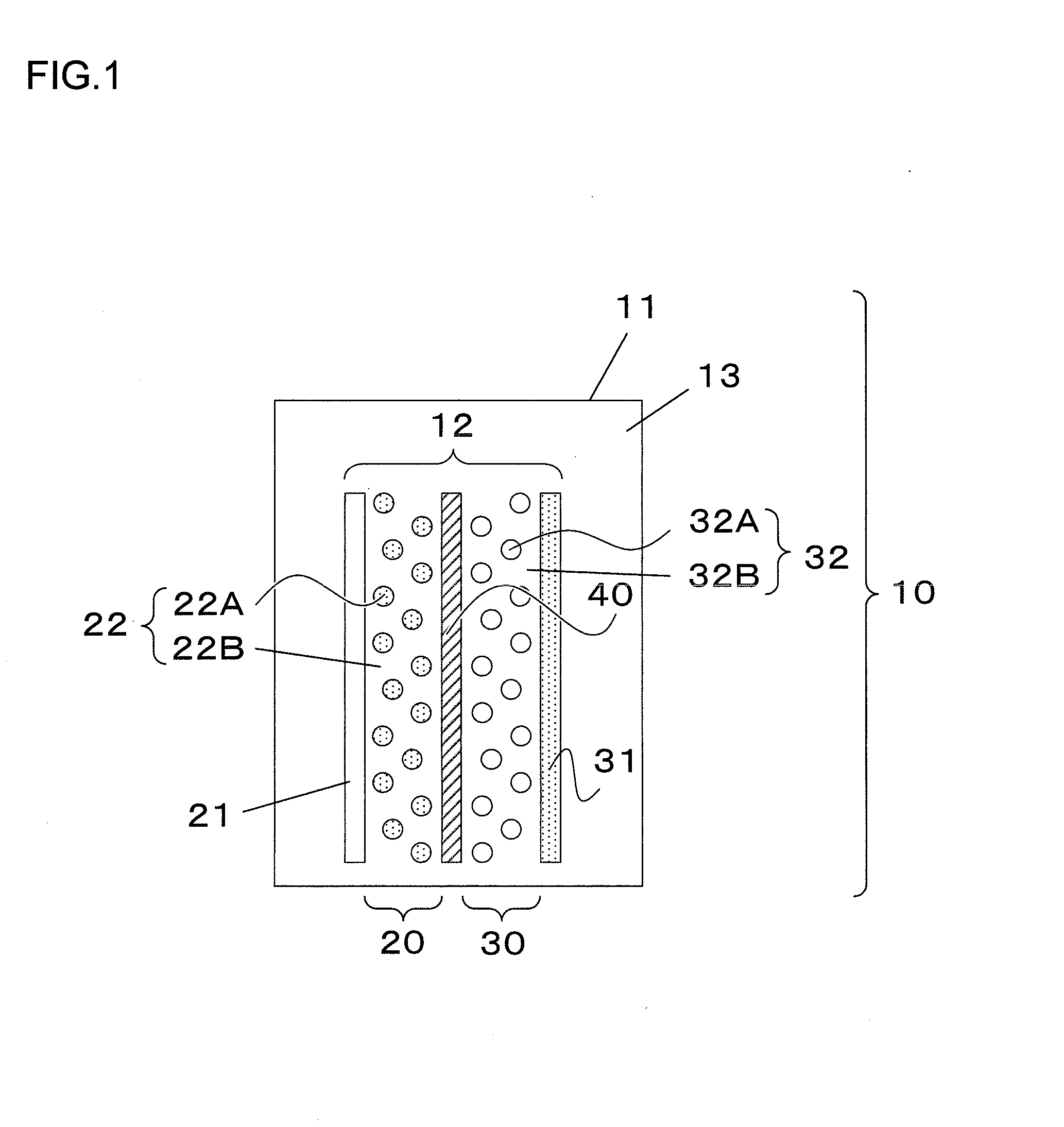

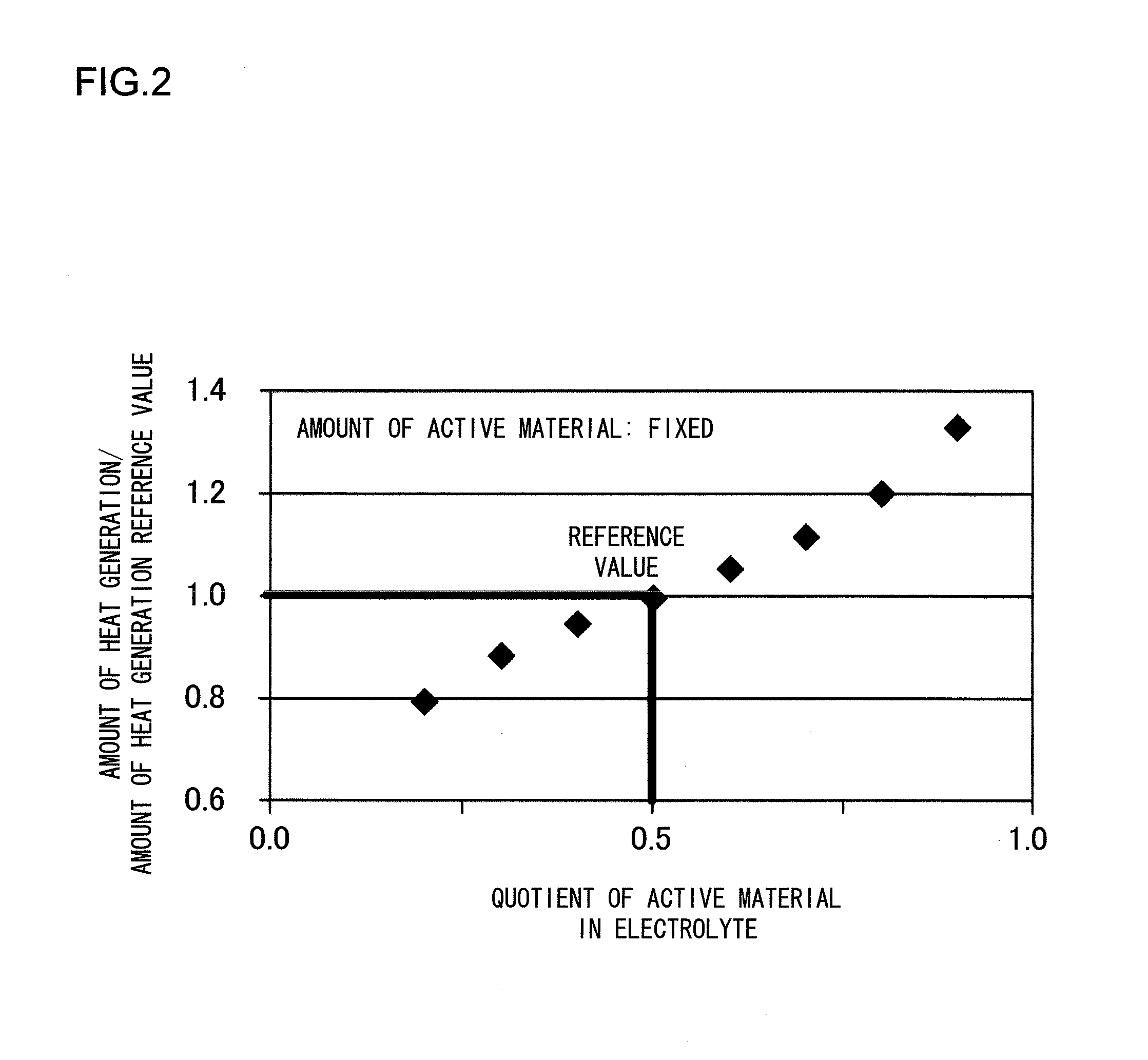

Storage Battery Cell, Assembled Battery, Assembled Battery Setup Method, Electrode Group, and Production Method of Electrode Group

InactiveUS20130017425A1No thickness unevennessLower performance requirementsCell seperators/membranes/diaphragms/spacersFinal product manufactureEngineeringBattery cell

A storage battery cell includes: an electrode group in which a positive electrode including positive electrode current collector foil provided with a positive electrode layer containing a positive electrode active material, a negative electrode including negative electrode current collector foil provided with a negative electrode layer containing a negative electrode active material, and a separator that intervenes between the positive electrode and the negative electrode are laminated; a battery cell container; and an electrolyte, wherein: the positive electrode active material and the negative electrode active material respectively are substantially uniformly distributed, and the positive electrode layer and the negative electrode layer are provided respectively with regions in which respective quotients of the positive active material and the negative active material in the electrolyte are varied.

Owner:HITACHI LTD

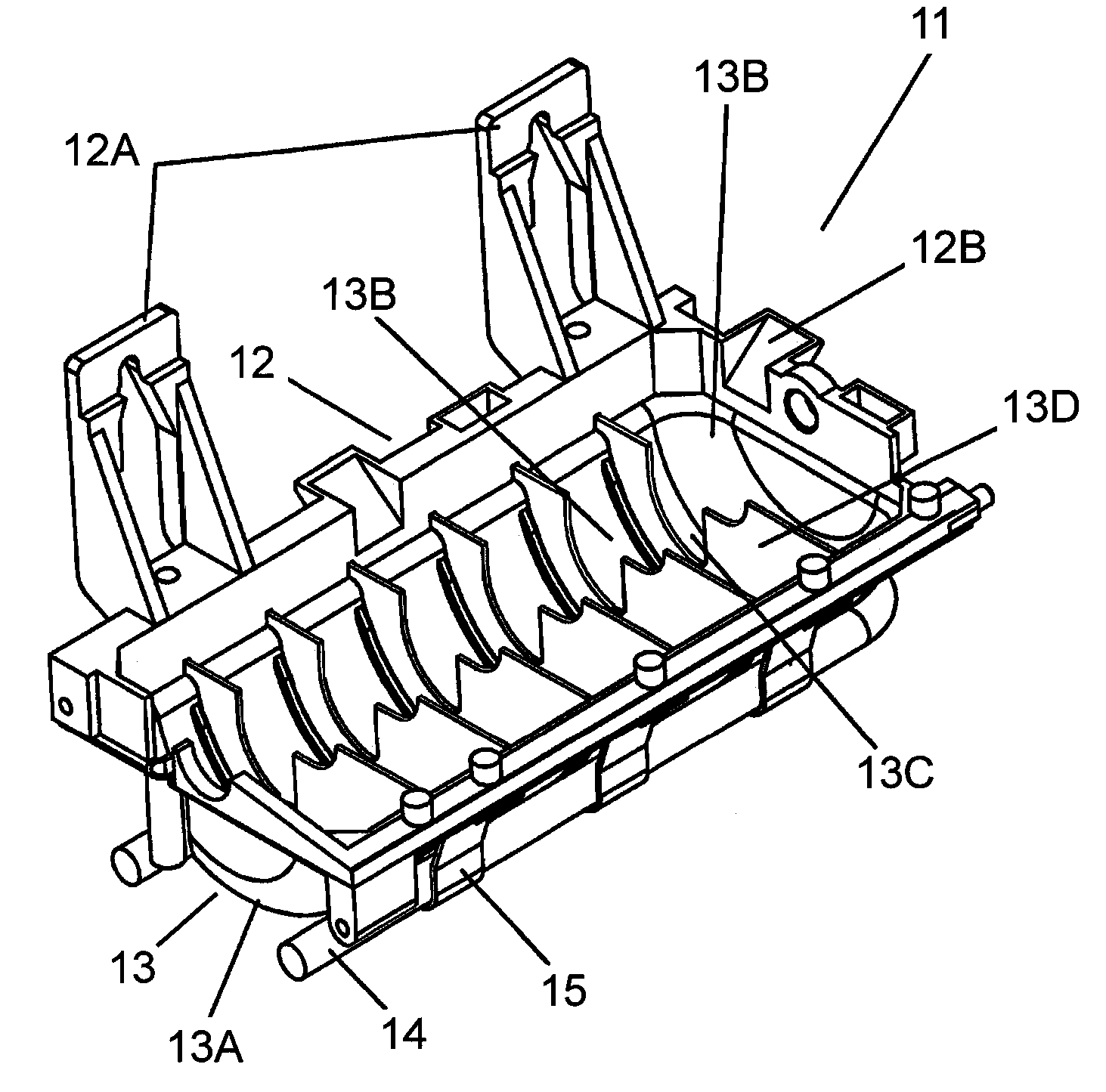

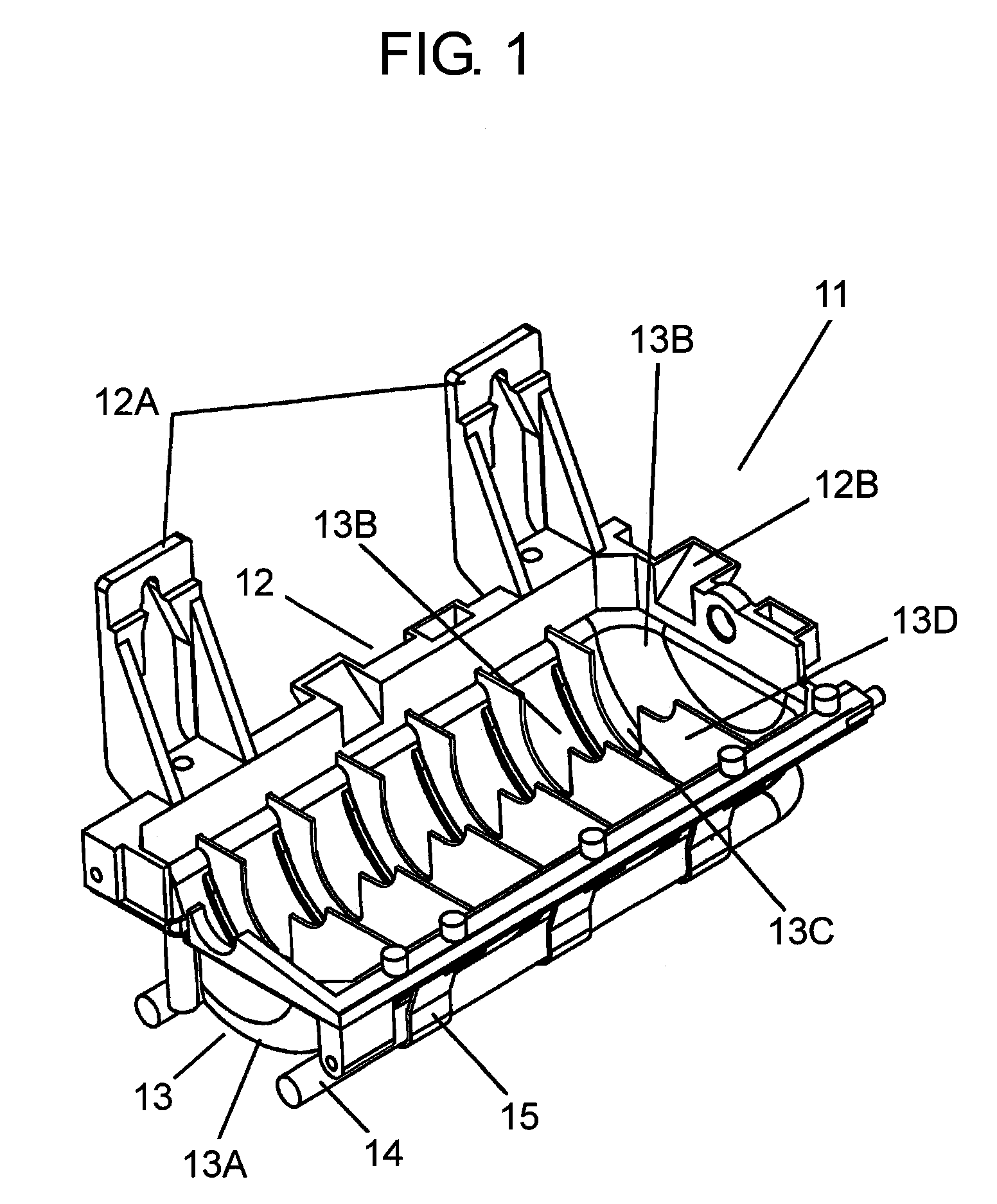

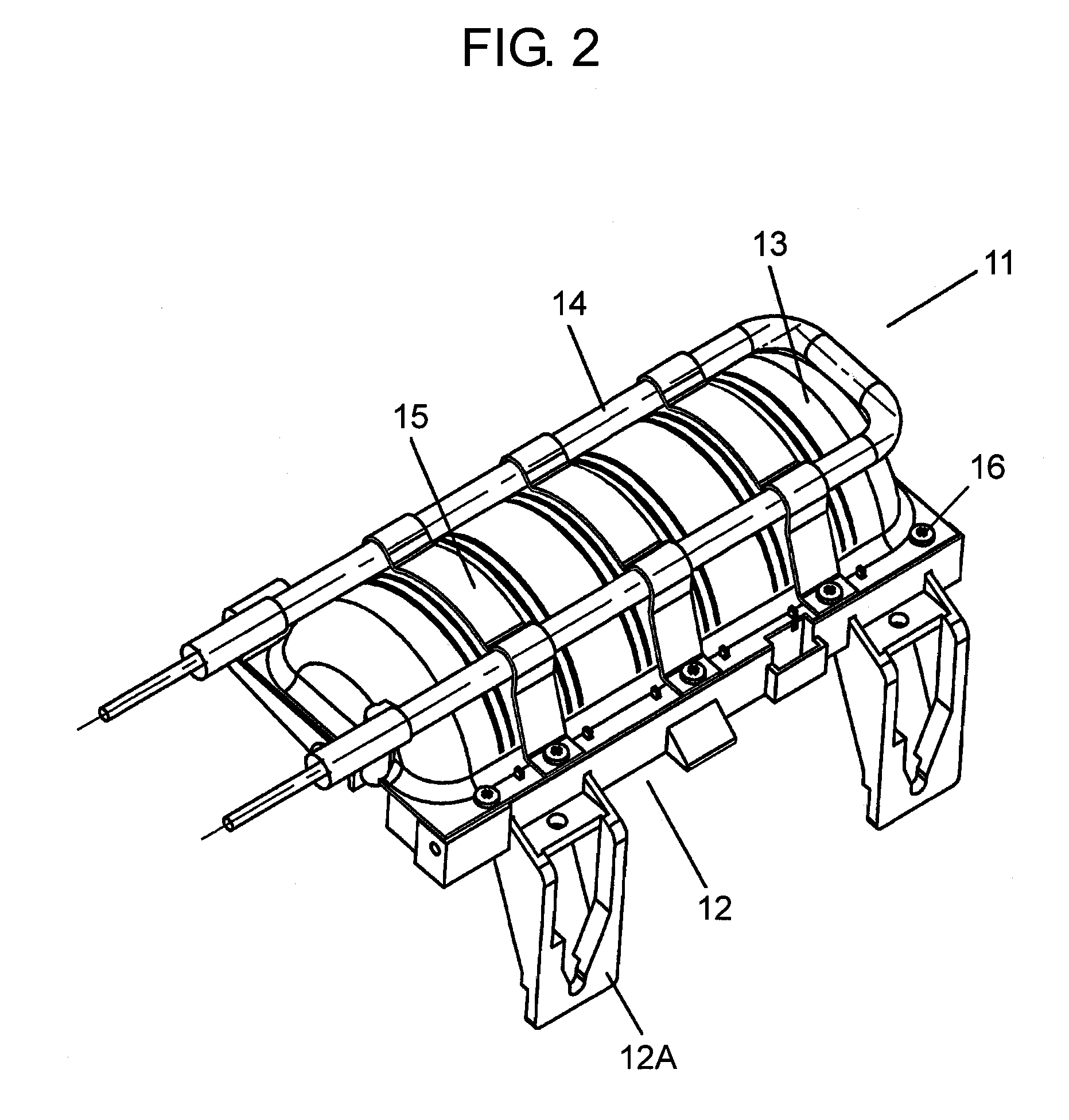

Ice-making tray

InactiveUS20090026349A1Shortening heater current-flowing timeEasy to fallLighting and heating apparatusIce productionBiomedical engineering

An ice-making tray includes an attachment part; a metal tray part; a heater for heating the tray part; and at least one heater guide. The tray part is formed as a separate body from the attachment part. The heater guide is made of metal and comes into contact with the heater and the tray part. The heater guide is attached to the attachment part to hold the heater, and transmits heat of the heater to the tray part.

Owner:PANASONIC CORP

Carrier structure for stacked-type semiconductor device, method of producing the same, and method of fabricating stacked-type semiconductor device

InactiveUS20060043600A1Improve production yieldReduce yieldSemiconductor/solid-state device detailsSolid-state devicesDevice materialSemiconductor package

A carrier structure for fabricating a stacked-type semiconductor device includes: a lower carrier that has laminated thin plates and has first openings for mounting first semiconductor packages thereon; and an upper carrier having second openings for mounting second semiconductor packages on the first semiconductor packages. The lower carrier composed of the laminated thin plates realizes an even plate thickness and reduces warps because stress is distributed to the thin plates. This results in an improved production yield. A pattern of the openings in the thin plates of the lower carrier may be formed by etching or electric discharging. The openings thus formed have reduced warps and burrs.

Owner:MONTEREY RES LLC

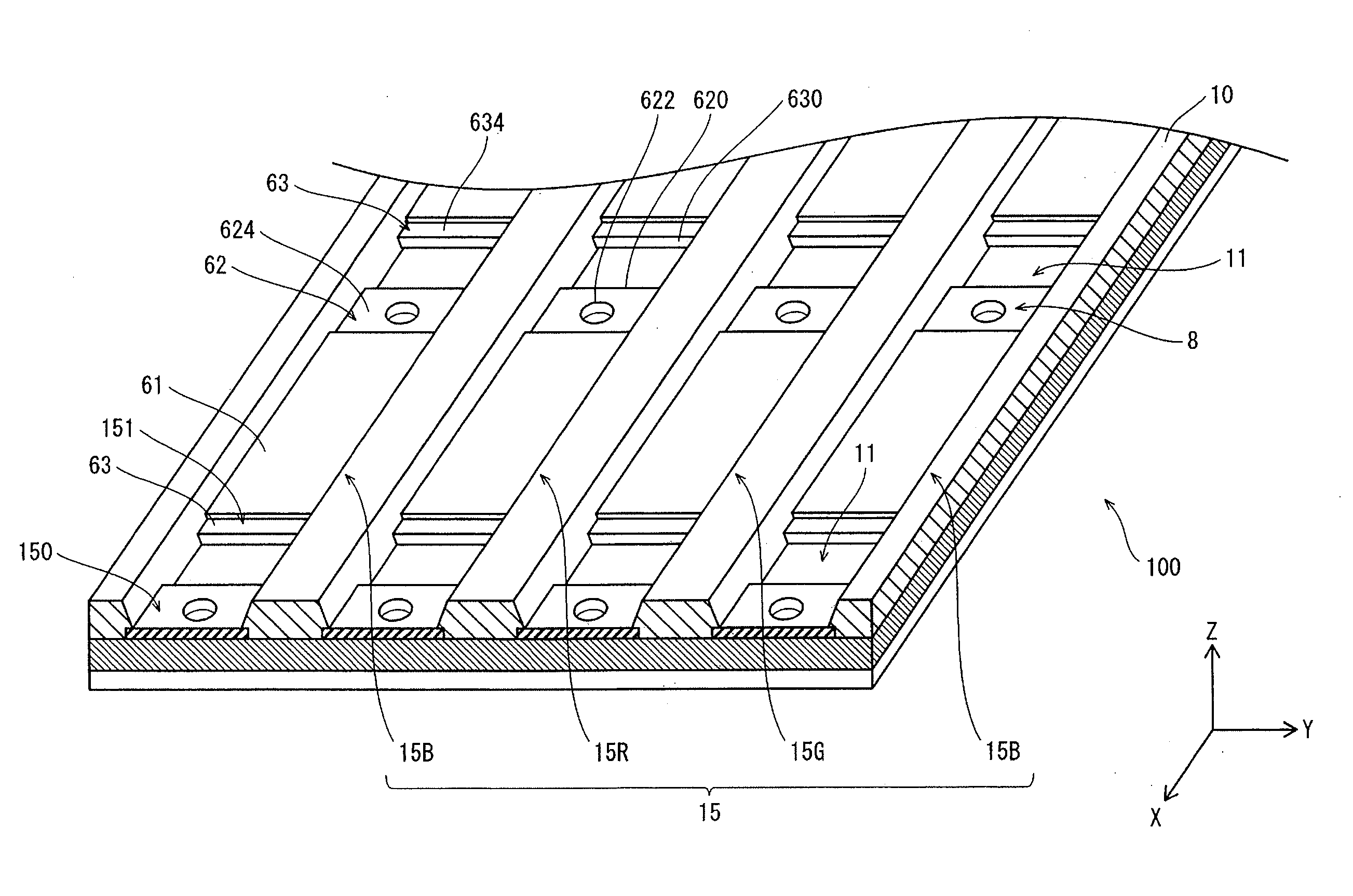

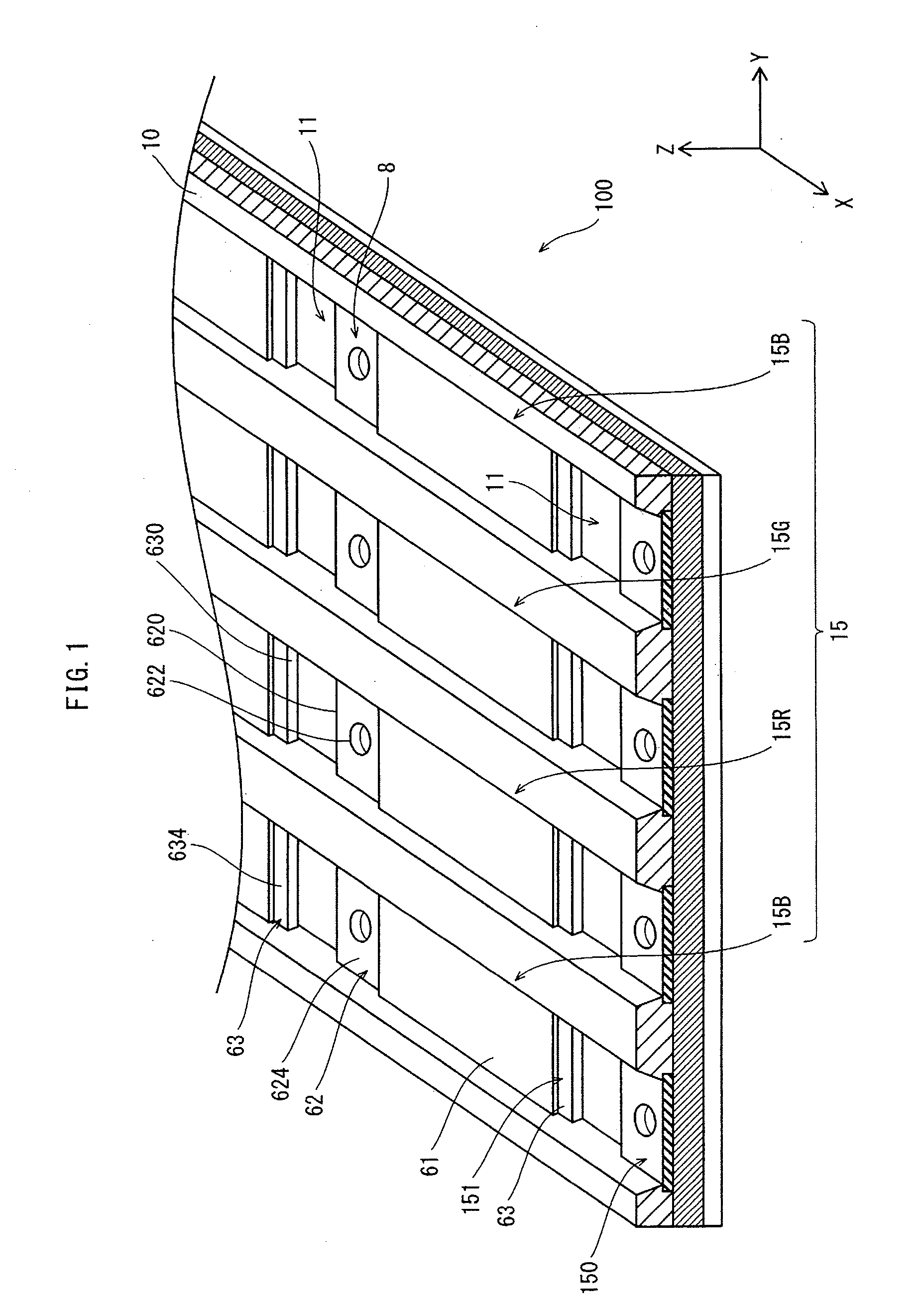

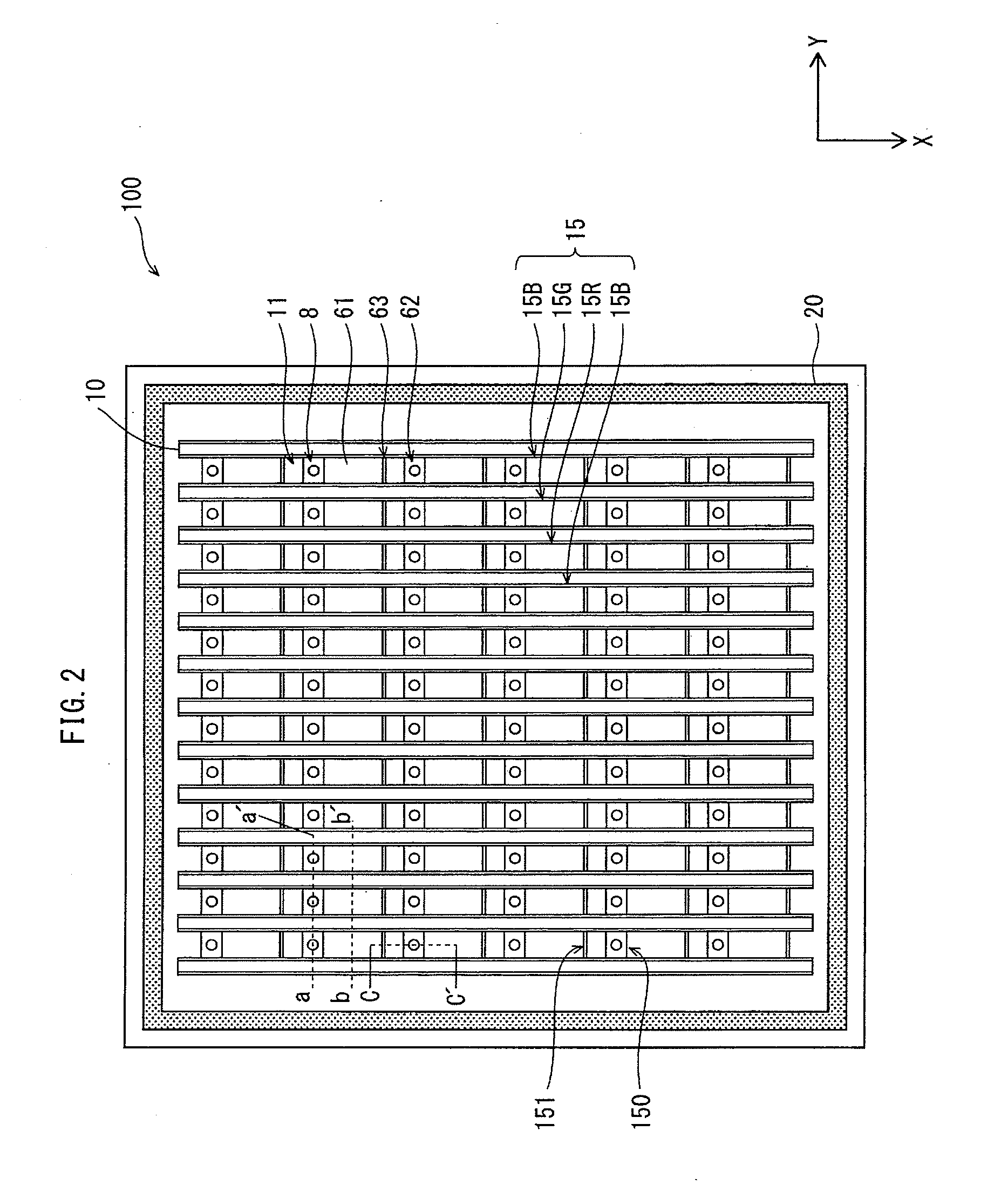

Organic el display panel and method of manufacturing the same

ActiveUS20120025224A1Prevent anomalous light emissionAvoid flowSolid-state devicesSemiconductor/solid-state device manufacturingMetallic materialsTransparent conducting film

An organic electroluminescence (EL) display panel and method of manufacturing an organic EL display panel. The display panel includes a substrate on which a thin-film transistor layer is formed, with an interlayer insulating film formed above the thin-film transistor layer. A plurality of strip-shaped barrier ribs are arranged in parallel on the interlayer insulating film. Each electrode of a plurality of first electrode groups has first electrodes arranged in a line and arranged between two adjacent barrier ribs of the plurality of strip-shaped barrier ribs, with each of the first electrodes including a transparent conductive film and a reflective metal film formed of a metal material. A plurality of light-emitting layers are each formed to cover a different electrode of the plurality of first electrode groups, while a second electrode is formed above the plurality of light-emitting layers. Each electrode of the plurality of first electrode groups is formed such that an end portion of the first electrode in a parallel direction with respect to the barrier ribs includes a single-film portion in which the transparent conductive film is not formed, and a portion of the first electrode other than the single-film portion includes a two-film portion in which the transparent conductive film is layered on the reflective metal film. A metal oxide film is formed on an entire surface of the single-film portion of each first electrode by partially oxidizing the metal material.

Owner:JOLED INC

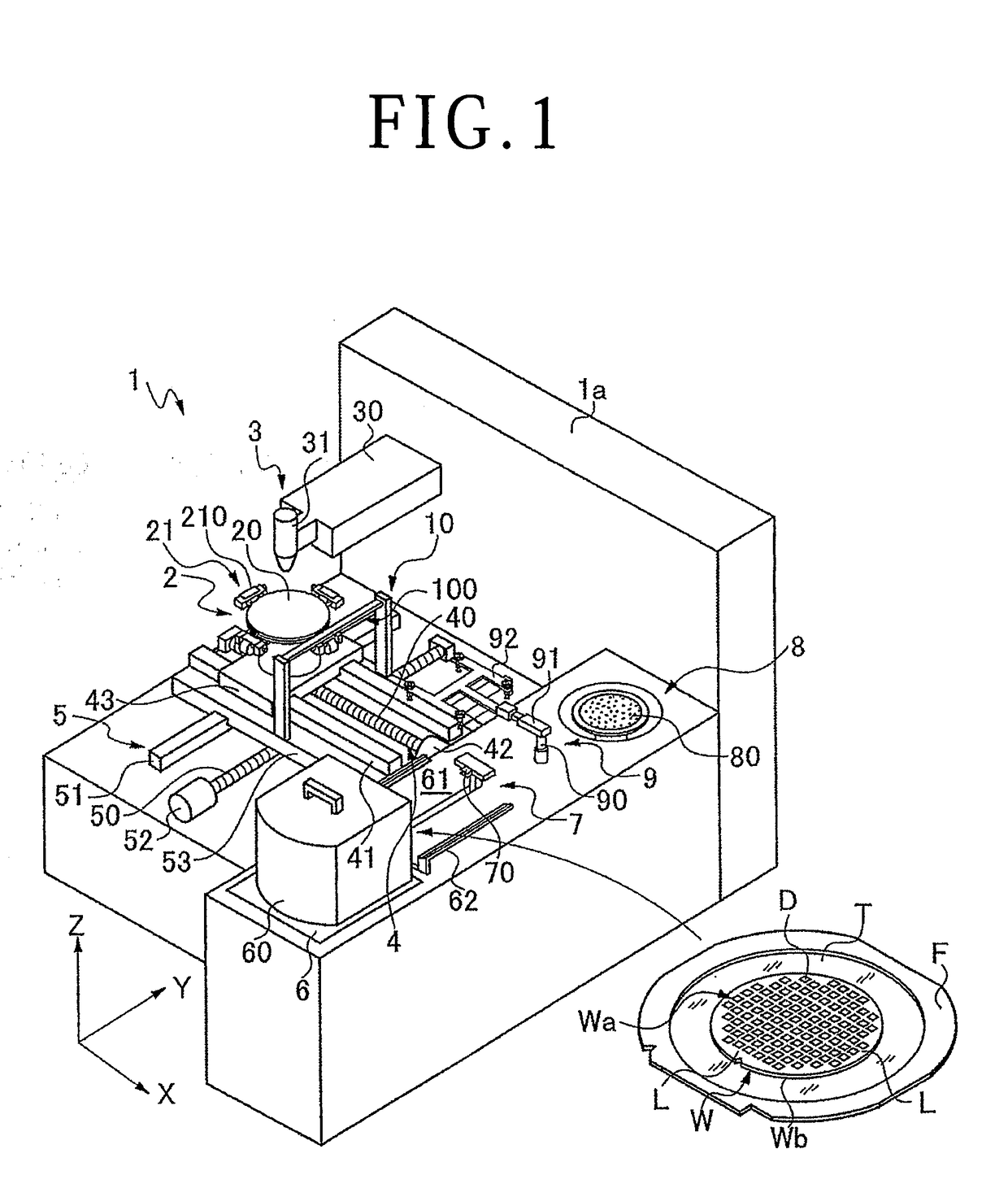

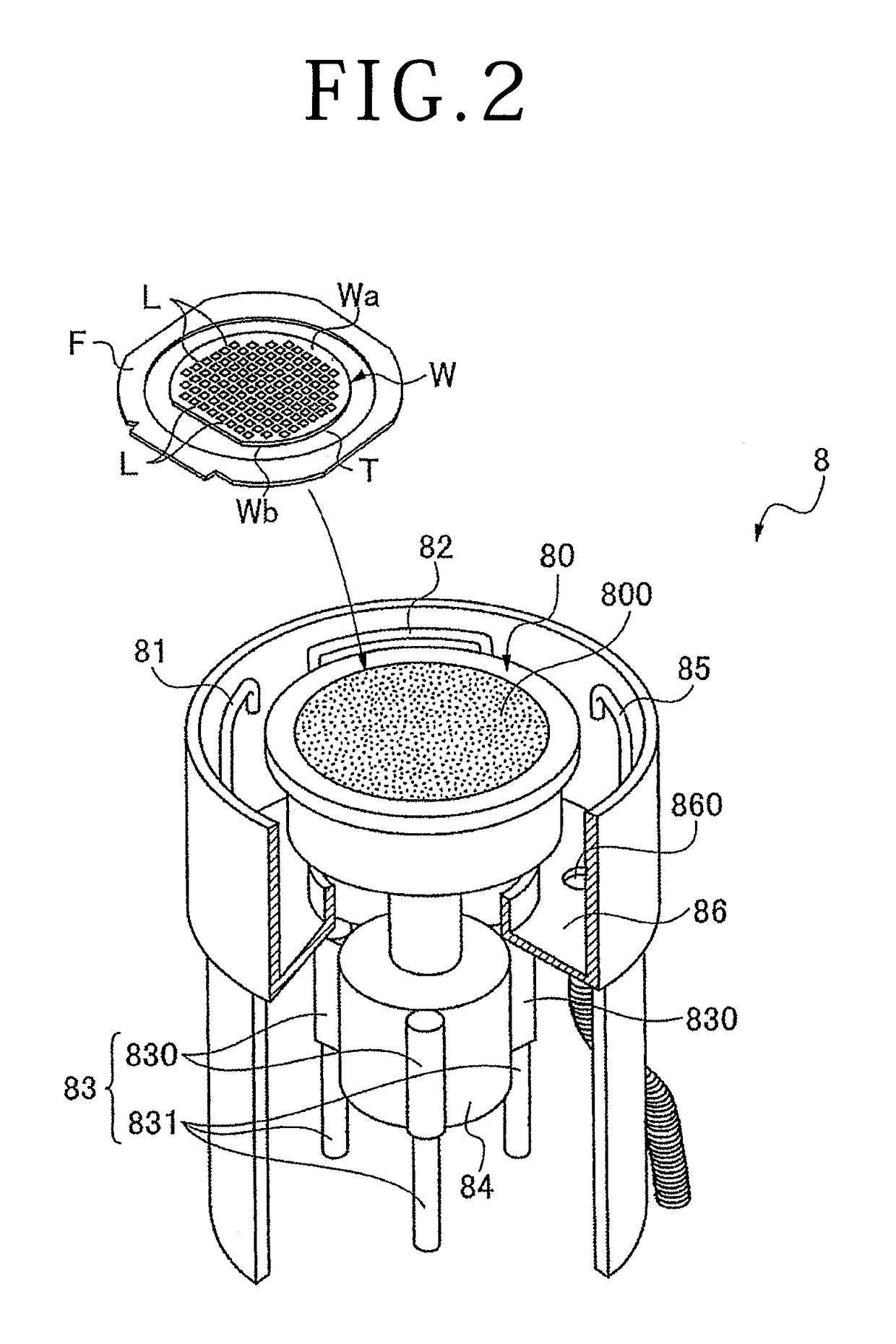

Chemical solution application apparatus and chemical solution application method

InactiveUS20060280865A1Improve efficiencyReduce wasteSolid-state devicesPhotomechanical apparatusChemical solutionPhysical chemistry

An object is to provide a chemical solution application apparatus capable of applying a chemical solution evenly and without irregularity by a spin coating method. A plurality of nozzles are provided for applying a chemical solution to an application object that is fixed over a stage. Each of the nozzles is individually mobile in vertical and horizontal directions. For this reason, controlling a discharging point or pattern is possible, and application responding to a wider viscosity range of chemical solutions is possible. By implementing the present invention, a chemical solution application apparatus equipped with a discharging method of a chemical solution by which a coating film having a small film thickness distribution over an entire substrate and an even thickness can be obtained, as well as for which use efficiency is improved by cutting down on waste of a chemical solution to be discharged.

Owner:SEMICON ENERGY LAB CO LTD

Light guide plate

InactiveUS20140198531A1Slim shapeImprove light utilization efficiencyMechanical apparatusPlanar/plate-like light guidesLight guideConditional expression

The light guide plate includes two layers having different particle concentrations, in which the thicknesses of the two layers are varied to change the combined particle concentration of the light guide plate, and conditional expressions of 0.3 mm≦Tlg≦4 mm and 0.3≦tcen / Tlg≦1 are satisfied when the thickness in the direction perpendicular to the light exit surface is defined as Tlg and the thickness at the center of the second layer is defined as Tcen. The light guide plate of the present invention can have a large and thin shape, can emit light having high light use efficiency and small luminance unevenness, can obtain a middle-high or bell-shaped brightness distribution and can be easily manufactured.

Owner:FUJIFILM CORP

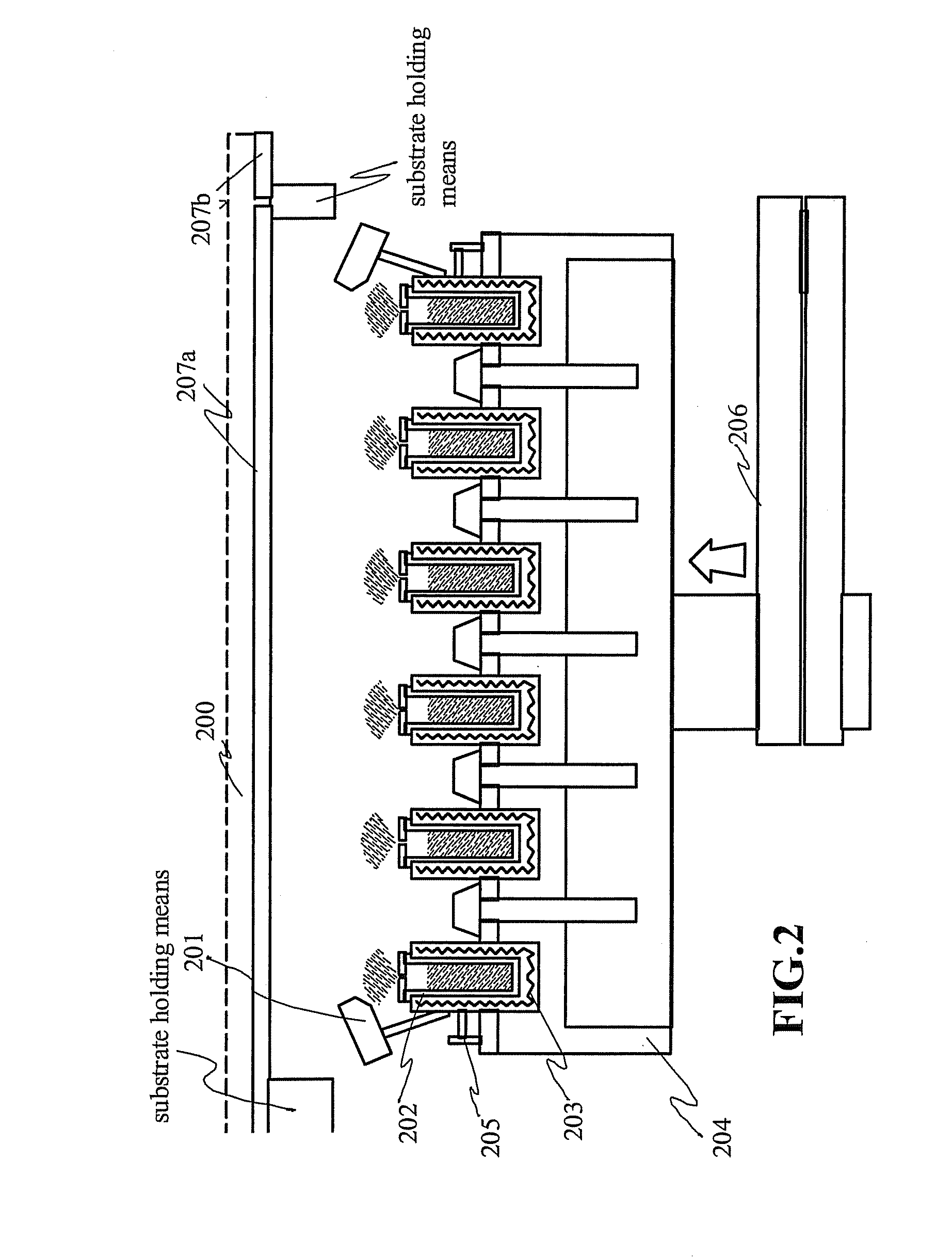

Manufacturing method of light-emitting device

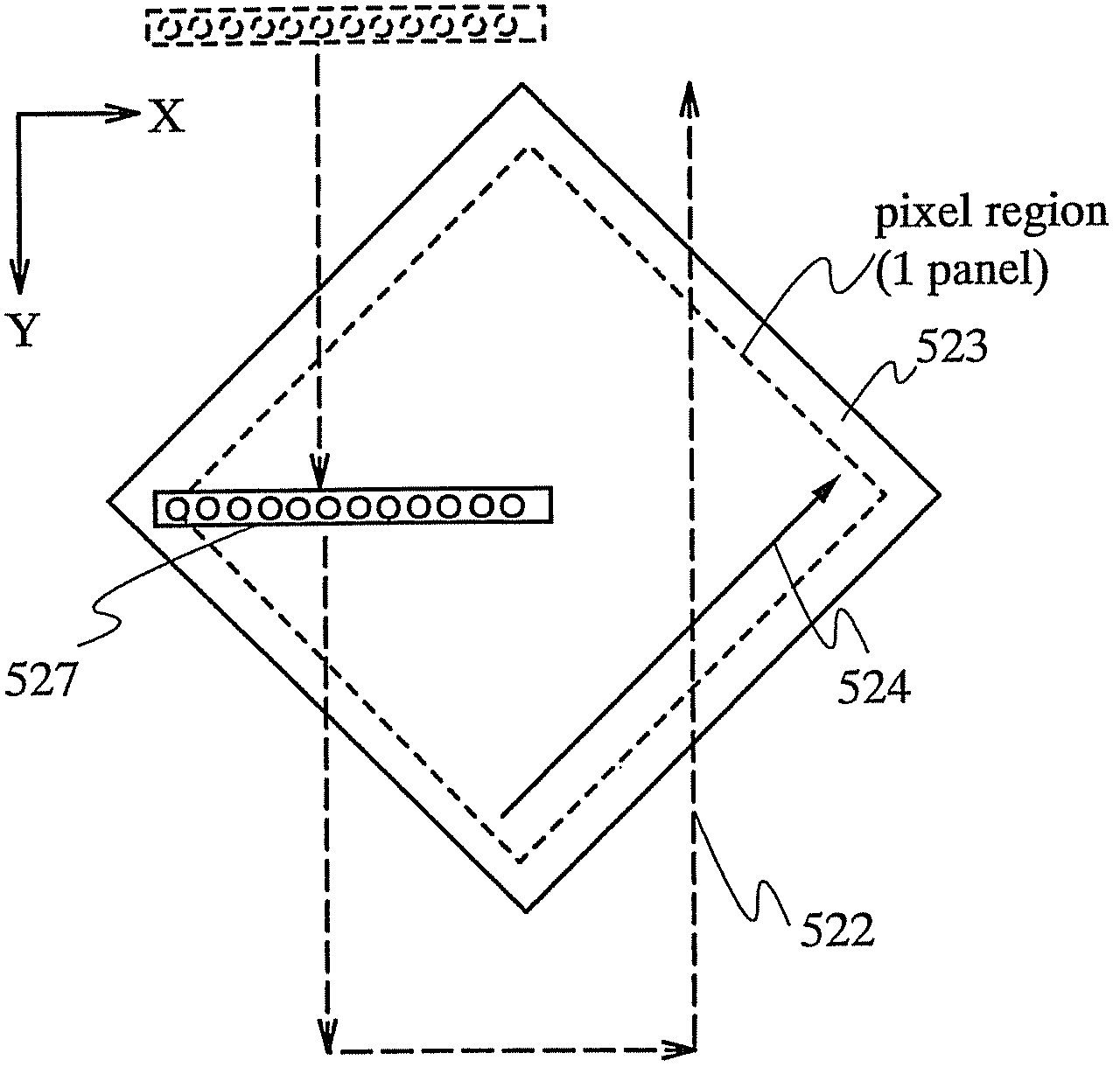

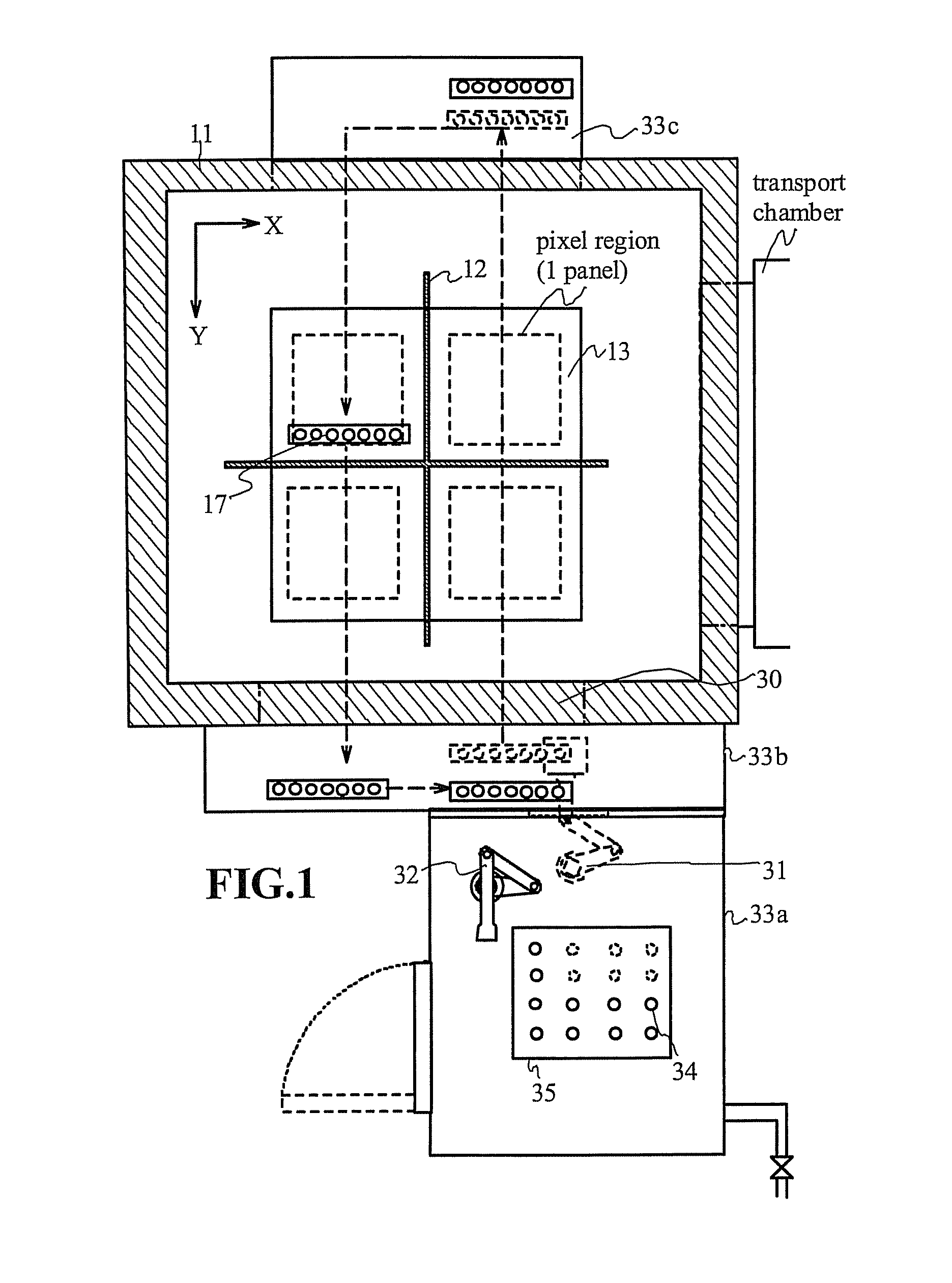

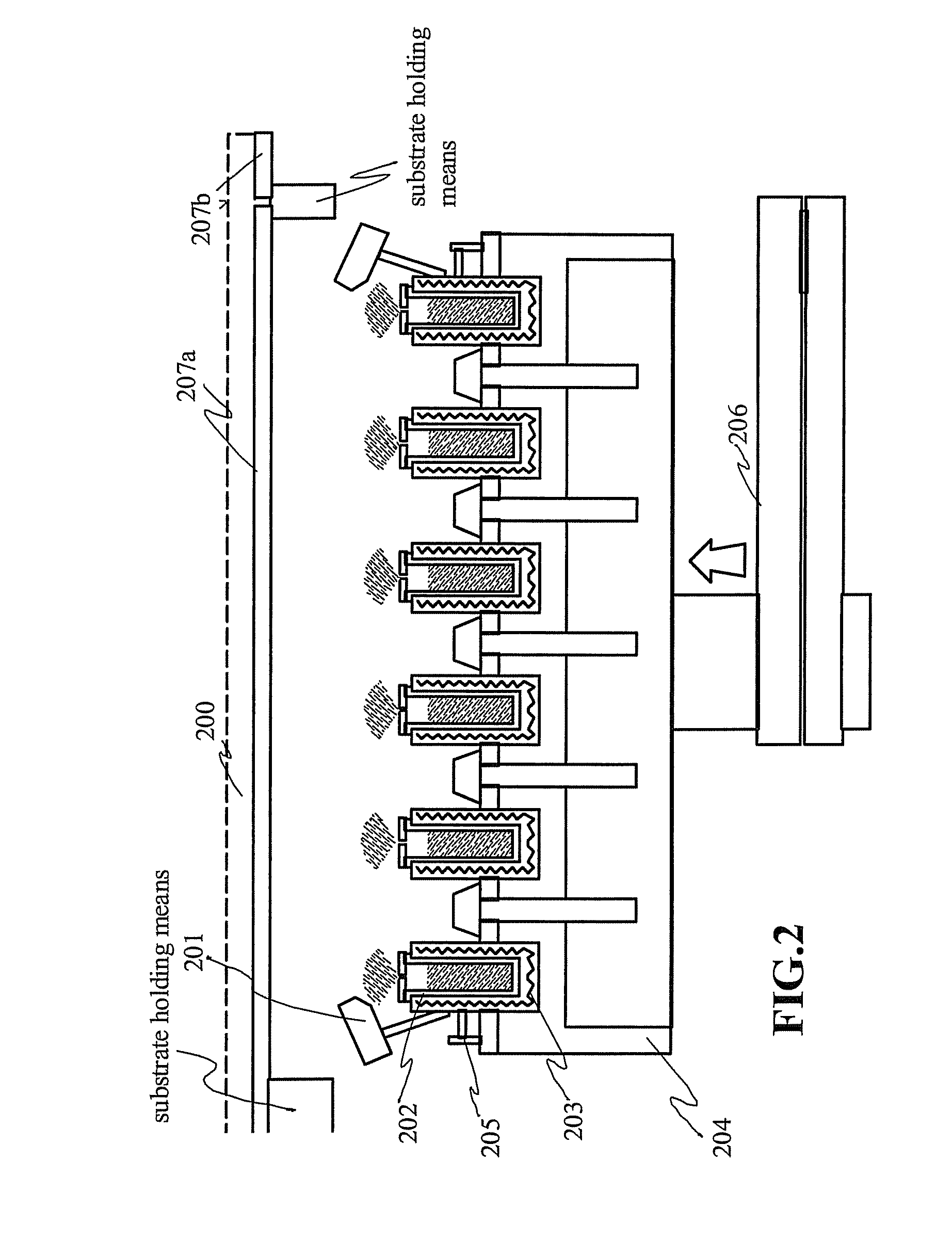

InactiveUS7943443B2Excellent in uniformity and throughputMaterial efficiencyElectroluminescent light sourcesSolid-state devicesGas phaseEvaporation

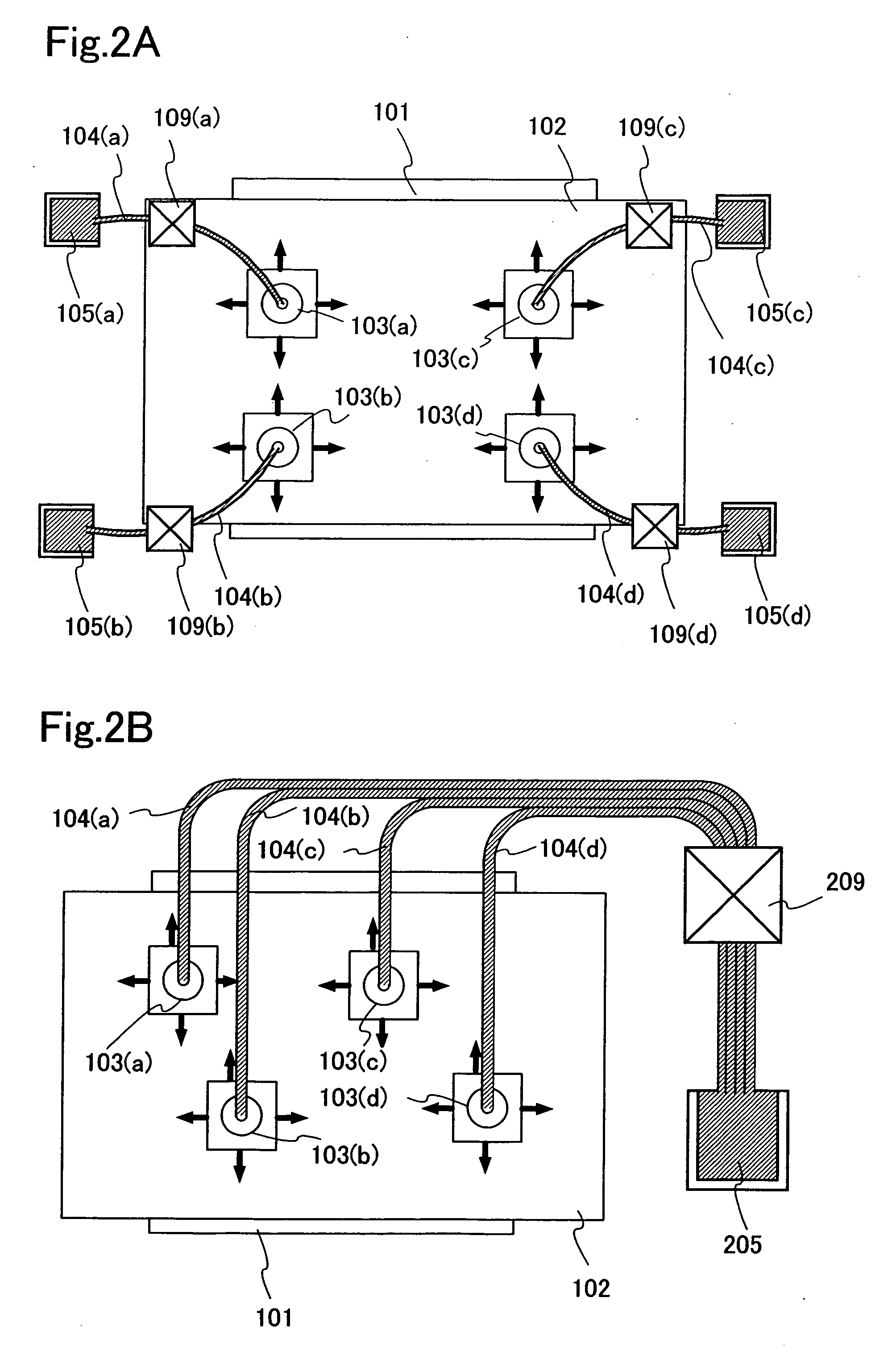

The present invention provides a vapor deposition method and a vapor deposition system of film formation systems by which EL materials can be used more efficiently and EL materials having superior uniformity with high throughput rate are formed. According to the present invention, inside a film formation chamber, an evaporation source holder in a rectangular shape in which a plurality of containers sealing evaporation material is moved at a certain pitch to a substrate and the evaporation material is vapor deposited on the substrate. Further, a longitudinal direction of an evaporation source holder in a rectangular shape may be oblique to one side of a substrate, while the evaporation source holder is being moved. Furthermore, it is preferable that a movement direction of an evaporation source holder during vapor deposition be different from a scanning direction of a laser beam while a TFT is formed.

Owner:SEMICON ENERGY LAB CO LTD

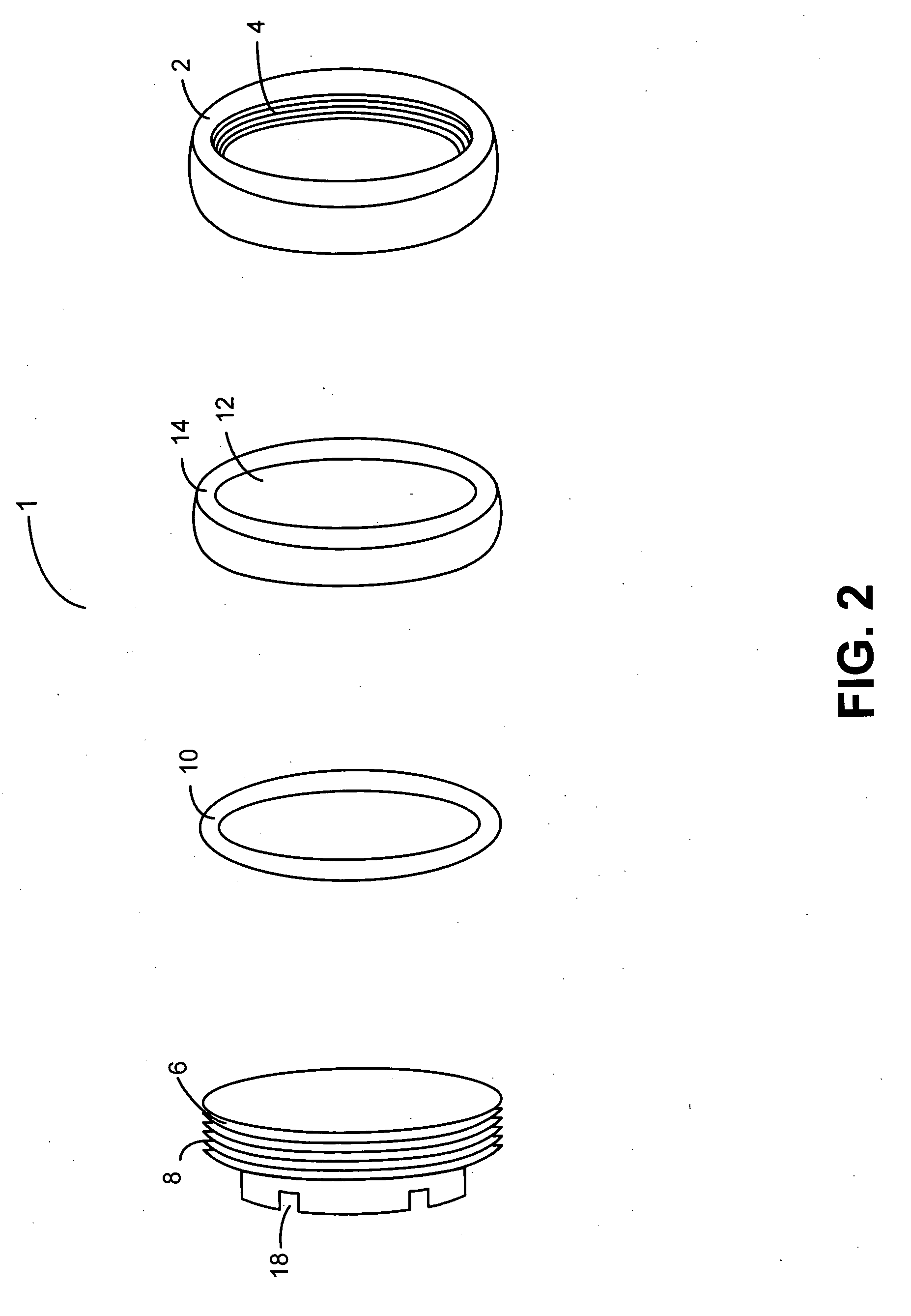

Light fixture lens retaining device and method

The present invention provides a retainer assembly and method for securely retaining a lens in a housing such as a light fixture bezel. An exemplary retainer assembly includes a lens and lens seal within a light bezel having threads and a contact surface formed on the bezel interior, a retaining ring having external features for engaging the threads on the bezel interior, and a contact ring disposed between the retaining ring and the lens to be secured in the bezel. An exemplary method involves the steps of placing a seal around the periphery and edge of a disc shaped lens, seating the lens within the lens bezel or retaining ring, and advancing the retaining ring within the bezel with a contact ring adjacent the lens and seal to prevent wear from rotation.

Owner:TORO CO THE

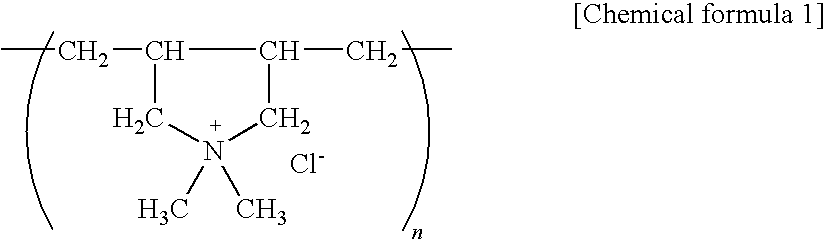

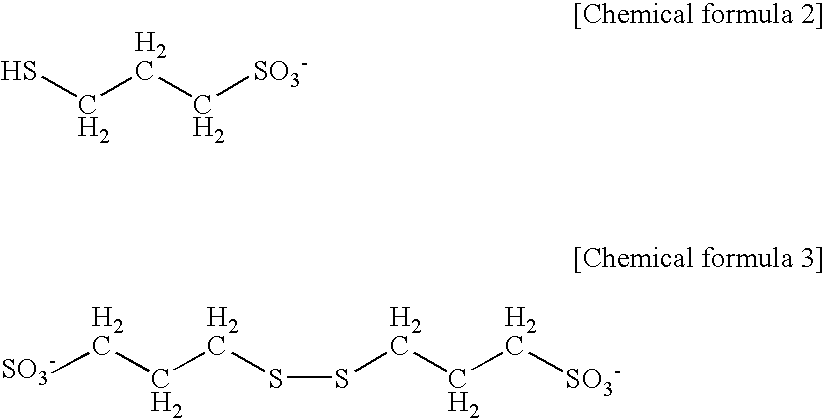

Production method of electro-deposited copper foil, electro-deposited copper foil obtained by the production method, surface-treated copper foil obtained by using the electro-deposited copper foil and copper-clad laminate obtained by using the electro-deposited copper foil or the surface-treated copper foil

InactiveUS20090166213A1Fast operationHigh speedDuplicating/marking methodsActive material electrodesQuaternary ammonium cationElectrolysis

An object of the present invention is to provide a production method which enables efficient production of an electro-deposited copper foil with further lower profile when compared to the low-profile electro-deposited copper foils which have been supplied to the market and is excellent in mechanical strength. For the purpose of achieving the object, a production method adopted obtains the electro-deposited copper foil by electrolyzing a sulfuric acid based copper electrolytic solution which contains a quaternary ammonium salt polymer having cyclic structure and chlorine, wherein for the quaternary ammonium salt polymer contained in the sulfuric acid based copper electrolytic solution, a DDAC dimer or higher polymer is used. For the quaternary ammonium salt polymer, a diallyl dimethyl ammonium chloride polymer having a number average molecular weight of 300 to 10000 is preferably used. The sulfuric acid based copper electrolytic solution preferably contains bis(3-sulfopropyl) disulfide or 3-mercapto-1-propanesulfonic acid that is a compound having a mercapto group.

Owner:MITSUI MINING & SMELTING CO LTD

Artificial intervertebral disc having a slotted belleville washer force restoring element

InactiveUS20050234554A1Improve securityStrong forceJoint implantsSpinal implantsIntervertebral discEngineering

An intervertebral spacer device includes first and second plates disposed in a spaced apart relationship, each plate having an inner surface and an outer surface, the inner surfaces of the opposing plates facing one another. The device also includes at least one restoring force providing element disposed between the inner surfaces of the plates, wherein a compressive load applied to the outer surfaces of the first and second plates is counteracted by the at least one restoring force providing element. The at least one restoring force providing element includes at least one slotted belleville washer having a convex shape when unloaded and a flatter shape when loaded, whereby one or more slots of the belleville washer widen when compressively loaded, and whereby the at least one slotted belleville washer is unloaded when no load is applied to the outer surfaces of the first and second plates, and is loaded when the compressive load is applied to the outer surfaces of the first and second plates. The second plate has an annular groove formed in the inner surface of the second plate, the device including a retaining wall and a retaining ring, whereby a wide end of the at least one belleville washer is captured by the retaining wall and the retaining ring for maintaining the wide end adjacent the inner surface of the second plate.

Owner:HOWMEDICA OSTEONICS CORP

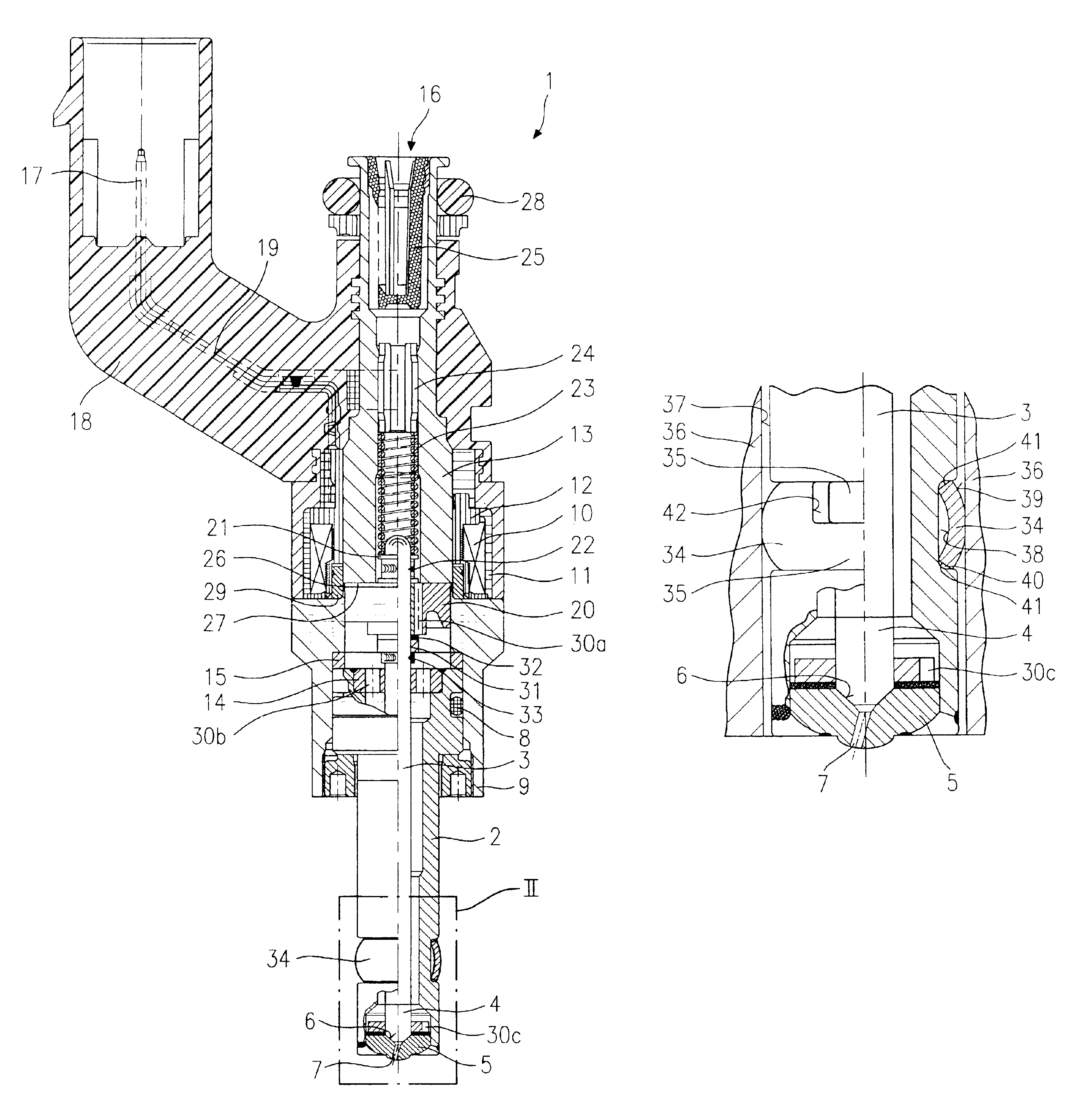

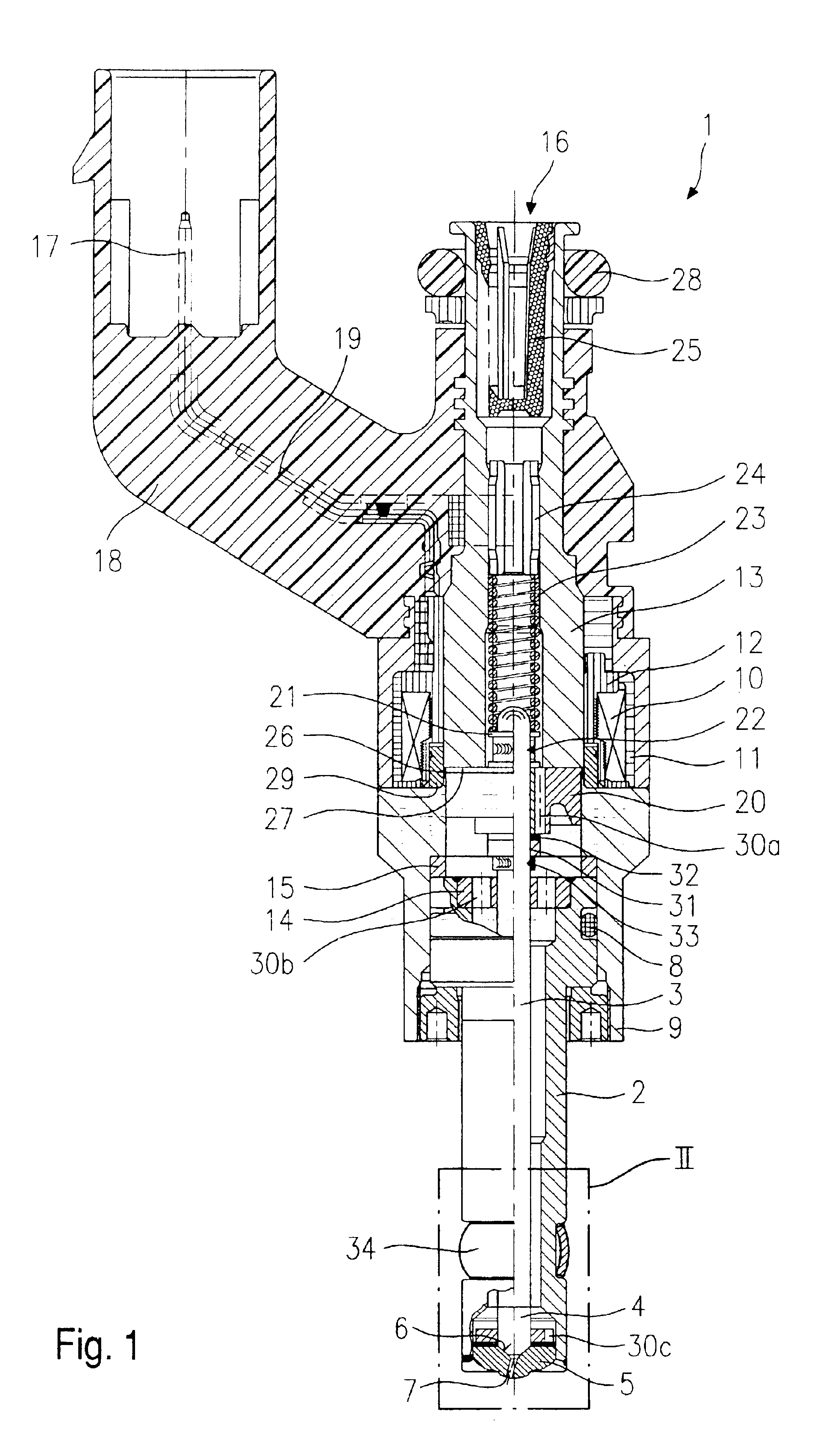

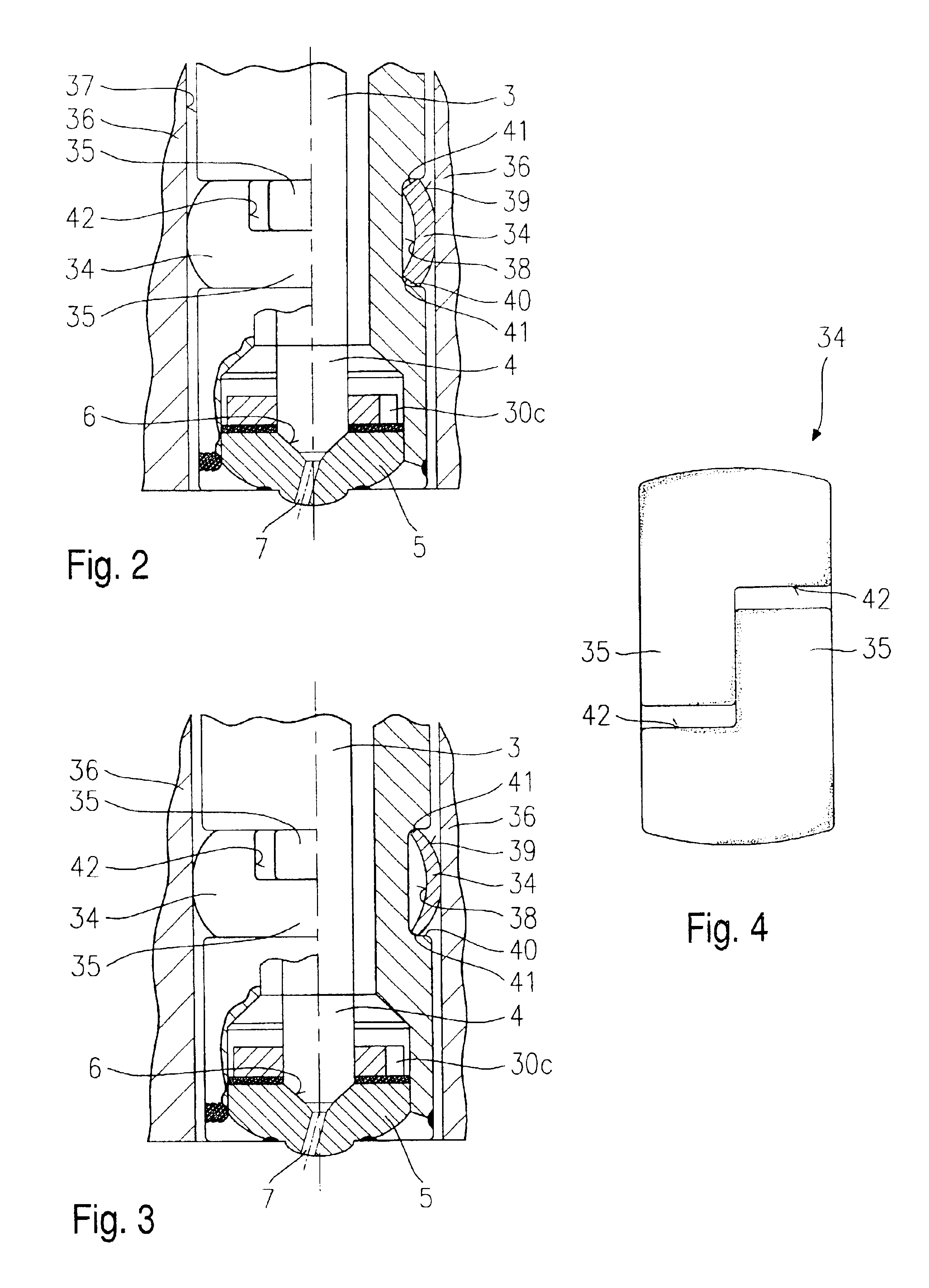

Fuel injection valve

InactiveUS6921033B2Easy to installReduce manufacturing costEngine sealsCylinder headsExternal combustion engineCylinder head

A fuel injector, particularly for the direct injection of fuel into the combustion chamber of a mixture-compressing internal combustion engine having external ignition, include a valve housing formed by a nozzle body and a sealing ring which seals the fuel injector from a cylinder head of the internal combustion engine. The sealing ring has a convexly curved profile, two ends of the sealing ring axially overlapping one another in a stepped manner.

Owner:ROBERT BOSCH GMBH

Manufacturing method of honeycomb structural body, and sealing material

ActiveUS7981475B2Avoid separationAvoid distractionExhaust apparatusConfectioneryHoneycomb structureRaw material

An object of the present invention is to provide a manufacturing method of a honeycomb structural body which makes the profile of a cross section perpendicular to the length direction thereof less likely to generate dispersion, and also makes the thickness of its sealing material layer thinner, and a sealing material that is suitably used in the manufacturing method of the honeycomb structural body. According to the present invention, the manufacturing method of a honeycomb structural body with a sealing material layer formed on the peripheral portion of a pillar-shaped porous honeycomb member includes a sealing material applying step of applying a paste-like sealing material, which is a raw material of the sealing material layer, onto a circumferential face of the pillar-shaped porous honeycomb member, and a scraping step of fitting a ring-shaped scraper, which can be brought into contact with the circumferential face of the pillar-shaped porous honeycomb member so as to slide thereon, to the pillar-shaped porous honeycomb member and moving said ring-shaped scraper in the length direction, thereby expanding the paste-like sealing material applied onto the circumferential face of the pillar-shaped porous honeycomb member so as to spread over the entire circumferential face of the pillar-shaped porous honeycomb member.

Owner:IBIDEN CO LTD

One-way damper and electronic devices using the one-way damper

InactiveUS7416063B2Preventing viscous fluid from leakingLarge damping torqueLiquid resistance brakesSpringsEngineeringFree edge

A one-way damper includes a cylindrical housing, a viscous fluid contained within the housing, a rotor rotatably disposed in the housing, and a valve body. The rotor has a center part for forming a rotational center, and a control wall extending radially outwardly from the center part for dividing an inside of the housing. The control wall has a distribution path. The valve body has a holding part for holding the center part, and a free edge part extending from one side of the holding part for opening-and closing the distribution path. A seal member prevents the viscous fluid from leaking between the housing and the rotor.

Owner:NIFCO INC

Semiconductor device and method for manufacturing the same

InactiveUS20050032334A1Evenly thickness-reducedGrind evenlySemiconductor/solid-state device detailsSolid-state devicesDevice materialSemiconductor chip

A method for manufacturing a semiconductor device which enables favorable back-surface grinding of a semiconductor substrate with preventing a warp in the substrate, thereby manufacturing a thickness-reduced semiconductor device. A projection electrode is formed on a surface of a wafer. A resin layer is formed on the wafer surface to a thickness to bury a top of the projection electrode. A cut groove is formed in the resin layer along a scribe line formed on the wafer. Thereafter, grinding is made on a back surface of the wafer by the use of a grinder or the like. A surface portion of the resin layer is removed by etching or the like, to expose the top of the projection electrode. The wafer is cut along the cut groove to obtain individual semiconductor chip pieces.

Owner:TAIWAN SEMICON MFG CO LTD

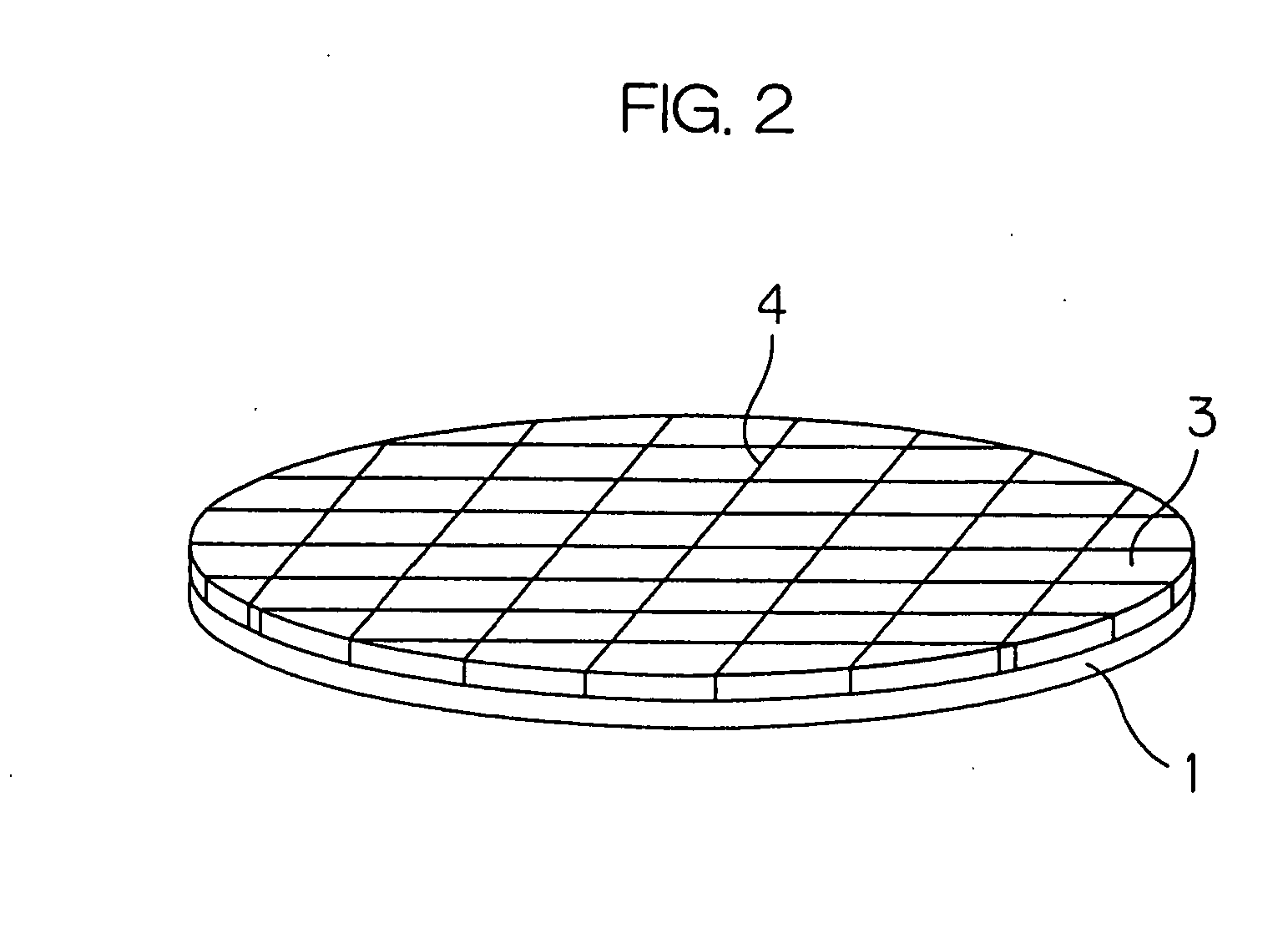

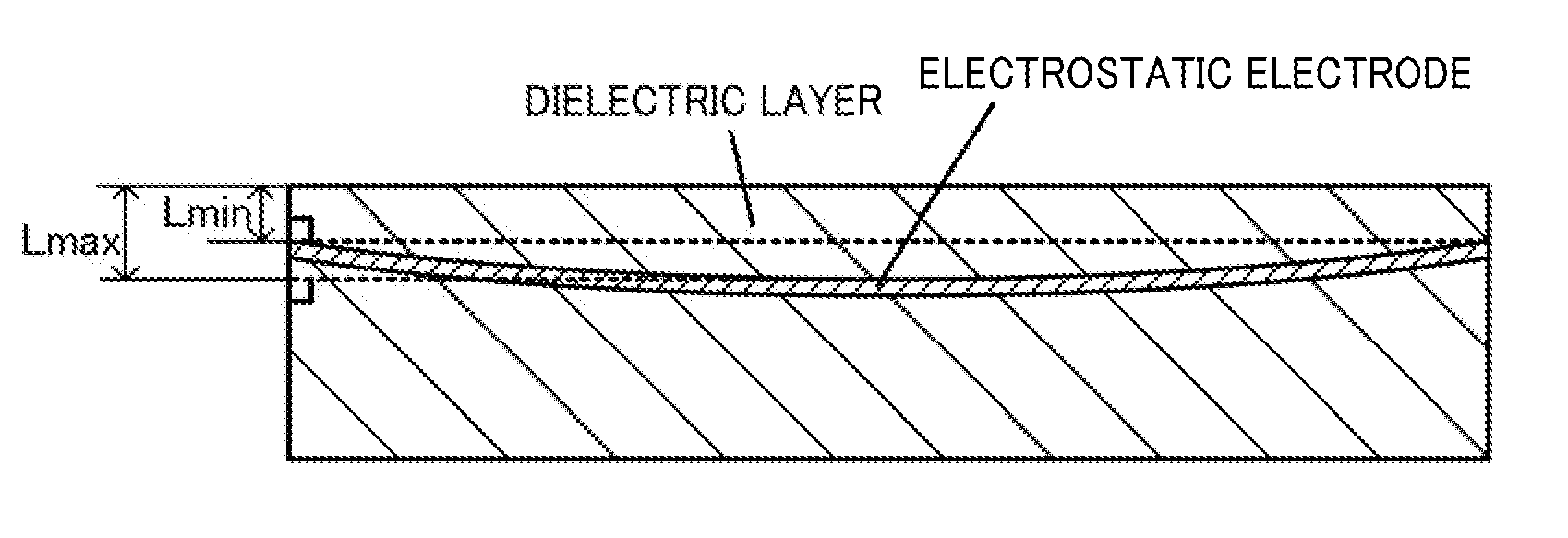

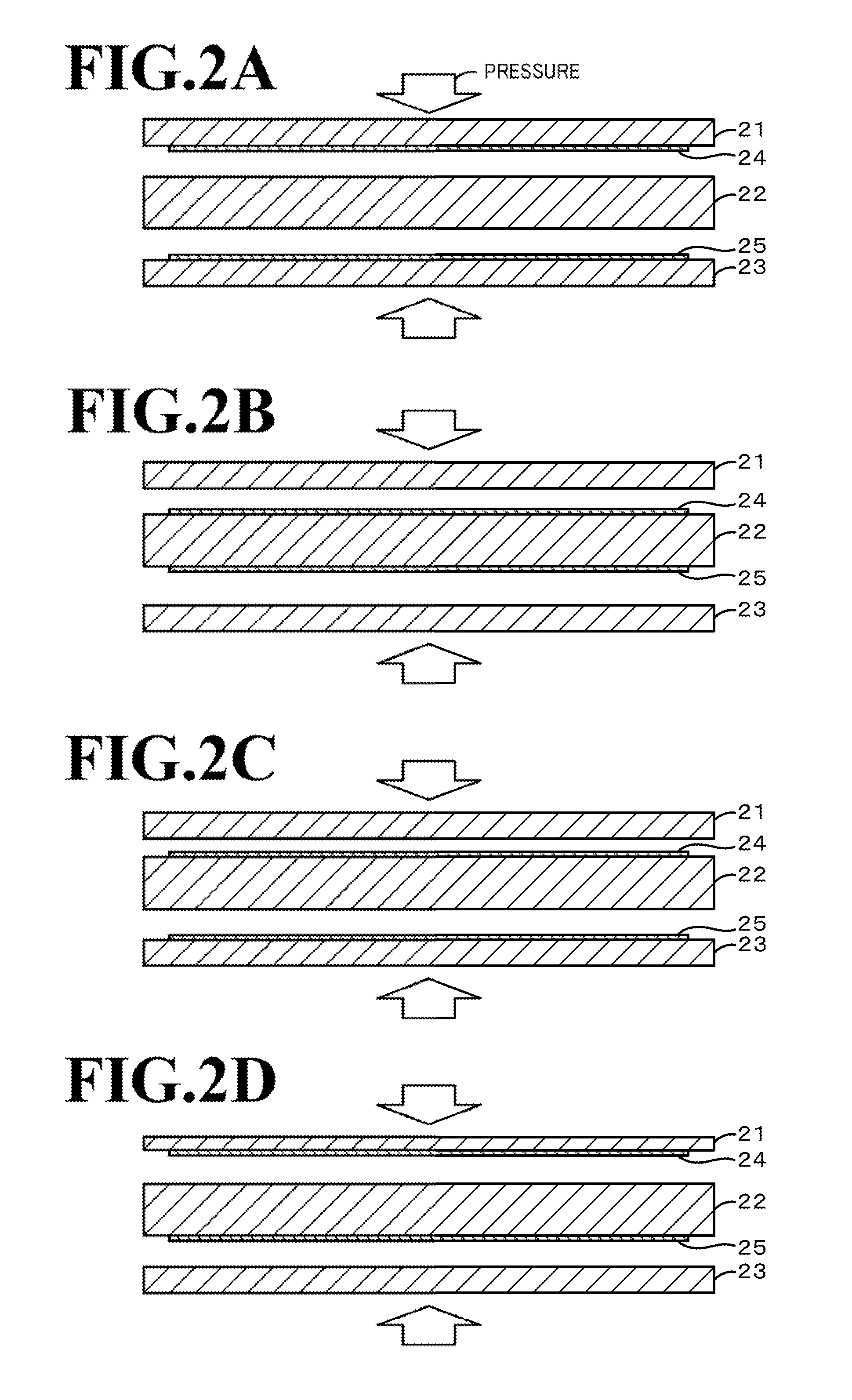

Method for producing electrostatic chuck and electrostatic chuck

ActiveUS20120248716A1Suppress generation of particleIncrease breakdown voltageSleeve/socket jointsSemiconductor/solid-state device manufacturingSolventHot press

A method for producing an electrostatic chuck includes the steps of (a) placing a ceramic slurry in a molding die, the ceramic slurry containing a ceramic powder, a solvent, a dispersing agent, and a gelling agent, gelatinizing the ceramic slurry in the molding die, and removing the molding die to obtain first and second ceramic molded bodies; (b) drying, debinding, and calcining the first and second molded bodies to obtain first and second ceramic calcined bodies; (c) printing an electrostatic electrode paste on a surface of one of the first and second ceramic calcined bodies to form an electrostatic electrode while assuming the first ceramic calcined body is to form a dielectric layer of an electrostatic chuck; and (d) superposing the first and second ceramic calcined bodies on each other to sandwich the electrostatic electrode and subjecting the first and second calcined bodies to hot-press firing.

Owner:NGK INSULATORS LTD

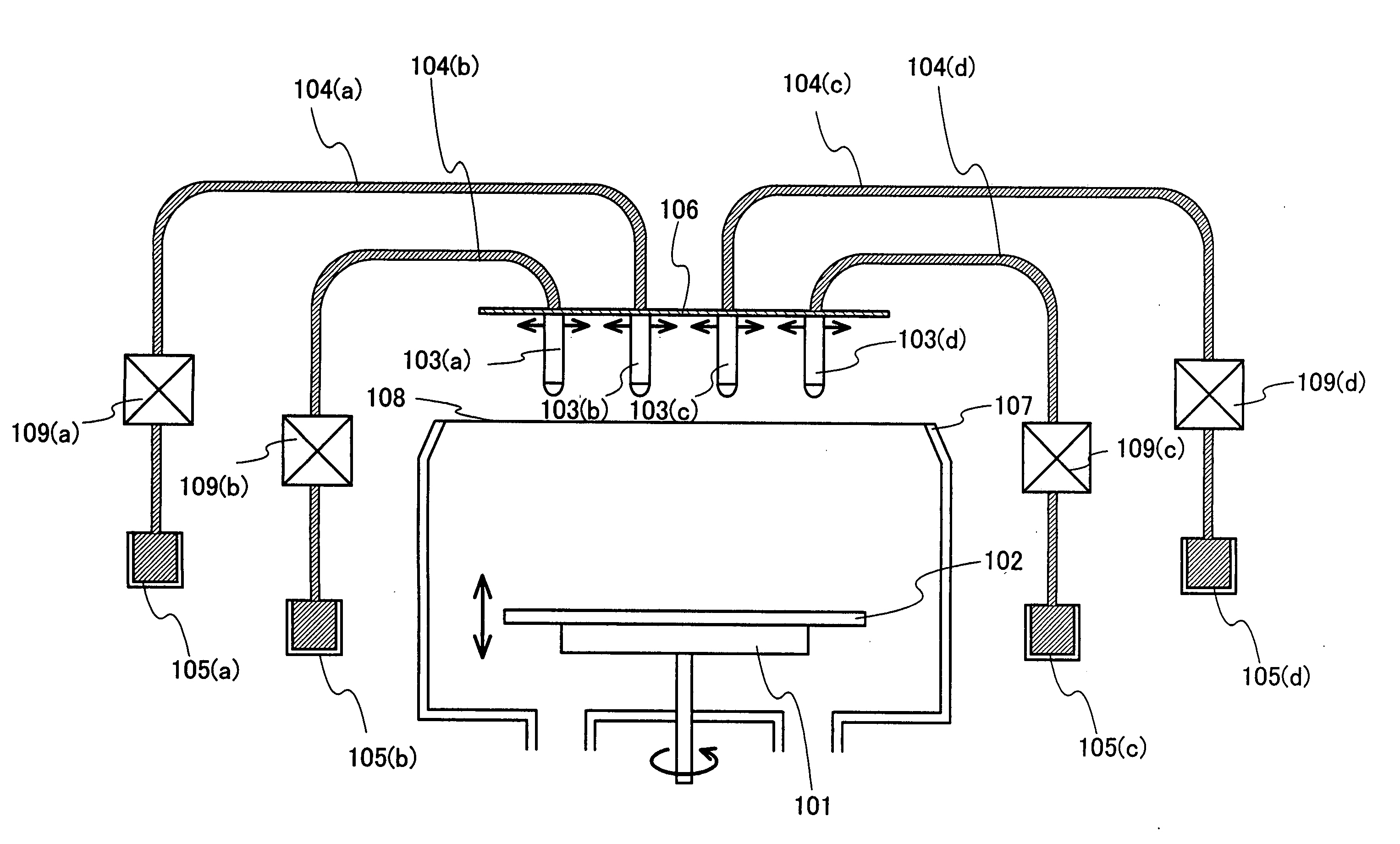

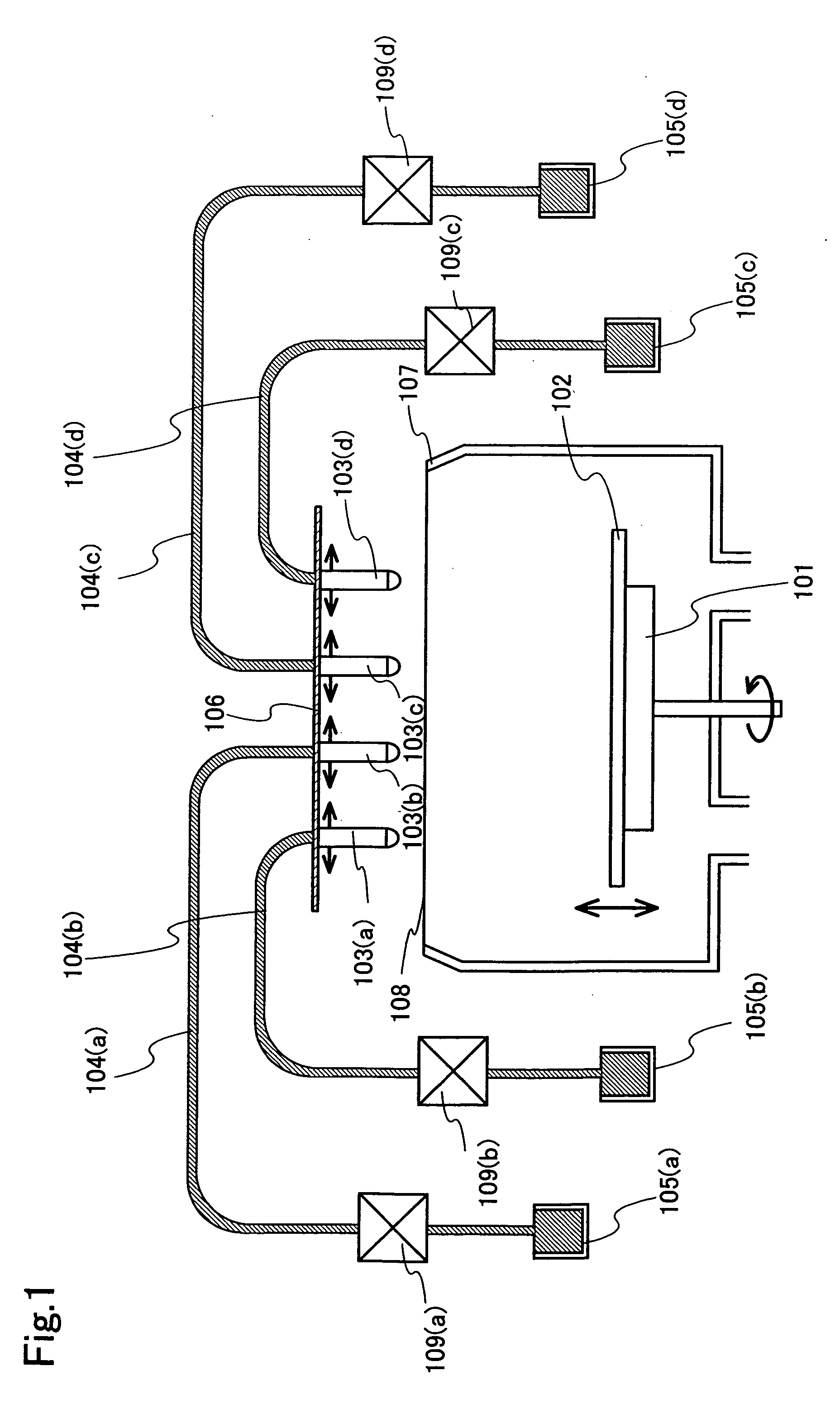

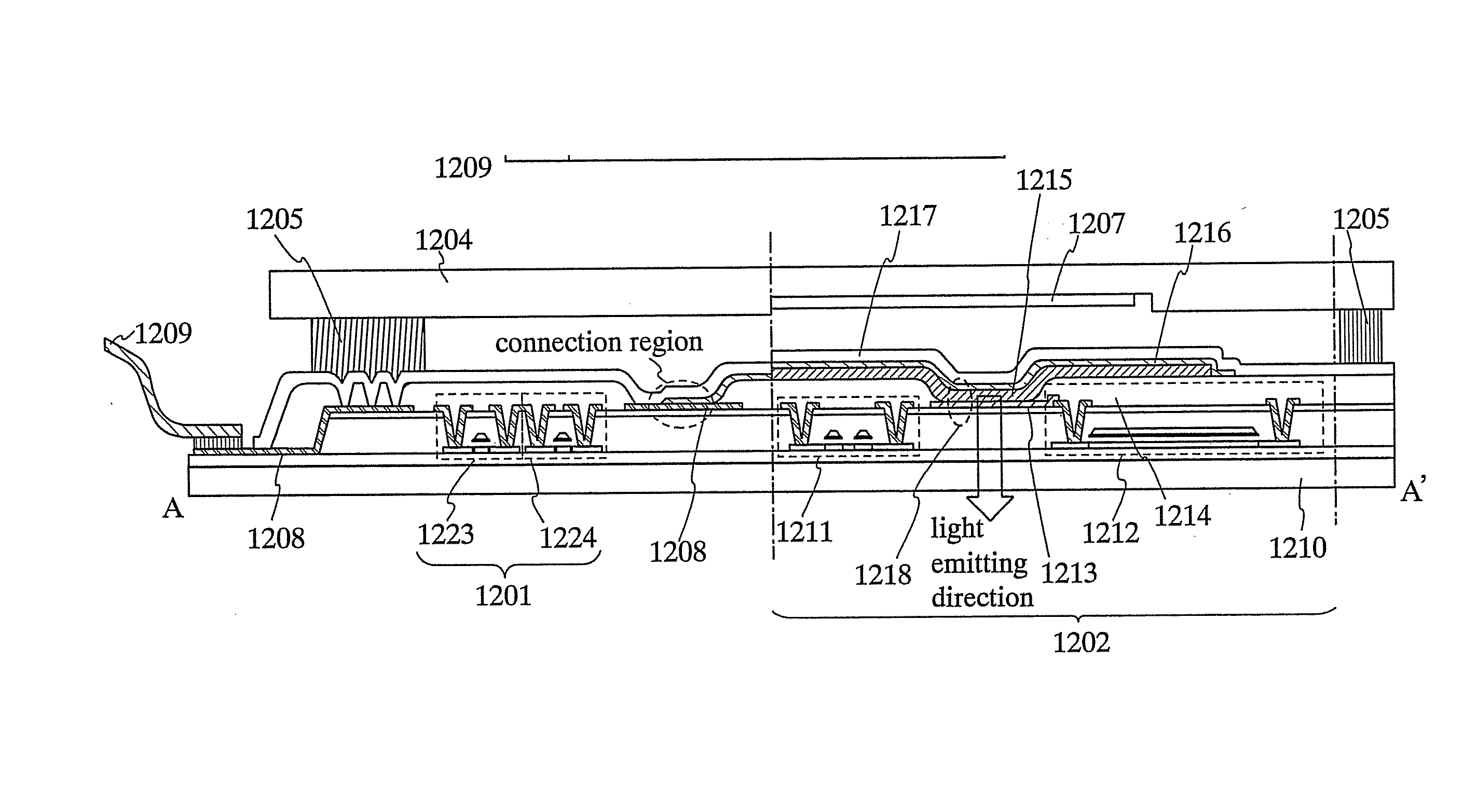

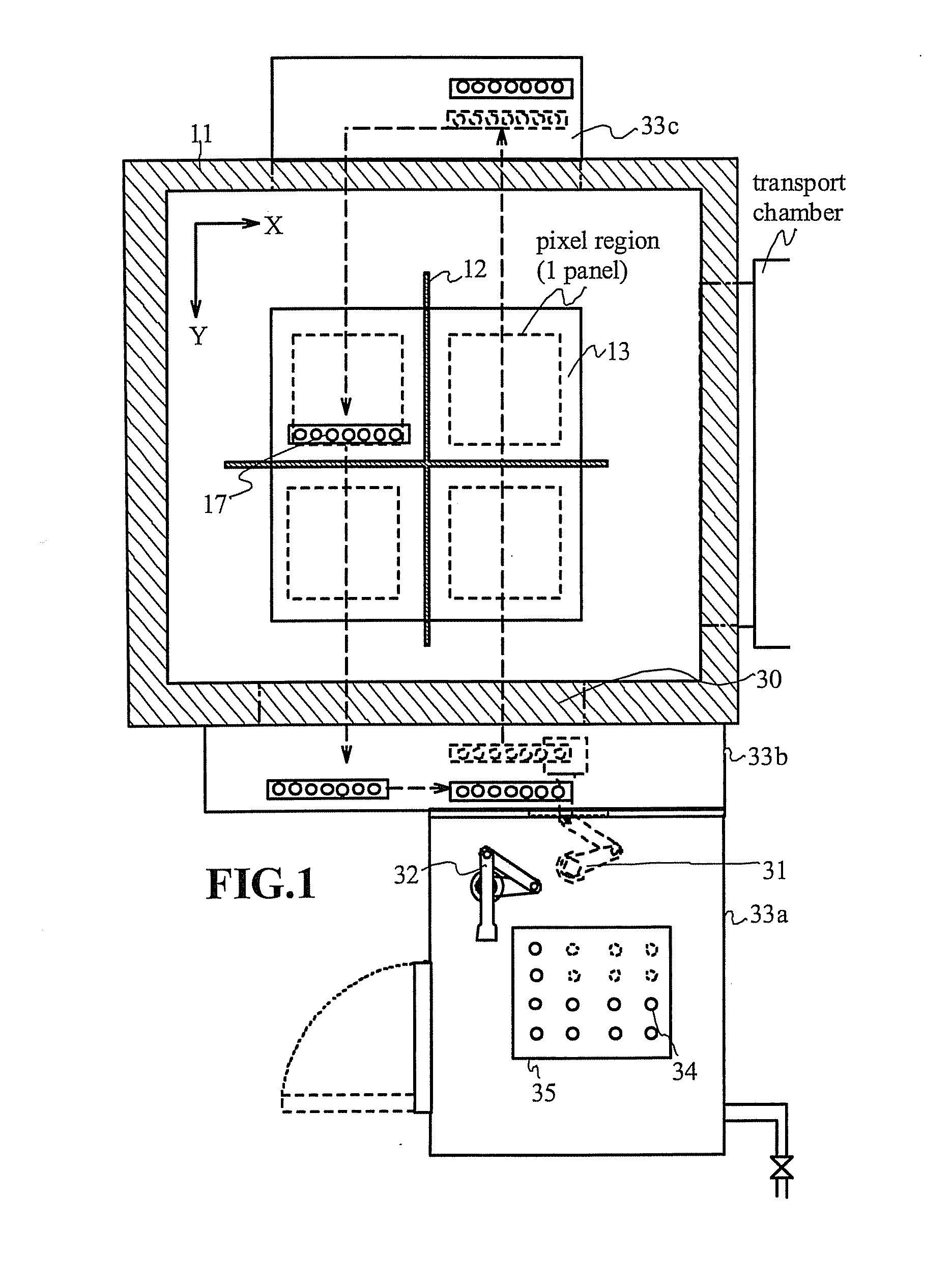

Fabrication System and Manufacturing Method of Light-Emitting Device

InactiveUS20080057602A1Shorten heating timeDegree of vacuum is increasedElectroluminescent light sourcesVacuum evaporation coatingProduction rateEvaporation

The present invention provides a vapor deposition method and a vapor deposition system of film formation systems by which EL materials can be used more efficiently and EL materials having superior uniformity with high throughput rate are formed. According to the present invention, inside a film formation chamber, an evaporation source holder in a rectangular shape in which a plurality of containers sealing evaporation material is moved at a certain pitch to a substrate and the evaporation material is vapor deposited on the substrate. Further, a longitudinal direction of an evaporation source holder in a rectangular shape may be oblique to one side of a substrate, while the evaporation source holder is being moved. Furthermore, it is preferable that a movement direction of an evaporation source holder during vapor deposition be different from a scanning direction of a laser beam while a TFT is formed.

Owner:SEMICON ENERGY LAB CO LTD

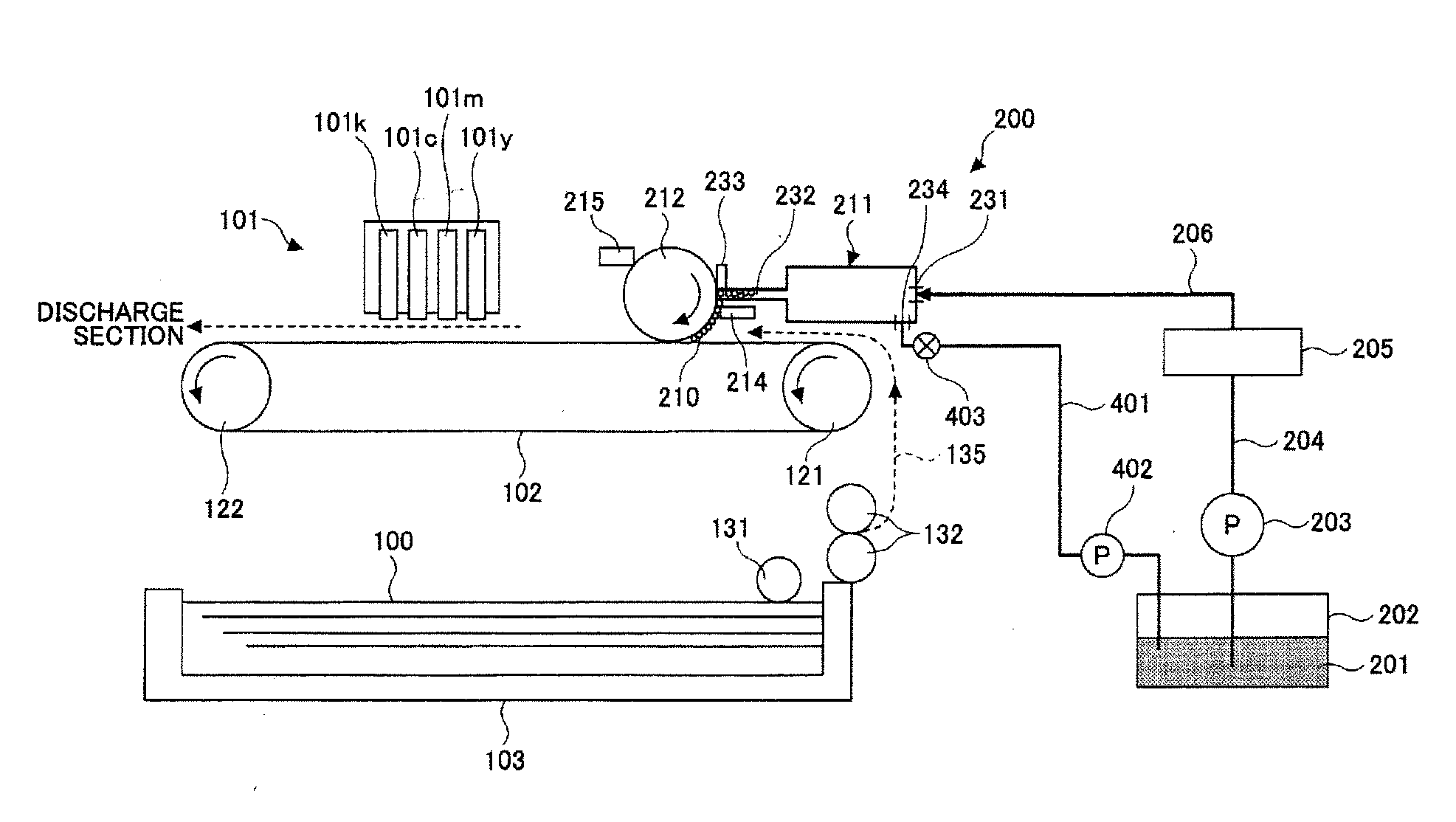

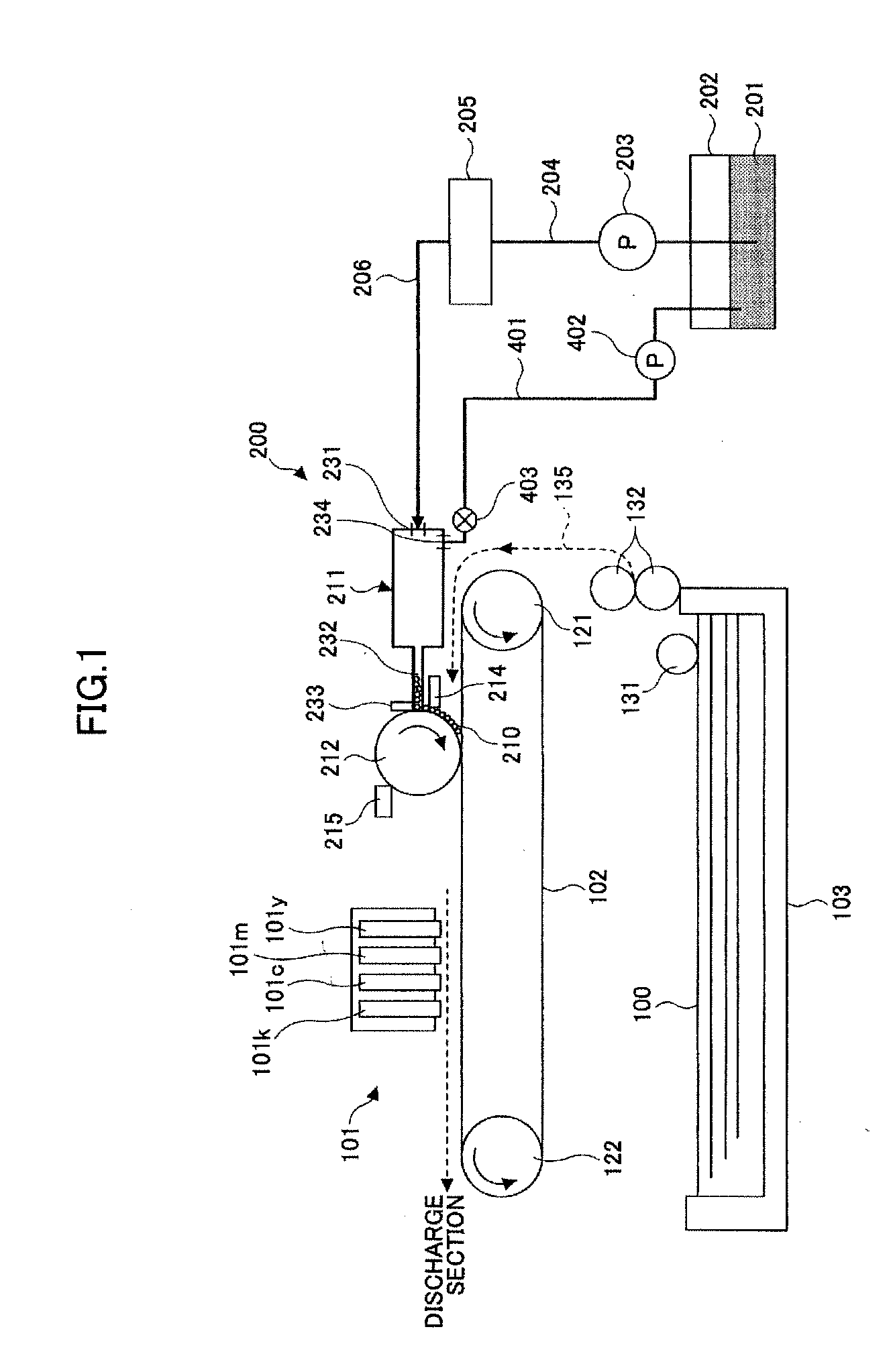

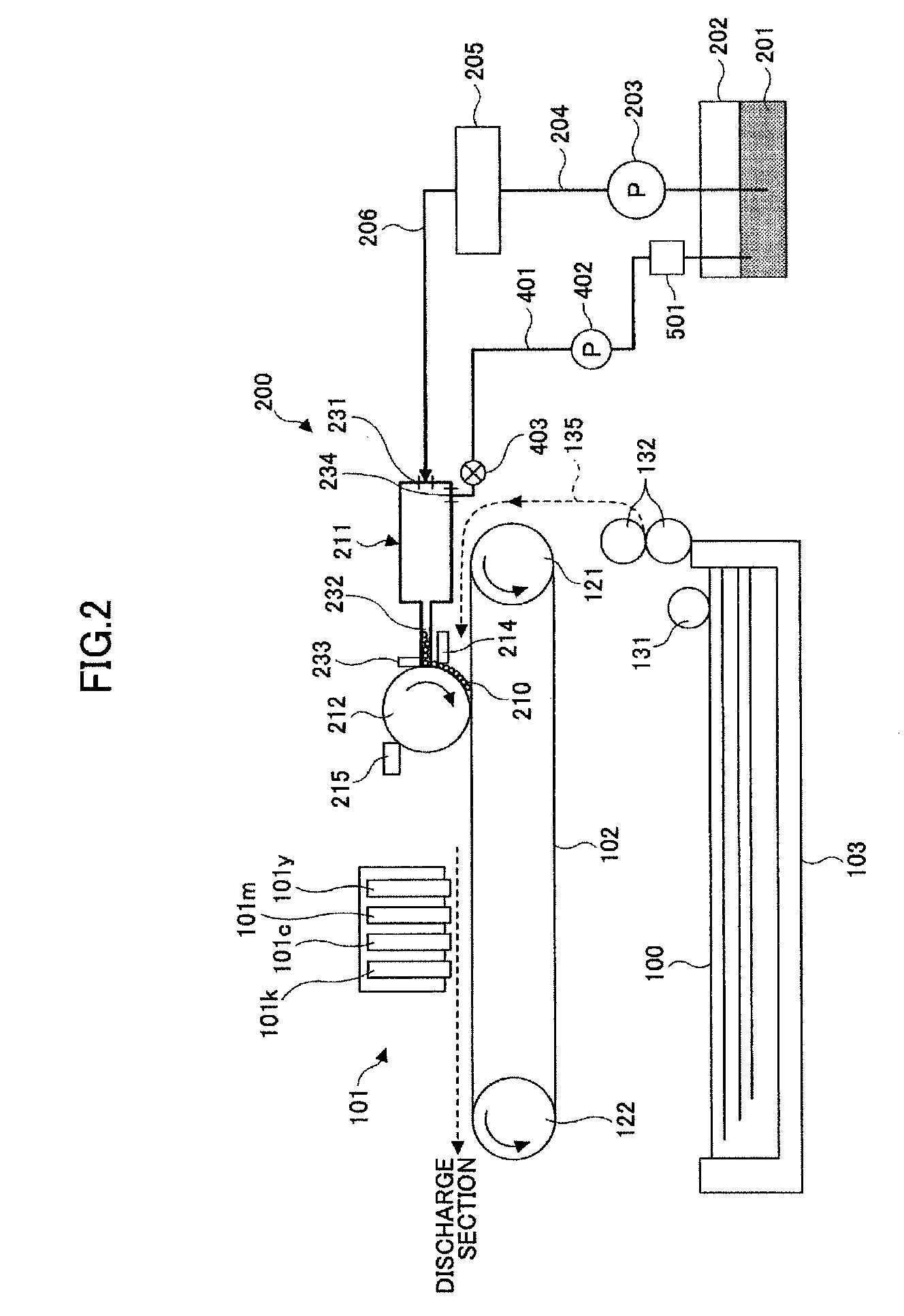

Image Forming Apparatus And Foam Application Device

InactiveUS20100245460A1Maintain qualitySupply amount is limitedLiquid surface applicatorsCoatingsImage formationEngineering

A disclosed image forming apparatus is capable of solving the problems of deterioration of a foam application function and driving systems caused by the dried and fixed foam remaining without being applied. The image forming apparatus includes a foam forming section forming foam, a reservoir section supplying foam formed by the foam forming section to an application roller, a discharge channel through which extra foam is collected from the reservoir section, and a heating unit for heating the extra foam to return the extra foam to a liquid form. The discharged liquid prepared by defoaming the foam discharged through the discharge channel is returned to a container containing the defoamed liquid.

Owner:RICOH KK

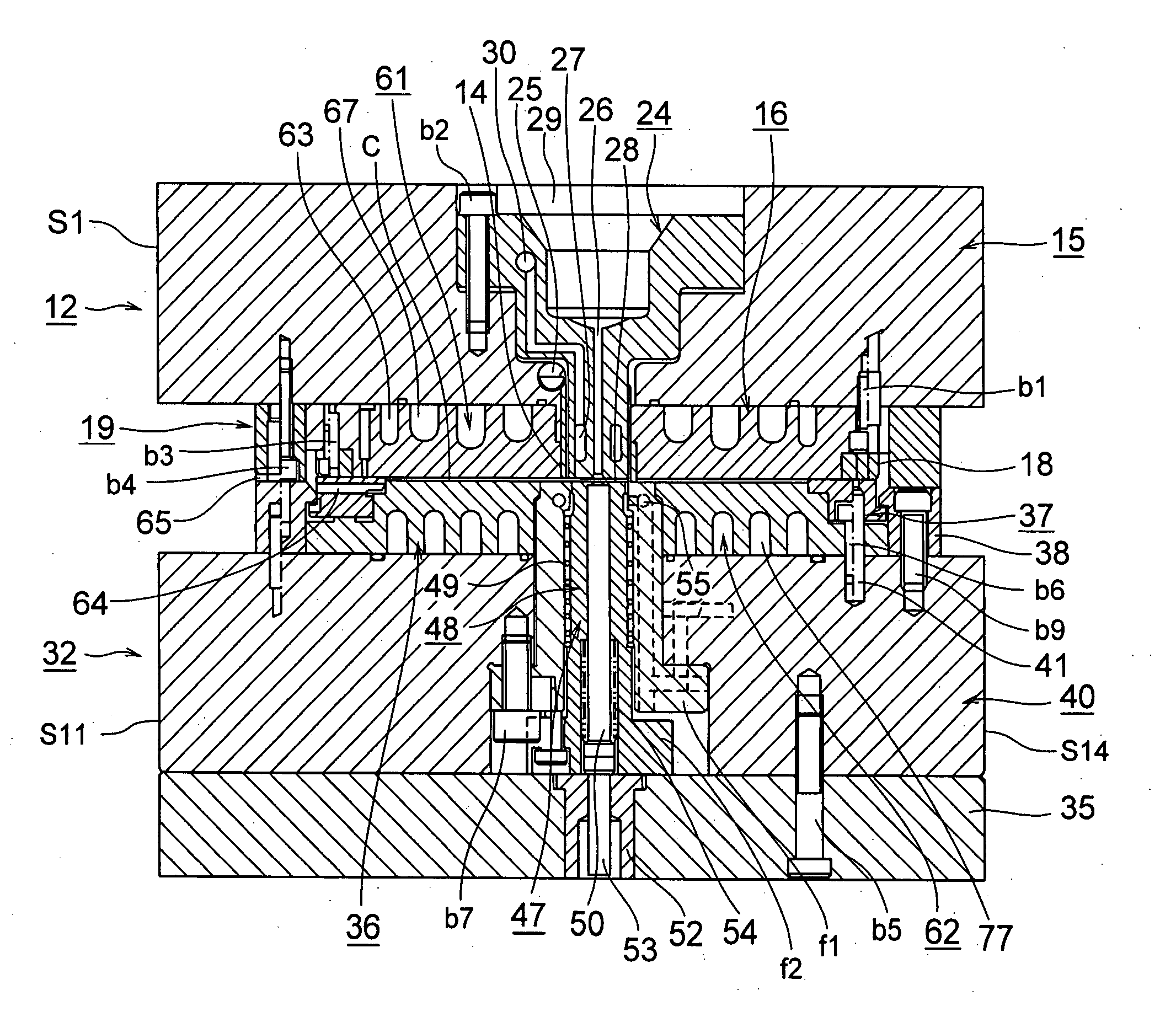

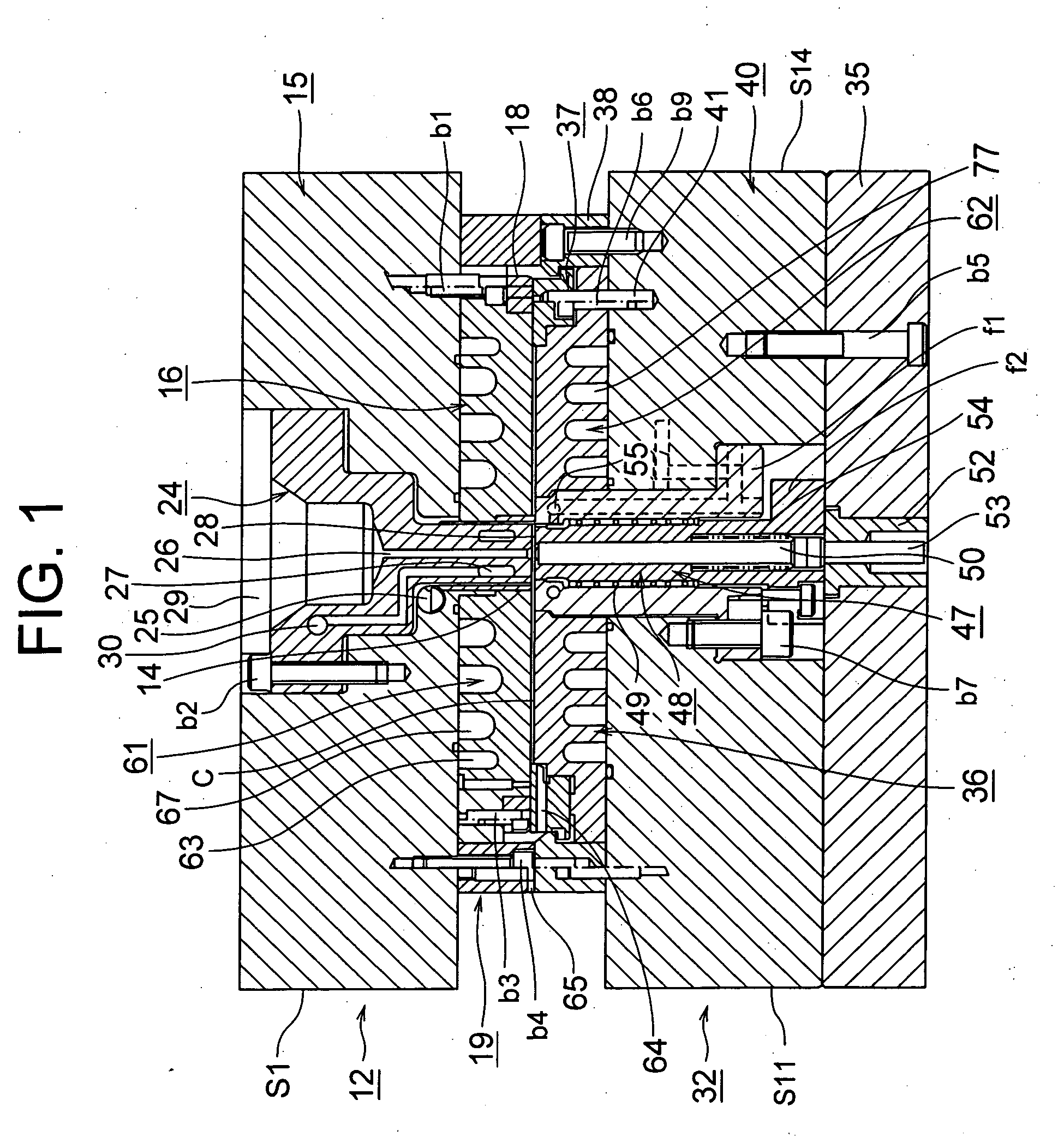

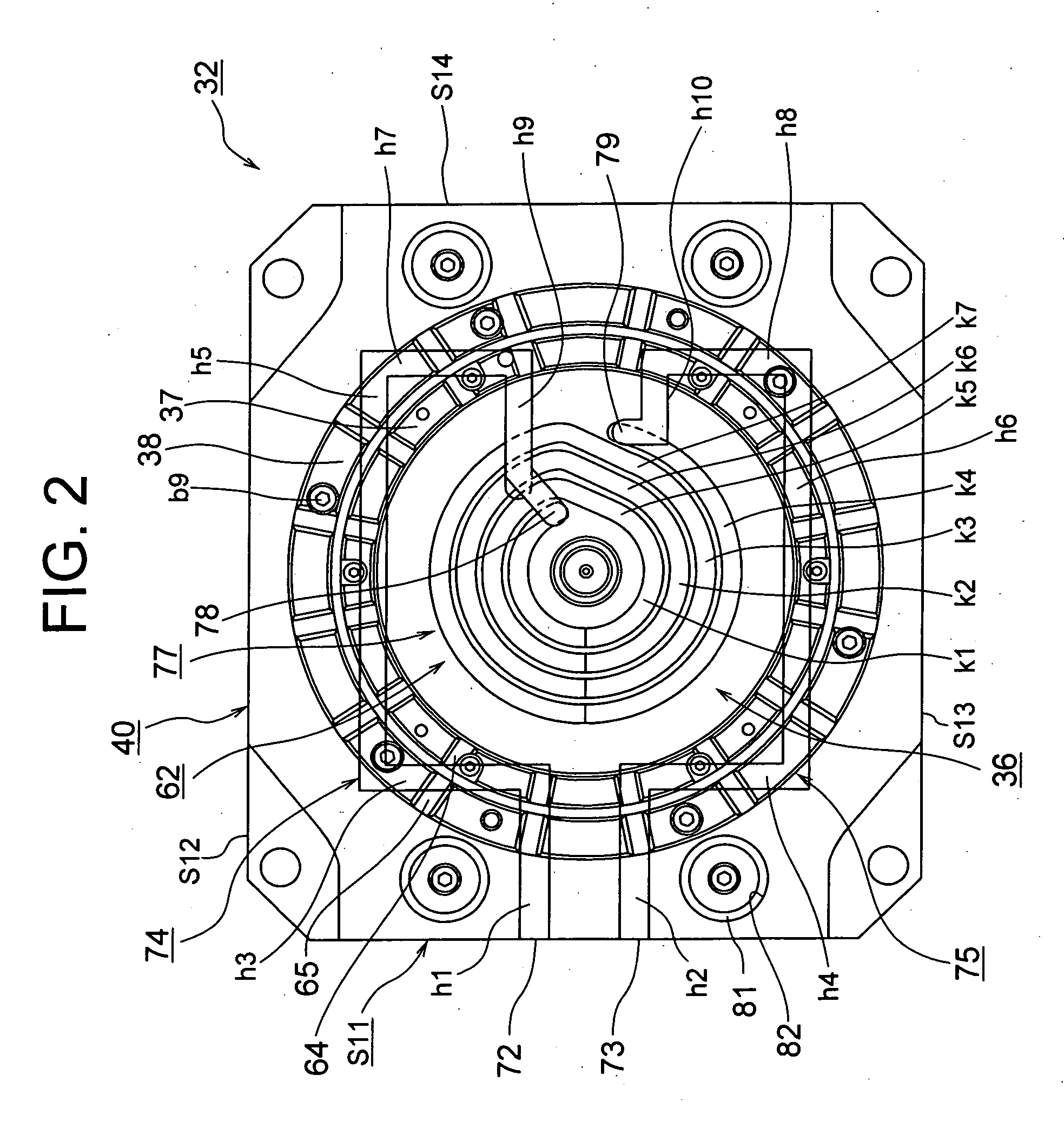

Disc-molding mold molded product and moloding machine

InactiveUS20050220925A1No thickness unevennessQuantity of heatConfectioneryOptical articlesMolding machineEngineering

An object is to provide a disc-molding mold which can increase the degree of transfer of a pattern of a stamper to thereby improve quality of molded products, as well as a molded product and a molding machine. In the vicinity of the outer peripheral edges of first and second disc-shaped members, the cooling capacity of the medium flow passage of the stamper-side disc-shaped member is made lower than the cooling capacity of the medium flow passage of the non-stamper-side disc-shaped member. On the stamper side, the quantity of heat radiated from the outer peripheral edge of the stamper-side disc-shaped member to the outside of the disc-molding mold can be reduced, whereby over-cooling of the stamper-side disc-shaped member can be prevented. As a result, a local deterioration in the degree of transfer, which would otherwise occur in the vicinity of the outer peripheral edge of the cavity space (C), can be prevented, and thus the degree of transfer of the fine pattern can be improved over the entire cavity space (C) As a result, quality of molded products can be improved.

Owner:SUMITOMO HEAVY IND LTD +1

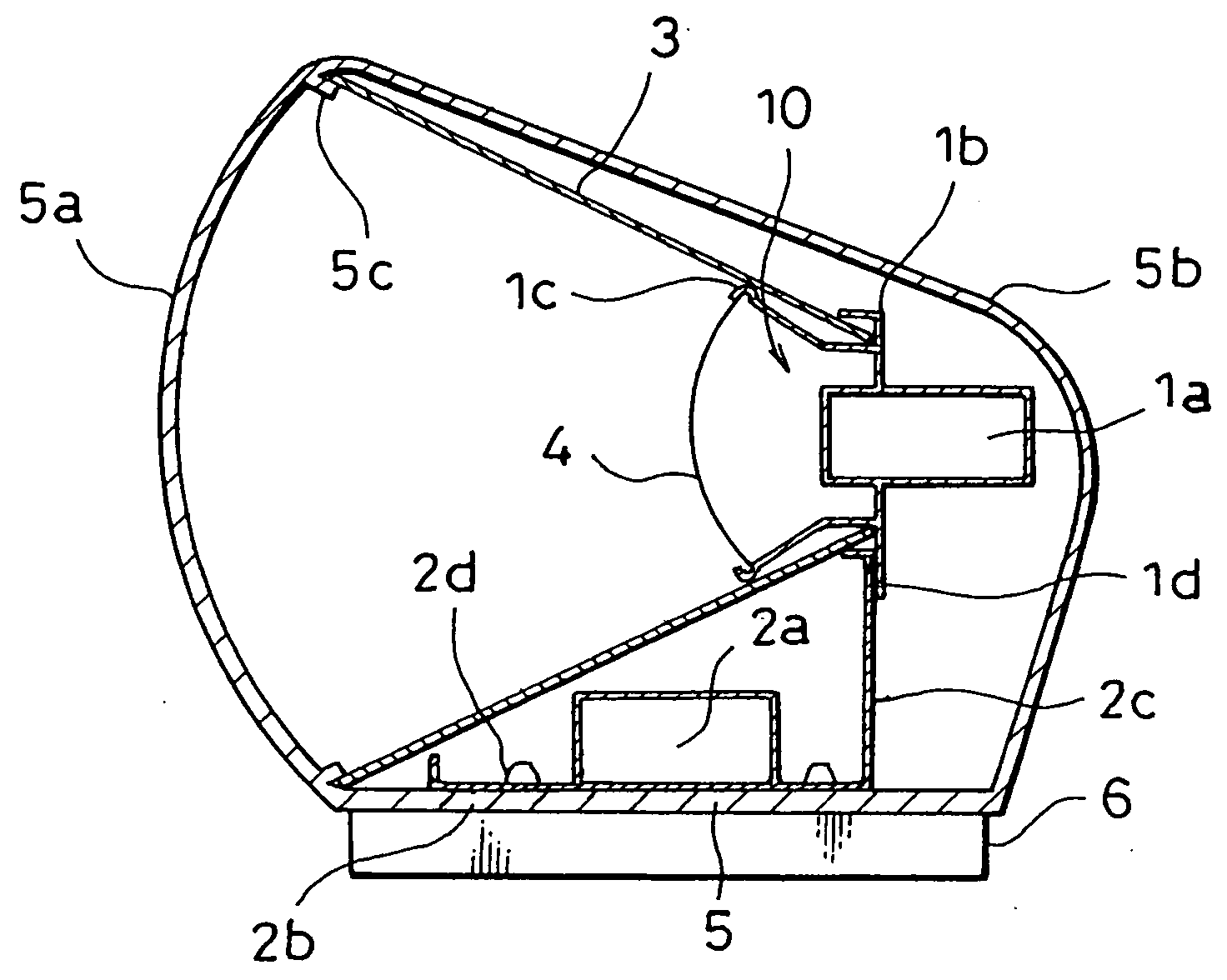

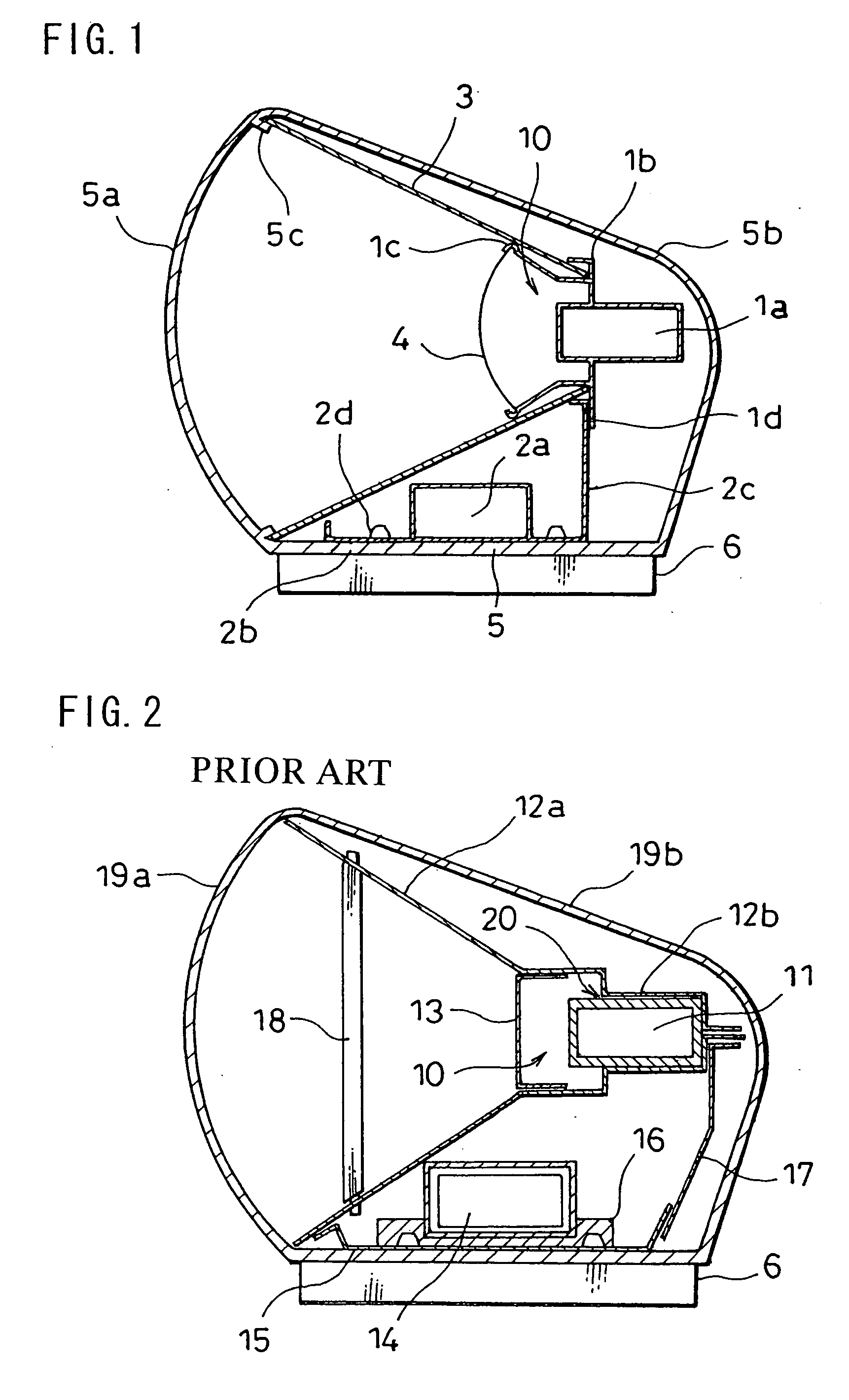

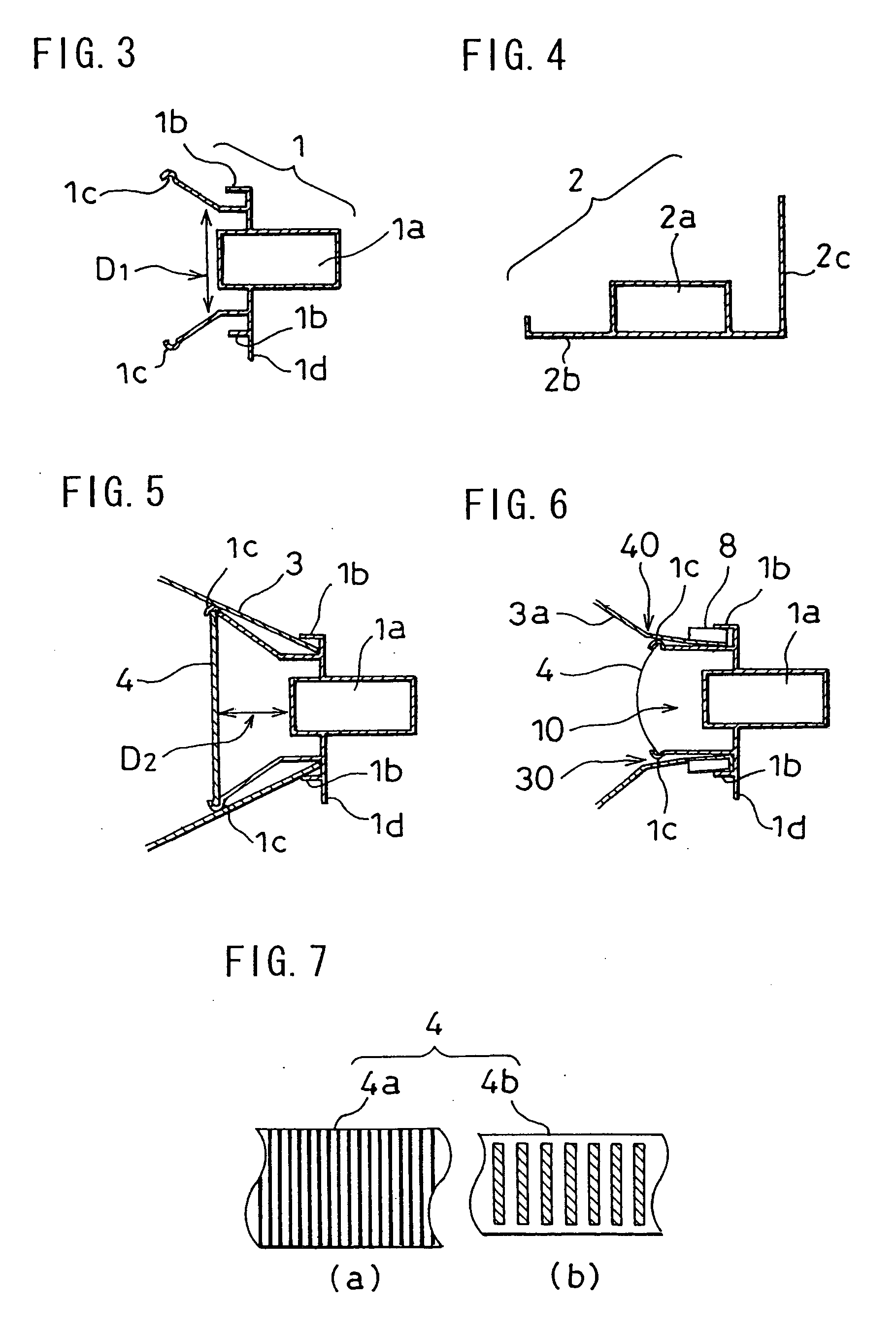

Slot array antenna

InactiveUS20050040993A1Reduce weightEasy to assembleWaveguide hornsAntenna supports/mountingsSlot-waveguideCross polarization

An object of the invention is to provide a slot array antenna in which unstable factors for contact of an adjustment portion comprising a slot waveguide and a waveguide holder are removed, a number of parts is decreased to save weight, and assembly is simplification. Accordingly, this invention is to constitute a radiation portion (1) unitedly of a slot waveguide (1a), a flare holder (1b), and a supported portion (1d), if necessary, further adding a screen holder (1c) for a screen (4) for cross polarization suppression. Furthermore, this invention is to constitute a reinforcement feeder (2) unitedly of a feeder waveguide (2a), a reinforcement portion (2b) and a reinforcement connector (2c) in the case of an open type antenna.

Owner:TAIYO MUSEN

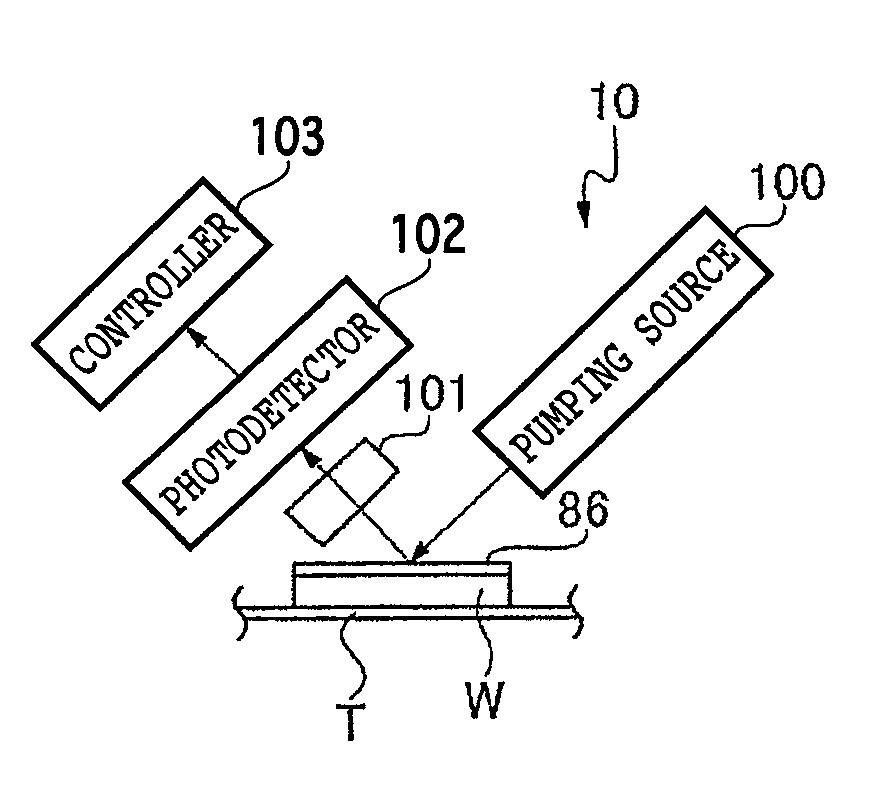

Protective film detecting method for laser processing

ActiveUS20170176331A1Accurate measurementDecrease productivitySemiconductor/solid-state device testing/measurementSolid-state devicesTectorial membraneLaser processing

Disclosed herein is a protective film detecting method of detecting the formed condition of a protective film formed on the front side of a workpiece. The protective film detecting method includes a fluorescence intensity measuring step of forming a plurality of reference protective films having different thicknesses on the front sides of a plurality of reference workpieces, next applying excitation light absorbable by an absorbing agent contained in each reference protective film to each reference protective film, and next measuring the intensity of fluorescence emitted from the absorbing agent due to the absorption of the excitation light, and a threshold deciding step of deciding a threshold of the fluorescence intensity corresponding to a desired one of the different thicknesses of the reference protective films according to the fluorescence intensity measured above.

Owner:DISCO CORP

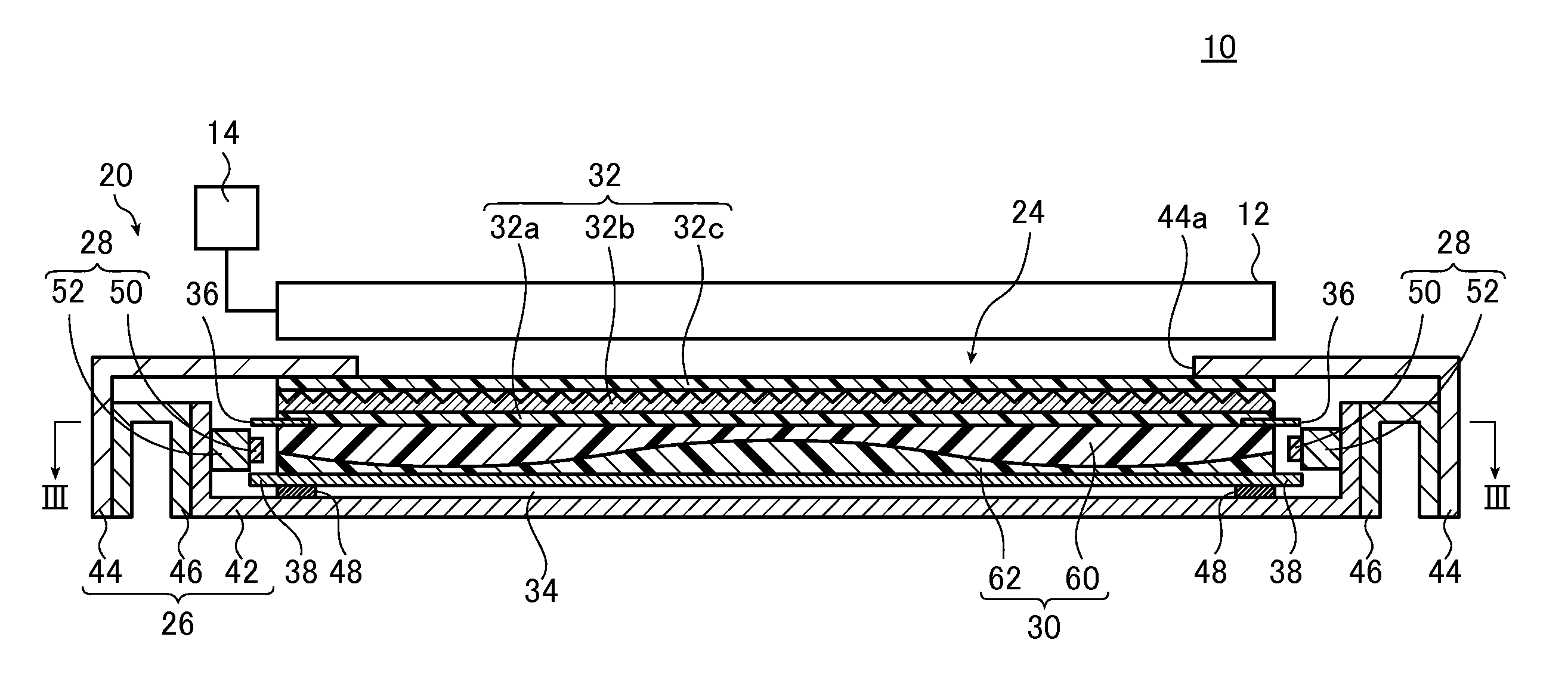

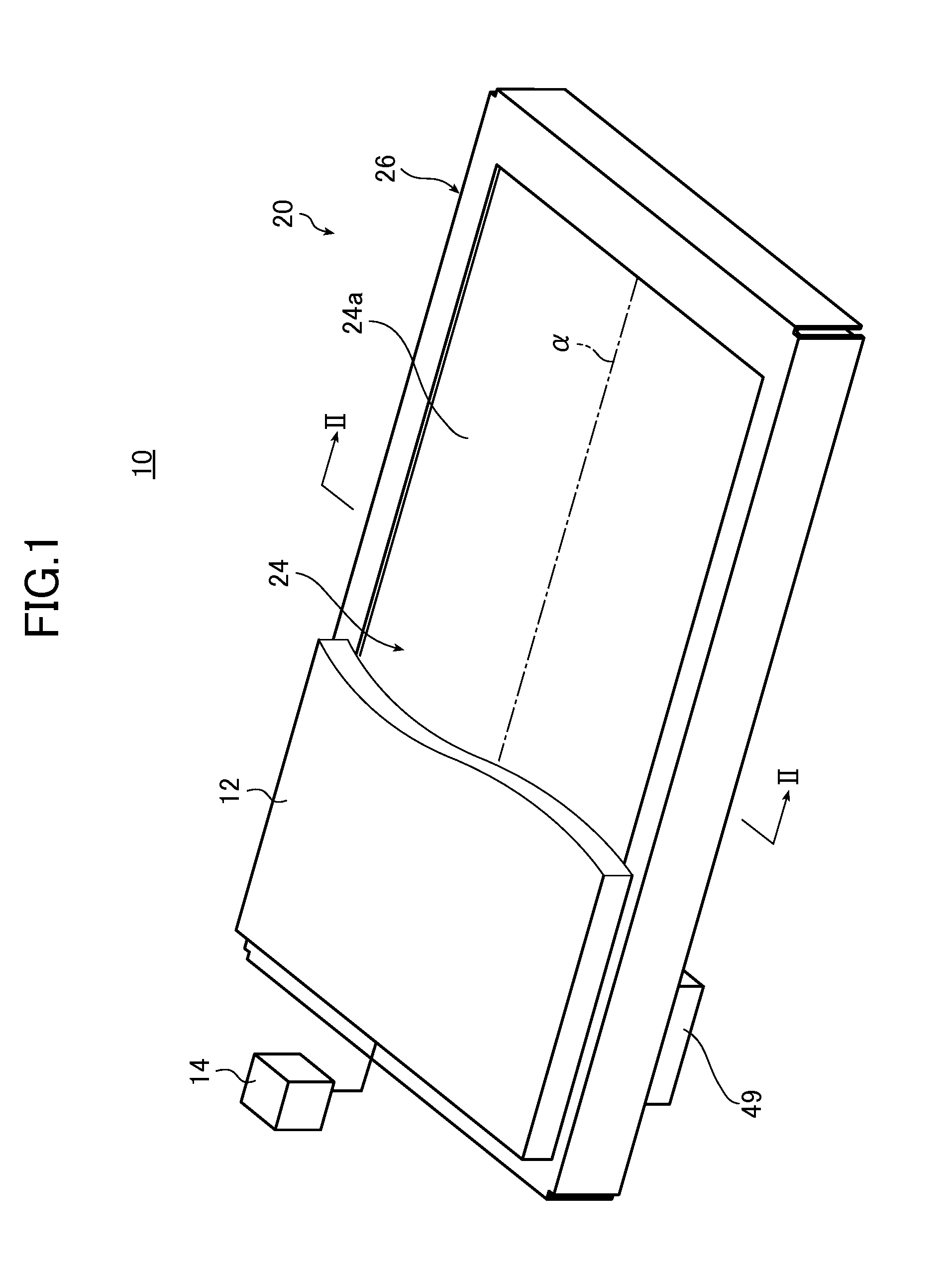

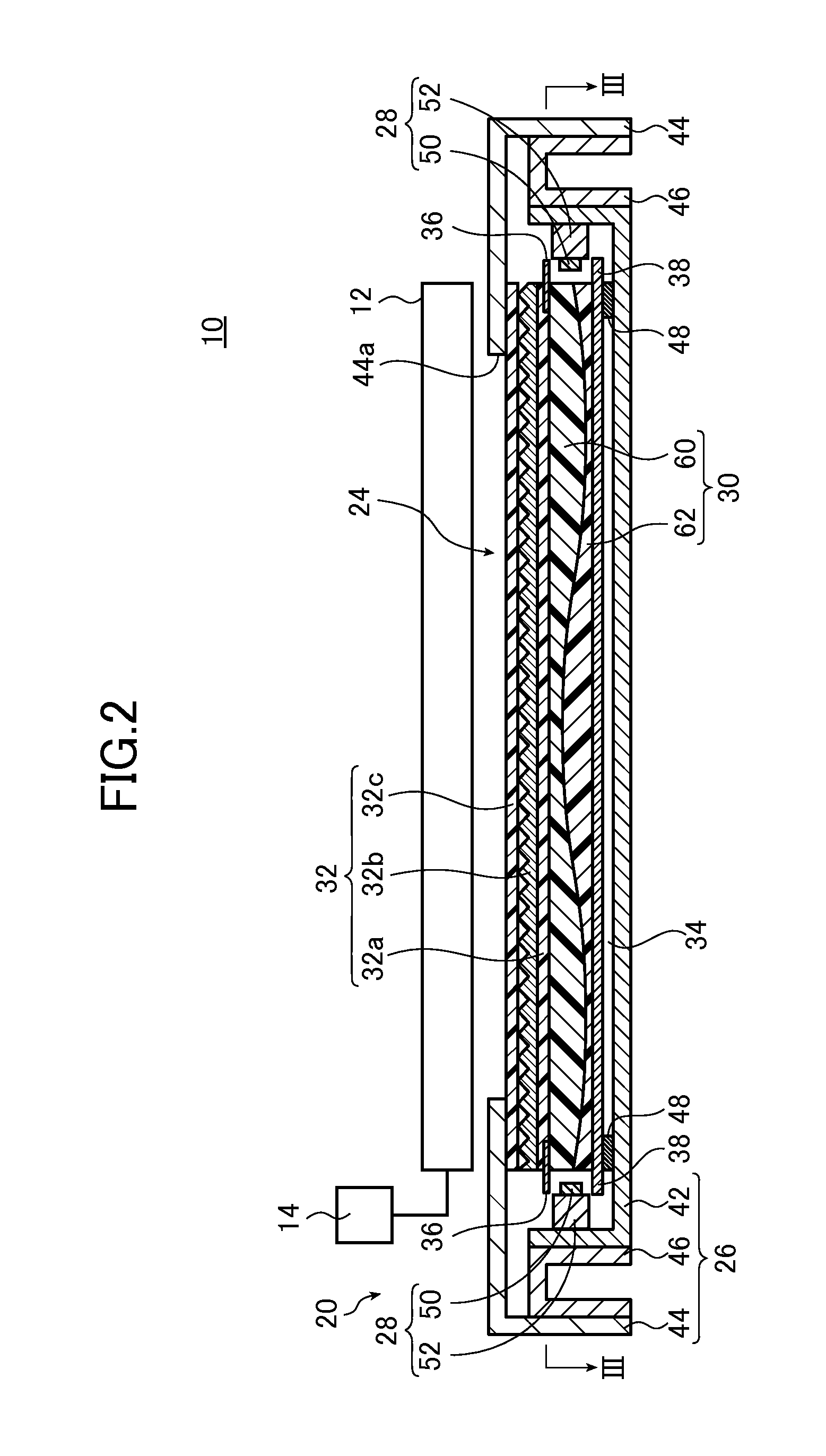

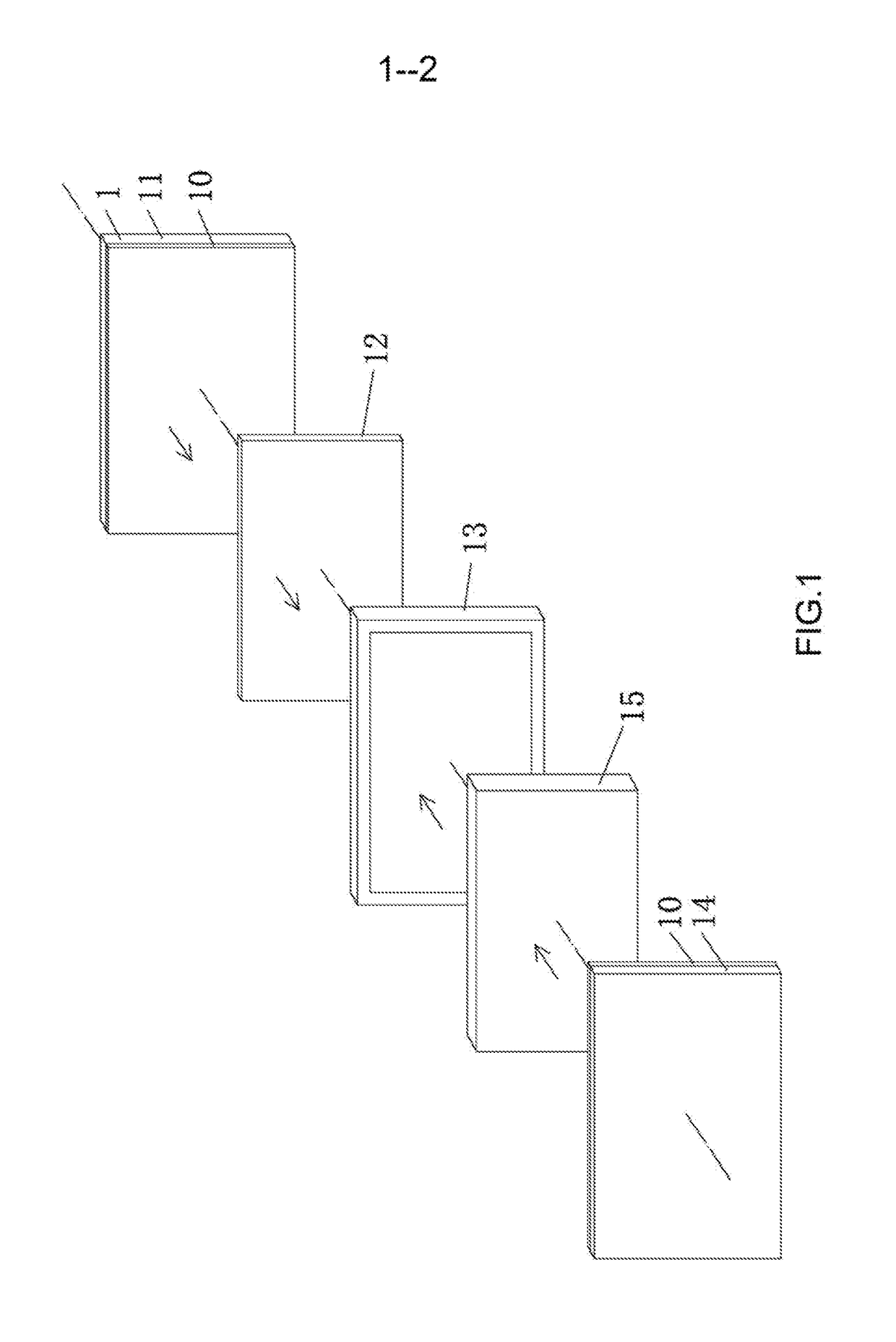

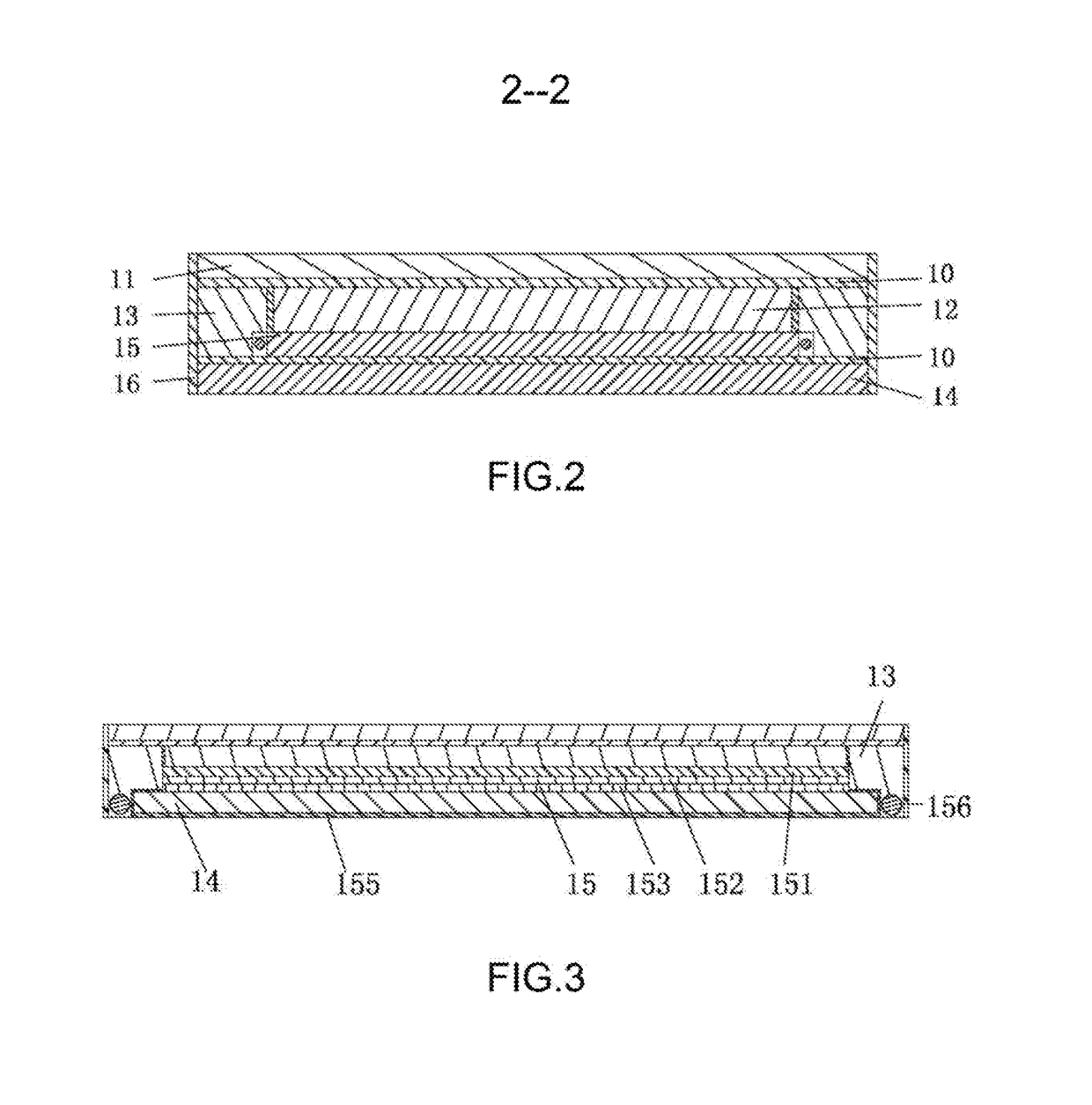

Integrated Fully-sealed Liquid Cryatal Screen and Manufacturing Process for Same

ActiveUS20180004028A1Eliminate the effects ofNo thickness unevennessMechanical apparatusLight guides for lighting systemsLiquid-crystal displayGlass cover

A manufacturing process for an integrated fully-sealed liquid crystal screen is disclosed. Components sequentially arranged are adhered to each other into a whole by a solid ultraviolet flexible adhesive, the components comprising a screen protecting glass, a liquid crystal screen set, a support frame and a rear glass cover plate and an edge lighting type backlight module being nested in the support frame The touch and display integrated screen manufactured by the process is fully-sealed, waterproof, damp-proof and ultrathin, all gaps of the screen protecting glass or the touch screen set, a liquid crystal display screen set and the side lighting type backlight module are eliminated, the image definition is improved, and also the brightness can be reduced to achieve a remarkable energy-saving effect.

Owner:OPTON (SHUNCHANG) OPTICS CO LTD

Method of diffusion bonding of nickel based superalloy substrates

InactiveUS20060283921A1Fine grain structureNo thickness unevennessWelding/cutting media/materialsWelding/soldering/cutting articlesLiquid phaseNickel based

A method of transient liquid phase bonding includes the use of an interlayer between the two substrates to be bonded that is alloyed with a melting point reducing element. The interlayer forms a liquid during the bonding process, resulting in superior surface contact between the interlayer and substrates during the bonding process. As the melting point decreaser diffuses out of the interlayer, the interlayer resolidifies, at which point bonding continues under the principles of diffusion bonding.

Owner:SIEMENS POWER GENERATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com