Ice-making tray

a technology for ice-making trays and trays, which is applied in the field of ice-making trays, can solve the problems of non-uniformity and non-uniformity of the caulking state, and achieve the effects of shortening the heater current-flowing time, and reducing the temperature difference of each par

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036]Embodiments of the present invention will be described below with reference to the drawings. It should be noted that the present invention is not limited to these embodiments.

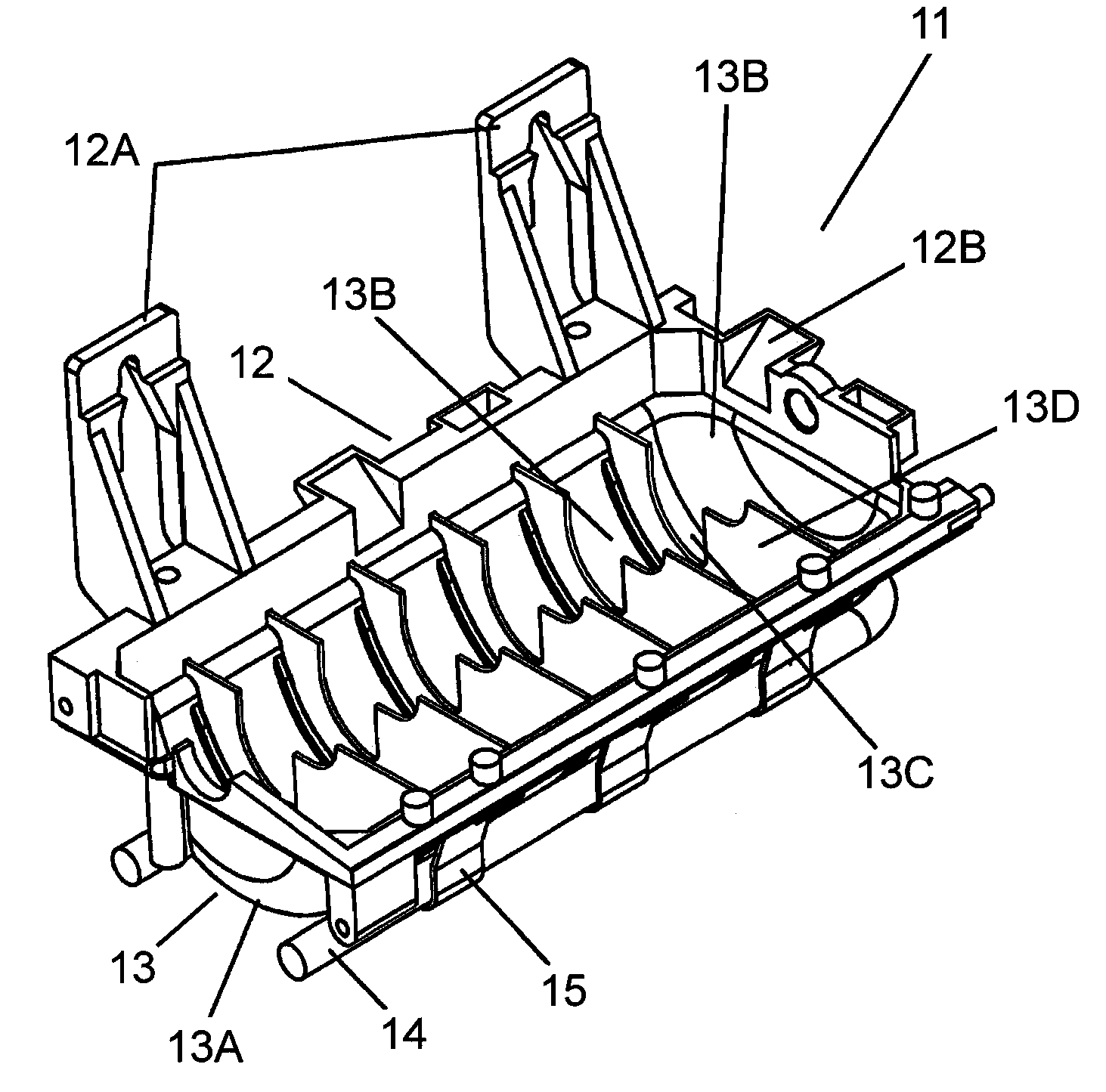

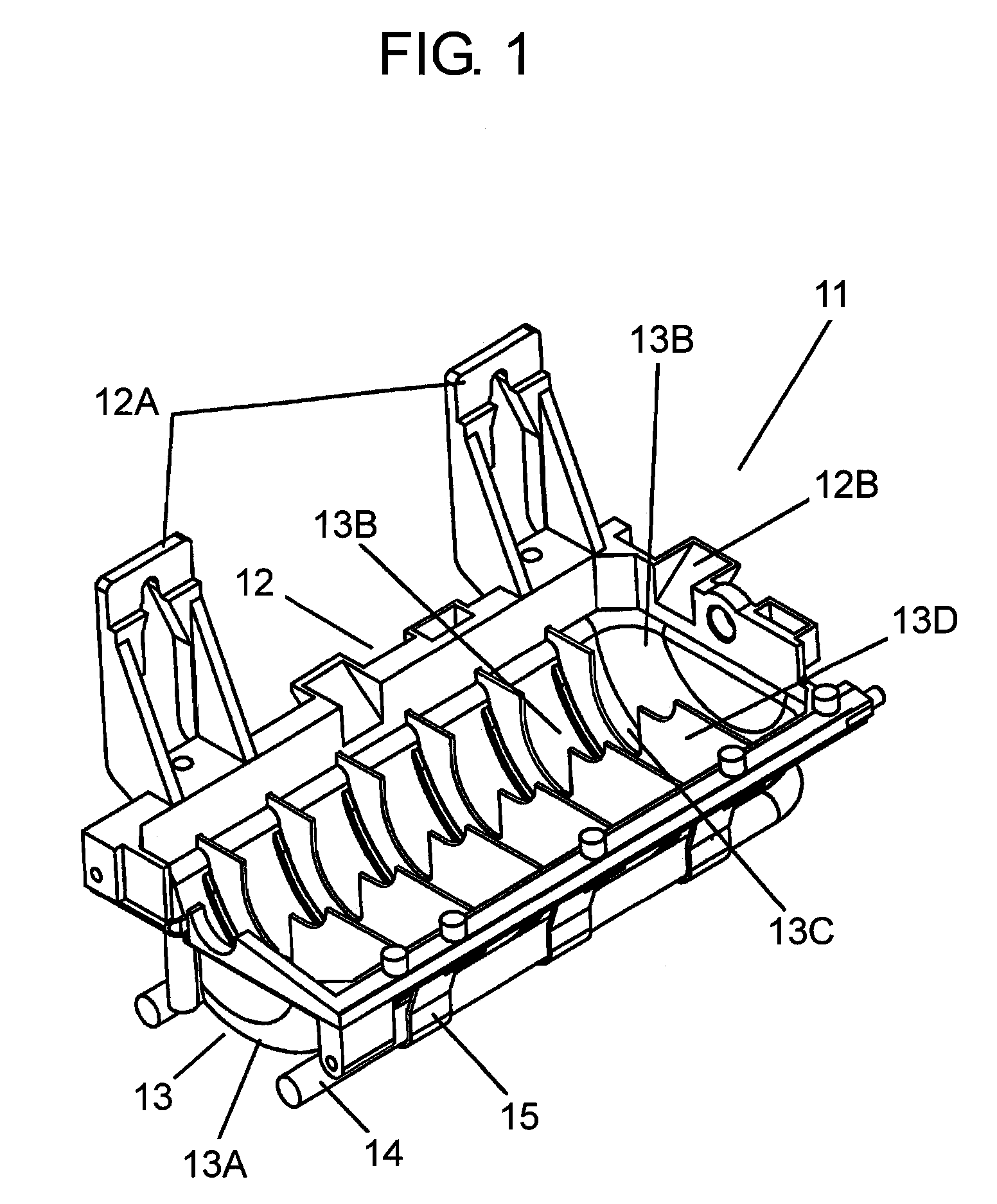

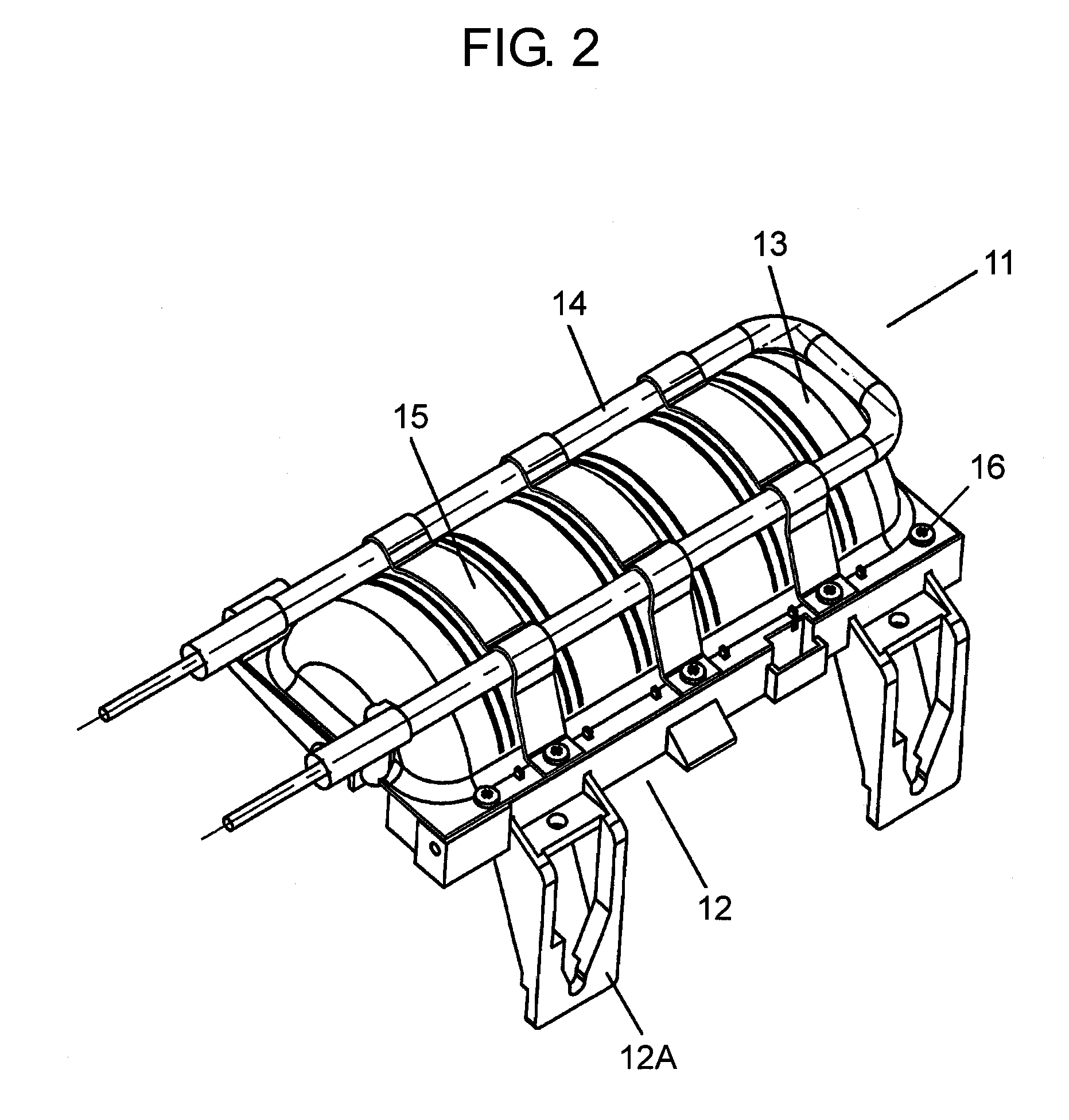

[0037]FIG. 1 is a perspective view of an ice-making tray according to an embodiment of the present invention, FIG. 2 is a perspective view of the ice-making tray seen from below, and FIG. 3 is a perspective view of an automatic ice-making device including the ice-making tray. FIG. 4 is a perspective view of a heater guide in the ice-making tray, and FIG. 5 is a cross sectional view of the ice-making tray. Ice-making tray 11 includes attachment part 12 for fixing ice-making tray 11 to a refrigerator or the like, metal tray part 13 formed as a separate body from attachment part 12, heater 14, and heater guide 15.

[0038]Tray part 13 has bottom surface 13A of semicircular cross section, and, for example, six partition plates 13D coupled to bottom surface 13A. Partition plate 13D divides the interior of tray pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| shape | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com