Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

128results about How to "No migration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flame-retardant polyacrylate emulsion and preparation method thereof

InactiveCN102604568AExpensive to resolveReduce dosageNon-macromolecular adhesive additivesMacromolecular adhesive additivesFunctional monomerAmmonium sulfate

The invention discloses a flame-retardant polyacrylate emulsion and a preparation method thereof. The flame-retardant polyacrylate emulsion consists of 100 parts of polyacrylate emulsion and 5-35 parts of flame retardant by weight parts, wherein the polyacrylate emulsion consists of ethylhexyl acrylate, butyl acrylate, methyl methacrylate, methacrylic acid, crylic acid, functional monomer, reaction emulsifier, emulsifier OP, ammonium persulfate and deionized water; the flame retardant consists of carbonized catalyst, carbonizer and expanding agent. The preparation method of the flame-retardant polyacrylate emulsion includes: utilizing the combined process of pre-emulsifying and seeding polymerizing and adding expansion flame retardant. The flame-retardant polyacrylate emulsion prepared by the preparation method has excellent flame retardancy, adhesivity, filming ability and stability and excellent waterproofness, and can be widely used in the industries of adhesives and coatings and the like.

Owner:SHANGHAI APPLIED TECHNOLOGIES COLLEGE

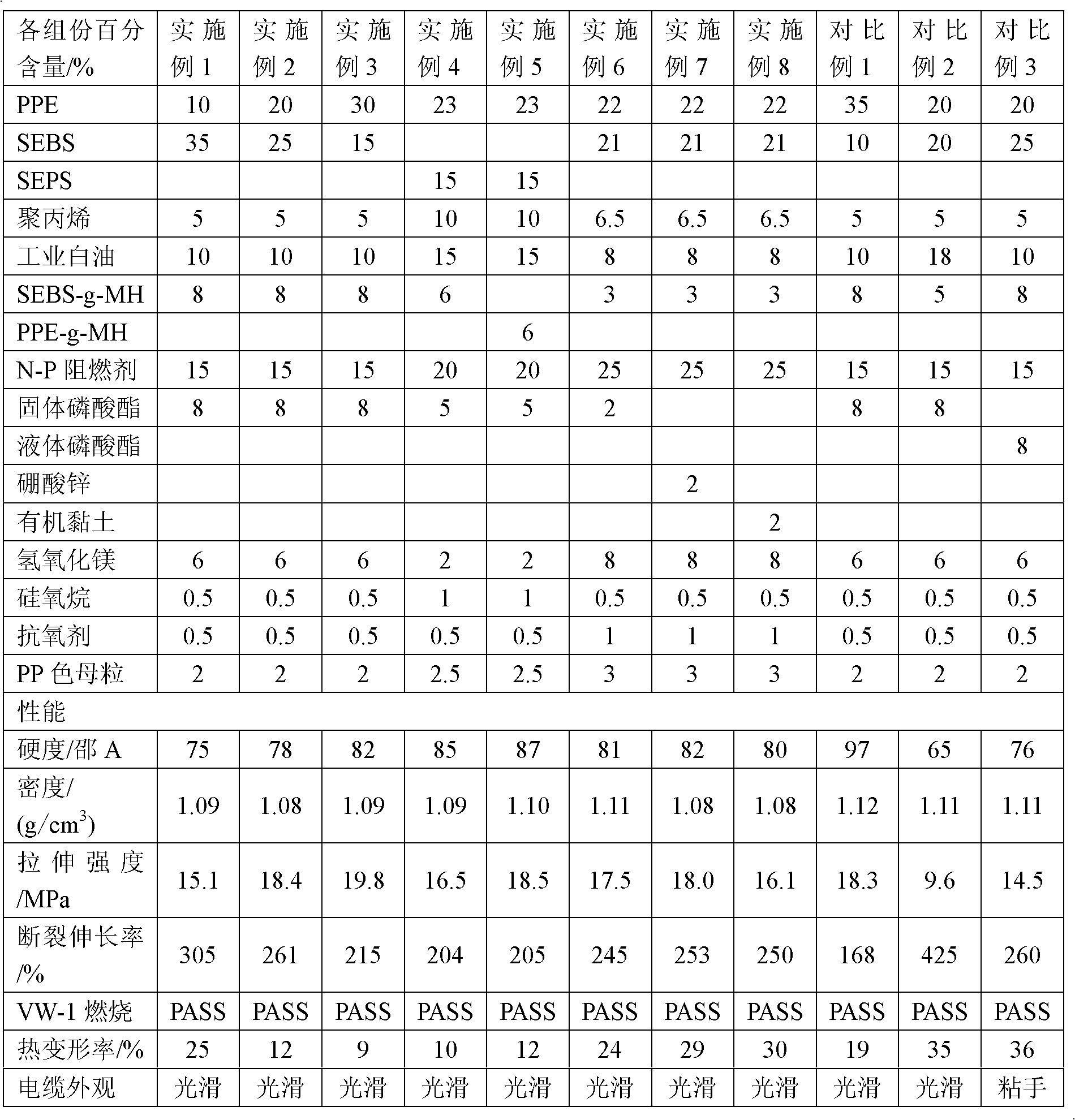

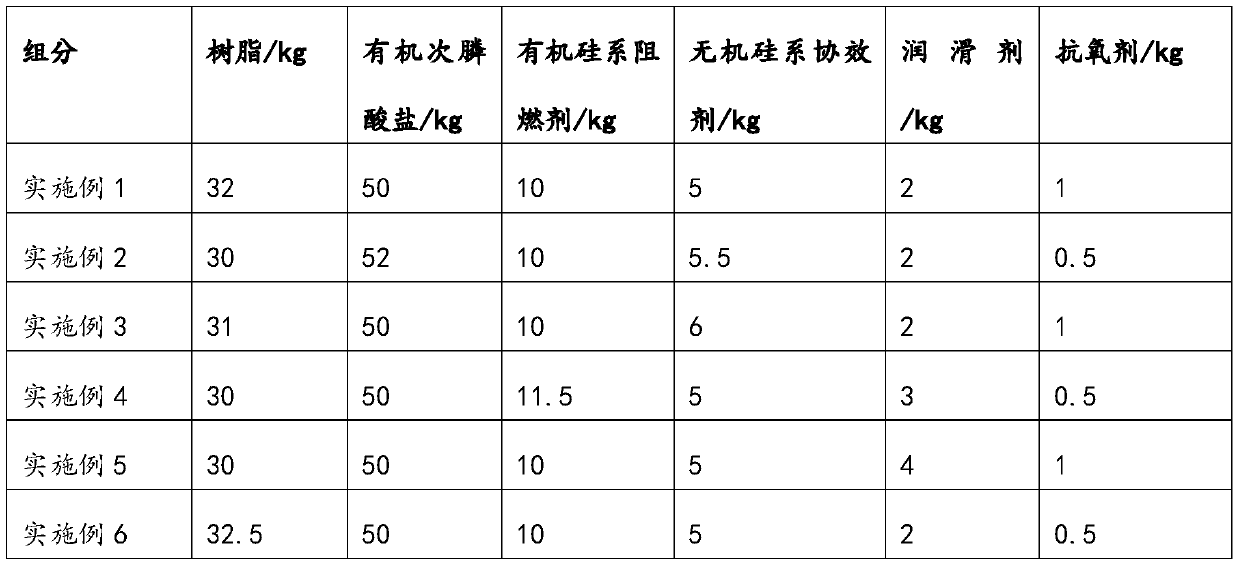

Flexible halogen-free flame-retardant polyphenyl ether electric wire cable shield material and preparation method thereof

InactiveCN102585428ANo migrationImprove flame retardant performancePlastic/resin/waxes insulatorsInsulated cablesElastomerPolyolefin

The invention relates to the field of halogen-free flame-retardant electric wire cable shield materials, in particular to a flexible halogen-free flame-retardant polyphenyl ether electric wire cable shield material and a preparation method thereof. The flexible halogen-free flame-retardant polyphenyl ether electric wire cable shield material is characterized by comprising the following raw materials in percentage: 10 to 30 percent of polyphenyl ether resin; 15 to 35 percent of styrene elastomer; 5 to 10 percent of polyolefin; 8 to 15 percent of plasticizing agent; 3 to 8 percent of compatilizer; 15 to 25 percent of main flame retardant; 2 to 8 percent of synergistic flame retardant; 2 to 8 percent of smoke suppressant; 0.5 to 1 percent of lubricant; 0.5 to 1 percent of antioxygen; and 2 to 3 percent of masterbatch. The flexible halogen-free flame-retardant polyphenyl ether electric wire cable shield material has favorable mechanical property, flexibleness, flame retardant property, heat resistance and processability.

Owner:浙江北化阻燃材料有限公司 +1

Non-halogen flame-proof urethane elastomer flame resisting agent and method of preparing the same

ActiveCN101108914ADoes not affect mechanical propertiesGood compatibilityPolyurethane elastomerPolymer science

The invention relates to a halogen-free flame retardant polyurethane elastomer flame retardant and the preparation method. The flame retardant comprises the following components and contents (weight per cent): melamine-formaldehyde coating ammonium phosphate 30 per cent to 70 per cent, triethylol isocyanurate 10 per cent to 35 per cent, melamine cyanurate 5 per cent to 20 per cent, phosphonate 10 per cent to 20 per cent, organic silane coupling agent 0.1 per cent to 0.5 per cent and antioxidant 0.1 per cent to 0.8 per cent. The preparation method of the flame retardant comprises the process steps such as the mixture of the melamine-formaldehyde coating ammonium phosphate. Compared with the prior art, the invention overcomes the defect of harm of halogen flame retardant polyurethane elastomer on the environment and the human body, endows the materials with certain difficult-flammability, has good compatibility with the polyurethane and has no effect on the mechanical properties of the polyurethane.

Owner:SHANGHAI RES INST OF CHEM IND

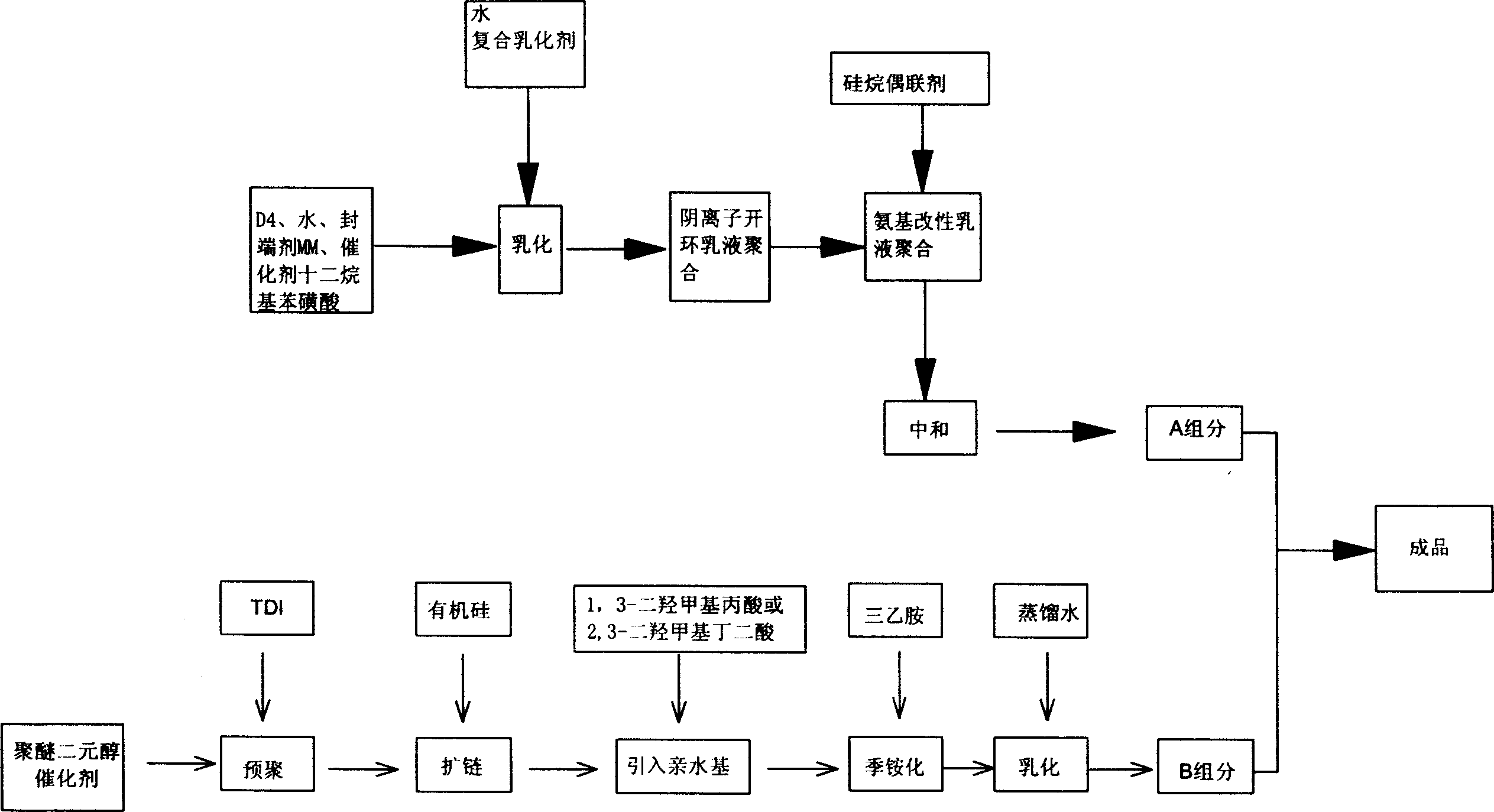

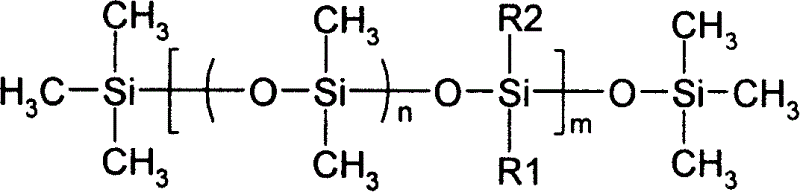

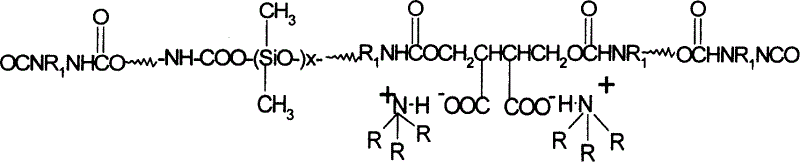

Poly siloxane leather coating material and its preparation method

InactiveCN1693578ANo migrationDoes not volatilizeCoatingsTextiles and paperPolymer scienceSolid content

The invention discloses a polysiloxane leather coating material, prepared of the below components: component A polysiloxane latex, wherein amine value of polysiloxane is 0.21-0.53, viscosity average molecular weight is 25,000-73,000, and solid content is 18-35%; component B polysiloxane-polyurethane copolymerized latex, wherein solid content is 18-35%; the weight ratio of components A to B is 2:1 to 5:1. The invention discloses a process method for preparing this painting material. After used, this painting material of the invention gives a leather warm high smoothness, thickness, silk-like soft handling and has good permanence; the process method of the invention has simple process flow, uses small amount of emulsifier and produces less pollutants.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

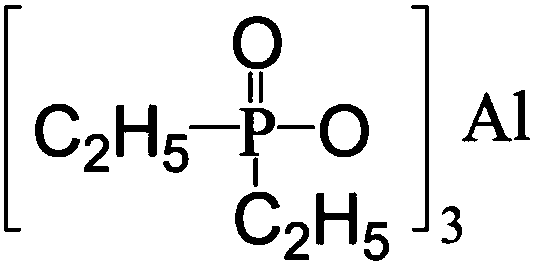

Halogen-free flame retarding compounded system based on phosphorus/aluminum compound, and application of same in glass fiber reinforced engineering plastic

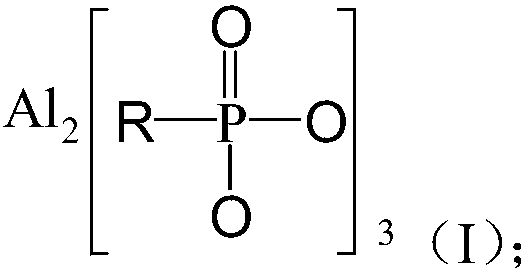

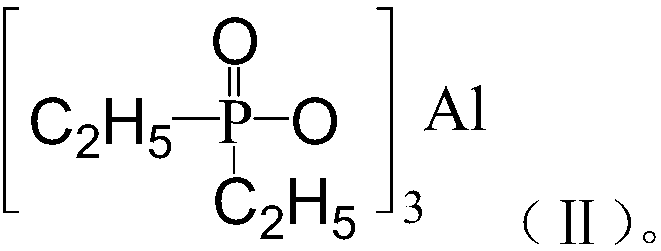

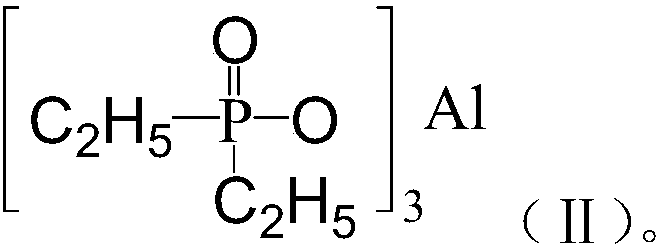

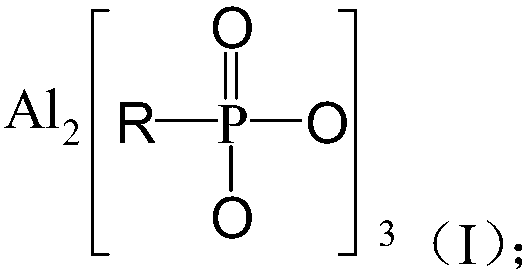

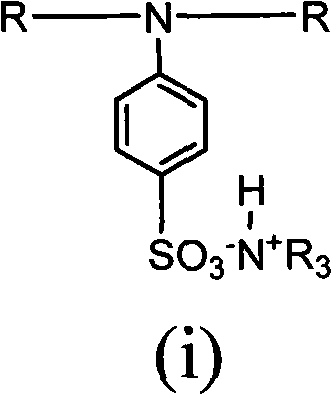

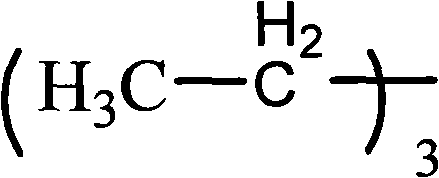

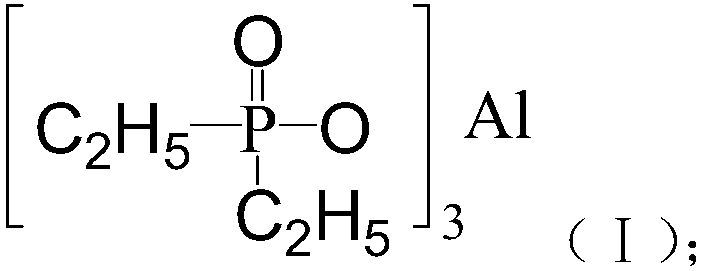

The invention discloses a halogen-free flame retarding compounded system based on a phosphorus / aluminum compound. The compounded system, on the basis of total weight of 100%, includes 40-90% of diethyl aluminum hypophosphite, 10-50% of organic aluminum phosphite, and 1-10% of a zinc salt thermal stable compound. The organic aluminum phosphite is represented as the structural formula (I), wherein Ris selected from C1-C6 straight-chain saturated aliphatic hydrocarbon groups, C1-C6 straight-chain unsaturated aliphatic hydrocarbon groups or aryl groups. The invention discloses a novel halogen-free flame retarding compounded system based on the phosphorus / aluminum compound; the system has high flame retarding performance, is free of migration and has no corrosion on equipment, can be applied to glass fiber reinforced engineering plastic to produce halogen-free flame-retarding glass fiber reinforced engineering plastic, which is used for manufacturing parts of products in the field of electronics and electric appliances.

Owner:JIANGSU LISIDE NEW MATERIAL

Masking tape containing printing layer and preparation method thereof

ActiveCN103725222AOvercome affinityProduction process is environmentally friendlyNon-fibrous pulp additionFilm/foil adhesivesWater basedEmulsion

The invention discloses a masking tape containing a printing layer and a preparation method thereof. The masking tape comprises a substrate, wherein one side of the substrate is provided with an adhesive layer, and the other side of the substrate is sequentially provided with a printing layer and a release layer; the substrate is masking tape base paper impregnated by a hydroxy butadiene-styrene emulsion; the printing layer is a water-based ink; the adhesive layer is a water-based acrylate pressure-sensitive adhesive; and the release layer is a water-based release agent. All the raw materials are water-based materials, and thus, the production technique is environment-friendly; and the product has the advantages of stable performance, long shelf life, low production cost and high added value.

Owner:广州市白云区麒胜装饰材料厂有限公司

Halogen-free flame-retardant compounding system coordinated with organic aluminum phosphite and application of same to glass fiber reinforced engineering plastics

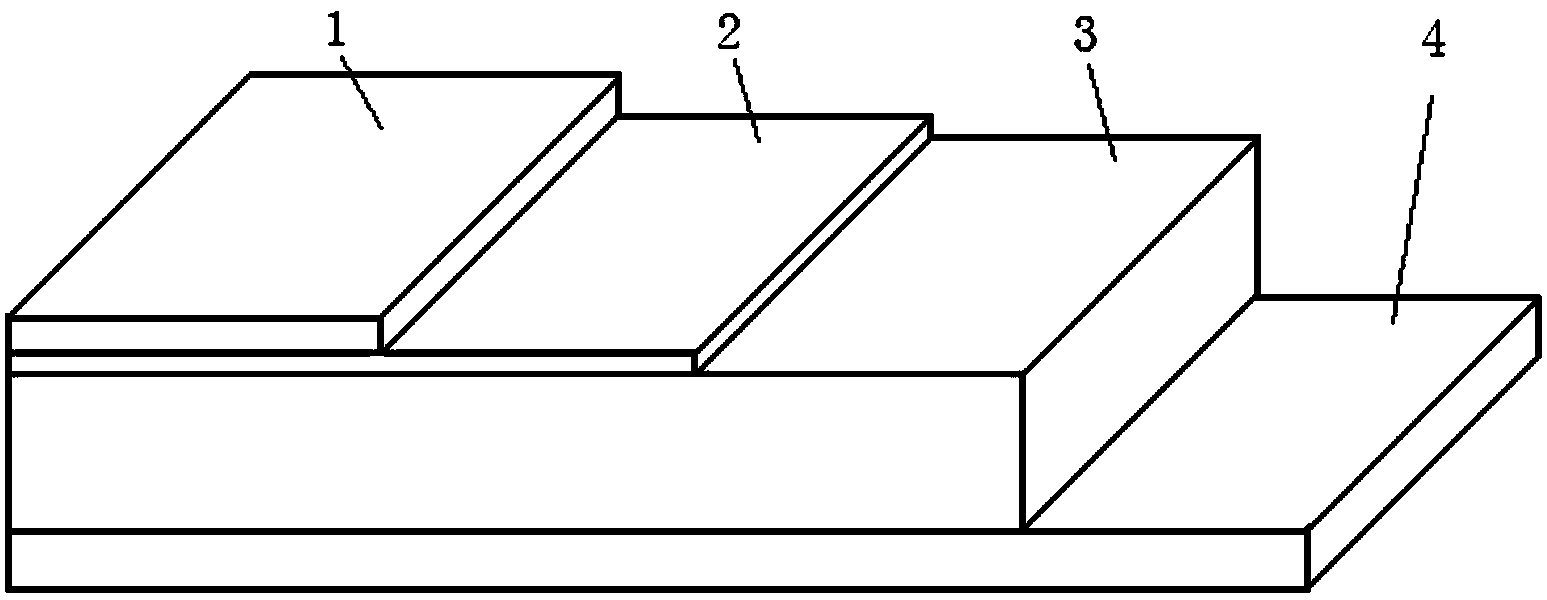

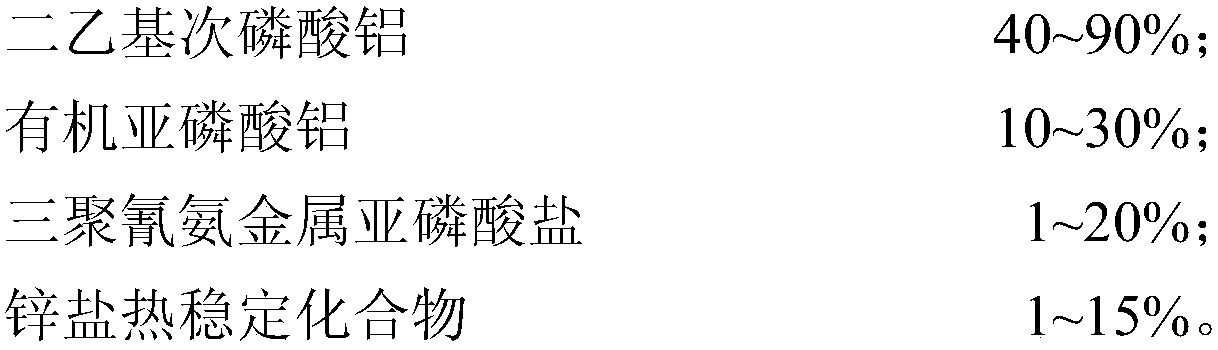

The invention discloses a halogen-free flame-retardant compounding system coordinated with organic aluminum phosphate. The compounding system comprises the following raw materials: in terms of a totalweight of 100%, 40-90% of aluminum diethylhypophosphite, 10-30% of organic aluminum phosphate, 1-20% of melamine metal phosphate and 1-15% of zinc stannate. The organic aluminum phosphate has a structural formula as shown in a formula (I) which is described in the specification. In the formula, R is selected from a group consisting of a straight-chain fatty acid saturated alkyl group with a carbon number of 1-6, a straight-chain fatty acid unsaturated alkyl group with a carbon number of 1-6 and an aryl group. The invention discloses the novel o halogen-free flame-retardant compounding systemcoordinated with organic aluminum phosphate. The halogen-free flame-retardant compounding system has the characteristics of high flame retardancy, no migration, no corrosion to equipment and the like,and can be applied to glass fiber reinforced engineering plastics to prepare halogen-free flame-retardant glass fiber reinforced engineering plastic materials used for the preparation of parts or products of electronic appliances.

Owner:ZHEJIANG UNIV

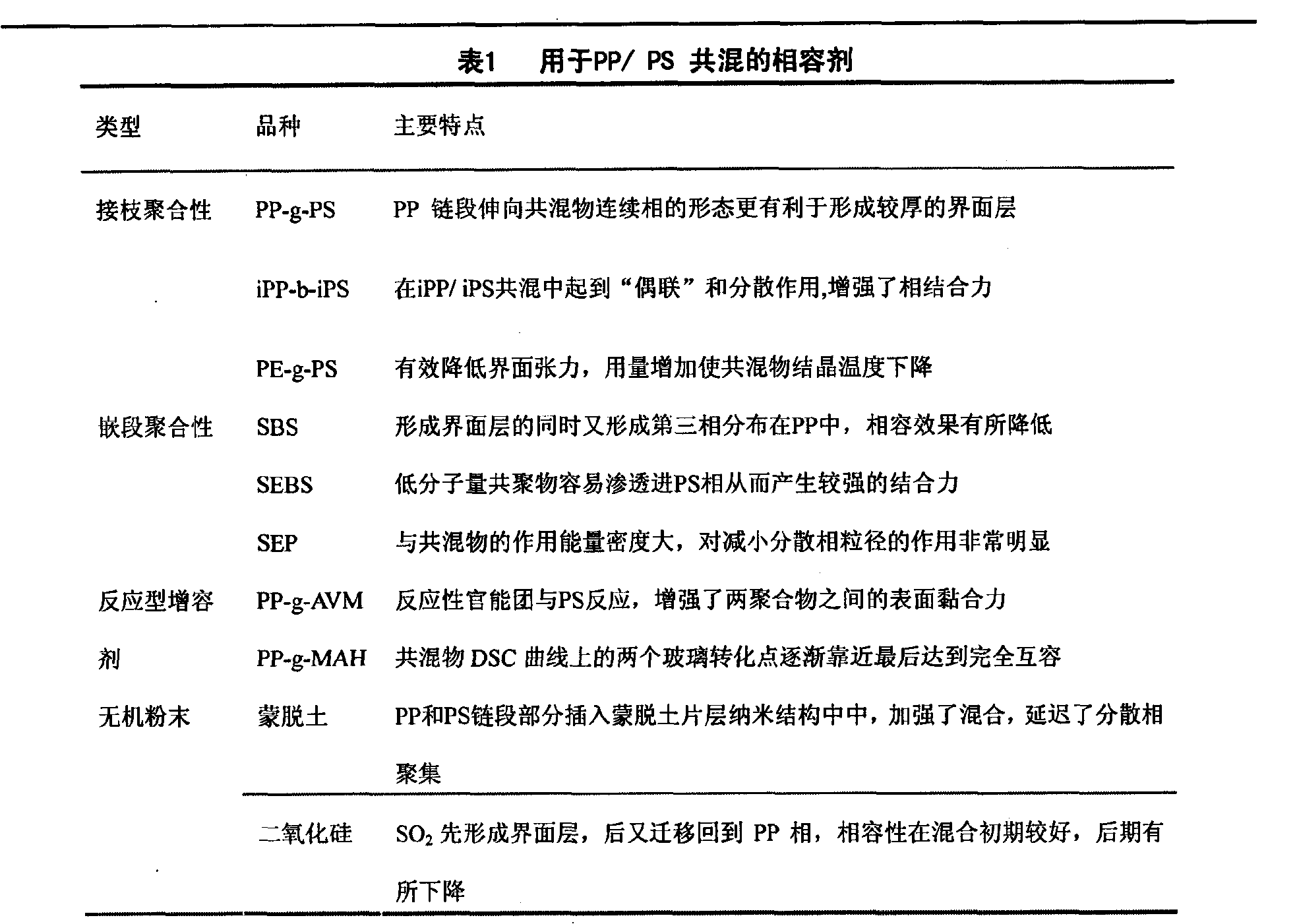

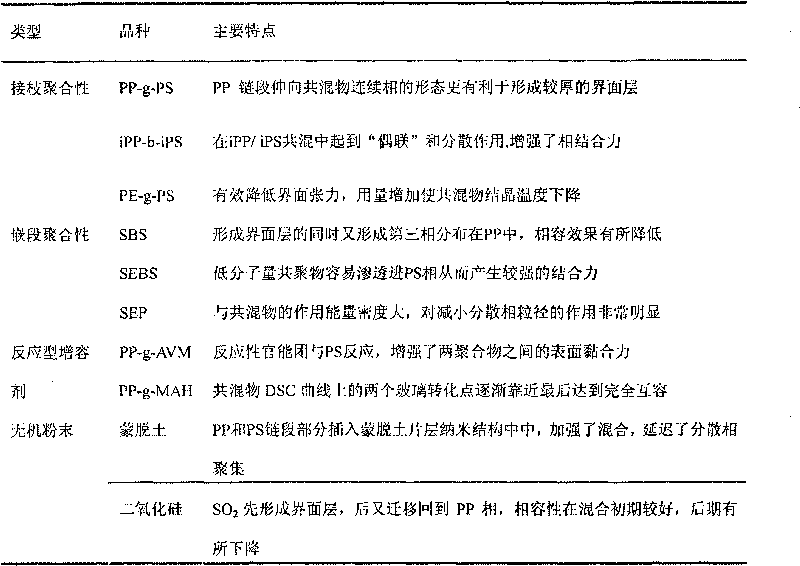

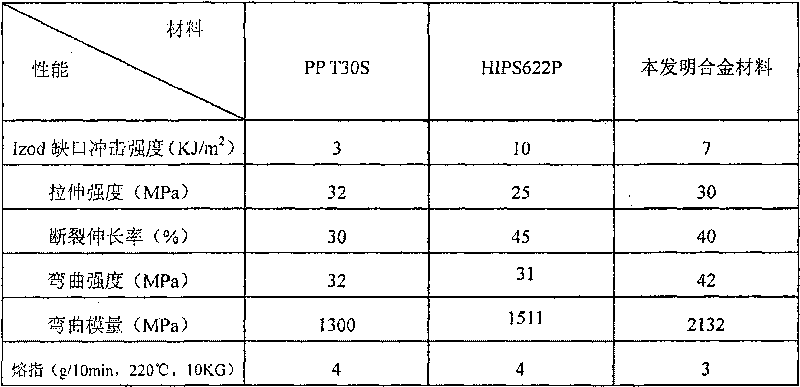

High-performance PS and PP alloy novel synthetic paper material

The invention provides a composition of a novel synthetic paper material and a preparation method. The invention comprises the following components in weight percent: 50-85% of polyolefin blend, 10% of inorganic mineral powder and 5-12% of auxiliary agent; then 0.1-1% of antioxidant calculated according to the total weight the above materials is added for pre-mixing; then a double-screw extruder is utilized for extrusion and pelletizing to manufacture into base resin with high steel and high toughness; and the comprehensive performances are all better than ordinary PP synthetic paper material,thus expanding the application range, and simultaneously by adding auxiliary agent (anti-static agent, antibacterial agent, aromatizing agent and the like), and by the processes of fusion, blending and even dispersion in the resin base body, different functional requirements can be satisfied. The paper manufactured from the high-performance PS and PP alloy novel synthetic paper material can be widely used in packaging, high-quality printed matters, tags, paper money, developing paper, tracing paper, express envelopes, paper fans, umbrellas and the like, can save a large amount of forest resource and water resource, and reduces sewage treatment pressure and energy consumption.

Owner:SICHUAN KINGFA TECH DEV

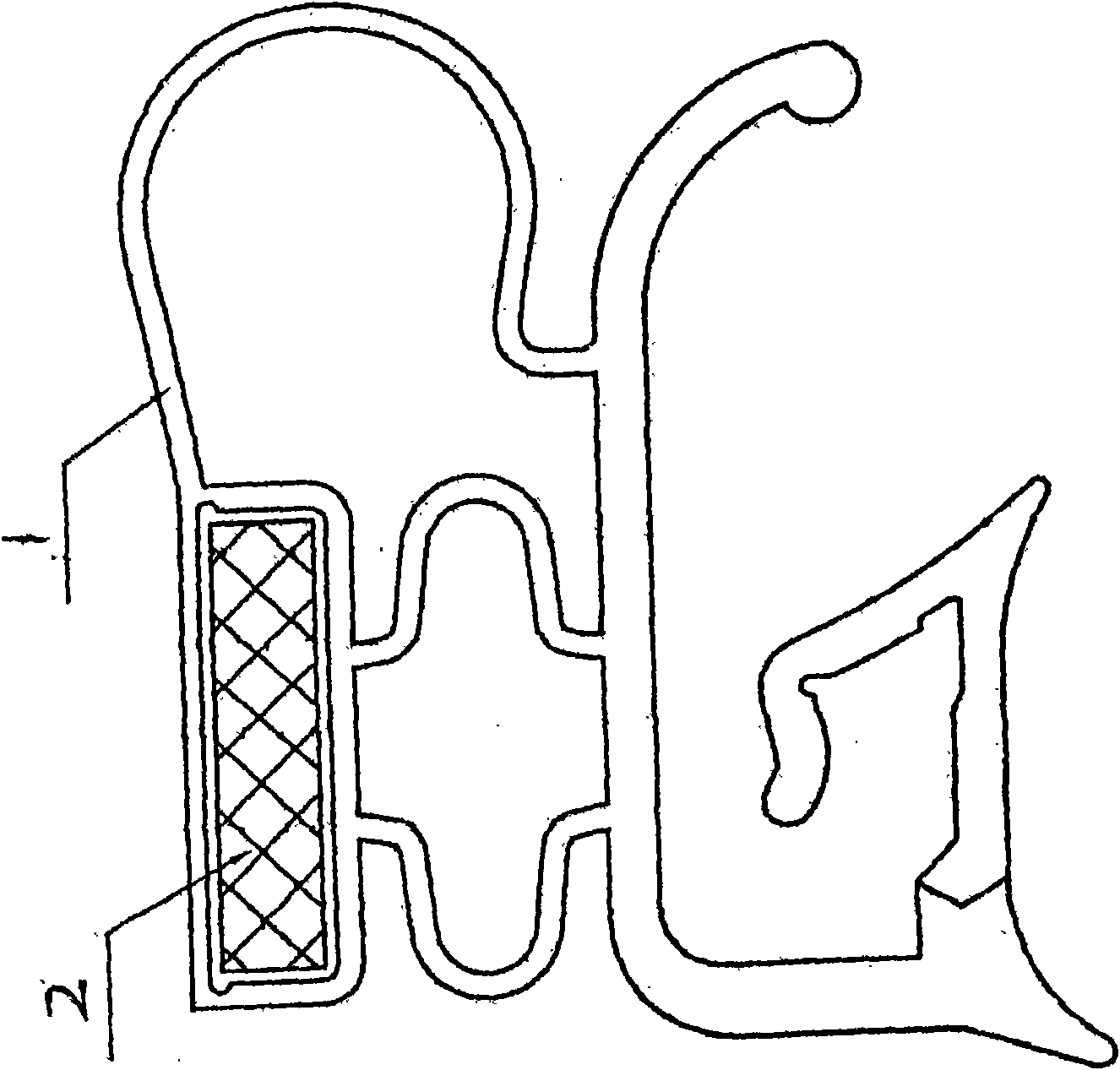

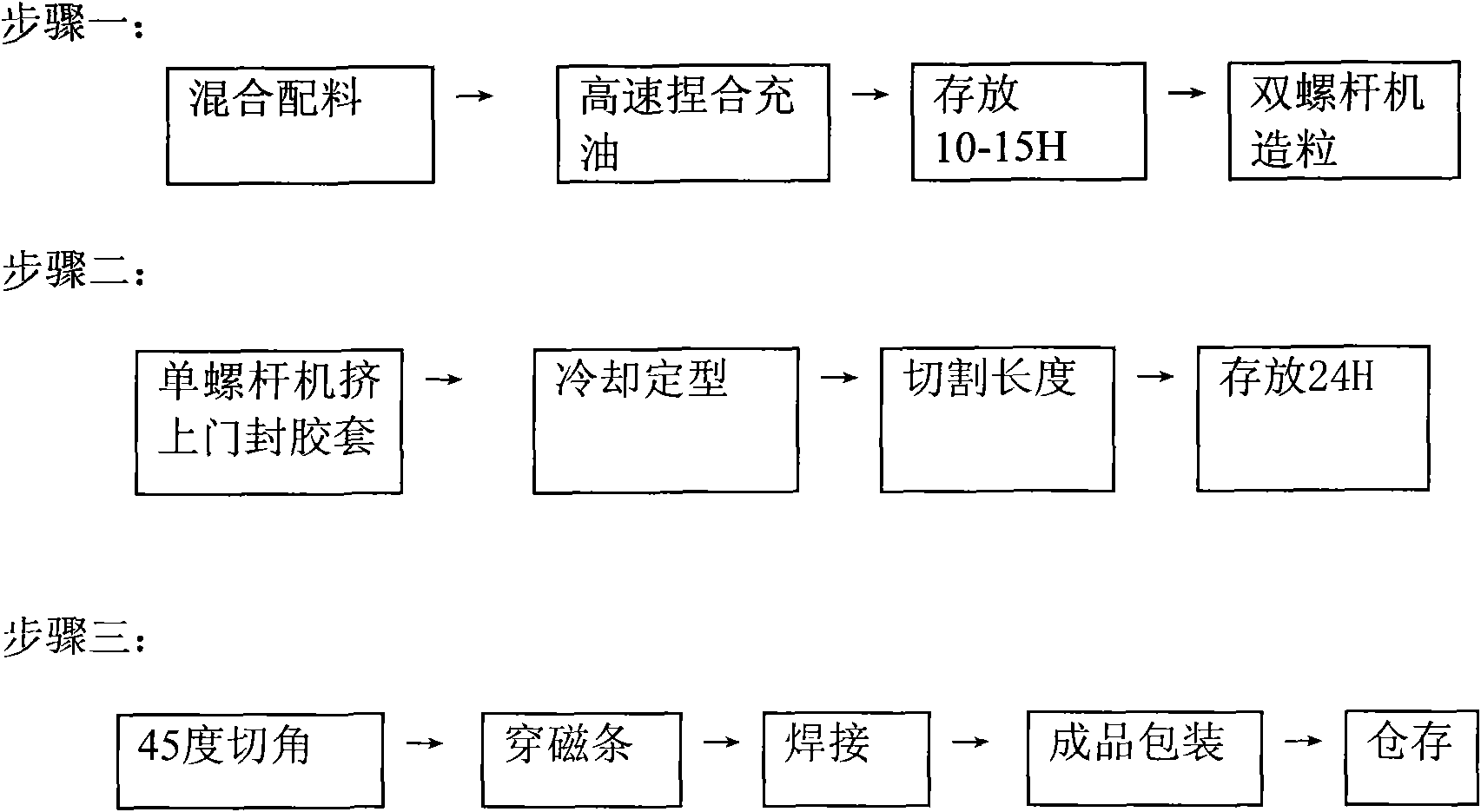

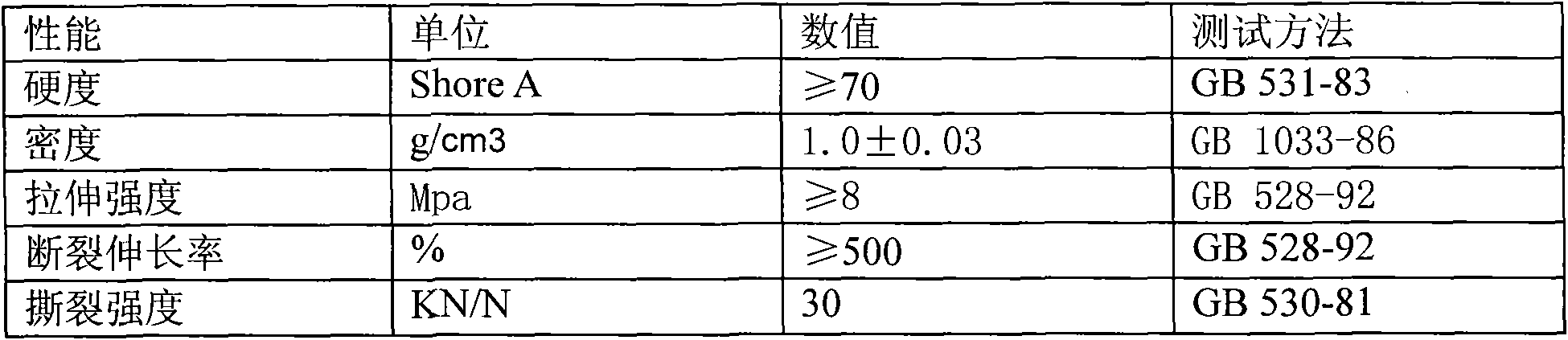

TPE material magnetic gasket for refrigerator and freezer and manufacture method thereof

ActiveCN101561214AImprove anti-agingGood UV resistanceDomestic cooling apparatusLighting and heating apparatusTO-18High volume manufacturing

The invention discloses a TPE material magnetic gasket for a refrigerator and a freezer, comprising a TPE elasticity gasket gum cover provided a magnetic strip which passes through the gum cover. The TPE elasticity gasket gum cover mainly comprises the following raw materials according to the parts by weight: 40 to 45 parts of SEBS, 15 to 18 parts of PP, 3 to 5 parts of PE, 25 to 30 parts of vash oil, 5 to 8 parts of CaCO3, 1.3 to 1.5 parts of lubricant, and 0.2 to 0.8 part of antioxidant. The magnetic gasket is applicable to the refrigerator, the freezer and other refrigerating equipment, and has the advantages of environmental protection, insensitiveness to adverse temperature changes, excellent sealing performance and elasticity maintenance, energy consumption, long service life and the like. The invention also provides a method for preparing the TPE material magnetic gasket, which has the advantages of simple process, being applicable to mass production and the like.

Owner:GUANGDONG SHUNDE ANHE MAGNETIC PROD

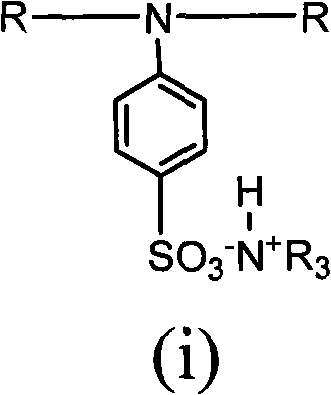

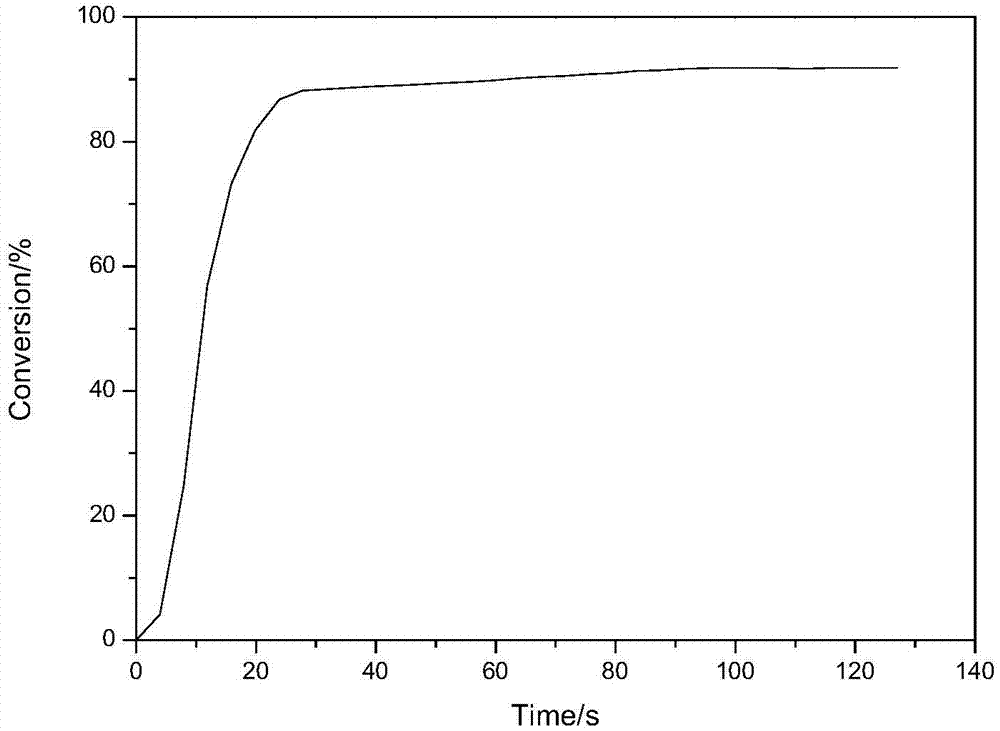

Aqueous macromolecular photoinitiator and preparation method thereof

The invention relates to an aqueous macromolecular photoinitiator and a preparation method thereof. The general formula of the aqueous macromolecular photoinitiator is (i). The aqueous macromolecular photoinitiator prepared by the method has the photoinitiating efficiency equivalent to a corresponding micro-molecular photoinitiator and has better compatibility with an aqueous light-cured resin; carboxylate ions and sulfosalt ions exist in a molecular chain simultaneously, so the resin has better water solubility than an aqueous macromolecular photoinitiator only containing carboxylate ions; and in addition, the price of an introduced chain extender (4-aminobenzenesulfonic acid) used for sulfonic acid group is lower than that of a conventional aqueous functional monomer (dihydromethylpropionic acid), so that the cost of products is reduced and the industrial production is facilitated. At the same time, in the method, the chain is extended by using the functional monomer with photoinitiating function, so the content of photoinitiating radicals in the resin per gram is improved and the aqueous macromolecular photoinitiator has better photoinitiating efficiency than the aqueous macromolecular photoinitiator taking end radicals as the photoinitiating radicals.

Owner:SHANGHAI UNIV

Acrylate emulsion used for vacuum aluminum plating and laser embossing and preparation method thereof

The invention relates to an acrylate emulsion used for vacuum aluminum plating and laser embossing and a preparation method thereof. The emulsion comprises the following components in parts by weight: 1-6 parts of polymerizable carboxylic acid, 18-80 parts of methacrylate, 12-50 parts of acrylate, 5-20 parts of silicon-including cross-linkable monomer, 2-4 parts of polymerizable emulsifier, 0.3-0.7 parts of pH buffer agent, 0.3-0.7 parts of initiator, 0.4-2.5 parts of neutralizer and water, wherein the weight ratio of the water to the total weight of the polymerizable carboxylic acid, the methacrylate, the acrylate, the silicon-including cross-linkable monomer and the polymerizable emulsifier is (1-1.5):1. According to the method provided by the invention, the polymerizable emulsifier is used; the prepared acrylate emulsion does not include a micromolecular emulsifier; the migration of the emulsifier does not exist in a later film forming process; furthermore, polymerizable silane is introduced in a polymerization process; and the degree of cross linking of the acrylate emulsion is improved, so as to give the advantages of high temperature resistance, no migration of the emulsifier, incapability of causing the filling in of a molded blackboard, and the like, to an emulsion film.

Owner:SHANGHAI WEIKAI CHEM +1

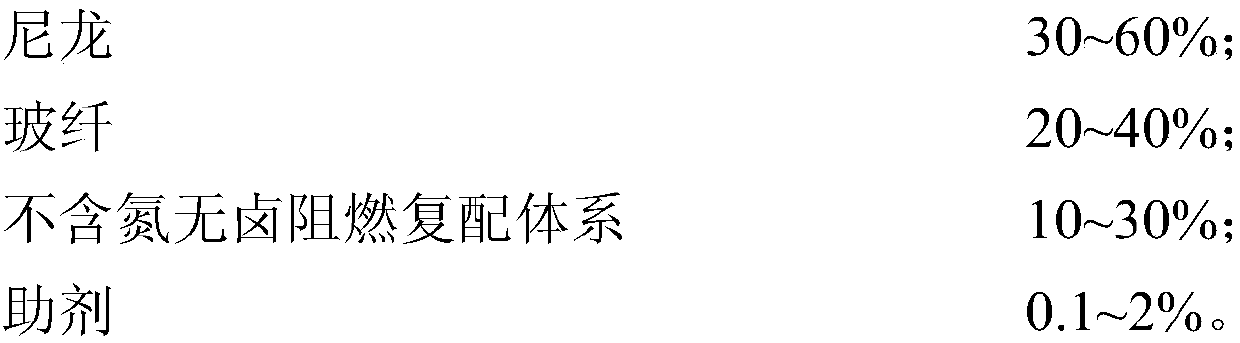

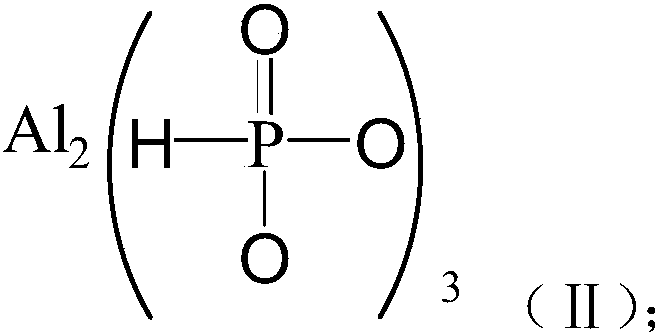

Nitrogen-free halogen-free flame-retardant complex system for glass fiber reinforced nylon and application of complex system

InactiveCN107698798ASolve corrosiveSolve defects such as easy migration and precipitationGlass fiberPhosphoric acid

The invention discloses a nitrogen-free halogen-free flame-retardant complex system for glass fiber reinforced nylon. The nitrogen-free halogen-free flame-retardant complex system comprises the following raw materials in percentage by weight: 60-90% of diethyl aluminum hypophosphite, 9-30% of aluminophosphite and 1-10% of zinc stannate. According to the nitrogen-free halogen-free flame-retardant complex system for glass fiber reinforced nylon disclosed by the invention, the nitrogen-free halogen-free flame-retardant complex system has the characteristics of being highly flame-retardant, migration-free, non-corrosive to equipment and the like, and the defects of the existing phosphorus and nitrogen complex flame-retardant system based on diethyl aluminum hypophosphite applied to the glass fiber reinforced nylon material are overcome. Moreover, the nitrogen-free halogen-free flame-retardant complex system can well adapt to a glass fiber reinforced nylon material system, and a halogen-free flame-retardant glass fiber reinforced nylon material with excellent overall performance is obtained.

Owner:JIANGSU LISIDE NEW MATERIAL

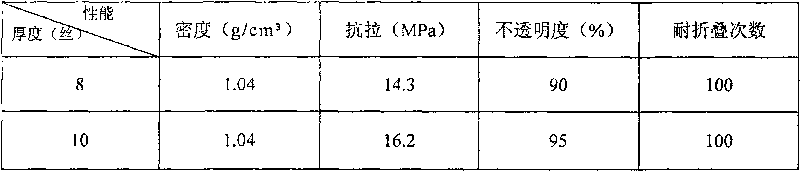

PS (polystyrene) alloy synthetic paper and preparation thereof

The invention relates to novel PS (polystyrene) alloy synthetic paper which improves the stiffness, the surface polarity and the surface hardness and resists the chemical corrosion. The paper molded by using an extrusion tape casting method has white appearance and opacity, excellent physical property and superior price, can replace current commonly-used calendered paper, and replaces products of common paper PE (polyethylene) and common paper composite BOPP (biaxially-oriented polypropylene) membranes. The novel PS alloy synthetic paper is applied to common printing materials and processing materials by the characteristics of water prevention and tear resistance, applied to data needing permanent preservation by the characteristic of excellent weather resistance, and adapts to various labels of packages of drink bottles and cans. The invention does not produce the environment pollution during the manufacture and use, can save a great quantity of forest resources and water resources for country, lightens the sewage treatment pressure, and reduces the energy consumption.

Owner:SICHUAN KINGFA TECH DEV

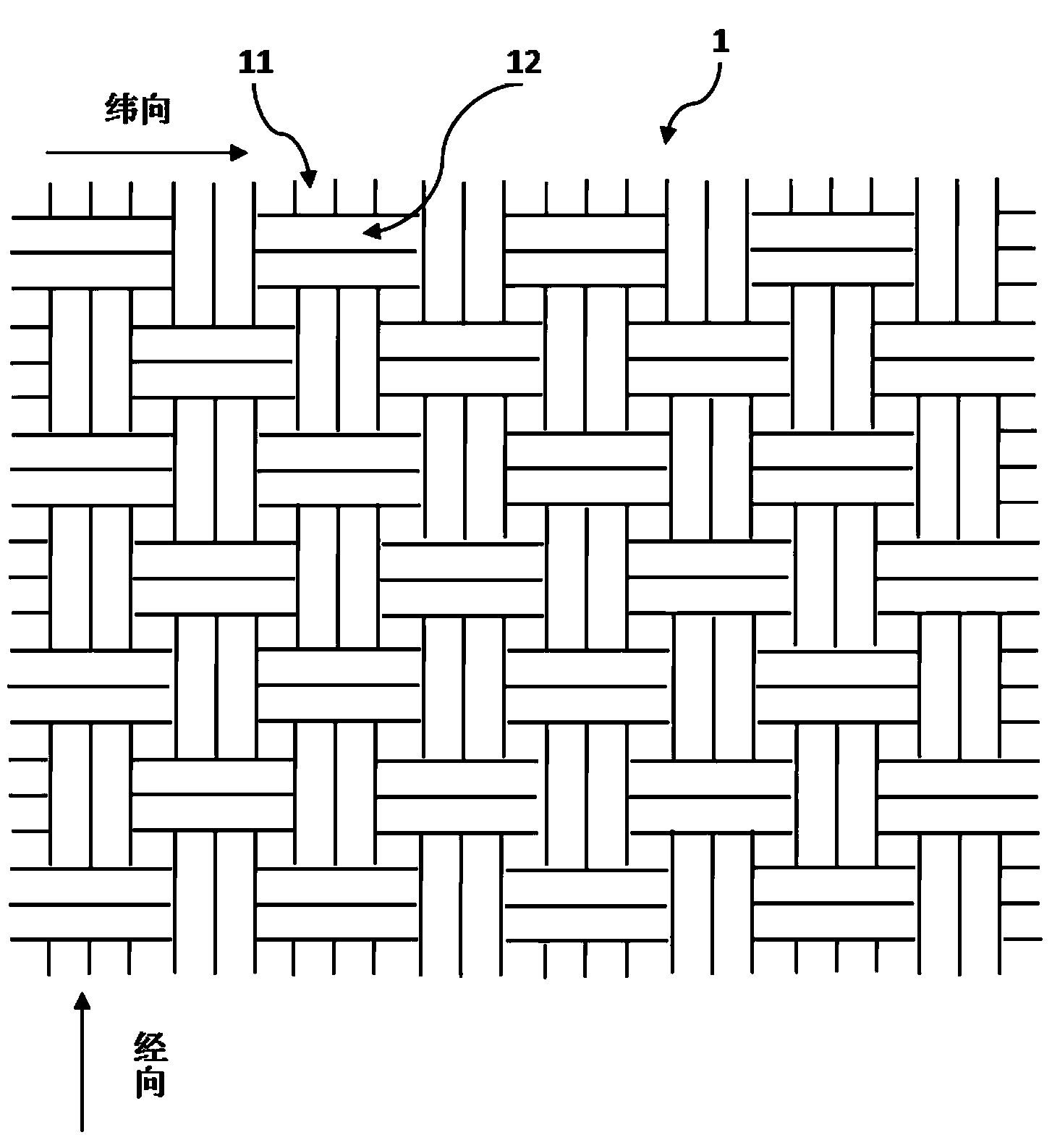

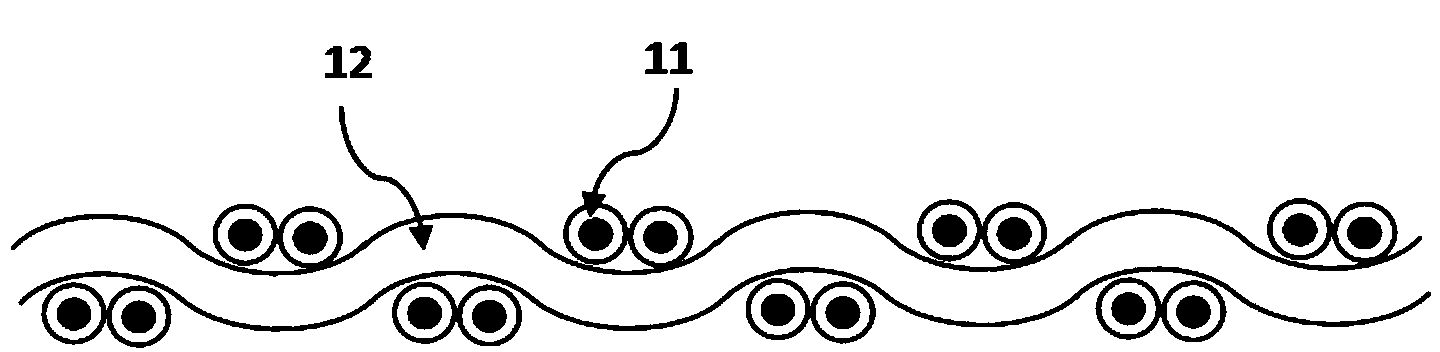

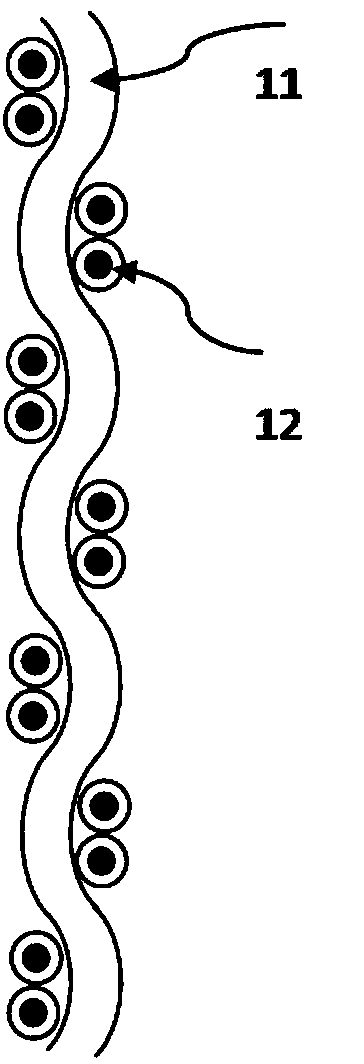

Halogen-free flame-retardant environment-friendly covered polyolefin yarn fabric and preparation method thereof

InactiveCN104233569AImprove breathabilityTranslucentHeating/cooling textile fabricsWoven fabricsPolyesterYarn

The invention relates to a halogen-free flame-retardant environment-friendly covered polyolefin yarn fabric and a preparation method thereof. The fabric is formed by weaving covered threads and has warp and weft structures; the covered threads comprise polyester fibers and halogen-free flame-retardant environment-friendly polyolefin composite materials covering the surfaces of the polyester fibers; the covered threads are 0.3-0.4 millimeter in diameter, rectangular or square gaps are reserved between the warp structures and the weft structures, and the aperture ratio is 2 to 10 percent; the halogen-free flame-retardant environment-friendly covered polyolefin yarn fabric is 0.55-0.75mm in total thickness and 350-420g / m<2>. The invention also provides a preparation method for the fabric. The fabric has the characteristics of sunshading, ultraviolet resistance, flame retardancy, high color fastness and the like of similar PVC (polyvinyl chloride) substrate fabrics, and also has the advantages of no halogen, environment friendliness, low smoke density during combustion, high self-cleaning property, high chemical stability, light weight, high air permeability and the like.

Owner:NINGBO XIANFENG NEW MATERIAL

Polymerizable water-soluble benzophenone type photoinitiator and preparation method thereof

ActiveCN104761661ANo migrationGood water solubilityOrganic compound preparationCarboxylic acid esters preparationSolubilityHydrogen

The invention provides a polymerizable water-soluble benzophenone type photoinitiator and a preparation method thereof. The preparation method comprises the following steps: enabling 3,3',4,4'-benzophenone tetracarboxylic dianhydride to react with an acrylate type monomer containing active hydrogen; introducing polymerizable double bonds into benzophenone molecules; and then adding an alkaline substance to react with carboxylic acid of a product self so as to improve the water solubility, thereby preparing the polymerizable water-soluble photoinitiator. The preparation method is simple to operate and high in product yield, and the obtained photoinitiator is migration-free, good in water solubility and high in initiation efficiency.

Owner:BEIJING UNIV OF CHEM TECH

Degradable polyethylene modified material and preparation method thereof

The invention relates to a degradable polyethylene modified material and a preparation method thereof. The degradable polyethylene modified material is mainly applied to the production of a disposable degradable plastic bag and is mainly prepared from high-density polyethylene, calcium carbonate, konjac glucomannan, corn starch and a foaming agent. Due to the water retentivity of the konjac glucomannan, the disposable degradable plastic bag prepared from the degradable polyethylene modified material can be maintained in a relative drying state, so that the deterioration and the smelliness of food wastes contained in the disposable degradable plastic bag are difficult to occur. Meanwhile, the disposable degradable plastic bag has stronger toughness due to the addition of the konjac glucomannan, so that the disposable degradable plastic bag is difficult to break. The disposable degradable plastic bag is easy to degrade by taking the konjac glucomannan as a raw material, so that the environment pollution is avoided. The plastic bag commonly used in the existing market is prepared from a single plastic polymer, so that character writing or printing on the plastic bag cannot be carried out. The disposable degradable plastic bag provided by the invention is molded in a blowing manner by using a foaming technique, so that the character writing or the pattern printing on the disposable degradable plastic bag can be carried out.

Owner:江西缘至家实业有限公司

Environment-friendly fireproof material for electrical equipment and preparation method thereof

ActiveCN106497339AReduce solubilityImprove thermal stabilityFireproof paintsEpoxy resin coatingsFiberCrack resistance

The invention provides an environment-friendly fireproof material for electrical equipment and a preparation method of the environment-friendly fireproof material, and belongs to the fields of fireproof materials and preparation technologies thereof. The environment-friendly fireproof material for the electrical equipment is characterized by being prepared from the following raw materials in parts by weight: 50 to 60 parts of modified epoxy resin, 30 to 40 parts of fluorocarbon resin, 60 to 90 parts of a fire retardant, 3 to 10 parts of expanded graphite, 3 to 10 parts of alumina silicate fiber and 2 to 8 parts of molecular sieves. The fireproof material provided by the invention is applied to fire protection of the electrical equipment, and is high in crack resistance, water resistance and weather resistance and good in expansion character; meanwhile, the heat release rate of a base material in a burning condition can be obviously reduced, and the quality loss is reduced; moreover, the fireproof material is small in smoke production quantity and good in environmental protection effect.

Owner:STATE GRID HENAN ELECTRIC ZHOUKOU POWER SUPPLY

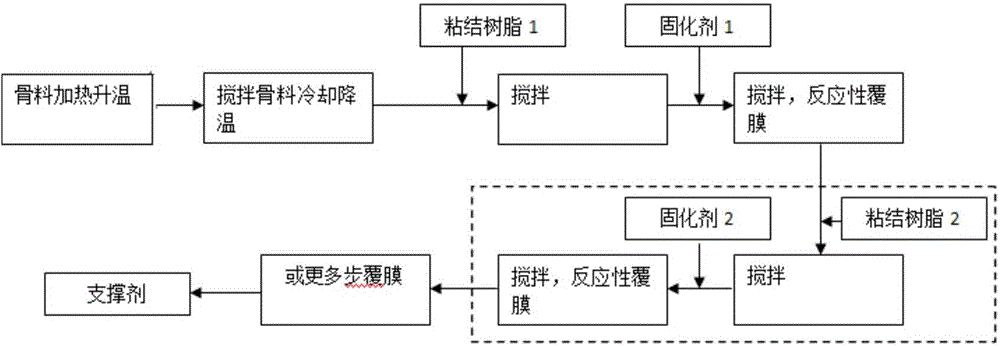

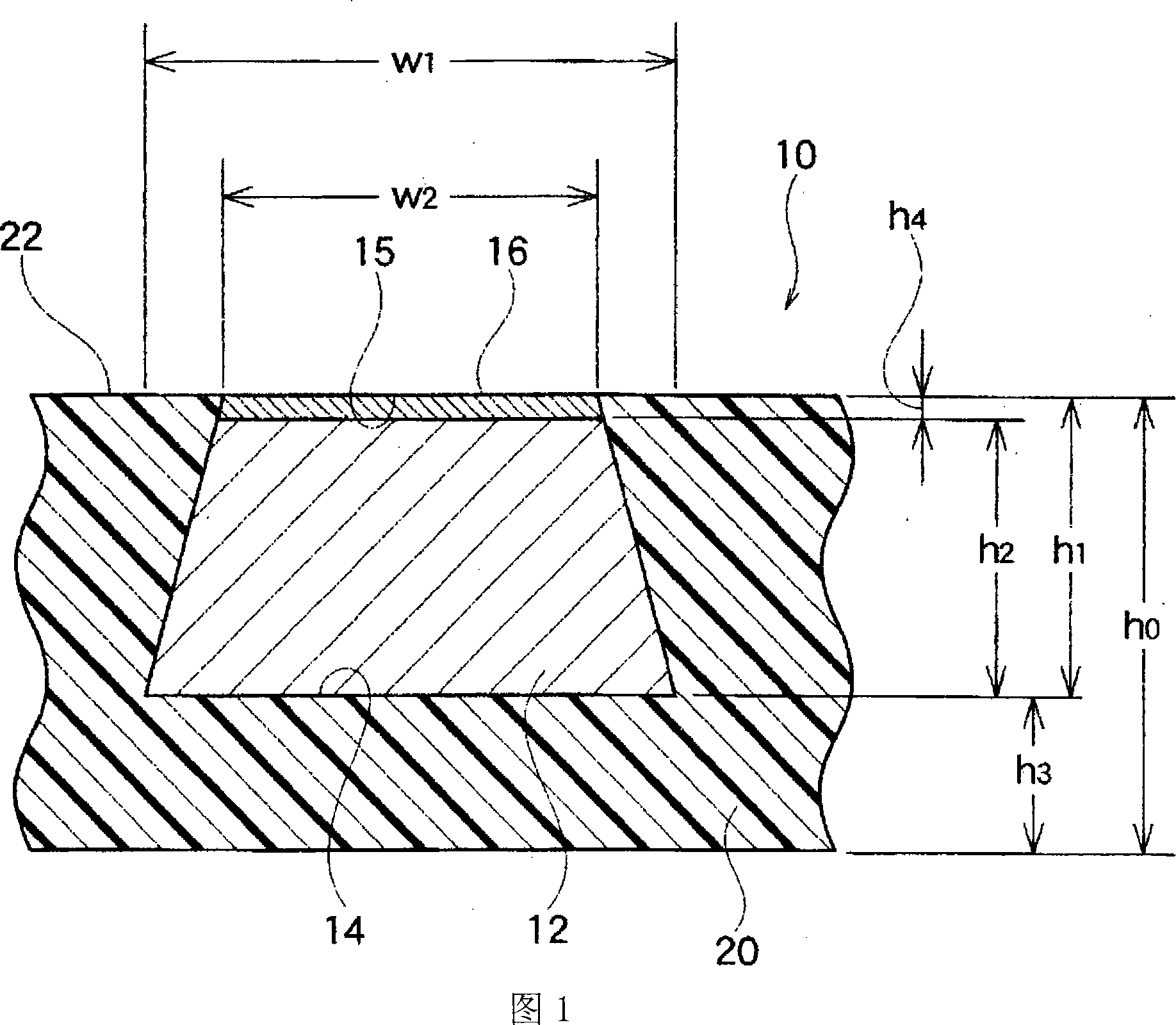

Proppant and preparation method thereof

The invention discloses a proppant and a preparation method thereof, and belongs to the technical field of oil and gas exploitation. The proppant comprises an aggregate and at least two layers of resin coated films coated on the aggregate, wherein the weight ratio of the aggregate to the resin coated film is 100:3-100:13; and the aggregate is quartz sand, ceramsite, glass microspheres, sintered bauxite, sintered aluminum oxide, sintered zirconium oxide or a mixture thereof, and the size of the aggregate is 10-200 meshes, preferably 20-70 meshes. By virtue of a multilayer film coating technology, the sphericity of the proppant can be improved, the density of the proppant can be reduced, and the chemical inertness and strength can be improved. The proppant disclosed by the invention can be widely applied to oil and gas field exploitation, is beneficial to improvement of the sand ratio, reduces the usage of fracturing fluid, eases the embedding of the proppant, improves the water resistance of the proppant, improves the fracture conductivity, and prolongs the effective fracturing period.

Owner:BEIJING RECHSAND SCI & TECH GRP

Halogen-free flame-retardant master batch and preparation method thereof, and glass fiber reinforced nylon material and preparation method thereof

Owner:江苏蔚观新材料科技有限公司

Preparation method for odorless regenerated rubber

ActiveCN104151660AGuaranteed high speed operationEffectively cut offPlastic recyclingVegetable oilPolymer science

The invention discloses a preparation method for odorless regenerated rubber. The preparation method is characterized in that tread rubber powder, an environment-friendly activator, a vegetable oil softener and water are added in the chemical desulfuration process; the environment-friendly activator is prepared from the following components in parts by weight: 3-3.5 parts of persulfate and 7-6.5 parts of aliphatic acid; the amount of the environment-friendly activator is 0.18%-0.29% of the mass of the tread rubber powder; the vegetable oil softener is prepared from cottonseed oil, colophony, pine tar oil, rap oil, drainage oil and olive oil; the amount of the cottonseed oil, the colophony, the pine tar oil, the rap oil, the drainage oil and the olive oil is 3.6%-4.6%, 0.6%-1%, 1.3%-1.9%, 1%-1.5%, 0.8%-1.4% and 0.7%-1.3% of the mass of the tread rubber powder respectively; the added quantity of water is 17%-20% of the mass of the tread rubber powder. According to the invention, products obtained through the preparation method are odorless without containing benzene compounds, are high in tensile strength, great in elongation and moderate in mooney point, and can reach the national-level standard of regenerated rubber; the products such as shoe soles produced from rubber prepared through the preparation method have no color migration.

Owner:普格三鑫环保资源科技利用开发有限公司

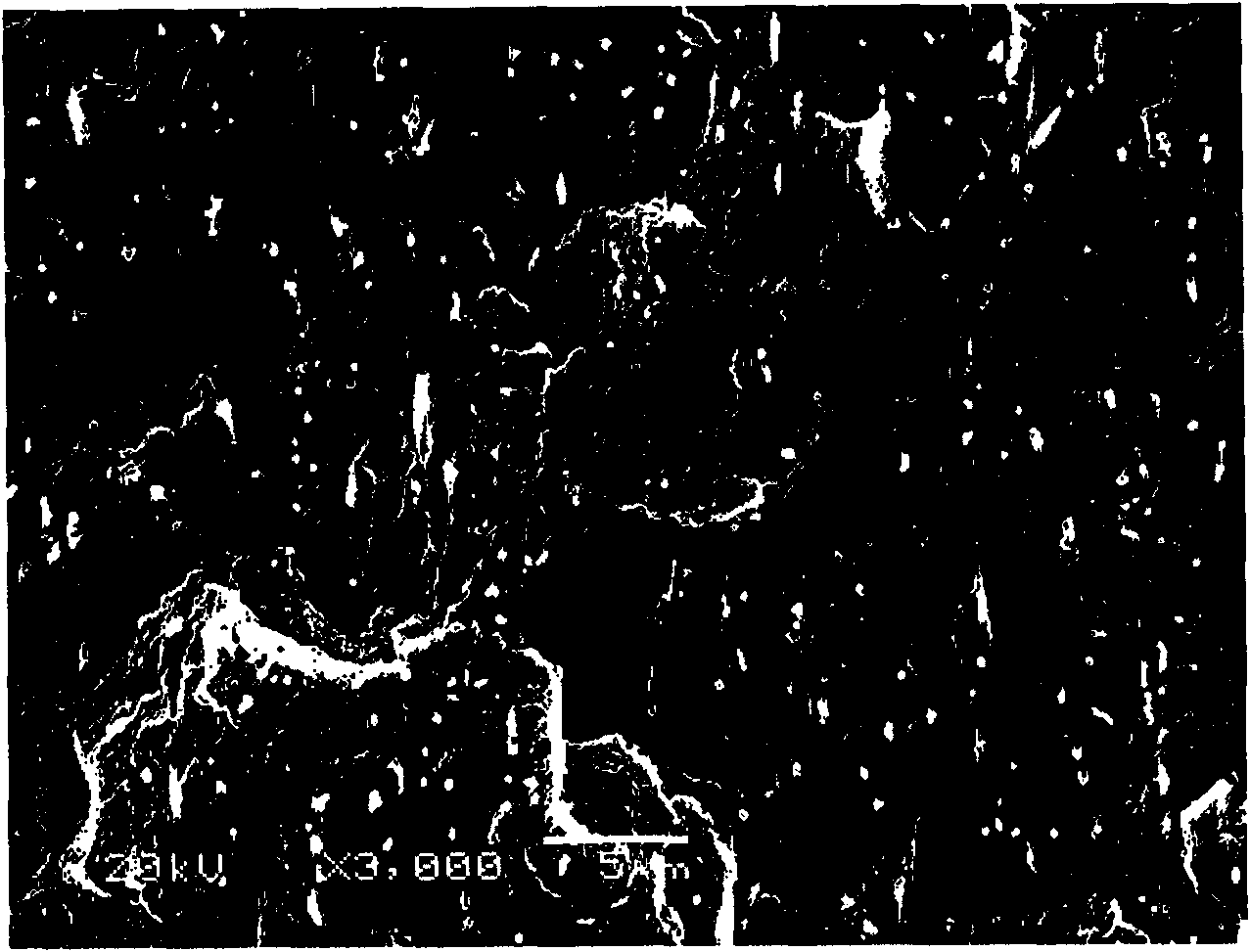

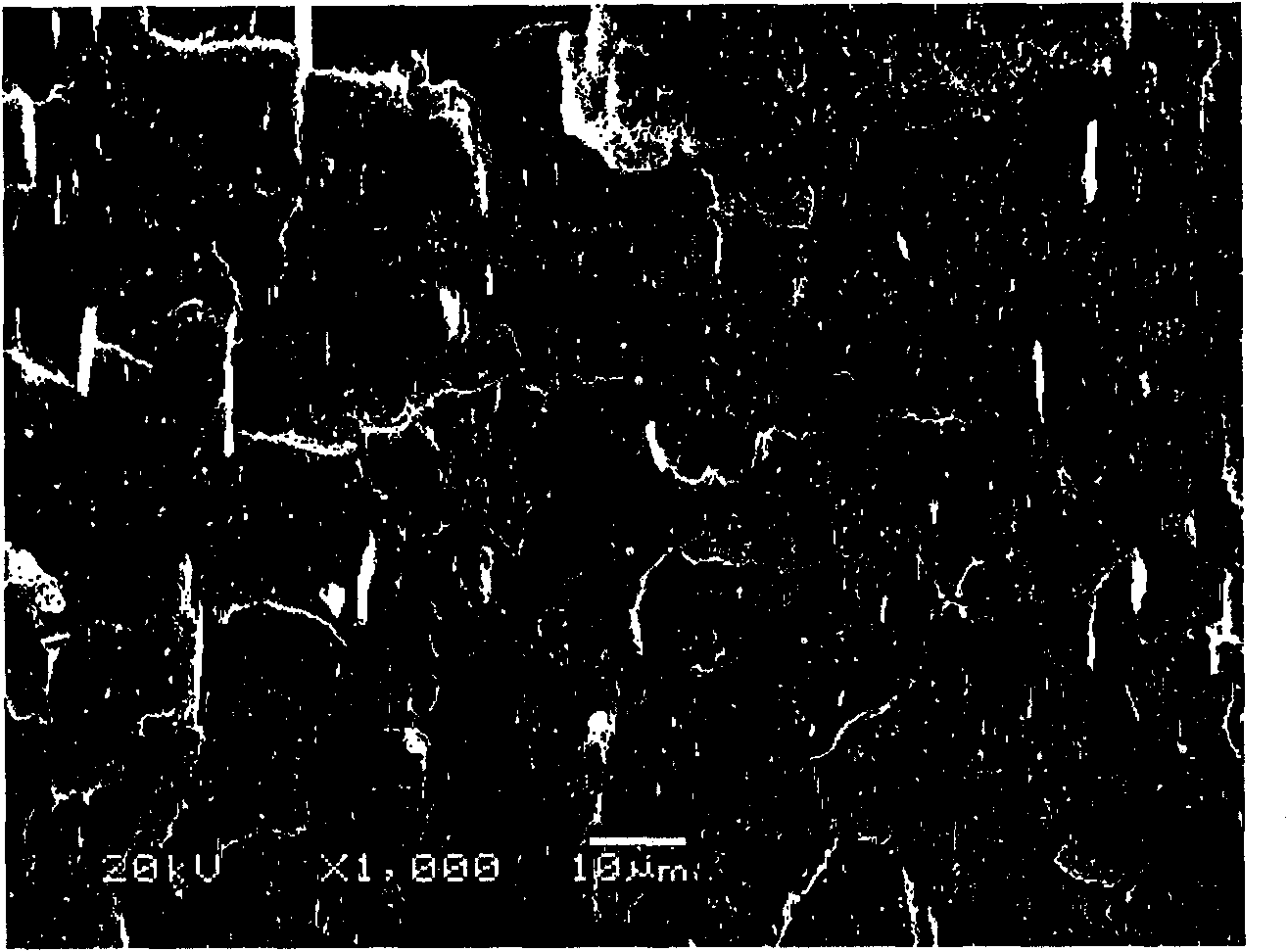

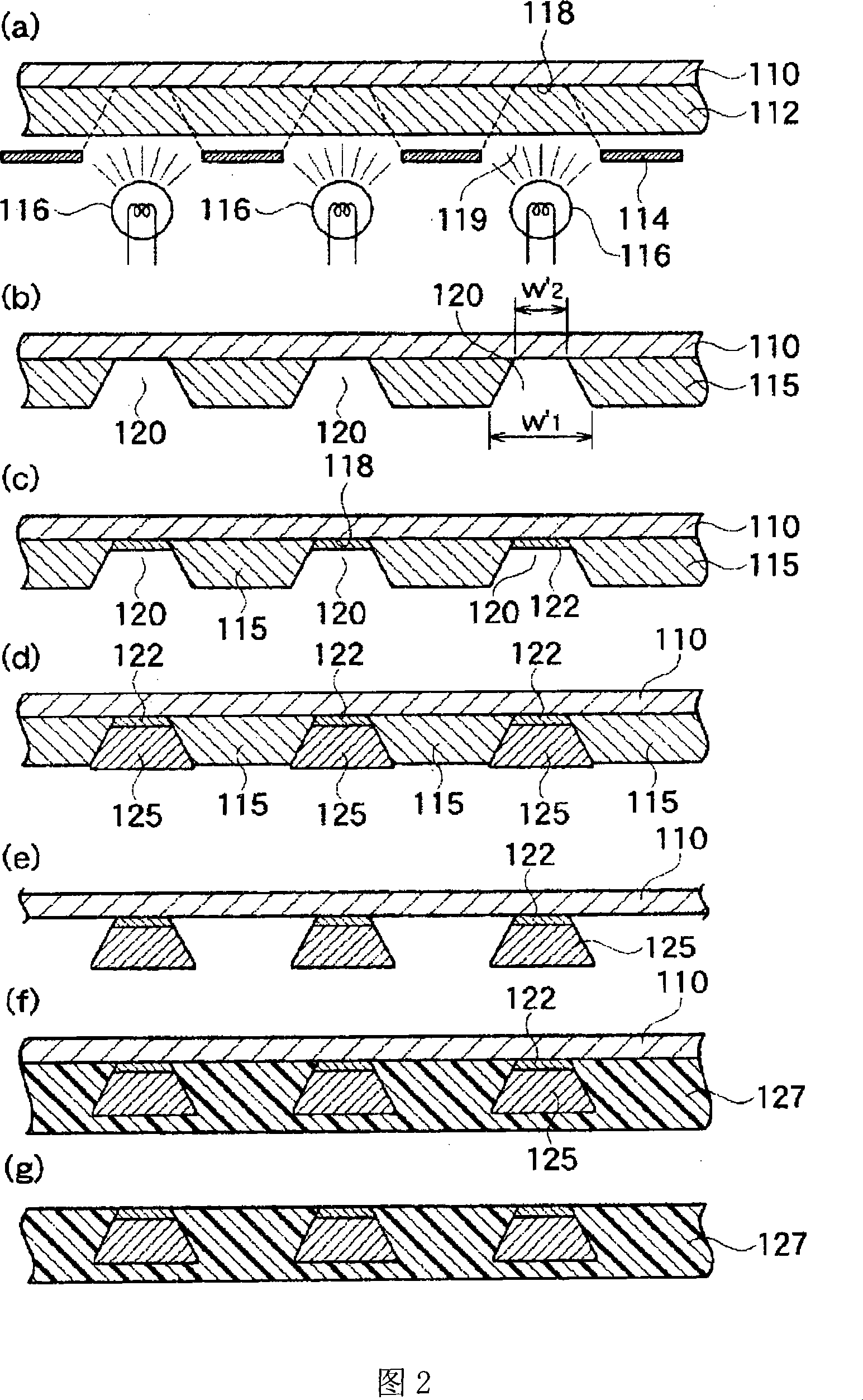

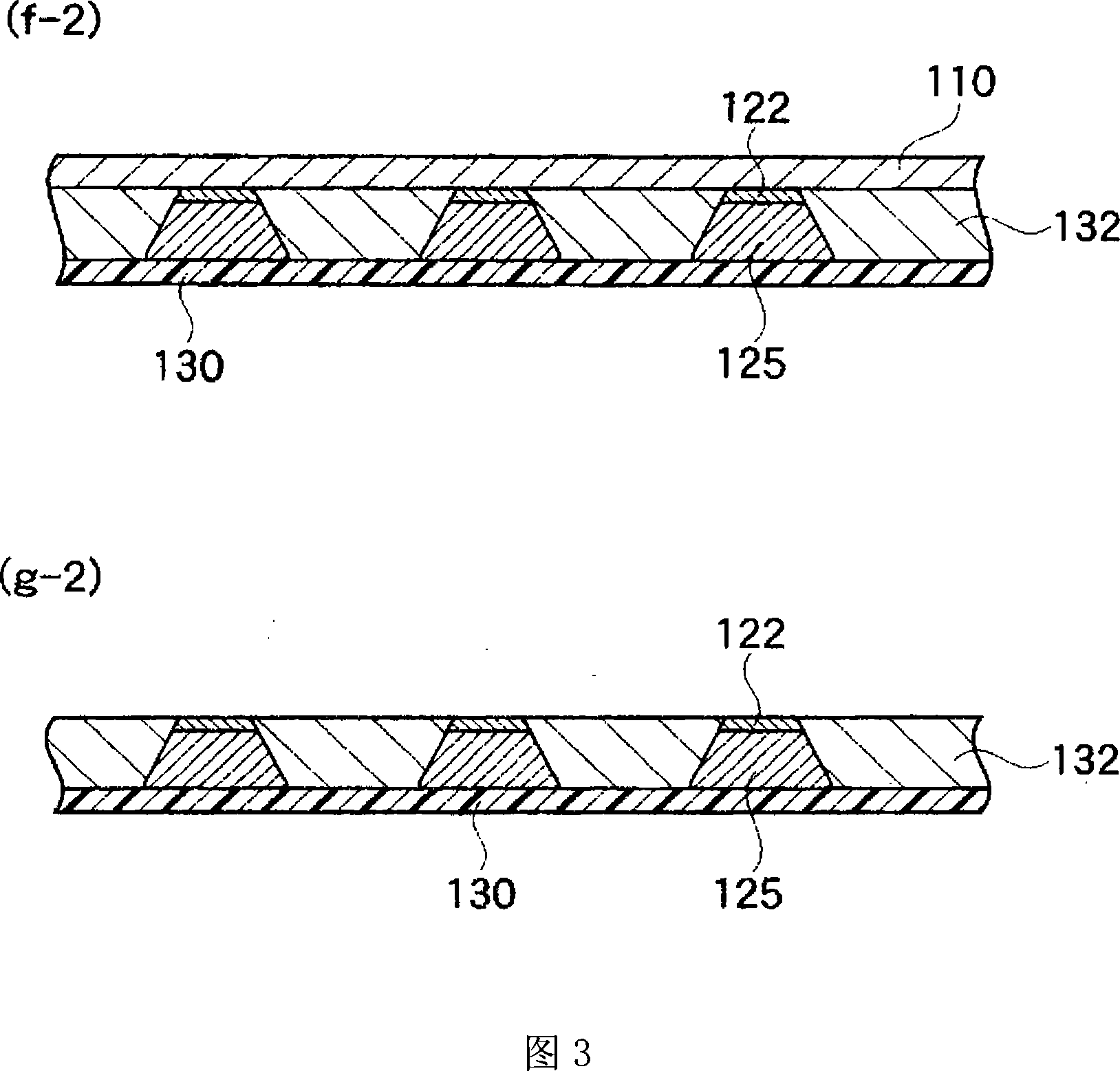

Circuit substrate and manufacturing method thereof

InactiveCN101123852AHigh bonding strengthThe problem of high wiring resistance does not occurSemiconductor/solid-state device detailsPrinted circuit aspectsHigh adhesionMetal

Owner:MITSUI MINING & SMELTING CO LTD

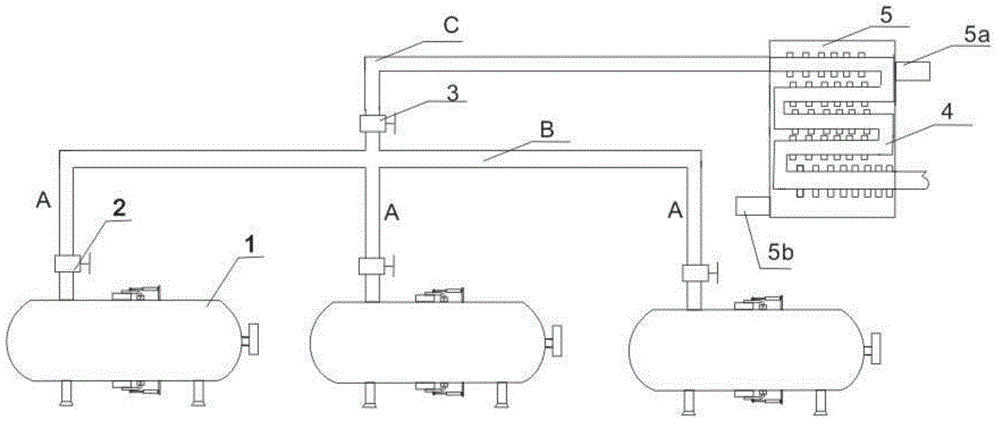

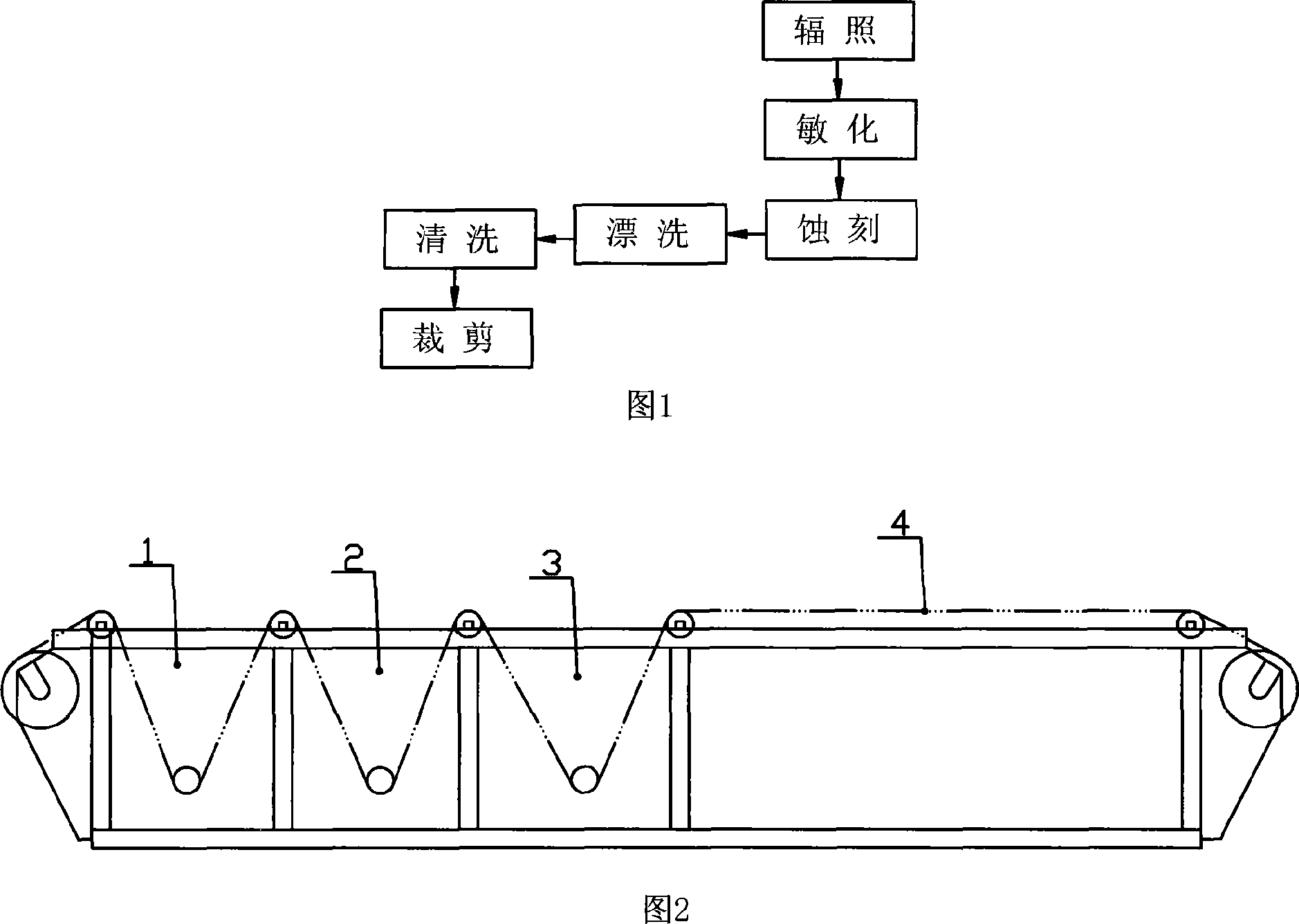

Nuclear pore filter membrane for precision medicine liquid filter and preparation method thereof

ActiveCN101104136AUniform pore sizeAccurate separationSemi-permeable membranesFiltering accessoriesHigh energyFiltration

The invention relates to the medical clinic transfusion field, more particularly, relating to the nuclear track microporous membrane used on a precision medical solution filter and the preparation method. The substrate membrane of the nuclear track microporous membrane used on the precision medical solution filter selects the polycarbonate as the material, and the nuclear track microporous membrane is obtained by high energy charged particle radiation and then sensitized and etching treatment to the substrate membrane, the apertures of the nuclear track microporous membrane are between zero point two micron and ten microns, the density of the nucleopores is that the membrane has five multiply one hundred and five to seven multiply one hundred and five pores per square centimeter. The preparation method of the nuclear track microporous membrane of the invention includes steps of radiation, sensitized treatment, etching and rinsing. The arrangement and application of the precision filter made by the nuclear track microporous membrane of the invention on the terminal of the infusion set of the disposable precision filtering infusion set can effectively filter the insoluble particles in the medical solution, and the filtration rate is more than or equal to ninety five percent, and hold the last pass of the medical solution form entering the human body, thus truly blocking the invasion of the insoluble particles to patients.

Owner:ZHEJIANG FERT MEDICAL DEVICE

Flame-retardant rubber cable material made from phosphorus-nitrogen expansion type flame retardant without halogen and preparation method thereof

InactiveCN103194011AEasy to processExtrusion process is goodRubber insulatorsCable/conductor manufacturePolymer scienceHalogen

The invention discloses a flame-retardant rubber cable material made from a phosphorus-nitrogen expansion type flame retardant without halogen. The rubber cable material comprises the following raw materials in parts by weight: 25-60 parts of natural rubber, 40-75 parts of butadiene-styrene rubber, 70-120 parts of IFR, 5-10 parts of white carbon black, 1-2 parts of ziram, 1-5 parts of vulcanizing agent, 6-8 parts of zinc oxide, 1-3 parts of stearic acids and 1-2 parts of antioxidants. The rubber cable material disclosed by invention has the beneficial effects that the cable material is easy to process, the extruded process is good; the compatibility of the basal body of the obtained flame-retardant rubber cable material made from the phosphorus-nitrogen expansion type flame retardant without halogen and compounding agents such as flame retardant is good, and no compounding agent transport exists; the products have excellent flame retardant property, good mechanical property and good low-temperature flexibility.

Owner:GUILIN UNIV OF ELECTRONIC TECH

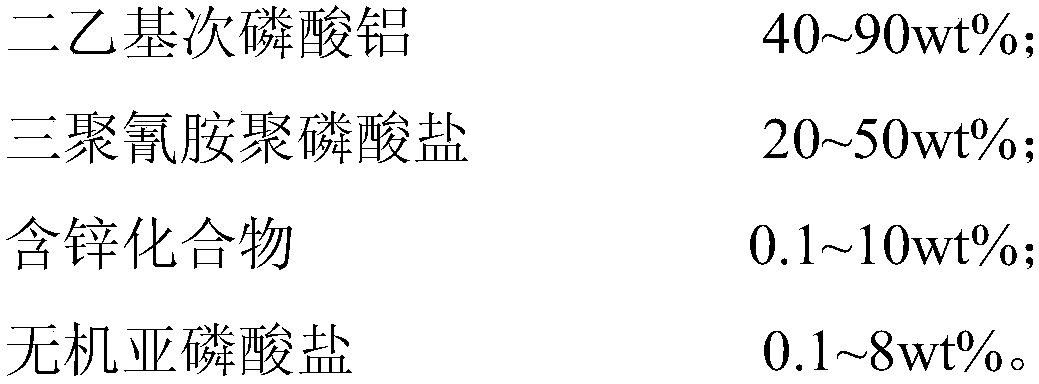

Phosphorus-nitrogen halogen-free flame retardant composition capable of improving thermal stability by utilizing inorganic metal phosphite and application of phosphorus-nitrogen halogen-free flame retardant composition

InactiveCN108997612AInorganic phosphite improves thermal stabilityHigh thermal stabilityEngineering plasticPolymer chemistry

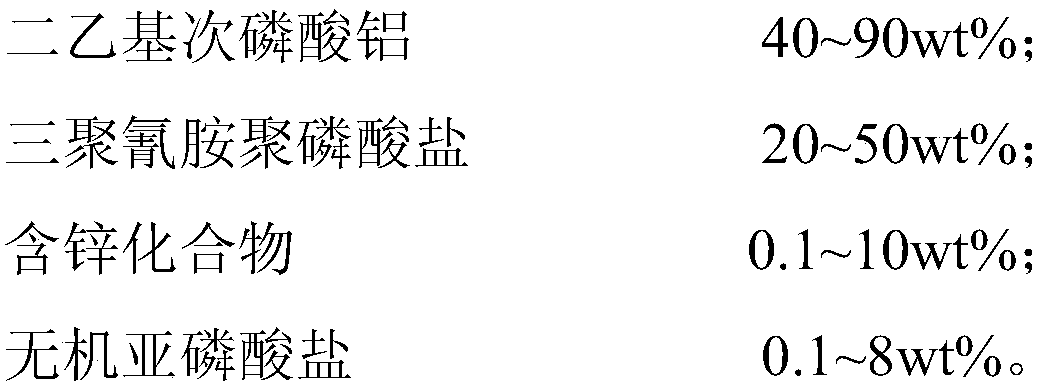

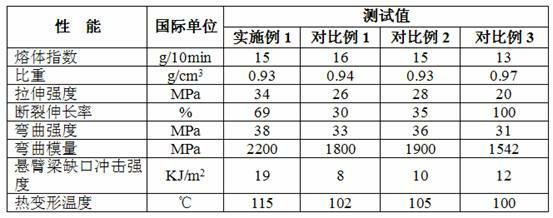

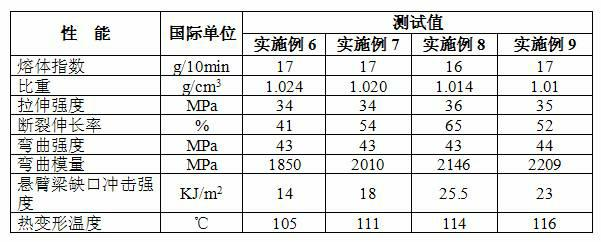

The invention discloses a phosphorus-nitrogen halogen-free flame retardant composition capable of improving thermal stability by utilizing inorganic phosphite. The phosphorus-nitrogen halogen-free flame retardant composition is composed of the following raw materials by weight: 40 to 90 wt% of aluminum diethylphosphinate, 20 to 50 wt% of melamine polyphosphate, 0.1 to 10 wt% of a zinc-containing compound and 0.1 to 8 wt% of the inorganic phosphite. The flame retardant system provided by the invention has the characteristics of high flame retardancy, high thermal stability, no migration, no corrosion to equipment, etc. The flame retardant provided by the invention can be applied to glass fiber reinforced thermoplastic engineering plastics; and the halogen-free flame-retardant glass fiber reinforced thermoplastic engineering plastics containing the flame retardant provided by the invention can be used for preparation of parts or products in the fields of electronics and electrical appliances.

Owner:JIANGSU LISIDE NEW MATERIAL +1

High heat resistance low density high performance auto polypropylene composite and preparation method thereof

ActiveCN102070842AOffset shock performanceCounteracts the negative effects of impact performancePolypropylene compositesSewage treatment

The invention discloses a high heat resistance low density high performance auto polypropylene composite and a preparation method thereof. The polypropylene composite comprises the following components in percentage by weight: 50 to 84.5 percent of PP, 5 to 20 percent of flexibilizer, 5 to 15 percent of crystal whisker, 5 to 15 percent of talcpowder, and 0.5 to 2 percent of coupling agent. The preparation method comprises the following steps of: pre-mixing the components of PP and crystal whisker in a high speed mixer; transporting the mixed raw material into a twin screw extruder; and feeding material at the crystal whisker side into the twin screw extruder and performing fusion, extrusion and granulation to obtain the product. The product is characterized in high heat resistance, low density and high performance, and does not produce environmental pollution during manufacturing and use, thereby reducing the pressure on sewage treatment, and reducing energy consumption. Moreover, the composite neither produces the migration of toxic substance nor contains heavy metals. And the product completely meets the ROSH standard.

Owner:KINGFA SCI & TECH CO LTD +2

Thermostable polystyrene packing composition and preparing method

InactiveCN101746556AEvenly dispersedHigh elongation at breakFlexible coversWrappersPolystyrenePolypropylene

The present invention provides a novel material for producing yoghurt cups by extrusion molding, particularly a polystyrene (PS) / polypropylene (PP) alloy material having the advantages of good ductility, high strength, good stiffness, thermostability, large molding processing range and low cost on account of problems existing in the PS yoghurt packaging. The material consists of 40 to 70% by weight of PS, 15 to 85% by weight of PP, 8% by weight of inorganic mineral powder and 6 to 10% by weight of auxiliary. The raw materials are premixed, and extruded and pelletized by a double-screw extruder under common processing conditions, and a basic resin is produced. Then, a product mutually attached is made by taking the material as a middle layer and taking general purpose polystyrene (GPPS) layers as a top layer and a bottom layer by a three-layer co-extrusion molding processing technique, and the product is molded by co-extrusion without adhesive bonding.

Owner:SICHUAN KINGFA TECH DEV

Waterborne polyurethane emulsion for composite laser coating

The invention discloses waterborne polyurethane emulsion for a composite laser coating. The waterborne polyurethane emulsion is prepared by the following steps: performing vacuum dehydration on macromolecular polyhydric alcohol at the temperature of 120-130 DEG C for 1-1.5 hours, reducing the temperature to be 50-60 DEG C, adding diisocyanate and epoxy resin, raising the temperature to be 75-85 DEG C, and reacting for 2.5-3 hours; adding a hydrophilic chain extender and reacting for 1-2 hours; adding an alcohol chain extender and reacting for 2-3 hours, and adding acetone to reduce the viscosity during the period; adding a neutralizer, and carrying out a neutralization reaction at the temperature of 40-50 DEG C for 0.5-1 hour to obtain a neutralization product; adding the neutralization product into water in which an amine chain extender is dissolved, carrying out shearing emulsification at 30-40 DEG C for 0.5-2 hours while controlling the stirring speed to be 2000-4000rpm to obtain primary emulsion, and evaporating to remove acetone under reduced pressure to obtain the emulsion. The emulsion is a self-emulsified system and does not contain small molecular emulsifier, and an emulsifier migration phenomenon is avoided; the waterborne polyurethane emulsion is high in adhesive force with a base material, and interlayer separation is avoided; moreover, the waterborne polyurethane emulsion has high solvent resistance and paint film printability.

Owner:SHANGHAI CHENGYING NEW MATERIALS

Water-based color removing agent and preparation and use method and application thereof

InactiveCN105153856ANo bite colorNo migrationAntifouling/underwater paintsPretreated surfacesWater basedEmulsion

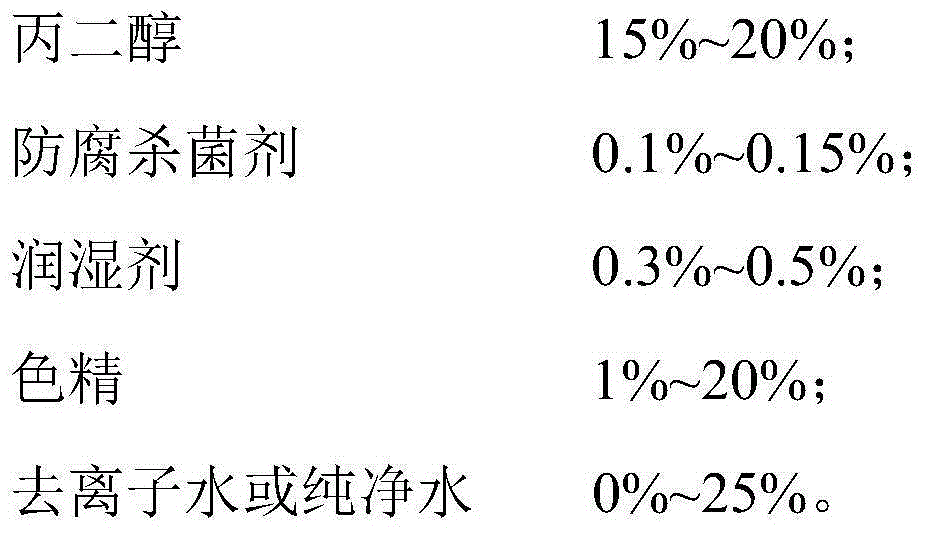

The invention discloses a water-based color removing agent and a preparation and use method and application thereof. The water-based color removing agent is prepared from, by mass, 30%-40% of acrylate emulsion, 3%-5% of inorganic thickening agents, 10%-15% of first solvents, 5%-10% of second solvents, 15%-20% of propylene glycol, 0.1%-0.15% of corrosion prevention bactericide, 0.3%-0.5% of wetting agents, 1%-20% of color concentrate and 0%-25% of deionized water or pure water. The water-based color removing agent has the characteristics that product colors are bright and even, and the water-based color removing agent is not prone to layer or coagulate and the like, has water characteristics and has the advantages of being high in transparency, good in permeability, high in retouching performance, excellent in erasing performance, slow in drying and the like, and the water-based color removing agent is not prone to being corroded or breeding bacteria. The water-based color removing agent is used for wooden products, the grain of the wooden products is clear and high in stereoscopic sense, and the good decoration effect on the wood products is achieved.

Owner:中华制漆(新丰)有限公司

PET (polyethylene terephthalate) antistatic protective film

InactiveCN103173154ANo migrationAvoid adsorptionFilm/foil adhesivesPolyesterPolyethylene terephthalate

The invention discloses a PET (polyethylene terephthalate) antistatic protective film. The protective film comprises a PET release film, an adhesive layer and a PET substrate, wherein an antistatic finish layer is arranged on one side of the PET substrate and is a PET polyester film; and the antistatic finish layer is fit with the PET release film via the adhesive layer. The protective film has the beneficial effects that the surface of the protective film is free from static material transfer; and the protective film has the functions of preventing dust and impurity adsorption and preventing static damages, improves the antistatic effect, enables the product performances to be durable and stable and can simultaneously achieve antistatic, adhesive-residue-free, repeated paste, ultrastrong antifouling and high transmittance effects.

Owner:KUNSHAN HANBAO TAPE TECH

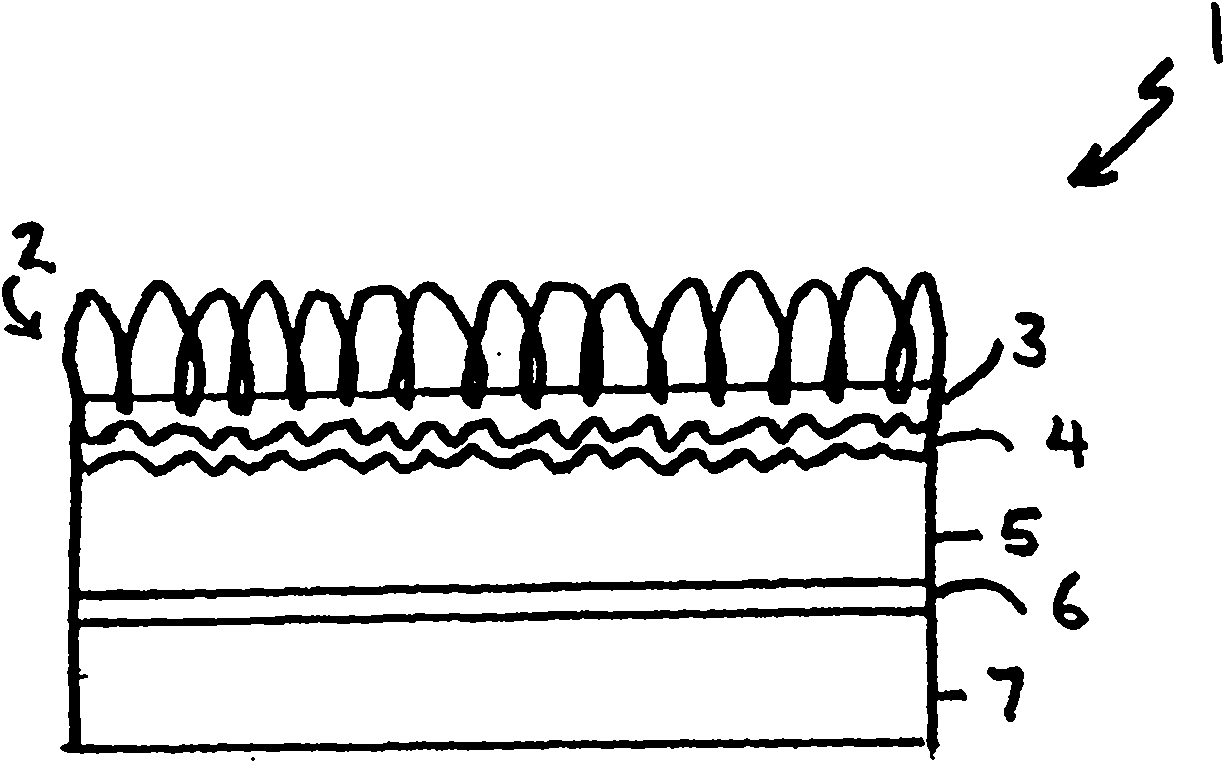

A carpet tile, a method for making a carpet tile and compositions for use in making a carpet tile

ActiveCN101918503AHeat stableSmooth migrationOther chemical processesLayered productsMethacrylic monomersPolymer chemistry

There is disclosed a precoating composition for making a carpet tile comprising: at least one copolymer derived from an acrylic or methacrylic monomer and a styrenic monomer; at least one copolymer derived from an acrylic ester and a methacrylic ester; at least one thickener; and water. There is also disclosed a precoated primary backing, a floor covering and a carpet tile prepared using the composition.

Owner:INTERFACE AUST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com