Preparation method for odorless regenerated rubber

A technology of reclaimed rubber and rubber mixing, which is applied in the direction of plastic recycling and recycling technology, which can solve the problem of high energy consumption and achieve the effects of good processing performance, high tensile strength and moderate Mooney value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

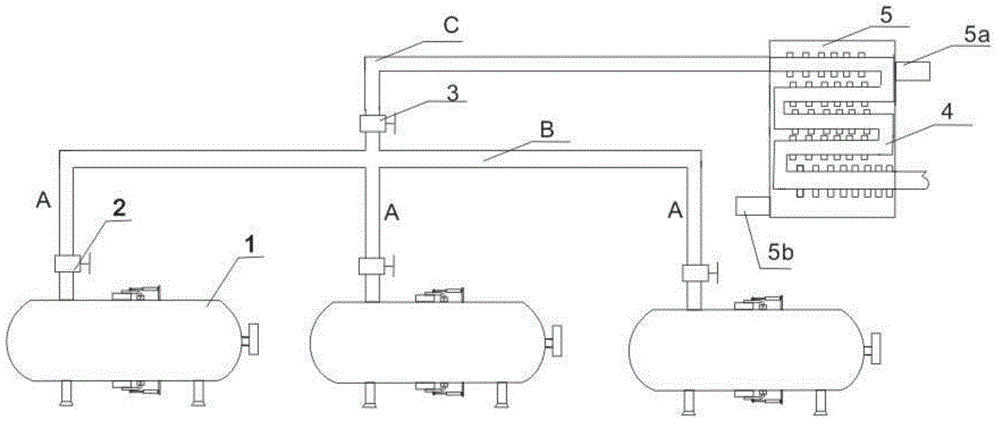

[0024] The desulfurization device used in this embodiment includes at least two desulfurization tanks 1 and vegetable oil softener preheating tanks 5, preferably four desulfurization tanks 1 here. The upper part of the desulfurization tank 1 is provided with a feed port and an exhaust port, and the lower part of the desulfurization tank 1 is provided with a discharge port. The exhaust port of each desulfurization tank 1 is connected to a pipeline A, and the pipeline A on the exhaust port of each desulfurization tank 1 A each communicates with the main pipeline B through a control valve 2, and the main pipeline B communicates with the pressure relief pipeline C through a valve 3. The upper part of the vegetable oil softener preheating tank 5 is provided with a vegetable oil softener inlet 5a and a gas inlet, and the vegetable oil softener is preheated. The lower part of the tank 5 is provided with a vegetable oil softener outlet 5b and a gas outlet, and the vegetable oil softene...

Embodiment 2

[0033] The desulfurization equipment of this embodiment is the same as that of Embodiment 1. The preparation of the odorless reclaimed rubber includes the steps of chemical desulfurization, rubber mixing and molding with tread rubber powder as raw material. Wherein the rubber mixing and molding processes are prior art, and will not be repeated here.

[0034] The desulfurization process is as follows: 1. Put the tread rubber powder into the first desulfurization tank 1, the particle diameter of the tread rubber powder is 30-32 mesh. Then add the preheated vegetable oil softener, environmental protection activator and water.

[0035] The environmental protection activator is prepared from potassium persulfate and fatty acid according to the ratio of weight and number of 3.25:6.75, and the addition amount of the environmental protection activator is 0.29% of the mass of the tread rubber powder.

[0036] The vegetable oil softener is composed of cottonseed oil, rosin, pine tar, ...

Embodiment 3

[0041] The desulfurization equipment of this embodiment is the same as that of Embodiment 1. The preparation of the odorless reclaimed rubber includes the steps of chemical desulfurization, rubber mixing and molding with tread rubber powder as raw material. Wherein the rubber mixing and molding processes are prior art, and will not be repeated here.

[0042] The desulfurization process is as follows: 1. Put the tread rubber powder into the first desulfurization tank 1, the particle diameter of the tread rubber powder is 30-32 mesh. Then add the preheated vegetable oil softener, environmental protection activator and water.

[0043] The environmental protection activator is prepared from sodium persulfate and fatty acid according to the ratio of 3:7 by weight and number, and the addition amount of the environmental protection activator is 0.25% of the mass of the tread rubber powder.

[0044] The vegetable oil softener is composed of cottonseed oil, rosin, pine tar, rapeseed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com