A carpet tile, a method for making a carpet tile and compositions for use in making a carpet tile

A composition and technology of carpet tiles, applied in the direction of floor fabrics, household utensils, chemical instruments and methods, etc., can solve the problem that carpet tiles are not very flexible and heavy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

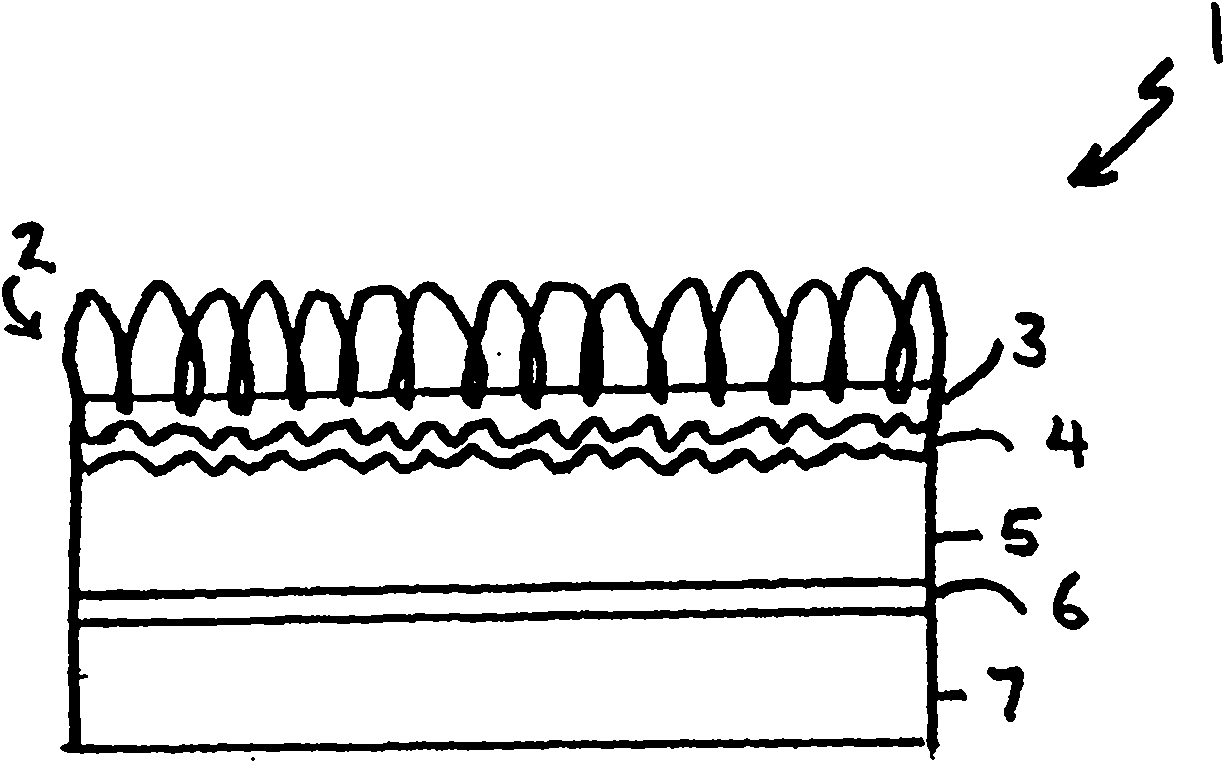

[0157] prepared with figure 1 Similar rug tiles shown. The primary backing is a polyester or polypropylene primary backing tufted from nylon yarn which has been precoated with the precoating composition of the present invention.

[0158] The precoat composition was prepared as follows:

[0159] 4.0 liters of Latercol D Thickener (BASF product) was added to 100 liters of water and mixed by a mixer for 10 minutes. The resulting solution was added slowly (2 liters per minute) to Acronol S728 51% solids (a BASF product) with mechanical stirring. Slow addition of the water / thickener solution to Acronol S728 ensures no curdling. Before addition, Acronol S728 was diluted with water to 25% solids and 20% of AX 8281 Acronol was added to the dry weight of Acronal S728. The solution was aged for 3 days to develop the final endpoint viscosity.

[0160] 50g / m 2 up to 100g / m 2 (dry weight) of the pre-coating composition is applied to the pre-tufted polyester fiber layer by roll coati...

Embodiment 2

[0166] A polyvinyl chloride composition forming a carpet tile backing layer was prepared. The composition contains:

[0167] Polyvinyl chloride copolymer resin (100% polyethylene homopolymer resin can replace copolymer resin);

[0168] 2.15kg of recycled glass per kg of resin. The glass is provided by the waste station glass recycling plant and is in the form of ≤ 300 microns, with a specific gravity of 2g / cm 3 ;as well as

[0169]A mixture of epoxidized soybean oil (75 wt %) and castor oil acetic acid (25 wt %) supplied as Grindsted Soft-n-Safe / c (Danisco product) was diluted with ethanol to the desired viscosity. A suitable viscosity is 200cps±10cps (using 2.5rpm No. 1 Spindle Brookfield viscometer). Since the specific gravity of glass is smaller than the standard limestone used, the specific gravity of standard limestone is 2.7g / cm 3 , to adjust the filling ratio to compensate for this. For example, limestone filler is usually added in an amount of 2.91 kg per kg of r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com