Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "Meet the requirements of long-term operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

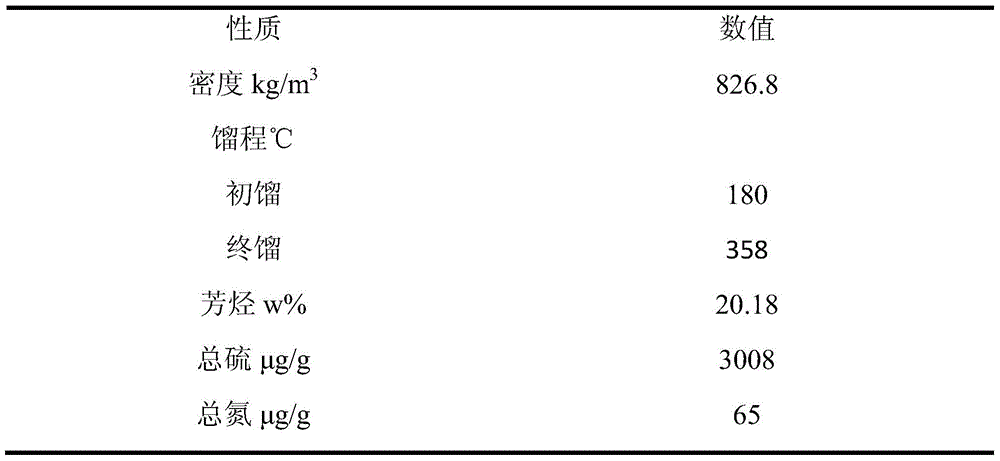

Method for producing high quality light white oil from base oil

ActiveCN107937024AHigh activityImprove water absorptionTreatment with hydrotreatment processesHydrocarbon oils treatment productsPtru catalystHydrogenation reaction

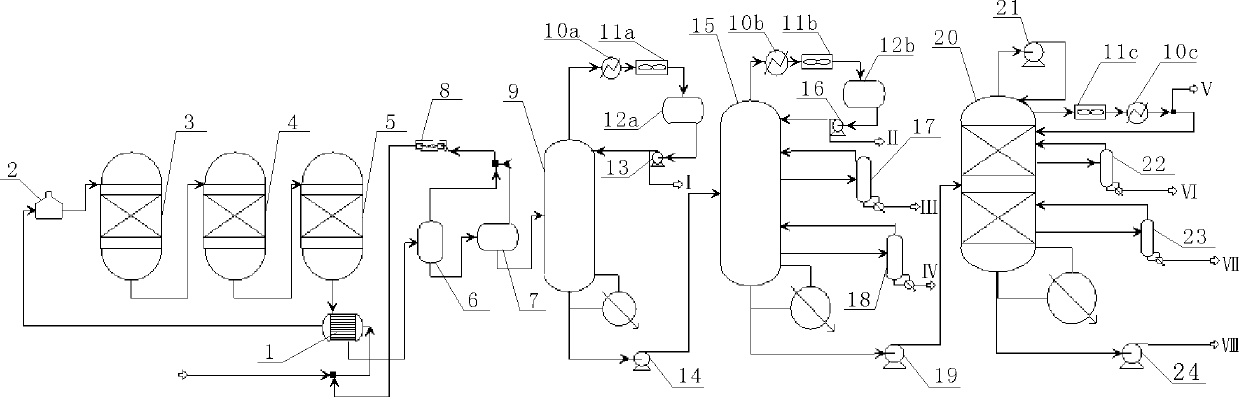

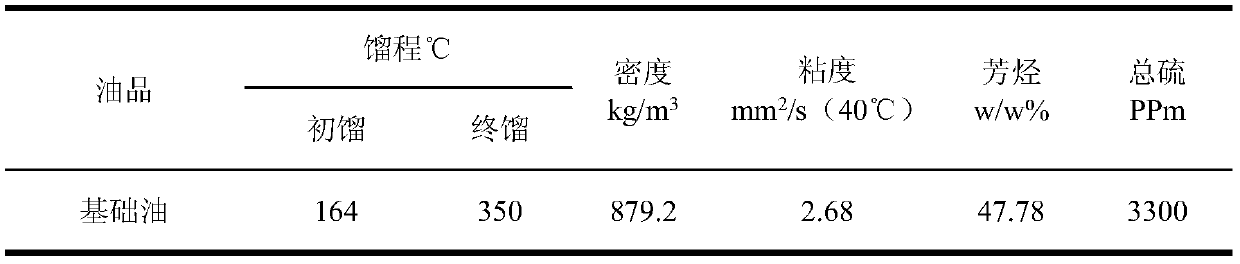

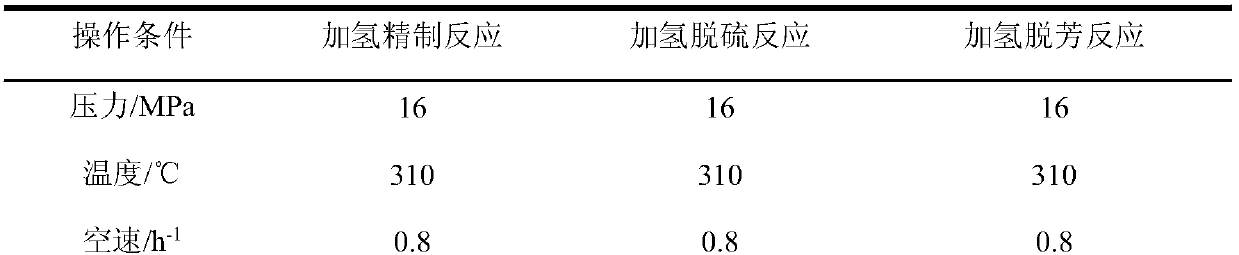

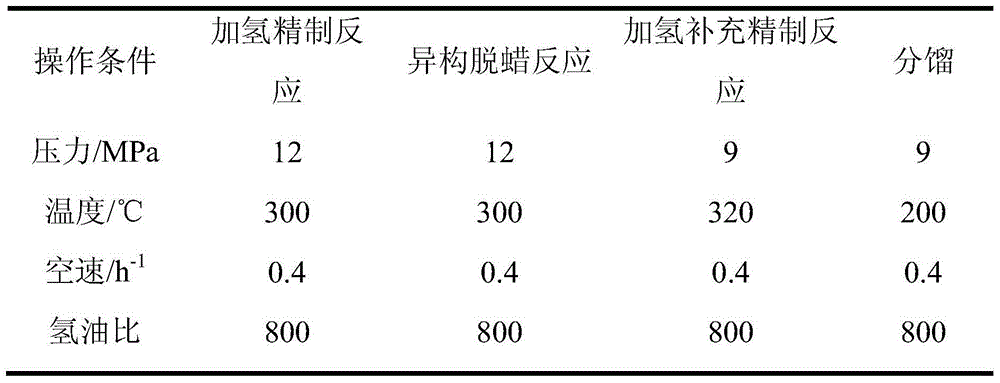

The invention discloses a method for producing high quality light white oil from base oil. The method comprises the following steps: the raw material base oil is heated to reaction temperature and fully mixed with hydrogen, and then enters a hydrogenation reactor loaded with a catalyst I for hydrofining under the action of the hydrofining catalyst I to remove most of S, N, and aromatic impuritiesin the raw material base oil; reacted products enter into two series reactors respectively loaded with a catalyst II and a catalyst III for contact with the catalyst II and the catalyst III to removethe S and perform dearomatization saturated reaction; obtained reactants are subjected to gas-liquid separation by a high-pressure separator and a low-pressure separator and then enter a fractionationsystem for fine cutting to obtain a variety of different grades of high-quality light white oil products. The method can produce the high-quality light white oil with good quality, high yield, shortdistillation range, high purity, low sulfur and low aromatics.

Owner:洛阳金达石化有限责任公司

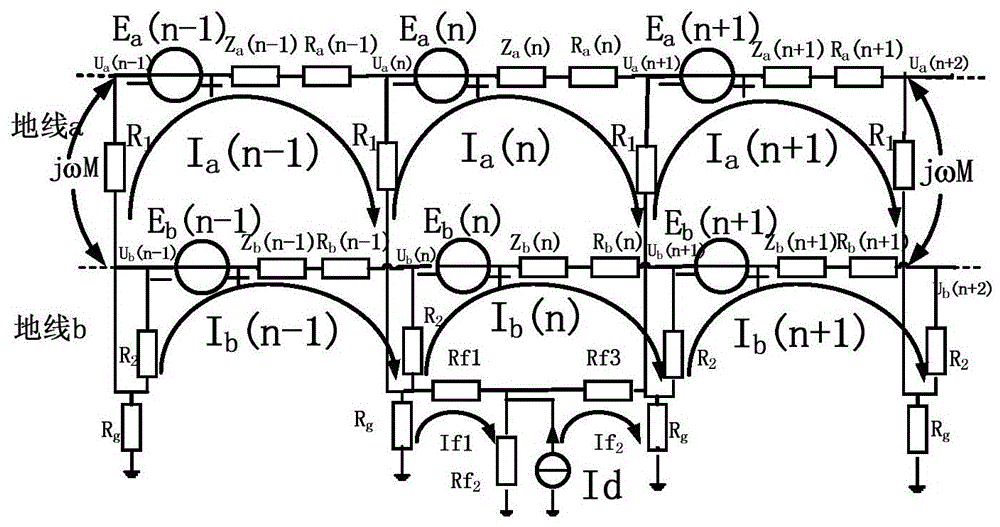

On-line monitoring and fault diagnosis system for power distribution network PT

ActiveCN103941079AHigh measurement accuracyReduce power consumptionFault locationMeasurement using digital techniquesSingle phaseElectromagnetic induction

Provided is an on-line monitoring and fault diagnosis system for a power distribution network PT. The system can be used for measuring three phase currents, three phase voltages, three line voltages and zero sequence voltage data of the power distribution network PT. Whether the system has a single-phase grounding fault, a ferromagnetic resonance fault and a PT line breakage fault can be accurately judged through actually-measured data. The system is composed of a current measurement terminal, a collector and a background server. The current measurement terminal is arranged on a three-phase line of the power distribution network PT, and the three phase currents of the power distribution network PT are measured according to the electromagnetic induction principle. The collector is arranged on a panel of a PT cabinet, receives data of the terminal, meanwhile, measures the phase voltages, the line voltages and a zero sequence voltage of the PT, and uploads the data to the background server. The background server is arranged inside a transformer substation, receives the data of the collector, and conducts on-line monitoring and fault diagnosis on the power distribution network PT. According to the on-line monitoring and fault diagnosis system for the power distribution network PT, technology is mature, and reliability is high.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING) +1

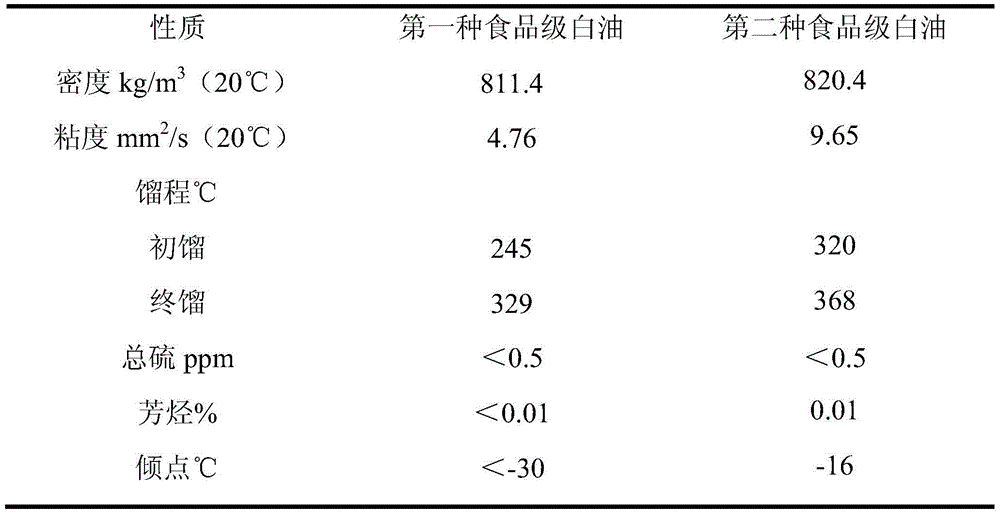

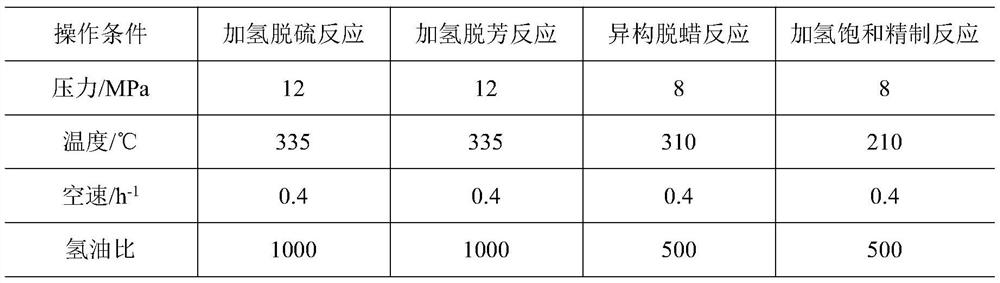

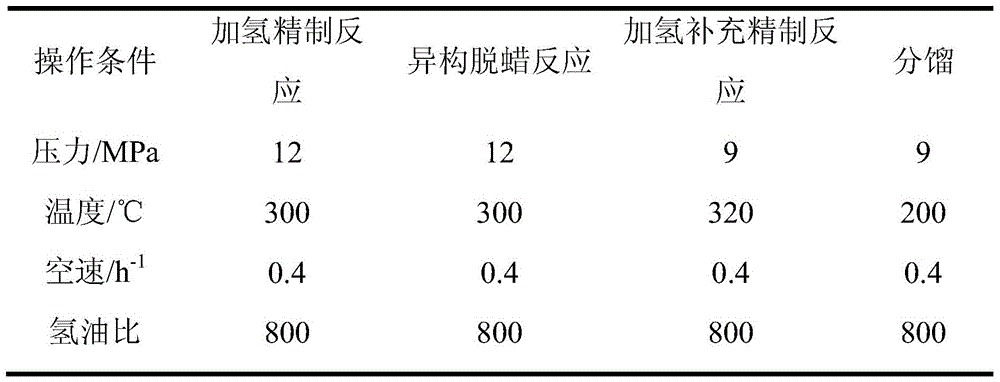

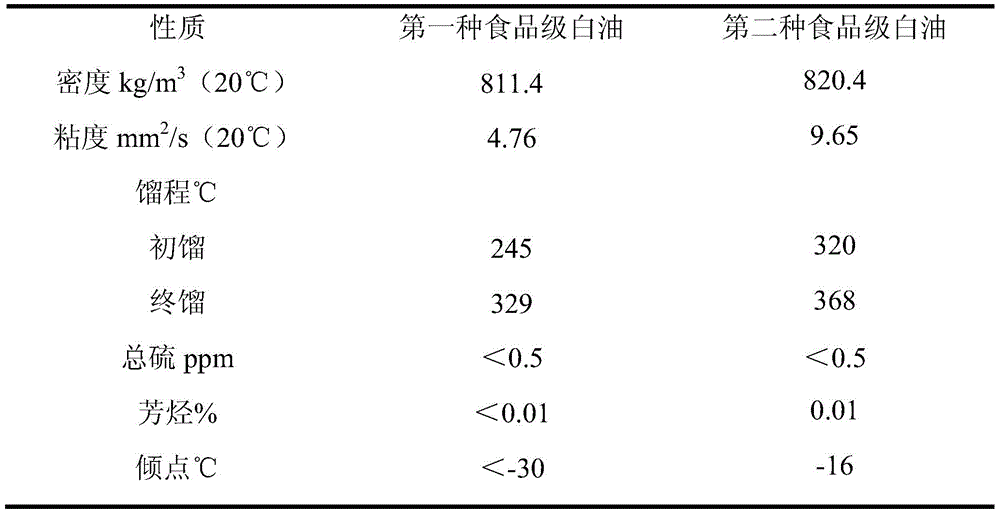

Method for producing food-grade white oil with atmospheric-vacuum extraction oil

ActiveCN104910963AWide distillation rangeExtended service lifeTreatment with hydrotreatment processesIsomerizationVacuum extraction

The invention discloses a method for producing food-grade white oil with atmospheric-vacuum extraction oil. According to the invention, the raw material atmospheric-vacuum extraction oil is heated; the oil is delivered into two serially connected reactors respectively loaded with a catalyst I and a catalyst II, and contacts the catalysts; under the effect of a hydro-refining catalyst, a hydro-treating reaction is carried out, and de-S, de-N and aromatic saturation reactions are carried out; a refined product is subjected to gas-liquid separation, stripping and fractionation, such that produced H2S is removed; a component with a boiling point higher than 230 DEG C is cut from a distillate, and is adopted as a feed of an isomerization dewaxing reaction; the isomerization dewaxing reaction is carried out with a catalyst III; an oil product produced through the isomerization dewaxing reaction is cooled, and is subjected to a hydro-finishing reaction with a catalyst IV; an oil product obtained after the reaction is subjected to product cutting in a fractionation system, such that the food-grade white oil with an aromatic hydrocarbon content lower than 0.01% w / w, a sulfur content lower than 1ppm, and a solidifying point lower than -30 DEG C is obtained.

Owner:洛阳金达石化有限责任公司

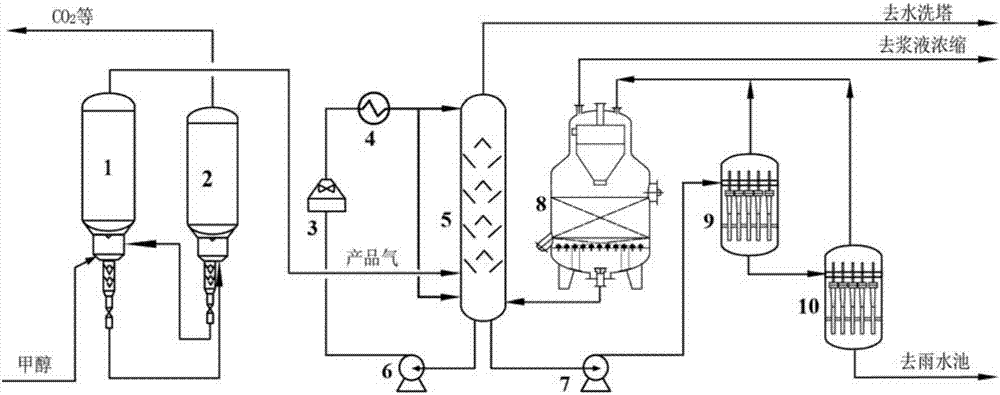

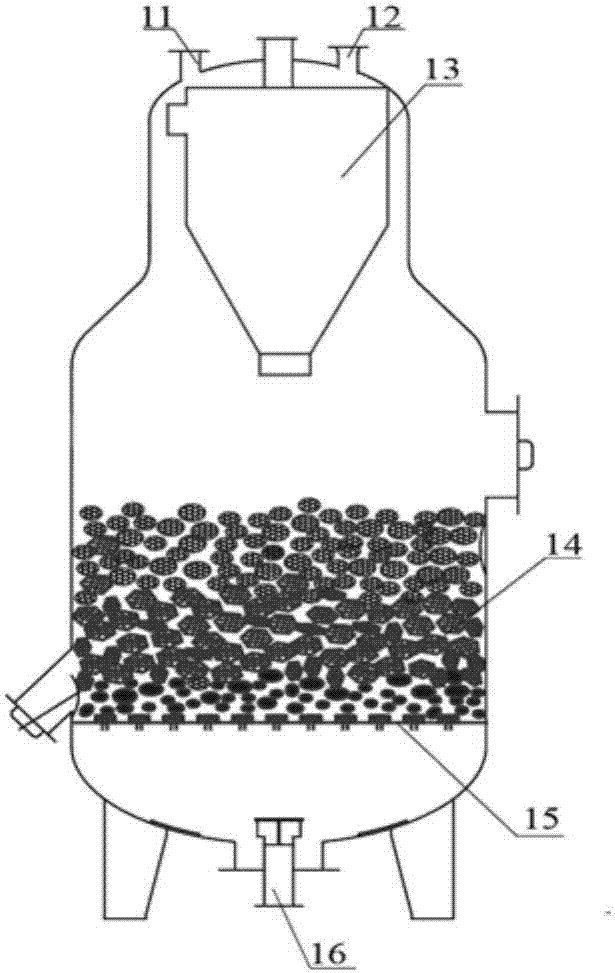

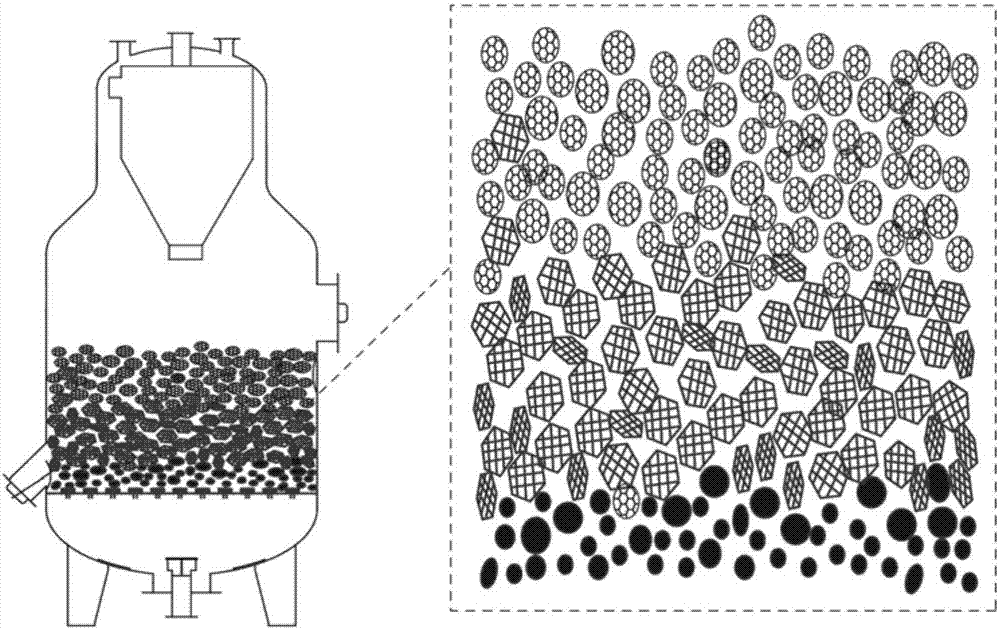

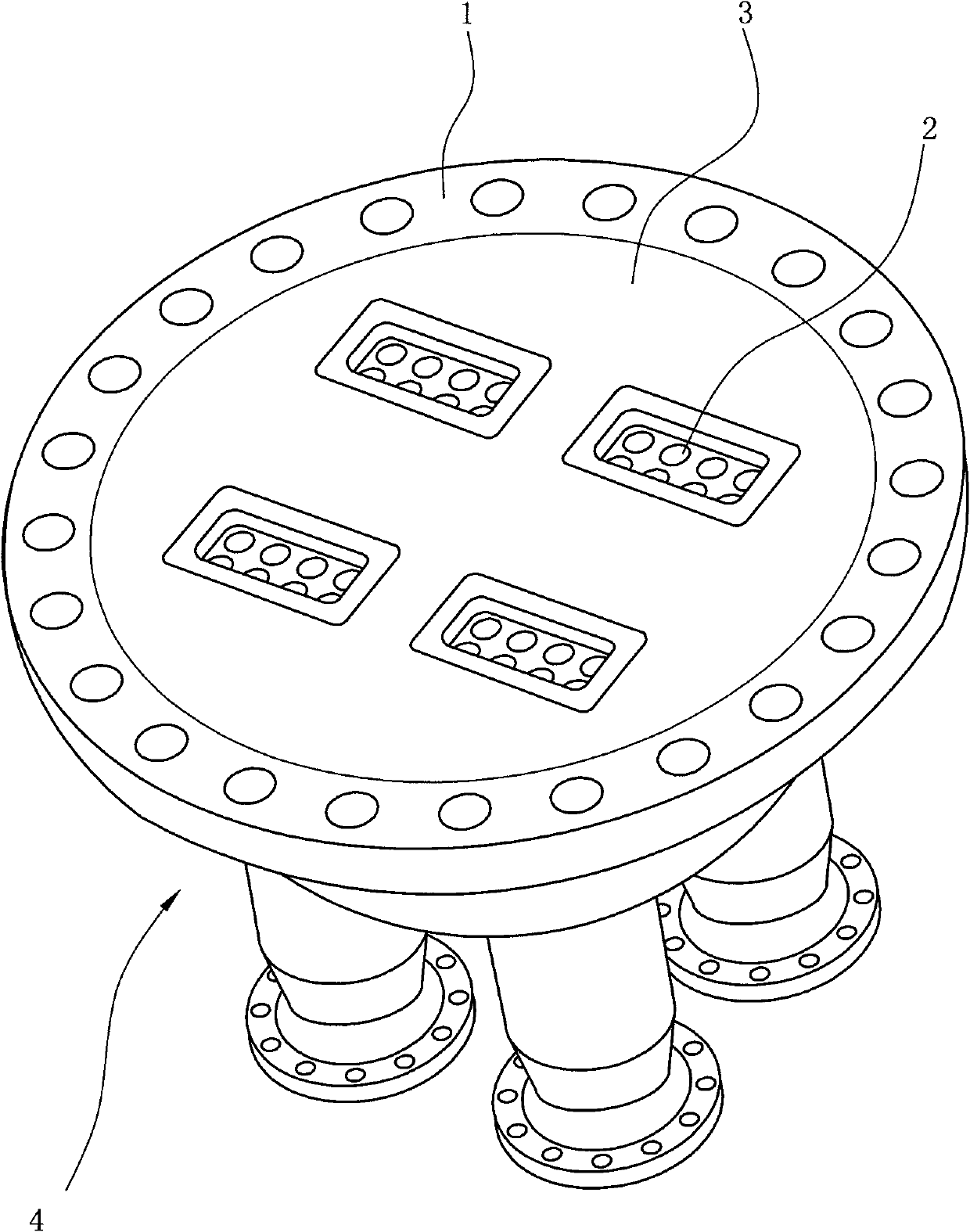

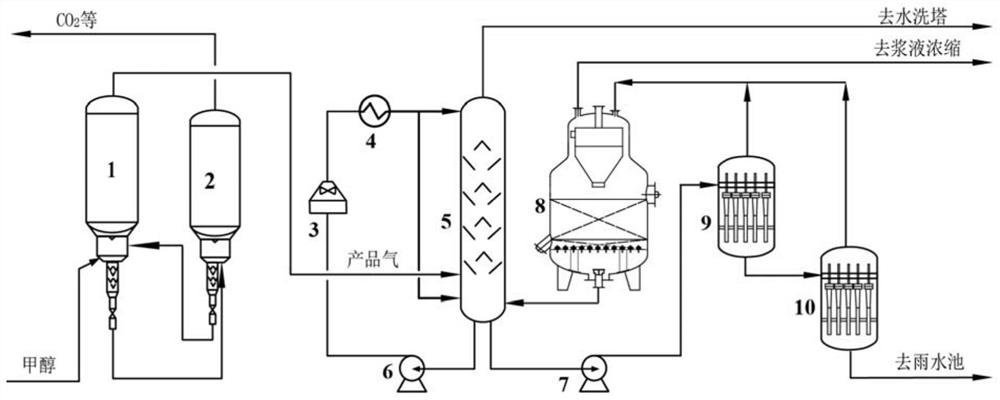

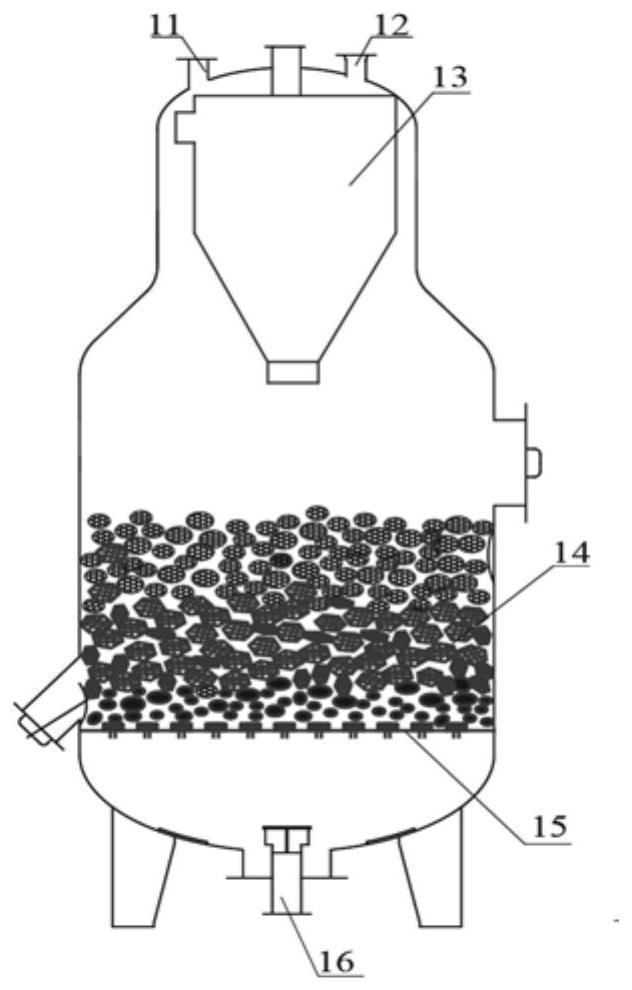

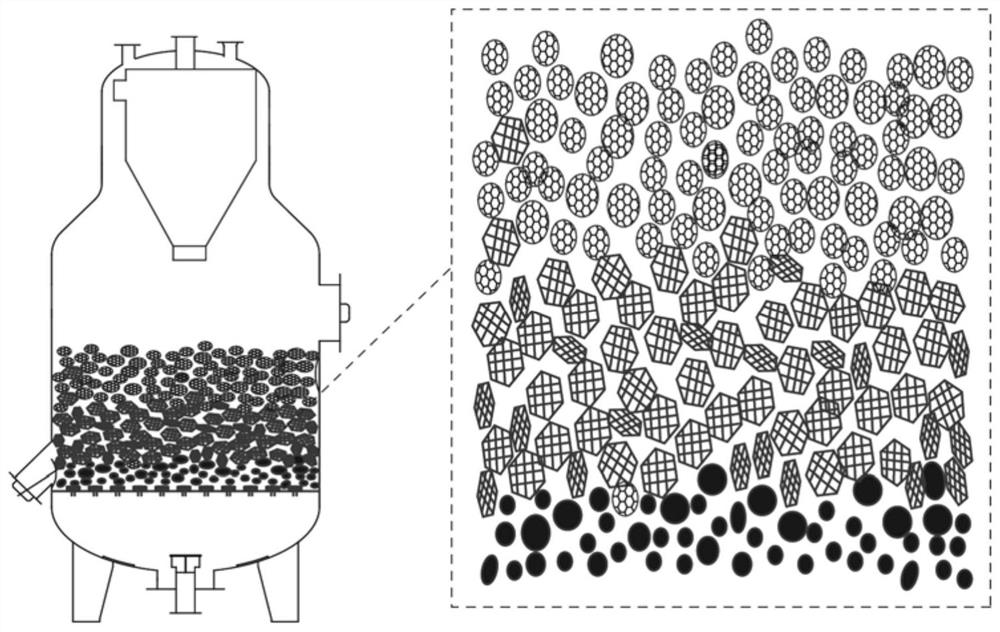

Ranking method of separation media in boiling bed separator

ActiveCN107512787AImprove filtering effectSimple and fast operationWater/sewage treatment by centrifugal separationTreatment involving filtrationCycloneRanking

The invention discloses and relates to a ranking method of separation media in a boiling bed separator. The method comprises the steps that a whirlcone is arranged at the upper part of the boiling bed separator; during the regeneration, the separation media in a filtering bed layer of the boiling bed separator is in a complete fluidized state; the separation media upwards enters the whirlcone; after cyclone ranking, the separation media flows out from the whirlcone in a sequence from high specific gravity to low specific gravity; after the back flushing regeneration is completed, the separation media is continuously used for purifying process water generated in a MTO (Methanol To Olefin) process, wherein the filtering bed layer of the boiling bed separator is formed by multiple layers of different separation media; the separation media particle size distribution is downwards reduced layer by layer; the specific gravity of the separation media is downwards increased layer by layer.

Owner:SHANGHAI HUACHANG ENVIRONMENT PROTECTION

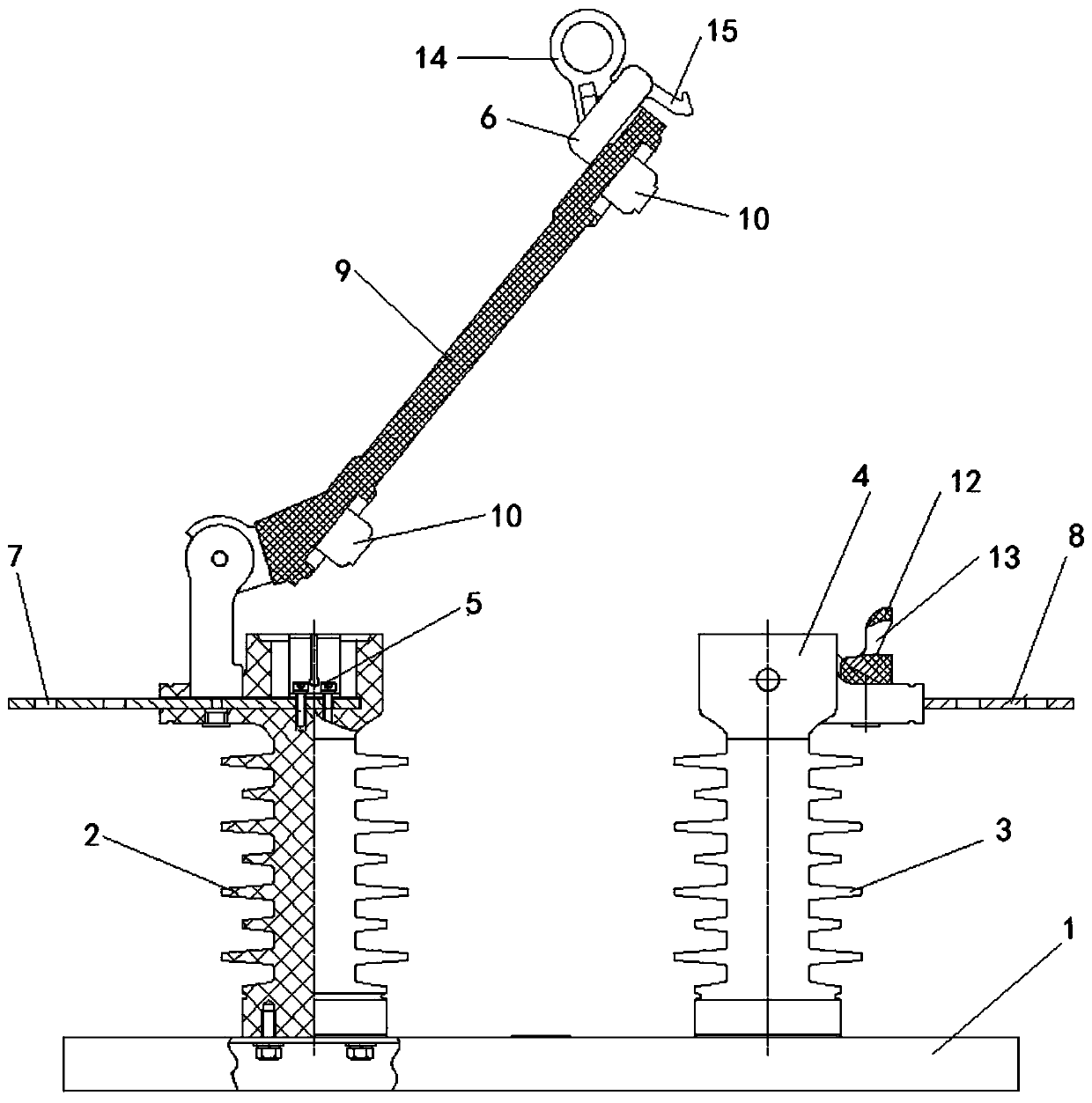

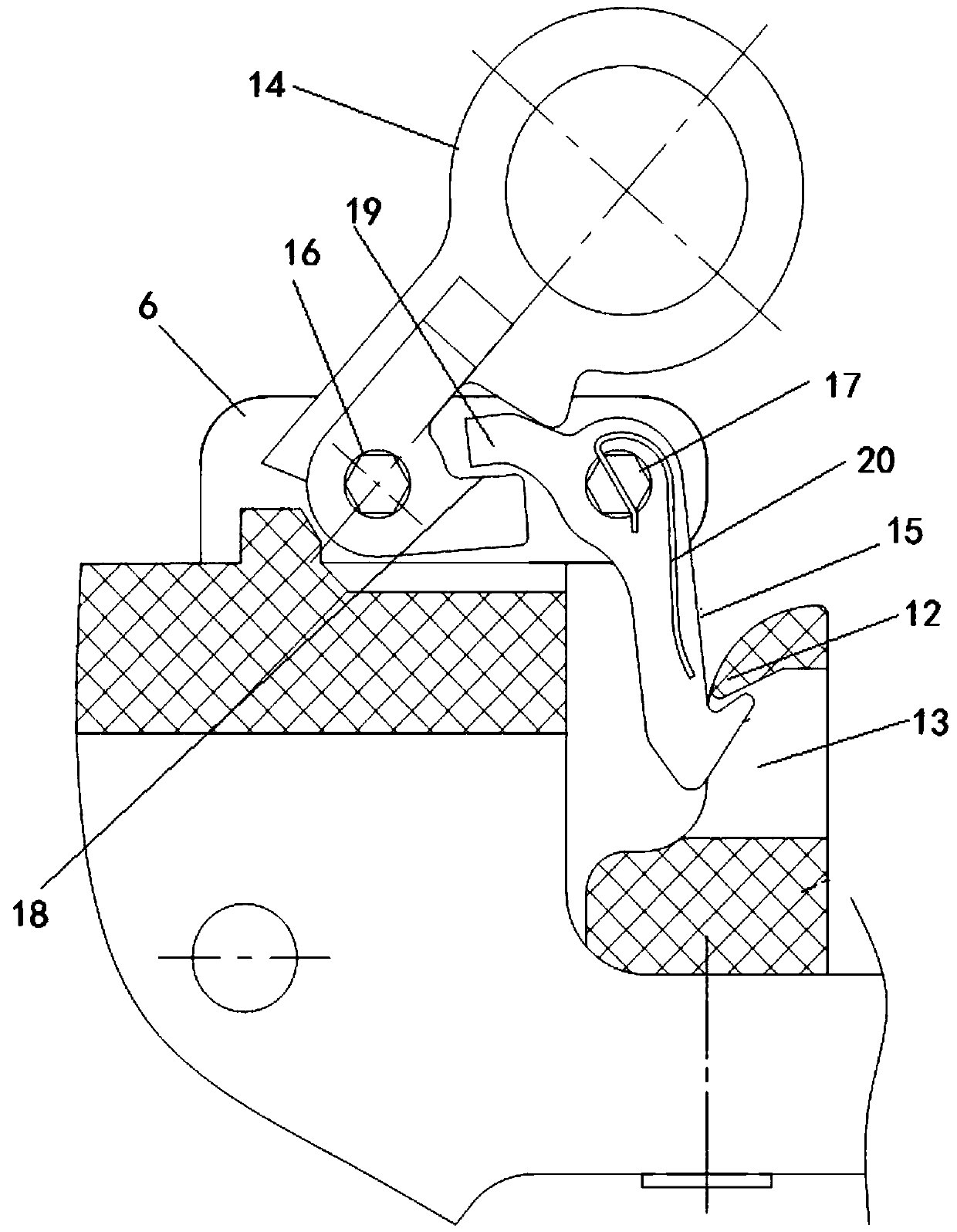

Novel double-column vertical open type outdoor high-voltage AC disconnecting switch

InactiveCN109559930ASimple structureEasy to useAir-break switch detailsElectrical conductorForeign object

The present invention discloses a novel double-column vertical open type outdoor high-voltage AC disconnecting switch. The switch comprises a bottom frame, a first pillar insulator, a second pillar insulator, a conductive loop, a static side contact socket, and a movable side contact socket. The conductive loop comprises a conductive blade, and the conductive blade is provided with a self-lockingdevice; a latching device is arranged above the second pillar insulator and on one side of the static side contact socket away from the movable side contact socket, and the side surface of the latching device is provided with a concave latching groove; the position of the concave latching groove is engaged with a hook body; the hook body is internally provided with a stainless steel leaf spring; the conductive loop adopts a fully enclosed structure; all conductors of the conductive loop are enclosed inside the insulating material; and a static contact, a static side wiring board and a movableside wiring board are installed in the insulator. According to the technical scheme of the present invention, the stainless steel leaf spring is arranged in the hook body, so that influence on the rotation sensitivity of the hook body caused by the exposure of the stainless steel leaf spring to the wind and rain can be avoided; and by using the fully enclosed structure of the conductive loop, short circuits caused by birds and foreign objects can be avoided.

Owner:池州江南电力设备有限公司

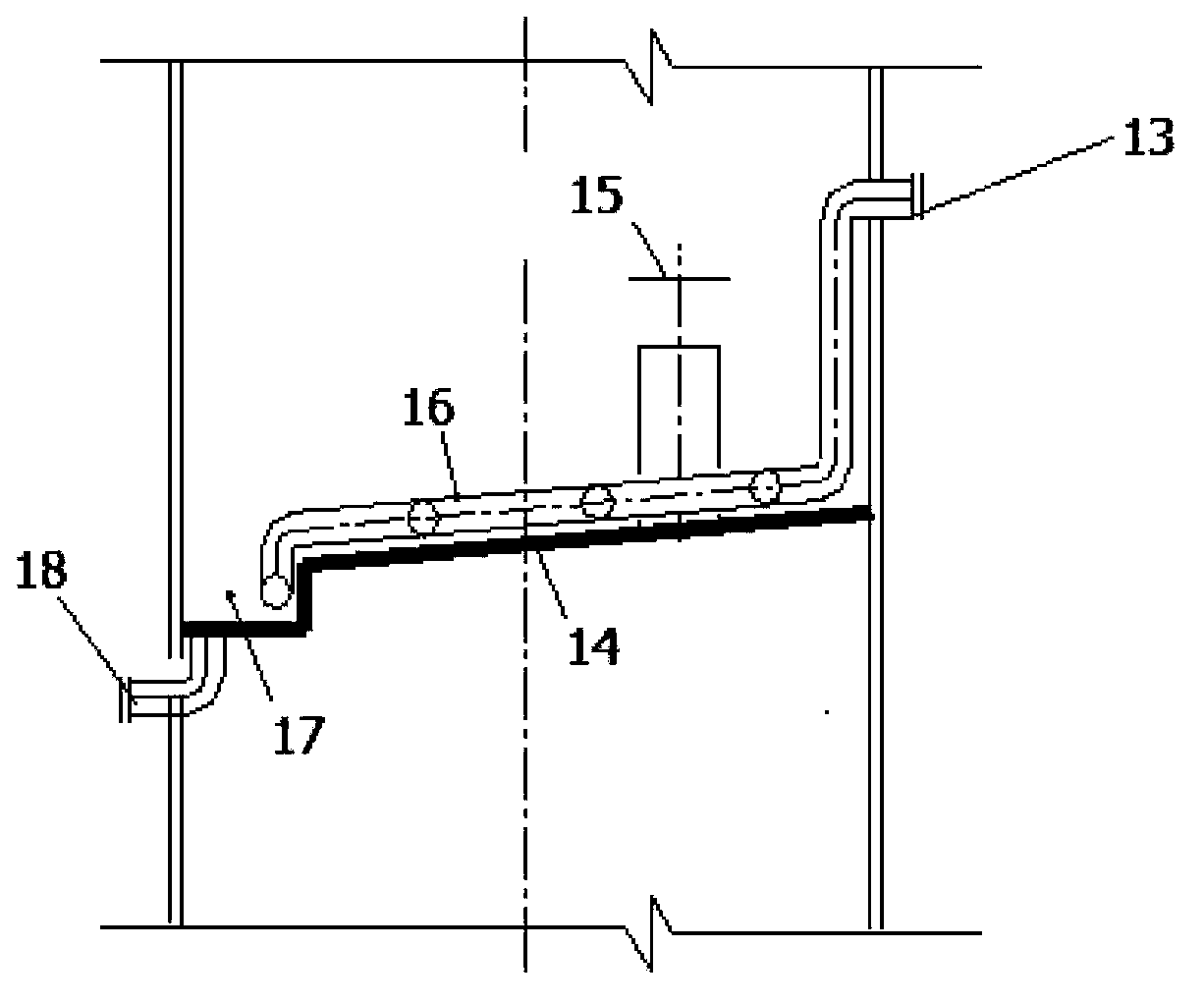

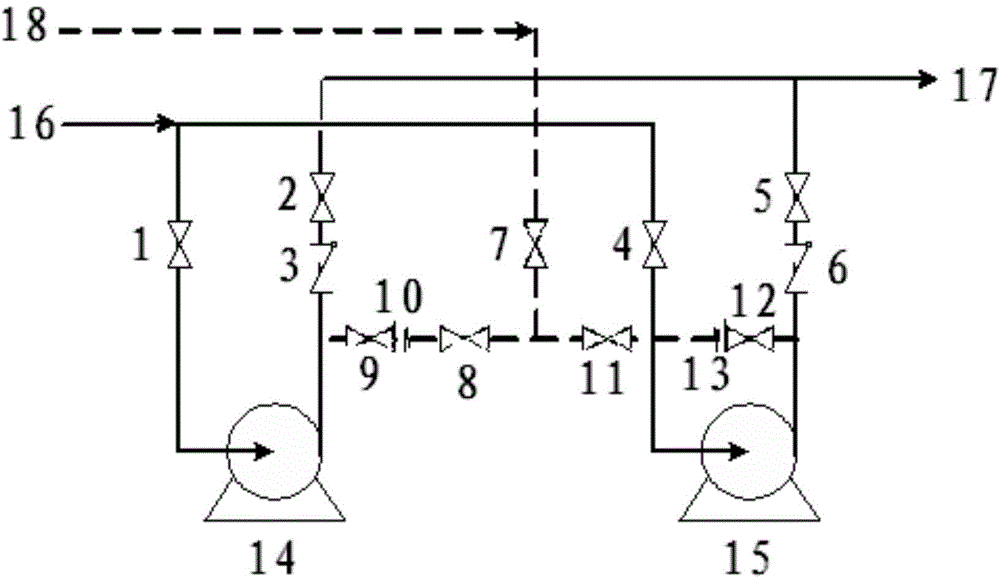

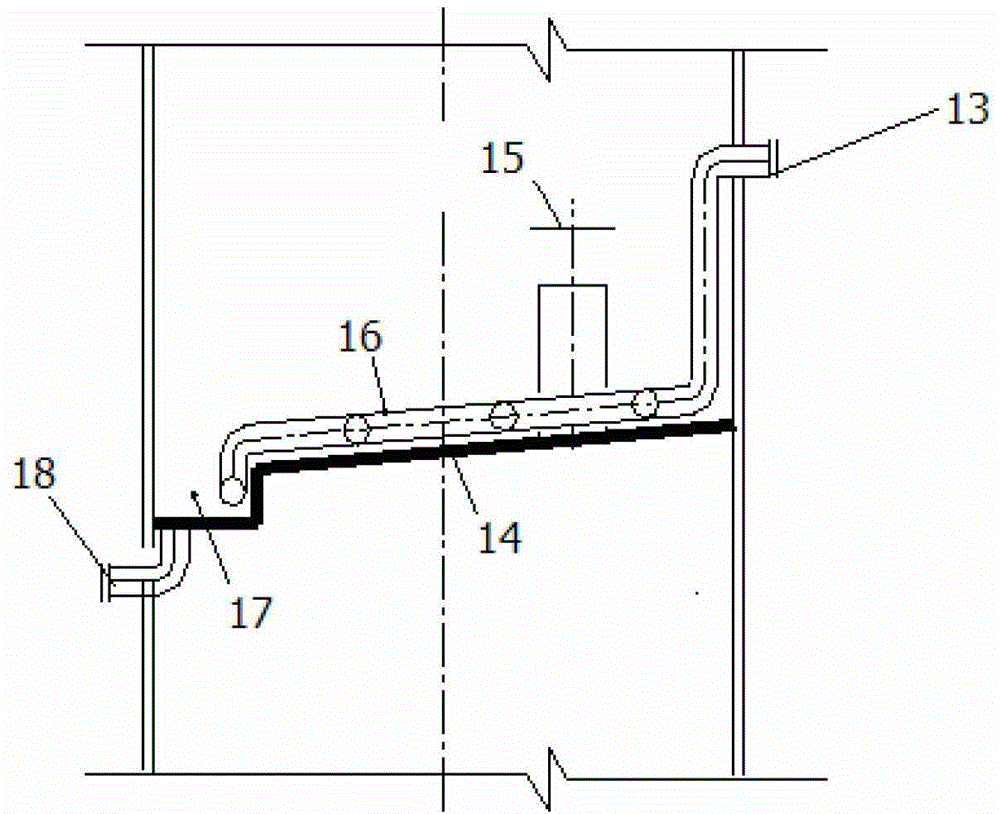

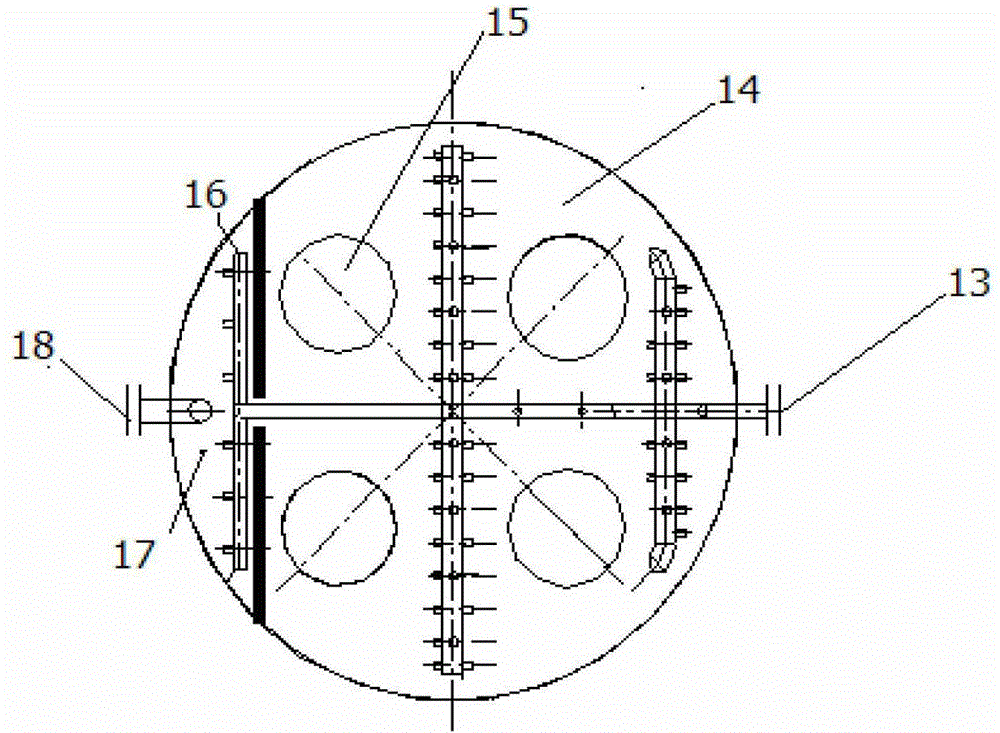

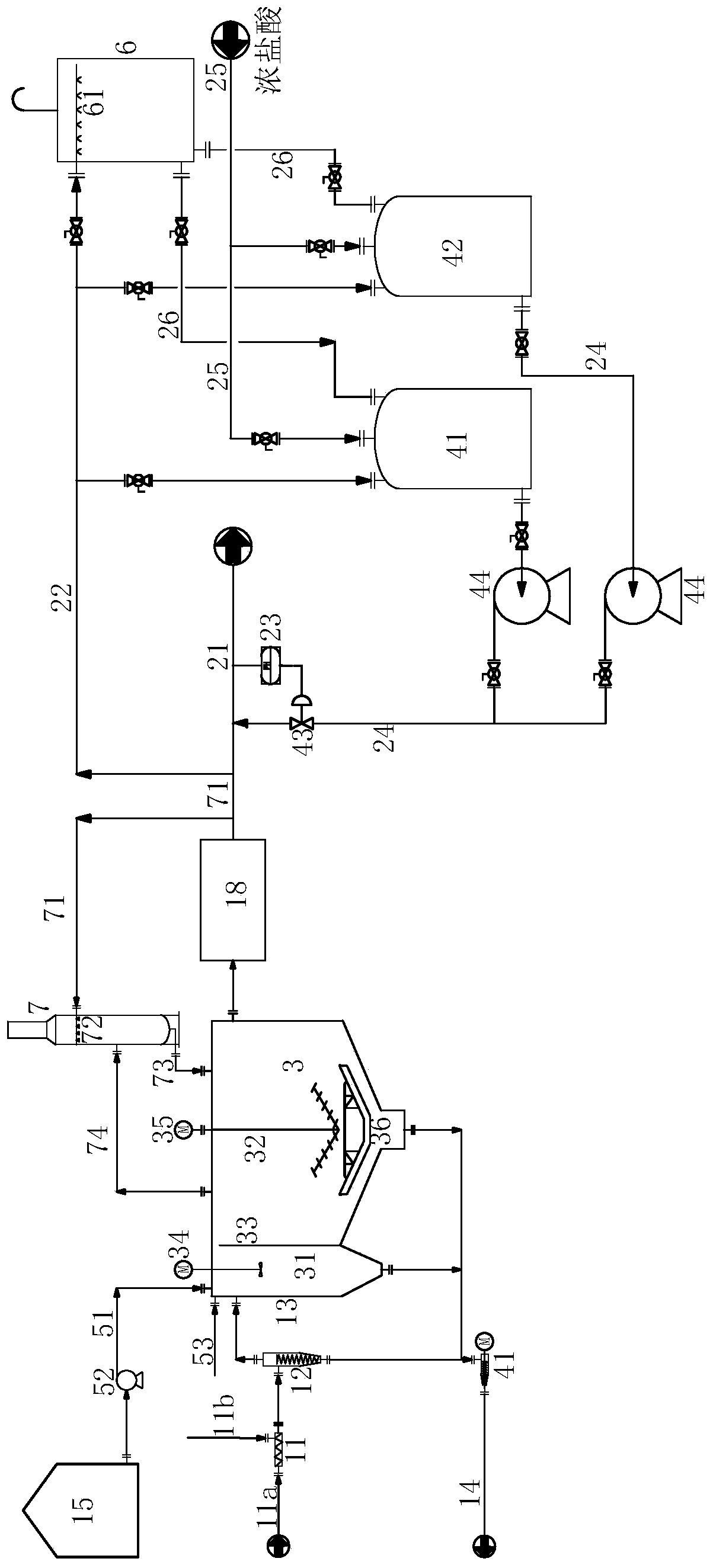

High temperature slurry machine pump preheating process

ActiveCN103982739BEliminate Wear HazardsReduce washoutPipe heating/coolingVena contracta diameterHot Temperature

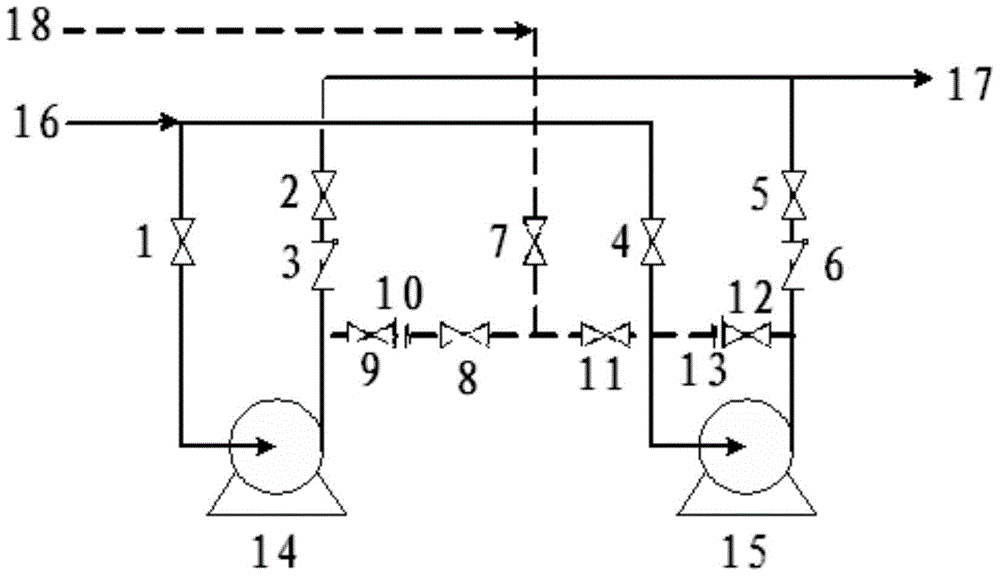

The invention relates to a preheating flow of a high-temperature oil slurry pump, and mainly solves the problems that a preheating pipeline and valves are flushed and abraded unavoidably and seriously since a preheating medium commonly contains a catalyst in the prior art, and once high-temperature oil slurry leaks, spontaneous ignition is quite easily caused. By using the preheating flow of the high-temperature oil slurry pump, the preheating medium is introduced from the preheating pipeline (18), passes through a preheating main valve (7) and then is divided into two paths; one path is sequentially connected with a gate valve (8), a restriction orifice plate (10), a root cutoff valve (9) and an oil slurry pump (14), and the other path is sequentially connected with a gate valve (11), a restriction orifice plate (13), a root cutoff valve (12) and an oil slurry pump (15). According to the technical scheme, the problems are better solved. The preheating flow of the high-temperature oil slurry pump can be used for preheating the high-temperature oil slurry pump.

Owner:CHINA PETROLEUM & CHEM CORP QINGDAO RES INST OF SAFETY ENG +1

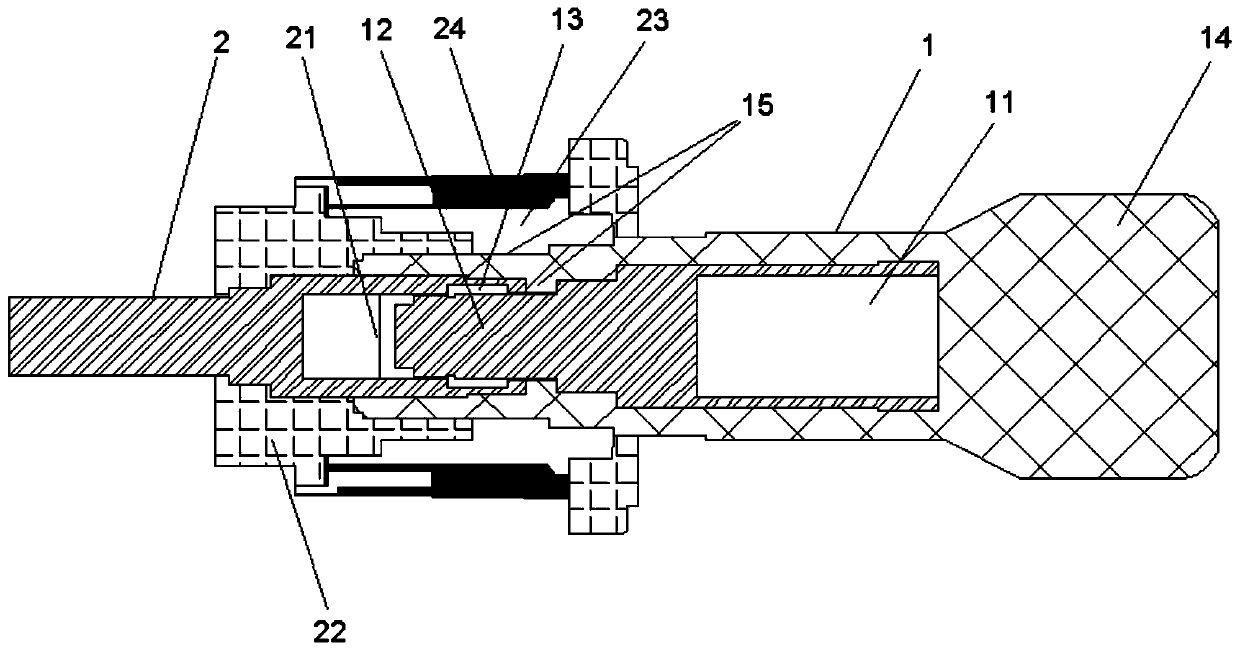

0.4 kV uninterrupted power operation rapid plugging device

PendingCN111446595AExcellent electrical performanceSafe and reliable operationSecuring/insulating coupling contact membersCoupling contact membersEngineeringStructural engineering

The invention discloses a 0.4 kV uninterrupted power operation quick plugging and unplugging device, which comprises a cable connection terminal and a base connection fitting, wherein a connecting hole connected with a cable is formed in the bottom of the cable connecting end of the cable connecting terminal, a watchband contact finger is arranged on the side wall of the fitting connecting end, aterminal head insulating sheath is arranged on the outer side of the cable connecting terminal, locking clamping grooves are formed in the fitting connecting end and the surface of the side wall of the terminal head insulating sheath on the outer side of the fitting connecting end respectively, the terminal connecting end of the base connecting fitting is provided with a connecting hole matched with the fitting connecting end and the watchband contact finger, the outer side of the base connecting fitting is provided with a base insulating sheath, the side wall of the base insulating sheath isprovided with a self-locking mechanism matched with the locking clamping groove, and the outer side of the self-locking mechanism is provided with an unlocking sliding sleeve capable of sliding frontand back. The insulation degree of overhead line jumper wire equipment can be increased, and it is ensured that 0.4 kv uninterrupted power distribution line construction is safe and reliable.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO

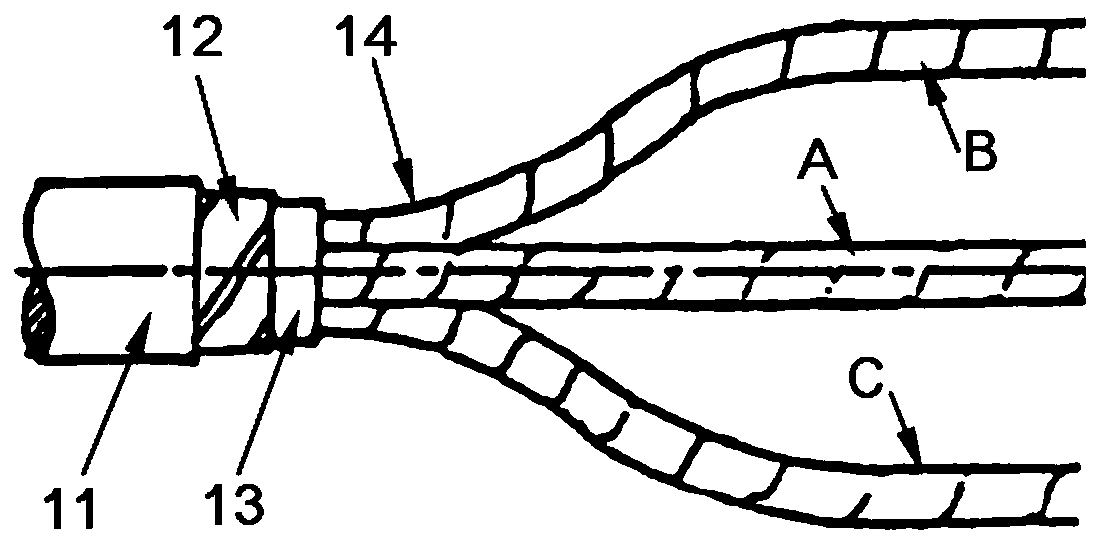

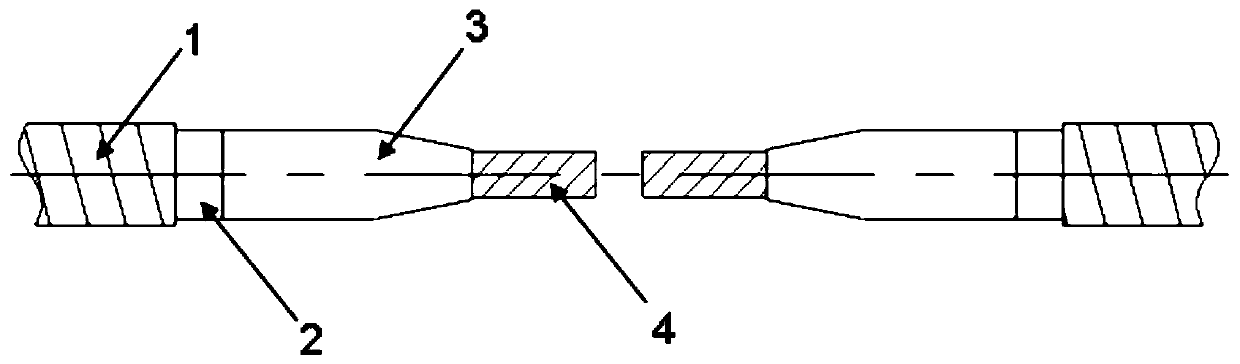

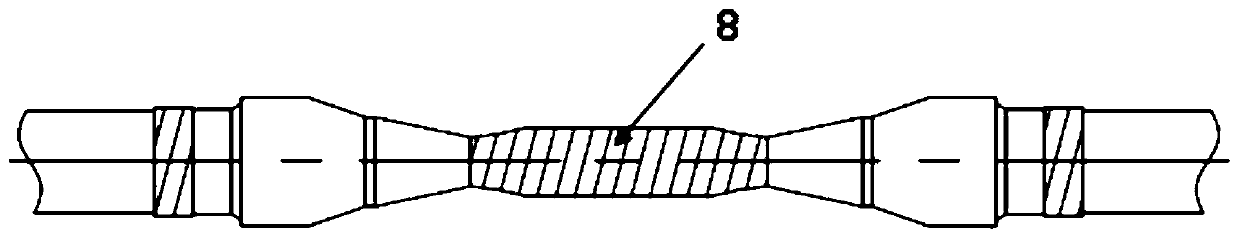

A cable wrapping intermediate joint and a manufacturing process thereof

PendingCN109245022AExcellent electrical performanceSafe and reliable operationCable junctionsApparatus for joining/termination cablesSingle phaseElectrical conductor

The invention provides a cable wrapping intermediate joint and a manufacturing process thereof, which are used for butt joint of two sections of three-core or single-core cables. The wrapping intermediate joint includes the connector wrapping connecting each single-phase cable, and the protective wrapping all the connectors; A tap wrap includes a pressure nozzle connected with a conductor core ofthat same-phase cable, a stress cone sleeved on the cable, a wound limiting step, a semi-conductive tape layer, an insulating tape layer, a tap shield layer, a copper mesh layer, a single-phase cablemetal shield tape, a PVC layer and a single-phase cable waterproof layer; The protective wrapping package comprises a binding layer, a cable metal shielding tape, a cable waterproof layer and a cablearmor layer from the inside to the outside. The winding intermediate joint of the invention can achieve the purposes of good connection, reliable insulation, good sealing performance, high mechanicalstrength, simple structure and convenient fabrication and installation of the conductor core of the cable, can ensure the safety and stability of the cable operation and obtain good economic benefits, and therefore has great popularization and application value.

Owner:SHANGHAI G&W ELECTRIC LTD +2

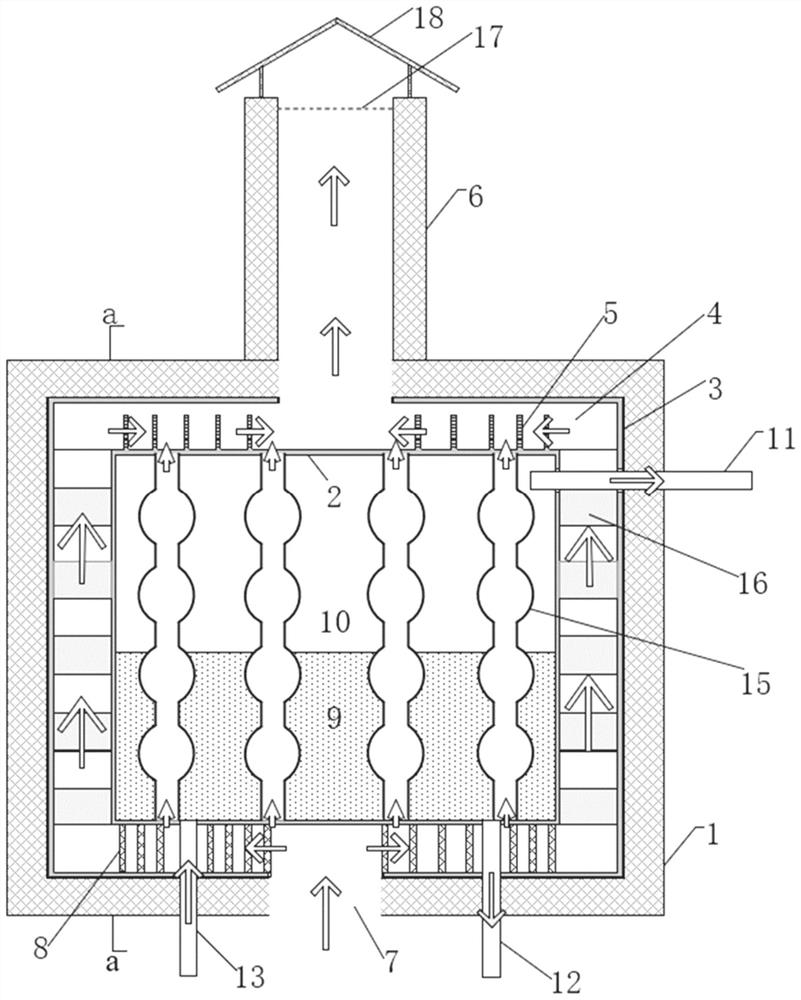

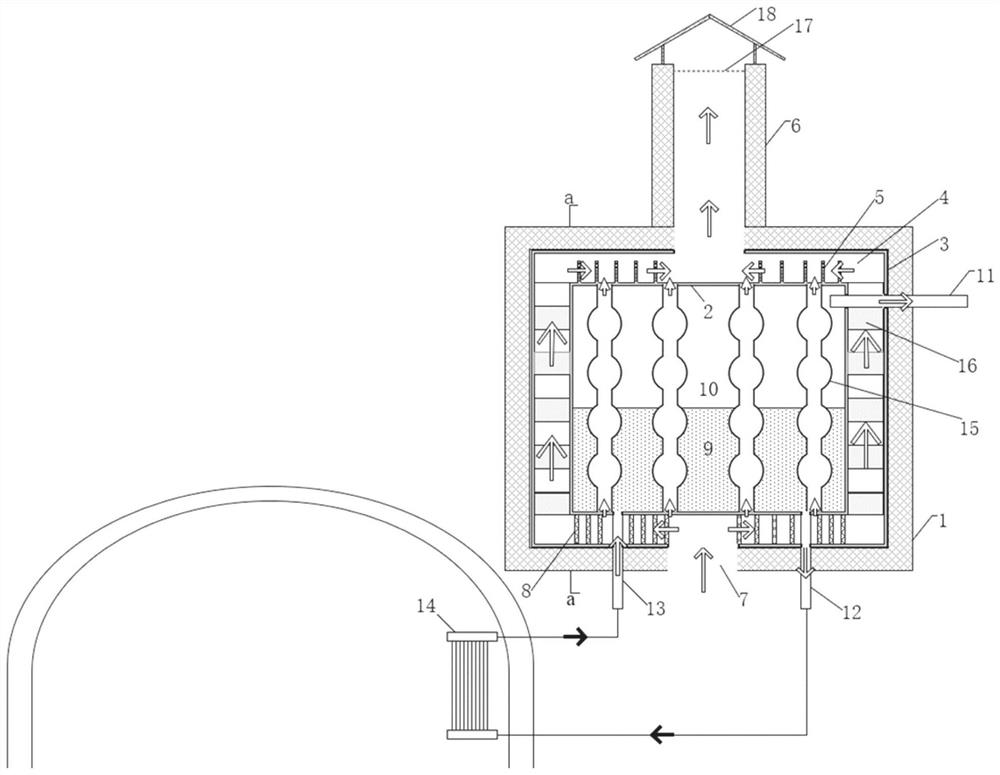

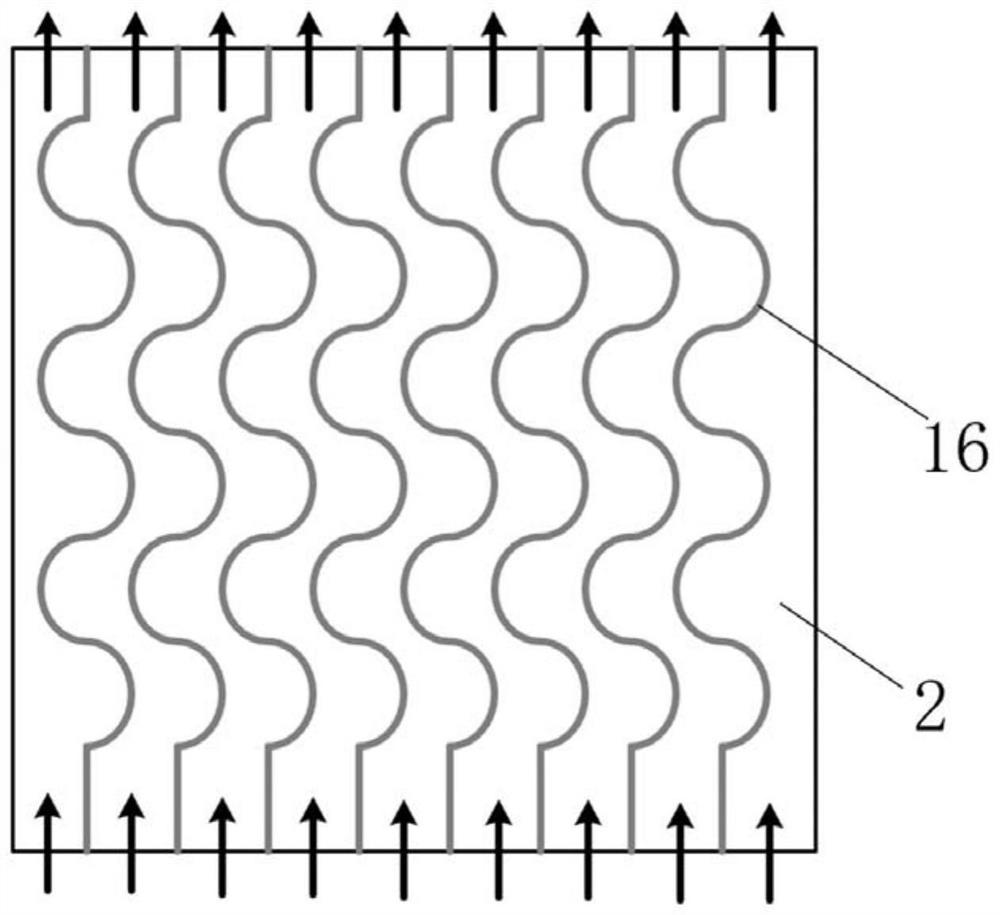

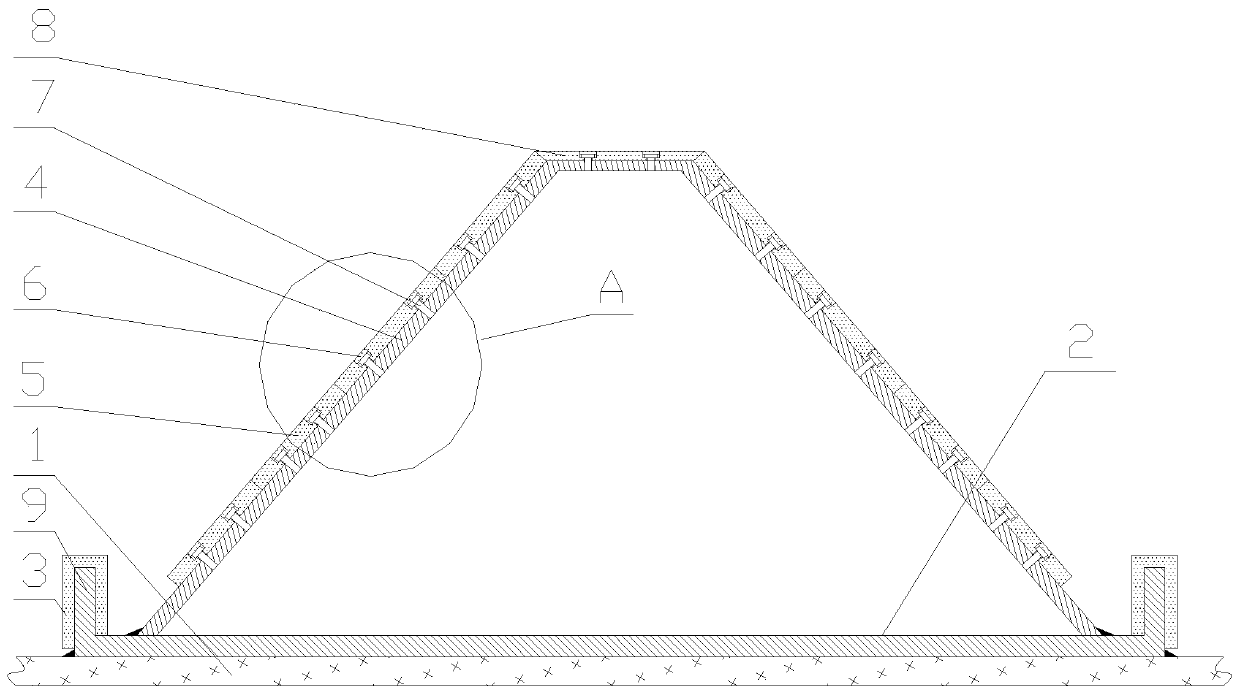

Efficient operation PCS long-term cooling water tank

ActiveCN113035387ALoss of integrityReduce external risksNuclear energy generationCooling arrangementEnhanced heat transferEnvironmental engineering

The invention provides an efficient operation PCS long-term cooling water tank. The PCS long-term cooling water tank is mainly composed of an outer-layer concrete shell, an inner-layer steel water tank and an efficient heat exchange parallel flow channel between the outer-layer concrete shell and the inner-layer steel water tank. The flow channel is formed by separation of an S-shaped vertical folded plate installed on the outer surface of the steel water tank, the bottom of the concrete shell serves as an inlet, and the top of the concrete shell serves as an outlet. And the outlet header pipe extends outwards to form a chimney structure. A plurality of large-pipe-diameter corrugated pipes penetrating through the upper surface and the lower surface of the water tank are arranged in the steel water tank. The efficient operation PCS long-term cooling water tank is applied to the PCS starting and long-term operation process under the condition of reactor water loss accidents, and passive air natural circulation with considerable flow speed is formed in the parallel flow channels by utilizing the high temperature of the outer surface of the steel water tank and the chimney effect; and efficient heat transfer of the outer surface of the water tank is achieved by means of reinforced heat transfer such as corrugated pipe. The process promotes long-term operation of the PCS system by reducing the water temperature of the PCS cooling water tank or reducing evaporation of water in the water tank.

Owner:HARBIN ENG UNIV

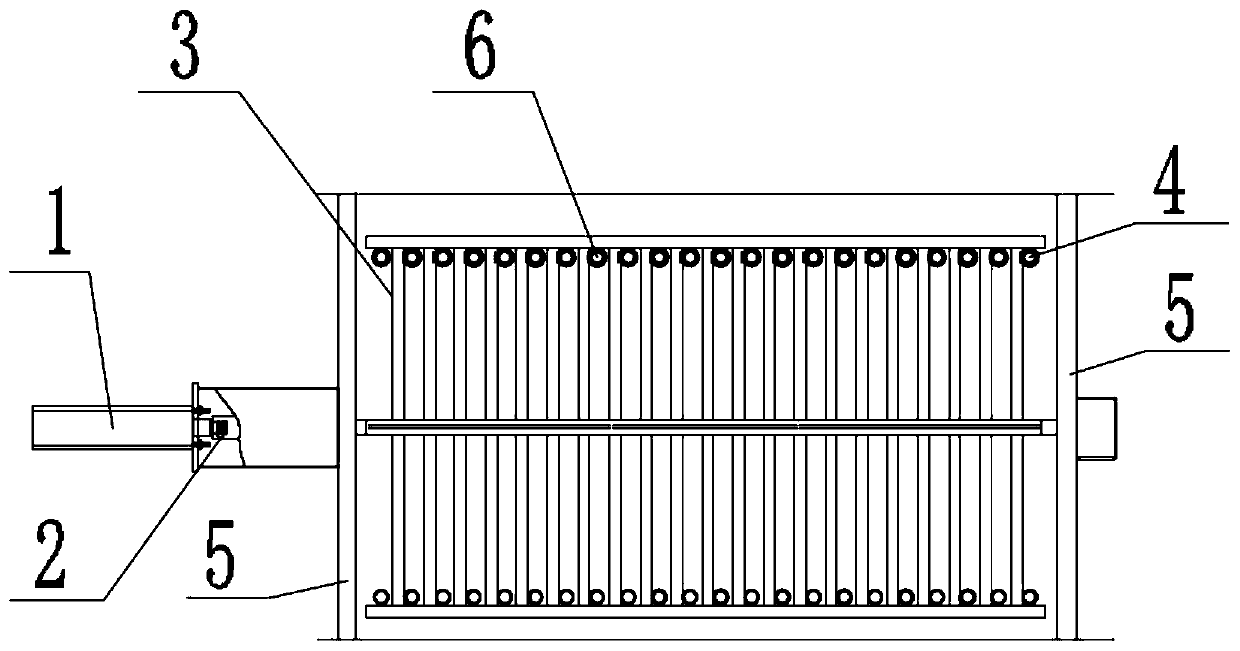

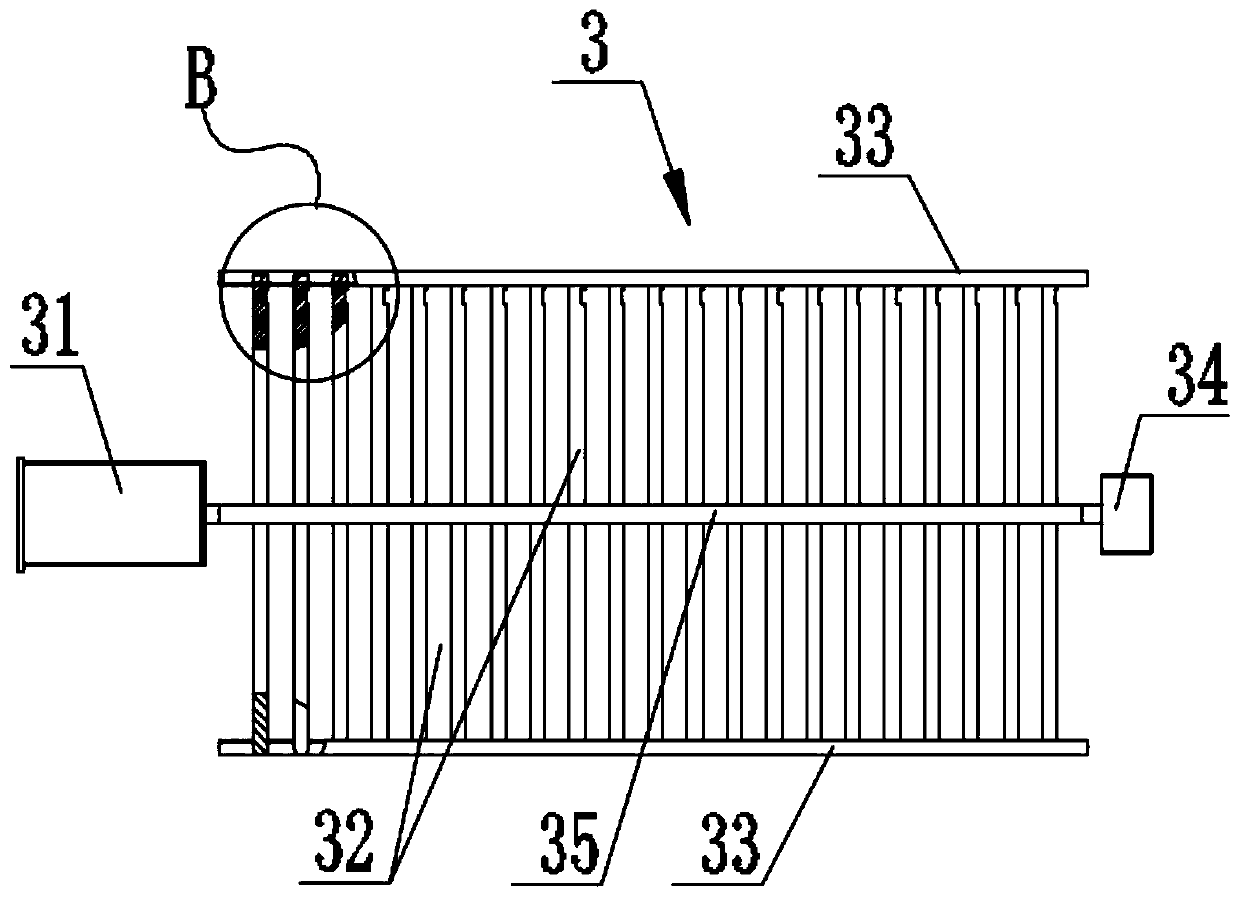

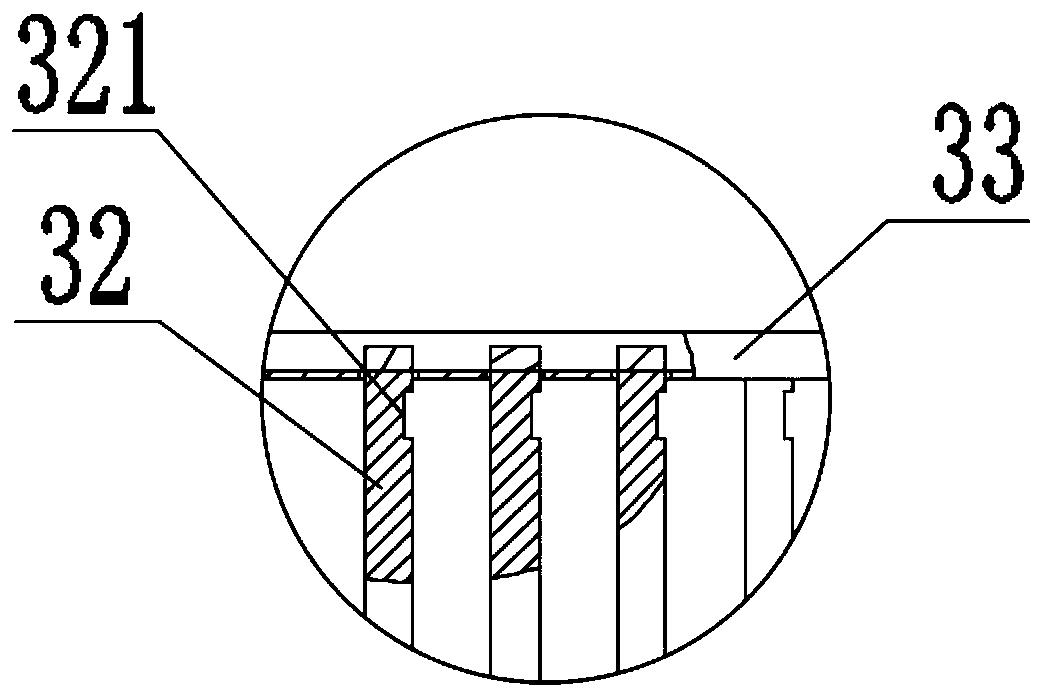

Boiler convection heating surface vibratory-hitting type deashing device and vibratory-hitting method

PendingCN111174224ACompact structureReasonable designSolid removalThermodynamicsMechanical engineering

The invention relates to a boiler convection heating surface vibratory-hitting type deashing device and a vibratory-hitting method. The boiler convection heating surface vibratory-hitting type deashing device comprises a vibratory-hitting bracket which is welded as an integrated frame structure; the middle part of the vibratory-hitting bracket comprises a bracket shaft; one end of the vibratory-hitting bracket is connected with a vibrating device; the bracket shaft is provided with a plurality of vertical rods in spaced manner in the axial direction; the plurality of vertical rods are symmetrically arranged by taking the bracket shaft as the axis; the tail ends of the vertical rods at each side are connected with a hanging rod; the hanging rods and the bracket shaft are arranged in parallel; the two hanging rods are used for hanging the vibratory-hitting bracket on a tube bundle of a heated surface of a boiler so that each vertical rod makes contact with the tube bundle of the heated surface of the boiler. According to the boiler convection heating surface vibratory-hitting type deashing device provided by the invention, the two ends of the vibratory-hitting bracket and a protective plate are directly sealed by adopting a housing structure by means of welding; the vibrating device, the vibratory-hitting bracket and the convection tube bundle are compactly combined together, sothe boiler convection heating surface vibratory-hitting type deashing device is compact in structure, reasonable in design, good in leakproofness, convenient to maintain, safe, reliable, long in service life, wide in application range, smaller in space usage and higher in automation degree.

Owner:上海工业锅炉(无锡)有限公司

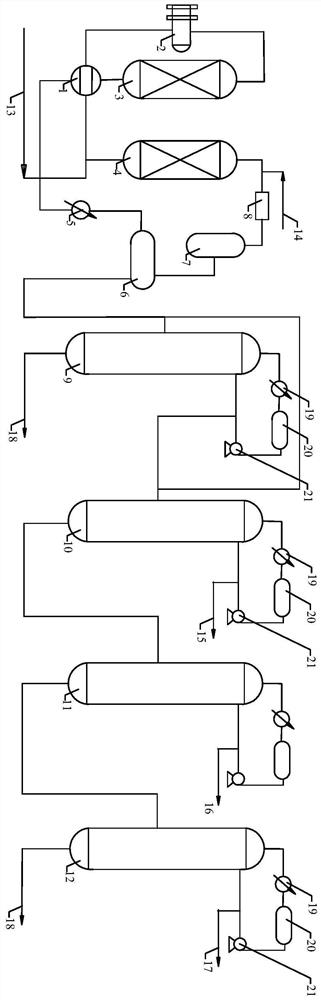

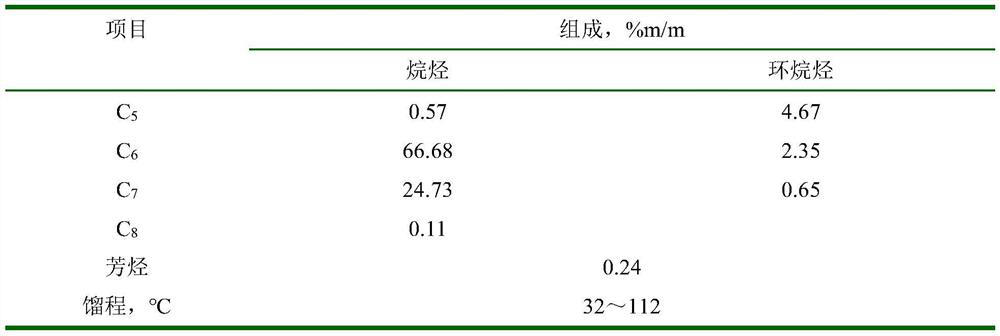

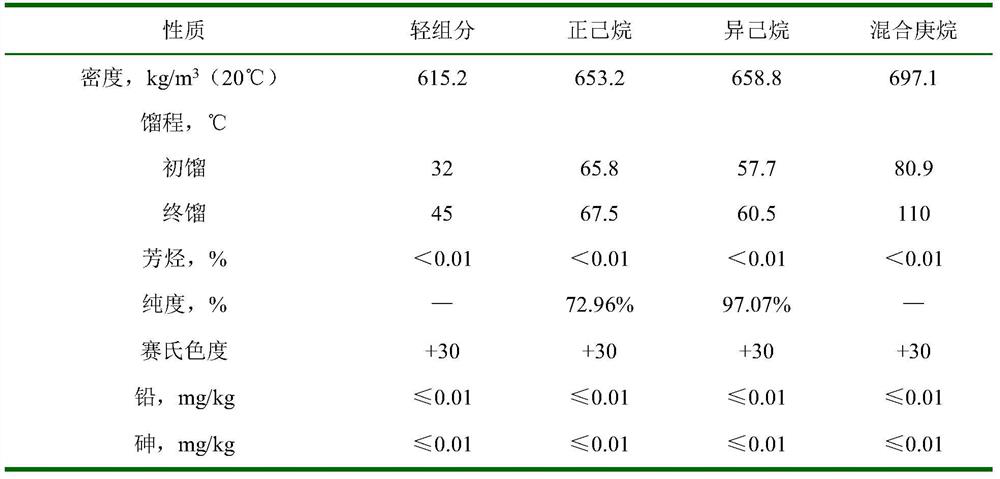

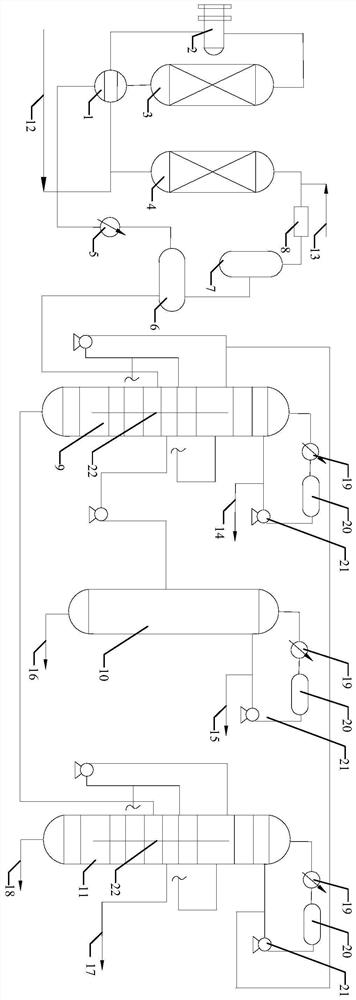

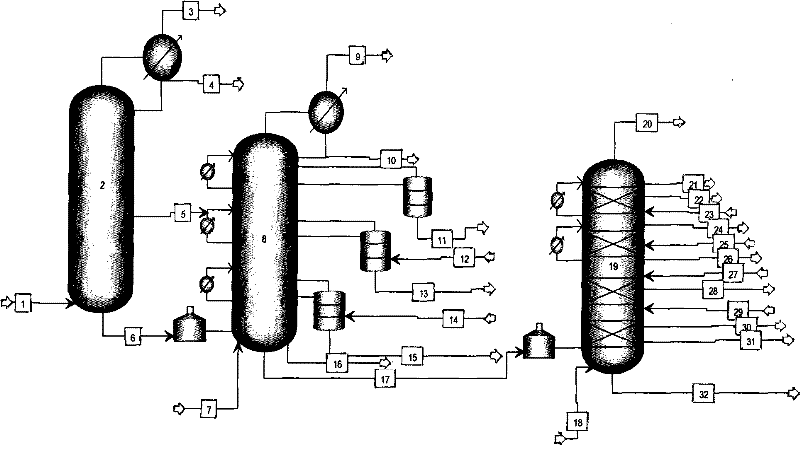

Method for producing n-hexane containing heptane raw material

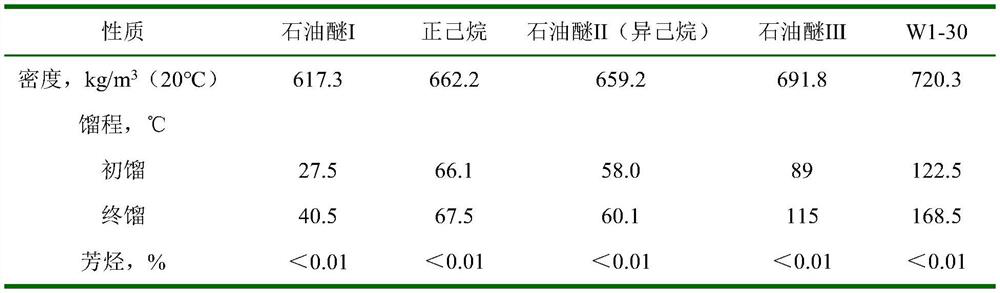

PendingCN112225633AWide distillation rangeHigh purityDistillation purification/separationCatalystsPtru catalystUnsaturated hydrocarbon

The invention relates to a method for producing n-hexane containing a heptane raw material, which comprises the following steps of fully mixing crude hexane with high heptane content with hydrogen, exchanging heat with a reaction product, heating to a reaction temperature by a heat exchanger, feeding into a hydrogenation reactor loaded with a catalyst, and performing hydrofining reaction under theaction of a hydrofining catalyst to remove aromatic hydrocarbon and unsaturated hydrocarbon in the raw material, carrying out gas-liquid separation on a product after the reaction through a low-pressure separator, and then feeding the product into a fractionation system for fine cutting, wherein the fractionation system comprises a heptane removal tower, a light component removal tower, an isohexane removal tower and an n-hexane removal tower which are connected in sequence, and after the reaction, enabling the product to enter a heptane removal tower to separate most heptane in the high-heptane-content crude hexane in a pre-fractionation manner, and then enter a light component removal tower, an isohexane removal tower and an n-hexane removal tower to finely cut the obtained mixed C6 component oil to obtain high-content n-hexane and isohexane products. The method provided by the invention can be used for obtaining high-purity isohexane, n-hexane products and heptane products.

Owner:洛阳金达石化有限责任公司

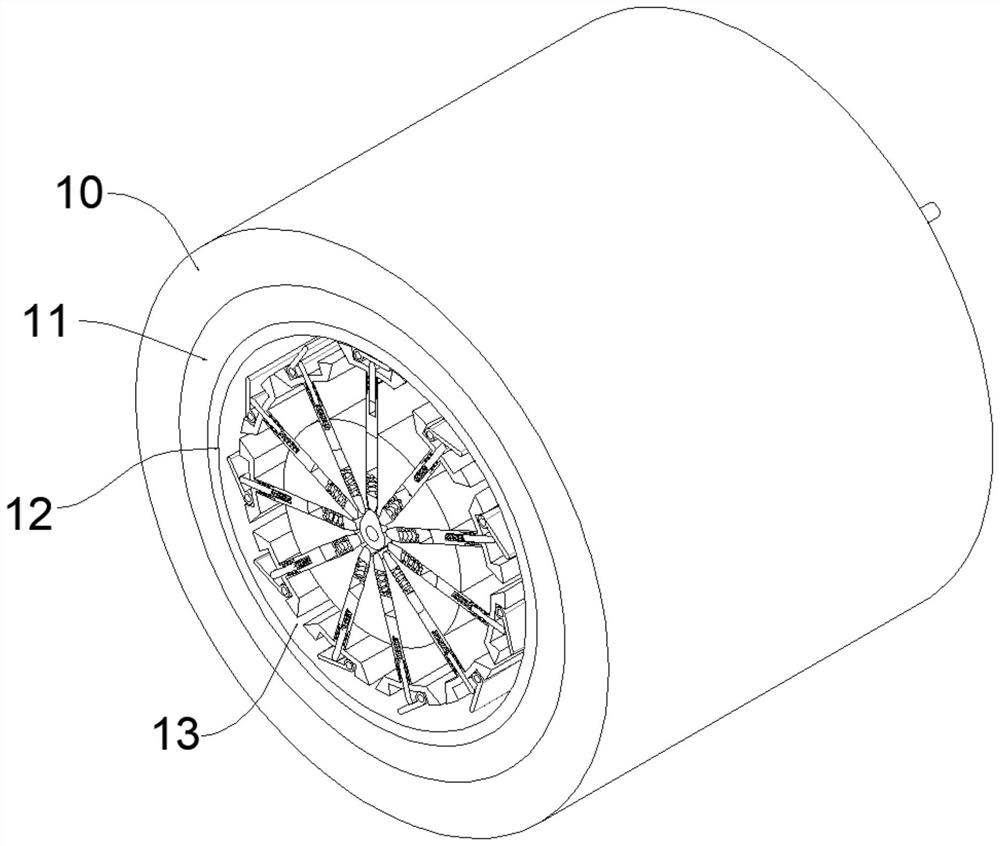

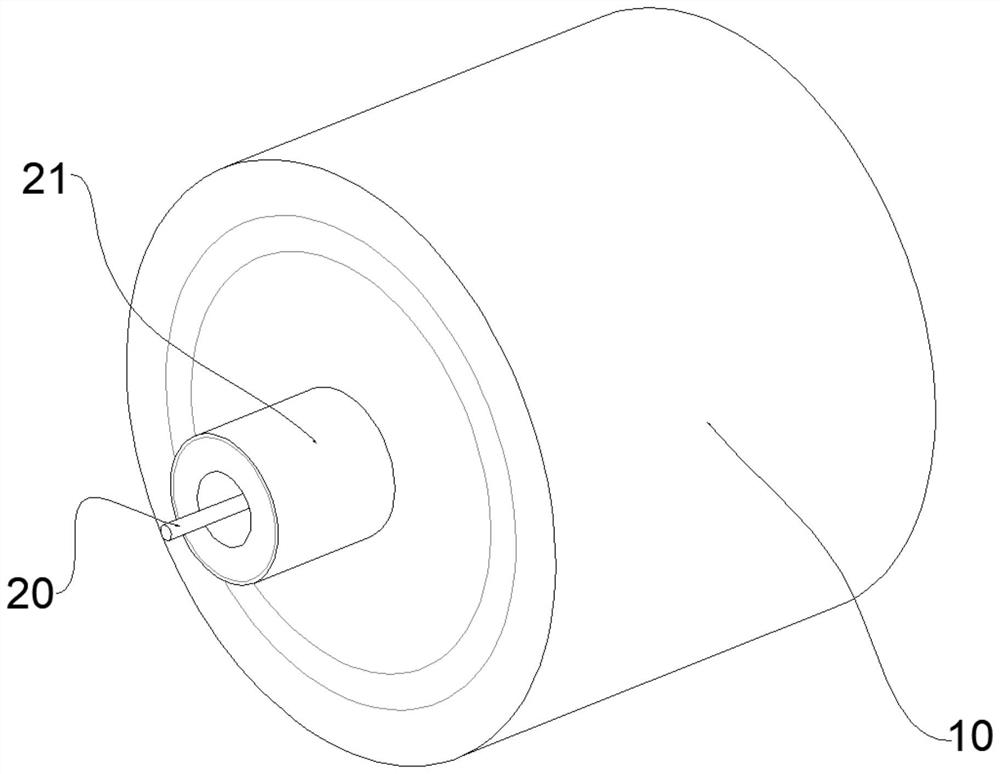

Flexographic printing equipment with high fitting degree and printing method

ActiveCN114571839AIncrease profitImprove printing qualityRotary letterpress machinesRelief printingLetterpress printingProcess engineering

The invention discloses flexographic printing equipment with high fitting degree and a printing method, and belongs to the field of flexographic printing equipment. The invention discloses high-fitting-degree flexographic printing equipment and a printing method. The high-fitting-degree flexographic printing equipment comprises a letterpress printing cylinder, a buffer layer, a supporting layer impact part, a roller core and a friction part. The letterpress printing cylinder, the buffer layer and the supporting layer are all cylindrical and are sequentially nested and fixedly arranged from outside to inside, a heating cavity is formed in the supporting layer, and the roller core is fixedly installed in the heating cavity in the axial direction of the supporting layer and coincides with the axis of the supporting layer. The letterpress printing cylinder is axially and rotatably mounted at the mounting position of the letterpress printing cylinder of the flexographic printing equipment, vibration is generated through impact of the impact plate and the supporting layer and is transmitted to the letterpress printing cylinder through the buffer layer, so that printing ink is quickly separated from the letterpress printing cylinder through slight vibration during printing of the letterpress printing cylinder, the utilization rate of the printing ink is increased, and the printing efficiency is improved. And meanwhile, the printing quality is improved.

Owner:HUBEI JINJIA PACKAGING CO LTD

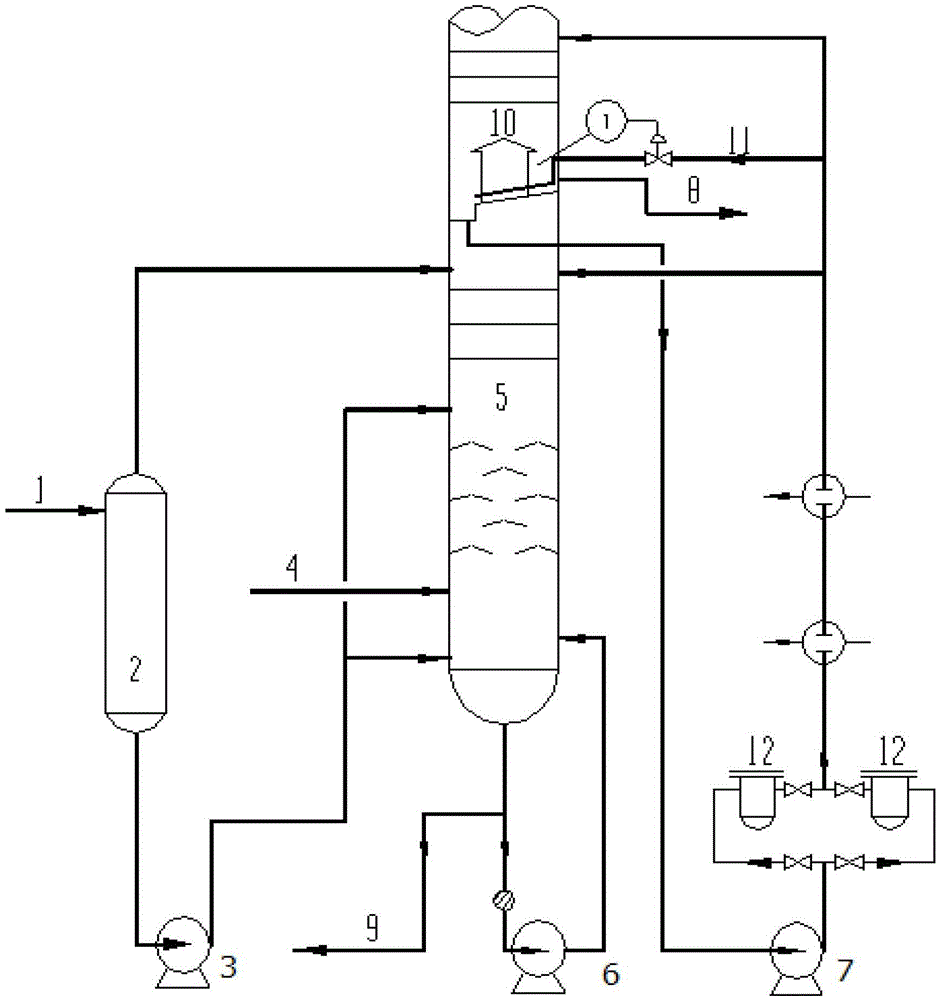

Method for preventing delayed coking fractionation tower high temperature section oil collection tank coking

The present invention relates to a method for preventing delayed coking fractionation tower high temperature section oil collection tank coking. According to the present invention, the bottom disk of the oil collection tank adopts an inclined design; a liquid collection tank is arranged on the lowest end; a circulation oil or wax oil cold reflux inlet pipeline is arranged on the highest end position of the inclined bottom disk, and is connected with a distributor inlet pipe; a distributor pipe and the distributor inlet pipe are vertically paved on the inclined bottom disk; the inclined bottom disk is provided with gas rise holes; a circulation oil or wax oil extraction pipeline is connected with a tank type filter; reaction oil gas enters the lower portion of a fractionation tower; the liquid collection tank is pumped out through a circulation oil or wax oil reflux oil pump; and after the coke powder-containing circulation oil or wax oil is filtered through the tank type filter to remove the carried coke powder, the obtained substance is divided into two parts to return to the coking fractionation tower, wherein the one part returns to the position below the oil collection tank, and the other part returns to the coking fractionation tower oil collection tank. With the method, high temperature coking is avoided, cleaning of the media in the tower is ensured, coking and coke powder deposition are effectively slowed down, and the oil collection tank coke powder deposition problem is solved.

Owner:PETROCHINA CO LTD +1

Preheating flow of high-temperature oil slurry pump

ActiveCN103982739AEliminate Wear HazardsReduce washoutPipe heating/coolingVena contracta diameterLine tubing

The invention relates to a preheating flow of a high-temperature oil slurry pump, and mainly solves the problems that a preheating pipeline and valves are flushed and abraded unavoidably and seriously since a preheating medium commonly contains a catalyst in the prior art, and once high-temperature oil slurry leaks, spontaneous ignition is quite easily caused. By using the preheating flow of the high-temperature oil slurry pump, the preheating medium is introduced from the preheating pipeline (18), passes through a preheating main valve (7) and then is divided into two paths; one path is sequentially connected with a gate valve (8), a restriction orifice plate (10), a root cutoff valve (9) and an oil slurry pump (14), and the other path is sequentially connected with a gate valve (11), a restriction orifice plate (13), a root cutoff valve (12) and an oil slurry pump (15). According to the technical scheme, the problems are better solved. The preheating flow of the high-temperature oil slurry pump can be used for preheating the high-temperature oil slurry pump.

Owner:CHINA PETROLEUM & CHEM CORP QINGDAO RES INST OF SAFETY ENG +1

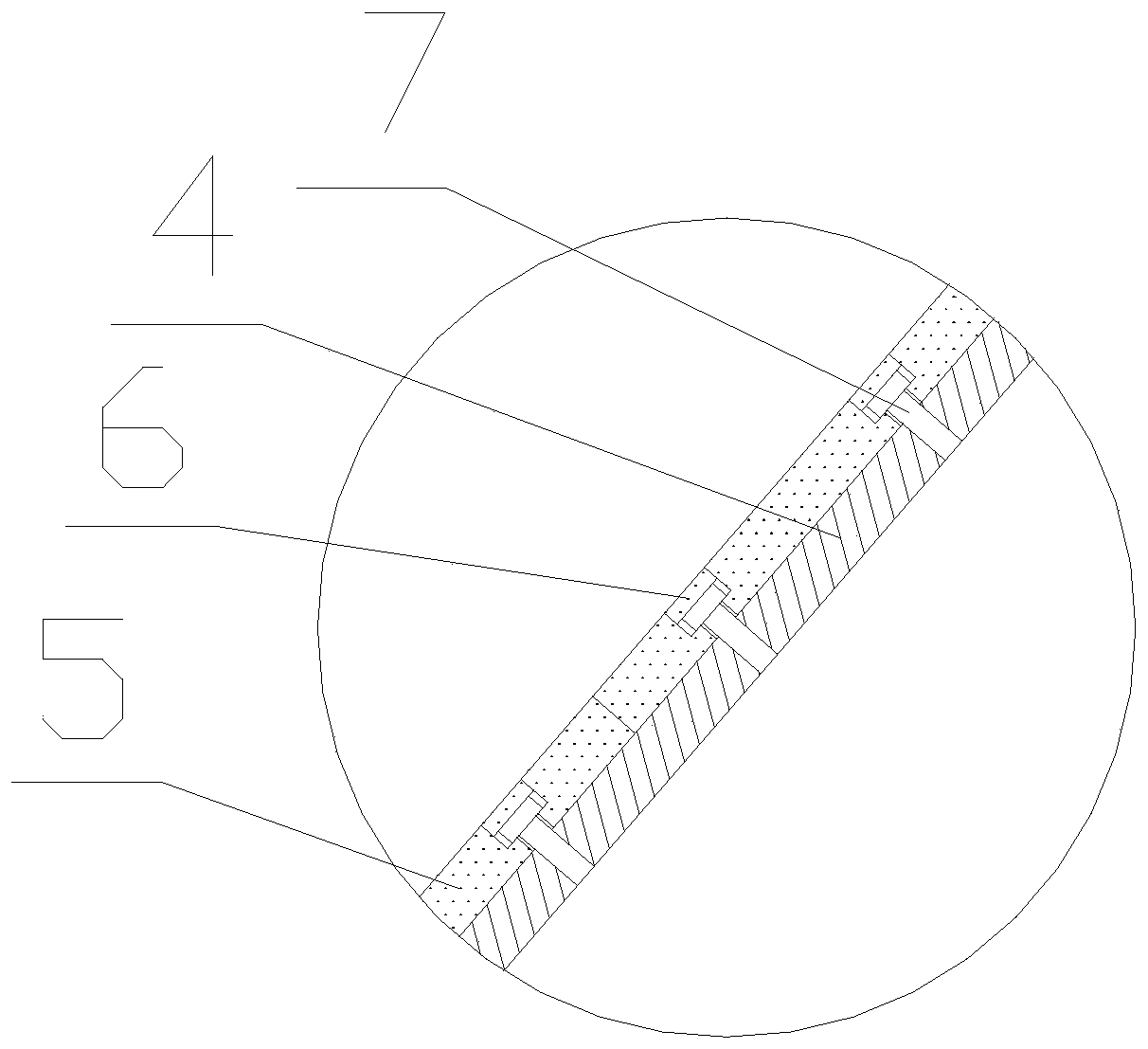

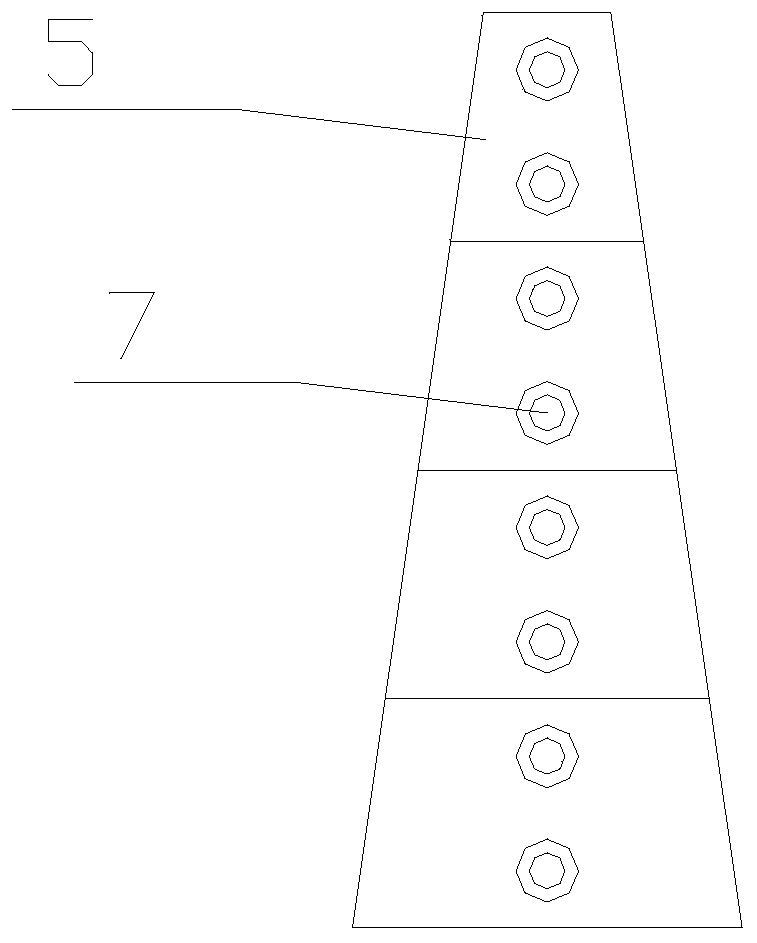

Blast furnace charging bucket material receiving and distribution device

PendingCN111172341AEvenly distributedImprove buffering effectBell-and-hopper arrangementEngineeringStructural engineering

The invention relates to a blast furnace charging bucket material receiving and distribution device. The blast furnace charging bucket material receiving and distribution device comprises a charging bucket center vertical column, a base plate, a base plate ceramic liner plate and a frustum of a regular pyramid; the base plate is fixed to the charging bucket center vertical column; the bottom of the frustum of the regular pyramid is fixed into the base plate, and the periphery of the base plate is provided with a baffle; the base plate ceramic liner plate is fixed to the baffle, and a groove isformed between the baffle and the frustum of the regular pyramid; frustum of the regular pyramid is in a big end down shape, the top surface of the frustum of the regular pyramid is provided with a polygonal ceramic liner plate adapting to the top surface of the frustum of the regular pyramid; the side surfaces of the frustum of the regular pyramid are provided with trapezoidal ceramic liner plates; and the trapezoidal ceramic liner plates and the polygonal ceramic liner plate are fixed to the frustum of the regular pyramid through a plurality of fastening bolts, and a ceramic buckle is fixedto the top of each fastening bolt. The blast furnace charging bucket material receiving and distribution device has the advantages of being resistant to impact during material receiving, good in buffering effect, high in abrasion resistance, uniform in material distribution, small in vulnerable part type during repairing, easy and fast to maintain and the like, the defects that a charging bucketlinear plate is fast in abrasion, short in service life and the like due to the fact that an original structure is uneven in material distribution are effectively overcome, and the blast furnace long-time operation requirement is met.

Owner:LAIWU IRON & STEEL GRP

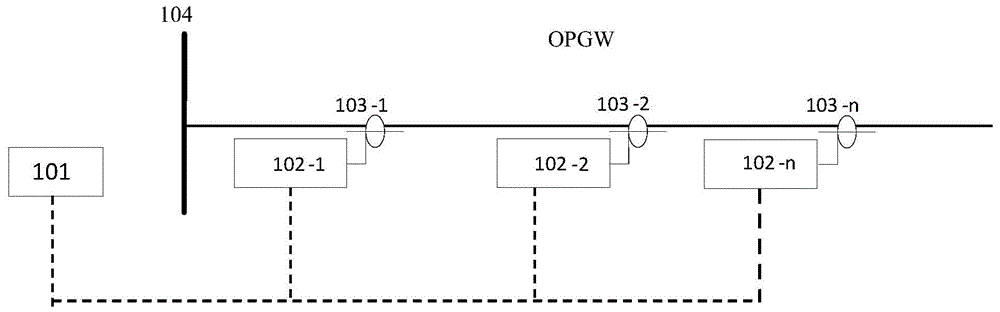

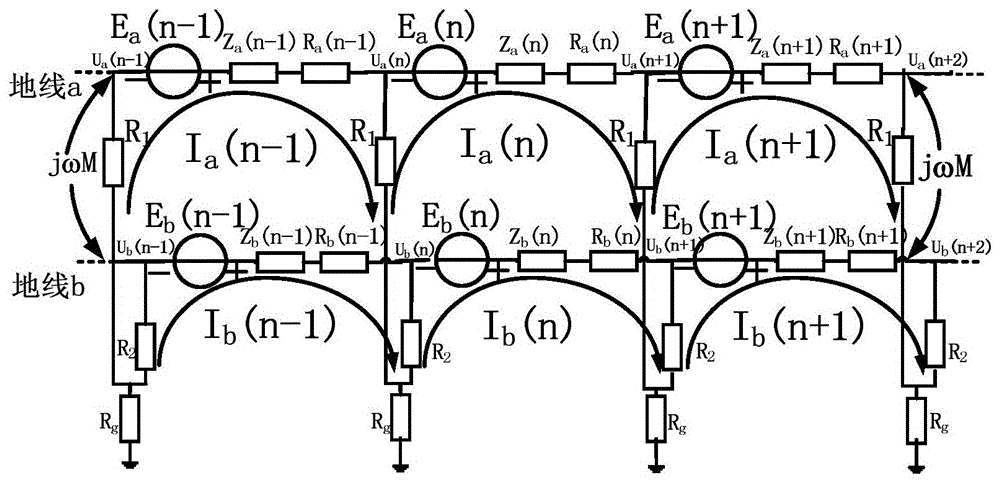

Full-line monitoring and diagnosis system and method for opgw line

ActiveCN103941138BReal-time monitoring of operating conditionsAlarm in timeThermometer detailsElectrical testingDiagnosis methodsMaster station

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING) +1

Method for preventing delayed coking fractionation tower high temperature section oil collection tank coking

The present invention relates to a method for preventing delayed coking fractionation tower high temperature section oil collection tank coking. According to the present invention, the bottom disk of the oil collection tank adopts an inclined design; a liquid collection tank is arranged on the lowest end; a circulation oil or wax oil cold reflux inlet pipeline is arranged on the highest end position of the inclined bottom disk, and is connected with a distributor inlet pipe; a distributor pipe and the distributor inlet pipe are vertically paved on the inclined bottom disk; the inclined bottom disk is provided with gas rise holes; a circulation oil or wax oil extraction pipeline is connected with a tank type filter; reaction oil gas enters the lower portion of a fractionation tower; the liquid collection tank is pumped out through a circulation oil or wax oil reflux oil pump; and after the coke powder-containing circulation oil or wax oil is filtered through the tank type filter to remove the carried coke powder, the obtained substance is divided into two parts to return to the coking fractionation tower, wherein the one part returns to the position below the oil collection tank, and the other part returns to the coking fractionation tower oil collection tank. With the method, high temperature coking is avoided, cleaning of the media in the tower is ensured, coking and coke powder deposition are effectively slowed down, and the oil collection tank coke powder deposition problem is solved.

Owner:PETROCHINA CO LTD +1

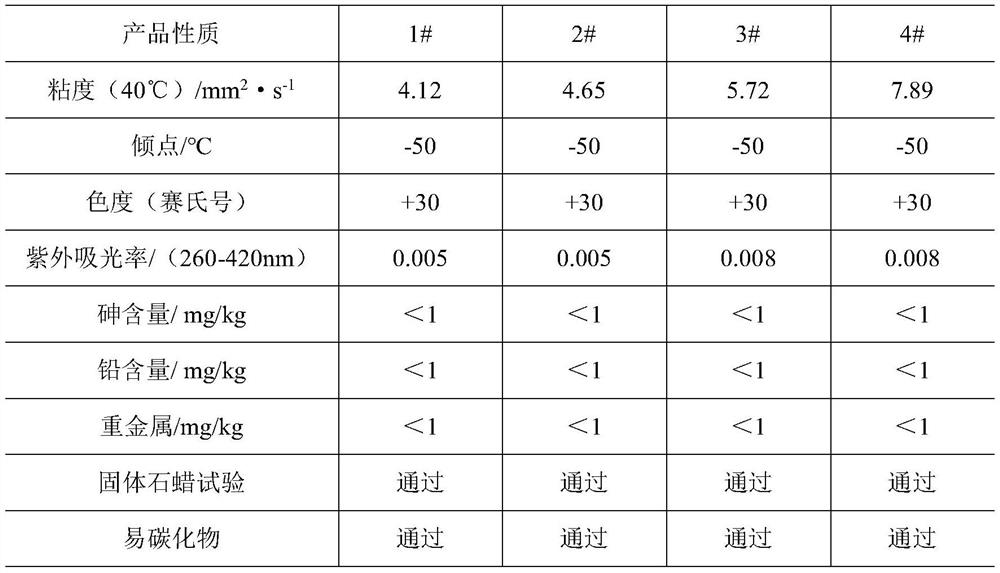

Production method of veterinary vaccine white oil adjuvant

PendingCN113278444AWide distillation rangeWide range of applicationsTreatment with hydrotreatment processesHydrocarbon oils treatment productsMineral oilBiomedical engineering

The invention provides a production method of a veterinary vaccine white oil adjuvant. The method comprises the following steps: 1) heating mineral oil as a raw material, adding the mineral oil into a first reactor, reacting with a hydrodesulfurization catalyst I to obtain a reaction product A, adding into a second reactor to react with a hydrogenation dearomatization catalyst II, and carrying out hydrogenation dearomatization and hydrogenation saturation reaction to obtain a reaction product B; 2) carrying out gas-liquid separation on the reaction product B in the step 1), heating, adding into a third reactor, carrying out hydroisomerization reaction with a hydroisomerization catalyst III, cooling a reaction product C, feeding into a fourth reactor, reacting with a hydrogenation saturation refining catalyst IV for hydrofinishing, and removing unsaturated hydrocarbon in the reaction product C to obtain a reaction product D; and 3) feeding the reaction product D obtained in the step 2) into a fractionation system for product cutting to obtain the veterinary vaccine white oil adjuvants with different viscosities. The veterinary vaccine white oil adjuvant has the advantages of being high in stability, good in animal absorbability, small in animal stress reaction, good in safety and continuous and stable in vaccine antibody.

Owner:牛同治

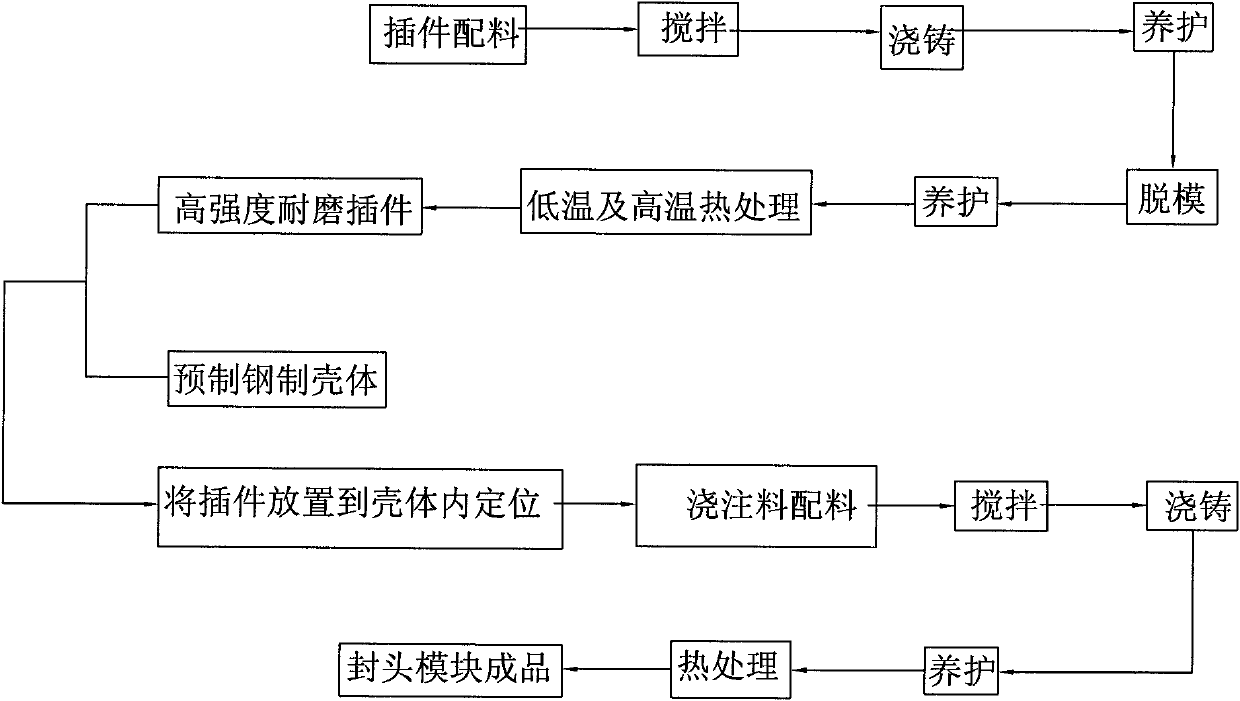

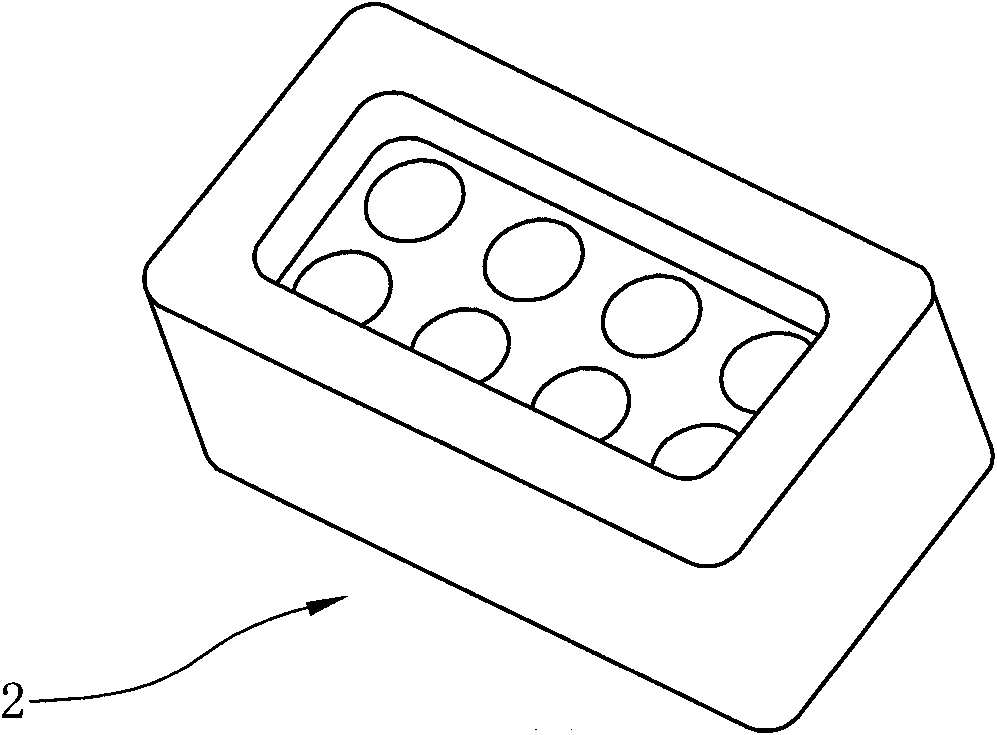

Manufacturing method for end socket module of quenching heat exchanger

ActiveCN102410771BMeet the requirements of long-term operationImprove performance indicatorsCeramic shaping apparatusHeat exchanger casingsPlate heat exchangerFilling materials

The invention relates to a manufacturing method for an end socket module of a quenching heat exchanger. The manufacturing method comprises the following steps: A) prefabricating a steel shell of the end socket module of the quenching heat exchanger; B) utilizing specially researched formula and technology to prefabricate a plug-in piece of the end socket module of the quenching heat exchanger; C) preparing filling materials according to the specially researched formula, uniformly stirring the filling materials, and then pouring the filling materials into a clearance between the shell and the plug-in piece; and D) performing heat treatment on the end socket poured with the filling materials according to the special technology, thereby acquiring the end socket module of the quenching heat exchanger provided by the invention. Compared with the prior art, the end socket module of the quenching heat exchanger which is prepared according to the manufacturing method provided by the invention has the advantages that all items of performance indexes are greatly promoted, the performance is more stable, the service life is more than 2 times of the service life of the end socket module in the prior art, and the demand on the long periodic running of the quenching heat exchanger is met.

Owner:CHINA PETROLEUM & CHEM CORP +2

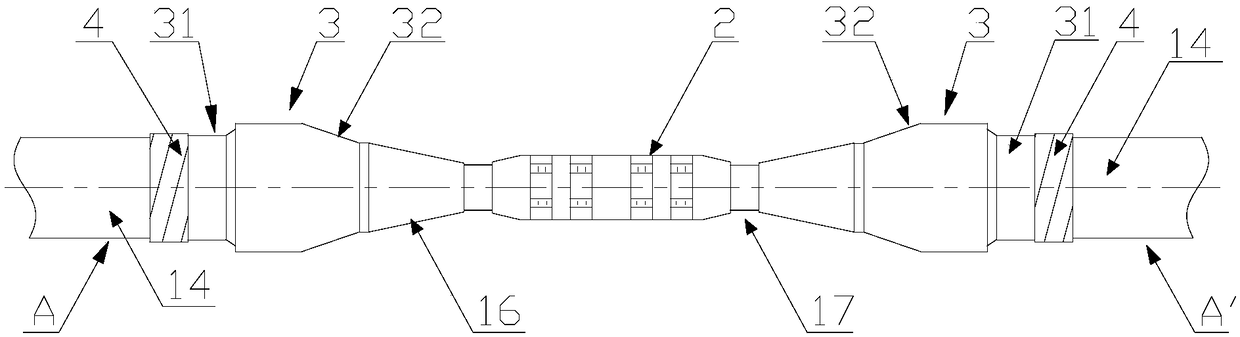

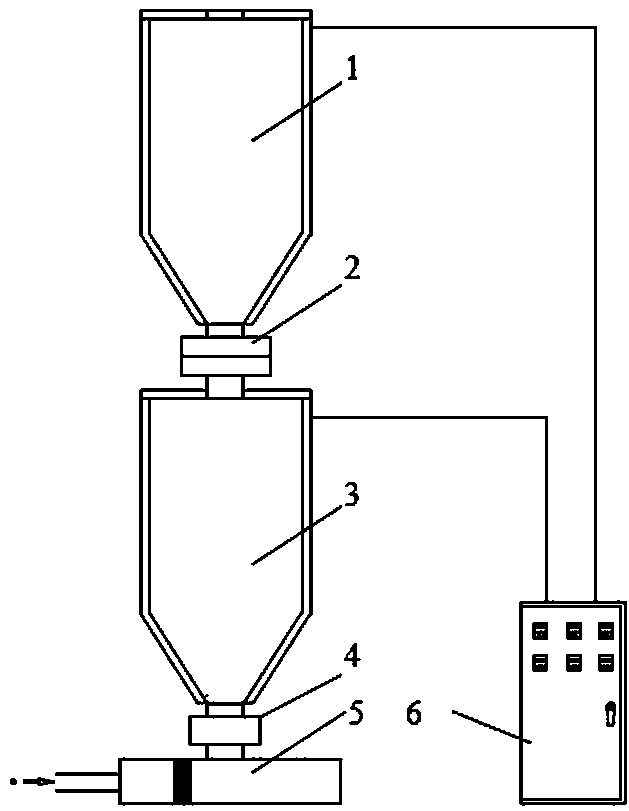

A method and device for treating crosslinking agent for high-voltage ultra-high-voltage ultra-clean insulating materials

Provided are a method and device for processing DCP of a high to ultrahigh voltage and ultra-clean insulating material. The method includes the following steps that (1) liquid is heated to melt, (2) deal-load filtering and storage are conducted, and (3) metering and gas shield injection are conducted jointly. The invention further discloses the device included in the method. The device comprises a melting tank, a filtering device, a storage tank, a metering device and a gas injection device, wherein the lower end of the melting tank is in threaded connection with the filtering device in a sealed mode; the storage tank is in sealed connection with the lower end of the filtering device; the metering device and the gas injection device are tightly connected into a whole; and the outer layers of the filtering device, the melting tank and the storage tank are provided with constant-temperature hoods with the temperature controlled by a temperature controller. The method and device can guarantee the dispersion uniformity and crosslinking stability of crosslinked polyethylene, improve the high electric field resistance of crosslinked polyethylene, meet the use demand for long-term operation of ultrahigh voltage cables, make DCP permeate into polyethylene particles by over 80%, and finally obtain crosslinked polyethylene ultra-clean materials meeting the condition to manufacture high to ultrahigh voltage cables.

Owner:QINGDAO HANHE CABLE

A kind of continuous production process of p-tert-butyltoluene

ActiveCN103274890BHigh activityImprove thermal stabilityMolecular sieve catalystsHydrocarbon by hydrocarbon and non-hydrocarbon condensationFixed bedTert butyl

The invention relates to a continuous production process of p-tert-butyl toluene, and in particular relates to a method for synthetizing the p-tert-butyl toluene through catalyzing toluene and tert butyl alcohol by using a metallic oxide-supported molecular sieve catalyst. The invention aims to overcome the shortcomings that catalysts corrode equipment, pollute the environment and are difficult to separate and incapable of being recycled and the like in traditional methods for synthetizing the p-tert-butyl toluene through liquid acid catalysis. The continuous production process of the p-tert-butyl toluene comprises the following steps of (1) preparation of the metallic oxide-supported molecular sieve catalyst and (2) synthetic reaction of the p-tert-butyl toluene. The process disclosed by the invention has the advantages of simpleness, environmental friendliness, low labour intensity and low production cost; by adopting the homemade metallic oxide-supported molecular sieve catalyst, the problems that the liquid acid catalysts corrode equipment and pollute the environment in the traditional production methods are solved; and in the meantime, the homemade catalyst is high in activity, good in heat stability, high in mechanical strength and capable of meeting the requirements of long-period operation in the continuous production process of fixed beds.

Owner:FAREAST KINGSTAR CHEM

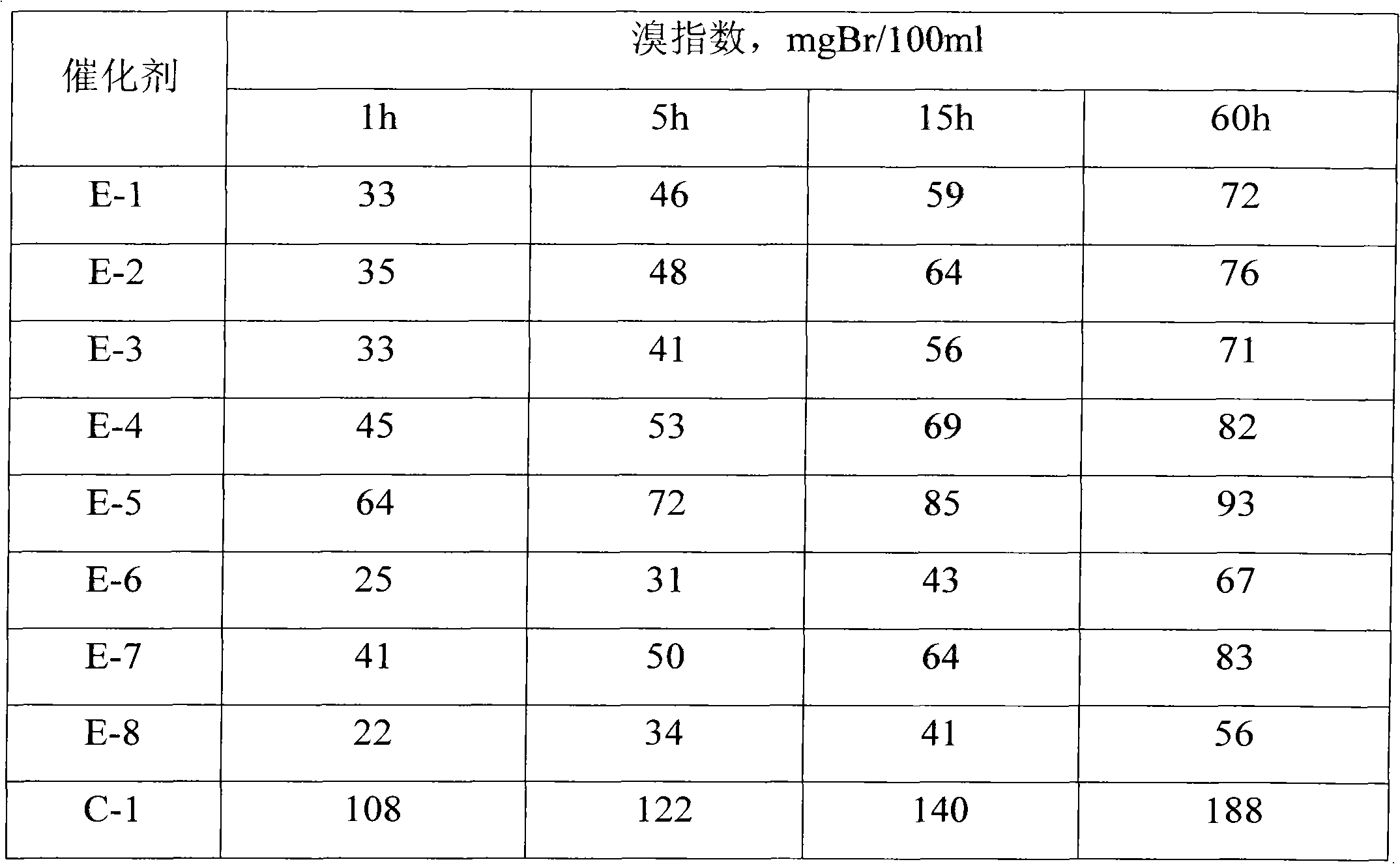

Refined triphenyl fraction catalyst and preparation method and application thereof

ActiveCN102309976BEfficient removalHigh aromatic contentMolecular sieve catalystsMolecular sieveHydrogen

The invention relates to a refined triphenyl fraction catalyst and a preparation method thereof and application of the catalyst to the process of catalyzing and refining triphenyl fraction under the non-hydrogen condition. The catalyst consists of a rare earth modified molecular sieve and halogen modified inorganic refractory oxide and is used for carrying out catalytic treatment on the triphenylfraction. Micro olefins in the triphenyl fraction can be effectively removed. The content of arenes is slightly increased. The catalyst has high activity and stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

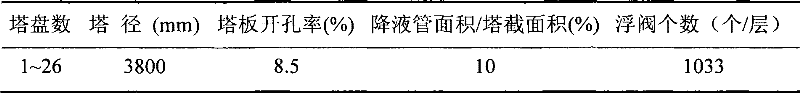

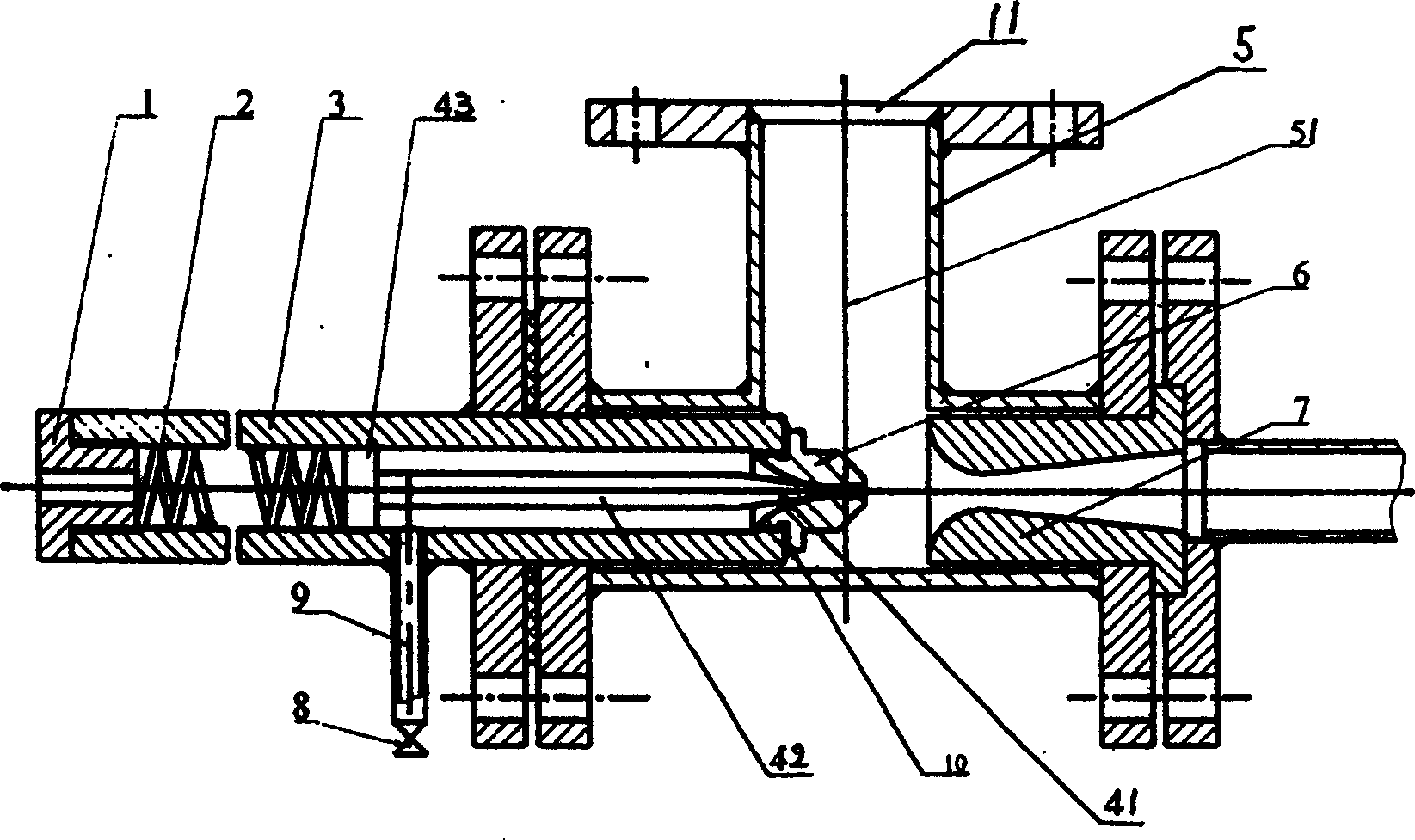

Fine processing method of crude hexane

ActiveCN112403013AGood activity at low temperatureImprove stabilityTreatment with hydrotreatment processesFractional distillationPtru catalystUnsaturated hydrocarbon

The invention relates to a fine processing method of crude hexane, which comprises the following steps of: fully mixing the raw material crude hexane with hydrogen, carrying out heat exchange with thereaction product, heating to 130-190 DEG C by a heat exchanger, introducing the mixture into a catalyst-loaded hydrogenation reactor, and carrying out hydrofining reaction under the action of a hydrofining catalyst to remove aromatic hydrocarbons and unsaturated hydrocarbons in the raw material; carrying out gas-liquid separation on a product after reaction through a low-pressure separator, and then feeding the product into a fractionation system for fine cutting; enabling the reaction product to firstly enter a first partition plate tower of the fractionation system to be separated, discharging a petroleum ether I product from the tower top, discharging mixed C6 from the side line, and then enabling the mixed C6 to enter an n-hexane removal tower to be further cut to obtain petroleum ether II and n-hexane products; and conveying a tower bottom product of the first partition plate tower to a second partition plate tower to be separated to obtain petroleum ether III and W1-30 products.The method has the advantages that a high-quality hexane product can be obtained, the byproduct utilization rate is increased, and the economic benefit is improved.

Owner:洛阳金达石化有限责任公司

Atmospheric vacuum distillation process for light crude oil

InactiveCN101475826BEasy to separateMain product quality assuranceVacuum distillationParaffin waxNaphtha

The invention discloses a process for performing normal vacuum distillation on light crude oil, which comprises the step of cutting the light crude oil into various oil distillates after forerunning, atmospheric distillation and vacuum distillation, wherein in the forerunning process, the feed temperature of a primary tower is controlled between 235 and 247 DEG C; and in the atmospheric distillation, the load of a normal primary reboiler is controlled between 1.8 and 2.1 MMkal / hr, the secondary steam stripping steam quantity is controlled between 525 and 575 Kg / hr, and the heat removal ratio of the tower top to the top circulation to the first middle part to the second middle part of an atmospheric column is equal to 1:2.2-2.5:3.2-4.2 : 4.6-5.2. The process can meet the requirements on processing the mixed raw oil containing a lot of light oil, in particular the mixed raw oil of which the yield of distillate oil is not less than 52 percent of that of the light oil before the temperature reaches 360 DEG C. The upper separation effect of the atmospheric column becomes good, and the quality of the main product is guaranteed. The processing quantity of the crude oil can reach 7.50 to 8.50 million tons per year, the yield of naphtha is not less than 1.00 million ton per year, and the yield of wax is at least 0.18 million ton per year. The main devices are not changed to save the investment greatly. In the process of adjustment, the work is not necessary to be stopped so that the process has the characteristic of easy operation, and can meet the requirement on long period of running.

Owner:EAST CHINA UNIV OF SCI & TECH

Air volume adjustable air control powder feeder

InactiveCN1207103CMeet the requirements of long-term operationOvercome the shortcomings of discontinuous powder feeding by mechanical controlBulk conveyorsLiquid spraying apparatusAir volumeContinuous operation

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Sorting Method of Separation Media in Fluidized Bed Separator

ActiveCN107512787BFast filtrationReduce dosageWater/sewage treatment by centrifugal separationTreatment involving filtrationCycloneFluidized bed

The disclosure relates to a separation medium sorting method in an ebullated bed separator, the method comprising: setting a cyclone on the upper part of the ebullated bed separator, during regeneration, the separation medium in the filter bed of the ebullated bed separator is in a fully fluidized state, The separation medium enters the cyclone upwards. After being sorted by the cyclone, it flows out of the cyclone in descending order according to the specific gravity. After the backwash regeneration is completed, it continues to be used for the purification of process water generated in the MTO process. Among them, the ebullated bed separator The filter bed is composed of multiple layers of different separation media, the particle size distribution of the separation media decreases layer by layer downward, and the specific gravity of the separation media increases layer by layer downward.

Owner:SHANGHAI HUACHANG ENVIRONMENT PROTECTION

A method for producing food-grade white oil by extracting oil under normal and reduced pressure

ActiveCN104910963BWide distillation rangeExtended service lifeTreatment with hydrotreatment processesIsomerizationVacuum extraction

The invention discloses a method for producing food-grade white oil with atmospheric-vacuum extraction oil. According to the invention, the raw material atmospheric-vacuum extraction oil is heated; the oil is delivered into two serially connected reactors respectively loaded with a catalyst I and a catalyst II, and contacts the catalysts; under the effect of a hydro-refining catalyst, a hydro-treating reaction is carried out, and de-S, de-N and aromatic saturation reactions are carried out; a refined product is subjected to gas-liquid separation, stripping and fractionation, such that produced H2S is removed; a component with a boiling point higher than 230 DEG C is cut from a distillate, and is adopted as a feed of an isomerization dewaxing reaction; the isomerization dewaxing reaction is carried out with a catalyst III; an oil product produced through the isomerization dewaxing reaction is cooled, and is subjected to a hydro-finishing reaction with a catalyst IV; an oil product obtained after the reaction is subjected to product cutting in a fractionation system, such that the food-grade white oil with an aromatic hydrocarbon content lower than 0.01% w / w, a sulfur content lower than 1ppm, and a solidifying point lower than -30 DEG C is obtained.

Owner:洛阳金达石化有限责任公司

Treatment method of high-copper circuit board wastewater based on gradient functional anode electrolysis

ActiveCN105540948BEfficient removalReduce concentrationSpecific water treatment objectivesTreatment involving filtrationReverse osmosisSlurry

The invention provides a gradient functional anodic electrolysis based treatment method for high-copper circuit board wastewater. The method comprises the steps: (1) electrolyzing the high-copper wastewater in a gradient functional anodic electrolytic bath; (2) enabling electrolyzed wastewater to enter an induced-crystallization precipitation tank, wherein a filter material is placed in the precipitation tank, and the high-copper wastewater is subjected to induced crystallization in the presence of a precipitant; and (3) enabling effluent, obtained after the induced crystallization, to enter a reverse osmosis procedure. According to the method provided by the invention, gradient functional anodic electrolysis and induced-crystallization precipitation procedures play a role in recovering copper ions; a product of electrolysis, i.e., ultrafine copper powder can be used for preparing base-metal slurry, and the added value is high; and the electrolytic process has a remarkable removing effect on organic substances, and the concentration of the organic substances entering reverse osmosis can be relatively low in light of the induced crystallization in the step (2), so that the requirements of reverse osmosis on long run are met. Copper is recovered, and the wastewater is purified, so that recycling requirements are met.

Owner:BEIJING GUOHUAN TSINGHUA ENVIRONMENT ENG DESIGN & RES INST CO LTD BEIJING CHINA

Method for prefabricating wrapping joint

PendingCN111431007AGood electrical performanceGuaranteed uptimeContact member assembly/disassemblyDustproof/splashproof/drip-proof/waterproof/flameproof connectionElectrical connectionEngineering

The invention discloses a method for prefabricating a wrapping joint. Stripping the metal shielding layer and the insulating outer shielding layer; stripping and cutting the main insulating layer andexposing a cable core, wherein the metal shielding layer and the insulating outer shielding layer are wrapped with semiconductors; the main insulating layer is sleeved with a prefabricated stress cone; a cable core of the cable is crimped through a copper connecting pipe; the copper connecting pipe is wrapped with a semiconductive belt; the outer side of the structure is sequentially wrapped withan insulating belt, a semiconductive belt, a copper net, a PVC belt and a waterproof belt, and connection of the cables at the two ends is completed. Electrical connection between cables at the two ends can be achieved, and the electrical performance, stability and reliability of the connector cable are improved.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +1

Pretreatment method for ammonia-containing high hardness wastewater

InactiveCN110104824AReduce the total hardness indexReduce consumptionWater/sewage treatment by centrifugal separationWater contaminantsPretreatment methodSludge

The invention relates to a pretreatment method for ammonia-containing high hardness wastewater. The method is characterized in that two inlets of a static mixer are respectively connected with a wastewater pipeline and a Na2CO3 solution conveying pipeline, the outlet of the static mixer is connected with a separator, the bottom outlet of the separator is connected with a sludge discharge pipeline,and the top outlet of the separator is connected with the inlet of a settling tank; a first settling trough and a second settling trough are arranged in the settling tank side by side, the bottom outlet of the first settling trough is connected with the sludge discharge pipe, and two inlets of the first settling trough are respectively connected with an alkali lye conveying pipeline and a reagentconveying pipeline; the bottom outlet of the second settling trough is connected with the sludge discharge pipeline; the top outlet of the second settling trough is connected with an ammonia washingtower, and the top inlet of the second settling trough is connected with the discharge port of the ammonia washing tower; the washing liquid inlet of the ammonia washing tower is connected with a first return pipeline, and the first return pipeline is connected with the qualified wastewater discharge port of a stripping system; and the outlet of the stripping system is connected with the first return pipeline and a biochemical treatment device.

Owner:SINOPEC NINGBO ENG +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com