A method and device for treating crosslinking agent for high-voltage ultra-high-voltage ultra-clean insulating materials

A technology of insulating material and treatment method, which is applied in the melt filtration treatment of cross-linking agent (DCP), and the gas is sprayed into the field of atomization, which can solve the problems of decomposition, uneven heating distribution, and need to import, and achieve the effect of ensuring accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

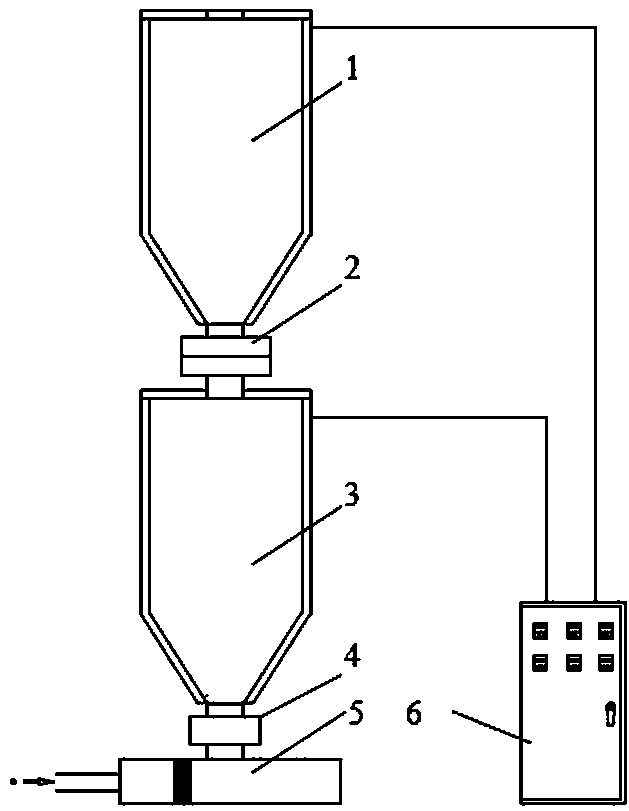

[0029] Such as figure 1 As shown, taking the process of melting, filtering, atomizing and adsorbing polyethylene for the crosslinking agent used in the manufacture of 500kV ultra-high voltage ultra-clean insulating materials as an example, the specific process is as follows:

[0030] Add the cross-linking agent (DCP) at normal temperature into the melting tank 1, heat the melting tank 1 to 38°C through the temperature controller 6 to melt the cross-linking agent, and keep the temperature. Flow through the filter device 2 under the action, place 2 layers of 400 mesh filter screens in the filter device 2, and the crosslinking agent after melting flows into the storage device 3 through the filter device 2. At this time, it is an ultra-clean crosslinking agent. The ambient temperature is consistent with the temperature of the outer melting tank 1, and is controlled by the temperature controller 6. The self-weight of the molten ultra-clean crosslinking agent flows into the metering d...

Embodiment 2

[0032] Such as figure 1 As shown, the process for producing 500kV ultra-high voltage ultra-clean insulating material cross-linking agent melt filtration atomization adsorption polyethylene is as follows:

[0033] Add the cross-linking agent (DCP) at normal temperature into the melting tank 1, heat the melting tank 1 to 39°C through the temperature controller 6 to melt the cross-linking agent, and keep the temperature. Flow through the filter device 2 under the action, place 3 layers of 500 mesh filter screens in the filter device 2, and the crosslinking agent after melting flows into the storage device 3 through the filter device 2. At this time, it is an ultra-clean crosslinking agent. The ambient temperature is consistent with the temperature of the outer melting tank 1, and is controlled by the temperature controller 6. The self-weight of the molten ultra-clean crosslinking agent flows into the metering device 4 for metering, and weighs according to the ratio of adding 2 pa...

Embodiment 3

[0035] Such as figure 1 As shown, the process for producing 500kV ultra-high voltage ultra-clean insulating material cross-linking agent melt filtration atomization adsorption polyethylene is as follows:

[0036] Add the cross-linking agent (DCP) at normal temperature into the melting tank 1, heat the melting tank 1 to 40°C through the temperature controller 6 to melt the cross-linking agent, and keep the temperature. Flow through the filter device 2 under the action, place 4 layers of 600 mesh filter screens in the filter device 2, and the crosslinking agent after melting flows into the storage device 3 through the filter device 2. At this time, it is an ultra-clean crosslinking agent. The ambient temperature is consistent with the temperature of the outer melting tank 1, and is controlled by the temperature controller 6. The self-weight of the molten ultra-clean crosslinking agent flows into the metering device 4 for metering, and weighs according to the ratio of adding 2 pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com