Method for producing food-grade white oil with atmospheric-vacuum extraction oil

A technology for extracting oil under normal and reduced pressure, which is applied in the petroleum industry, hydrocarbon oil treatment, hydrotreating process, etc. It can solve the problems of poor sulfur resistance performance, high production cost, and high reaction temperature of supplementary refined catalysts, and reduce equipment costs. Requirements, extended service life, low reaction temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

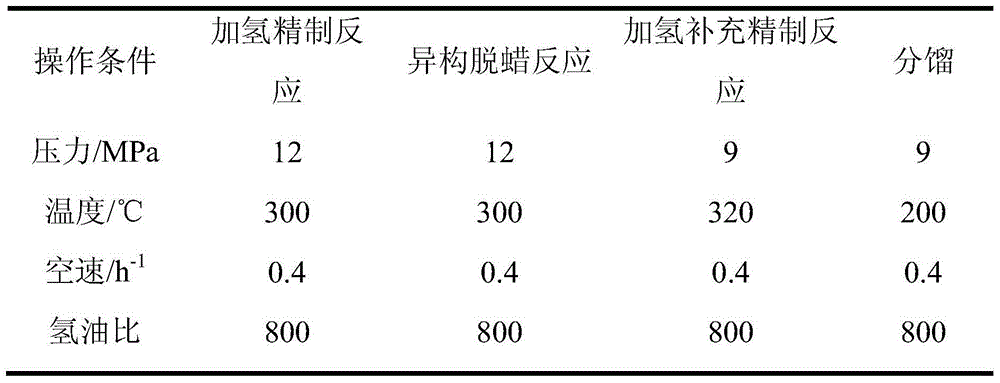

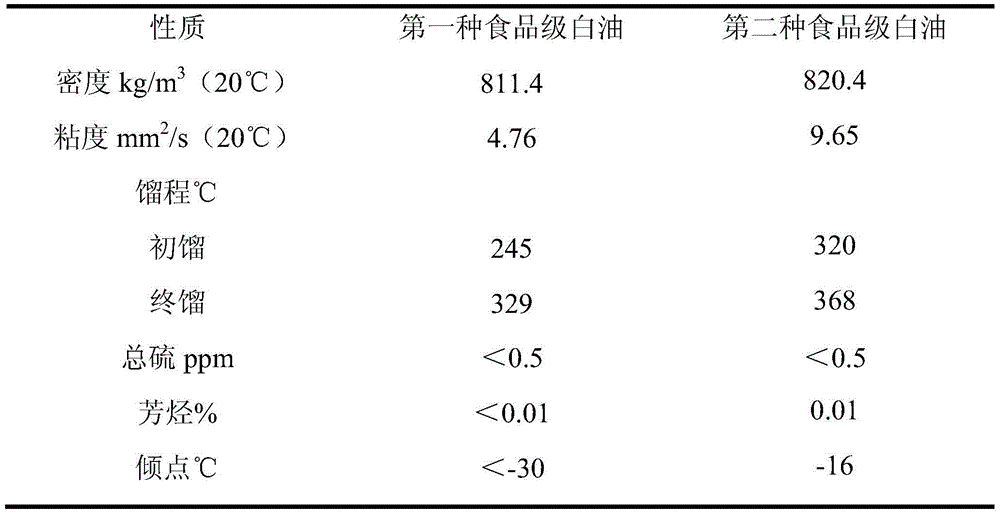

[0024] See Table 1 for the properties of the oil extracted from the raw material at atmospheric and vacuum pressure.

[0025] Table 1 Raw material properties

[0026]

[0027] A method for producing food-grade white oil by extracting oil under normal and reduced pressure, comprising the following steps:

[0028] Step 1. Heat the extracted oil under normal and reduced pressure to 300°C, mix it with hydrogen, introduce it into two series-connected reactors loaded with Catalyst I and Catalyst II respectively, contact with the catalyst, and carry out hydrofining under the action of hydrofining catalyst Reaction, Catalyst I is a W-Mo-Ni catalyst with a pore volume of 0.20-0.50mL·g -1 , the specific surface area is 150~260m 2 g -1 , Catalyst II is a W-Ni catalyst with a pore volume of 0.20-0.50mL·g -1 , the specific surface area is 90~150m 2 g -1 ;

[0029] Step 2, the product after refining is through gas-liquid separation, steam stripping and fractional distillation, rem...

Embodiment 2

[0039] See Table 4 for the properties of the oil extracted from the raw material at atmospheric and vacuum pressure.

[0040] Table 4 Raw material properties

[0041]

[0042] A method for producing food-grade white oil by extracting oil under normal and reduced pressure, comprising the following steps:

[0043] Step 1. Heat the extracted oil under normal and reduced pressure to 350°C, mix it with hydrogen, introduce it into two series-connected reactors loaded with Catalyst I and Catalyst II respectively, contact with the catalyst, and carry out hydrofining under the action of hydrofining catalyst Reaction, Catalyst I is a W-Mo-Ni catalyst with a pore volume of 0.20-0.50mL·g -1 , the specific surface area is 150~260m 2 g -1 , Catalyst II is a W-Ni catalyst with a pore volume of 0.20-0.50mL·g -1 , the specific surface area is 90~150m 2 g -1 ;

[0044] Step 2, the product after refining is through gas-liquid separation, steam stripping and fractional distillation, rem...

Embodiment 3

[0054] See Table 7 for the properties of the oil extracted from the raw material at atmospheric and vacuum pressure.

[0055] Table 7 Raw material properties

[0056]

[0057] A method for producing food-grade white oil by extracting oil under normal and reduced pressure, comprising the following steps:

[0058] Step 1. Heat the extracted oil under normal and reduced pressure to 350°C, mix it with hydrogen, introduce it into two series-connected reactors loaded with Catalyst I and Catalyst II respectively, contact with the catalyst, and carry out hydrofining under the action of hydrofining catalyst Reaction, Catalyst I is a W-Mo-Ni catalyst with a pore volume of 0.20-0.50mL·g -1 , the specific surface area is 150~260m 2 g -1 , Catalyst II is a W-Ni catalyst with a pore volume of 0.20-0.50mL·g -1 , the specific surface area is 90~150m 2 g -1 ;

[0059] Step 2, the product after refining is through gas-liquid separation, steam stripping and fractional distillation, rem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com