Inferior distillate oil combination hydrogenation modified method

A technology for hydrotreating and upgrading distillate oil, applied in hydrotreating process, petroleum industry, gasoline stabilization and other directions, can solve the problems of unfavorable product quality, distillate oil such as diesel oil cannot meet product quality requirements, etc., saving equipment and operation. The effect of low cost and deep modification degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

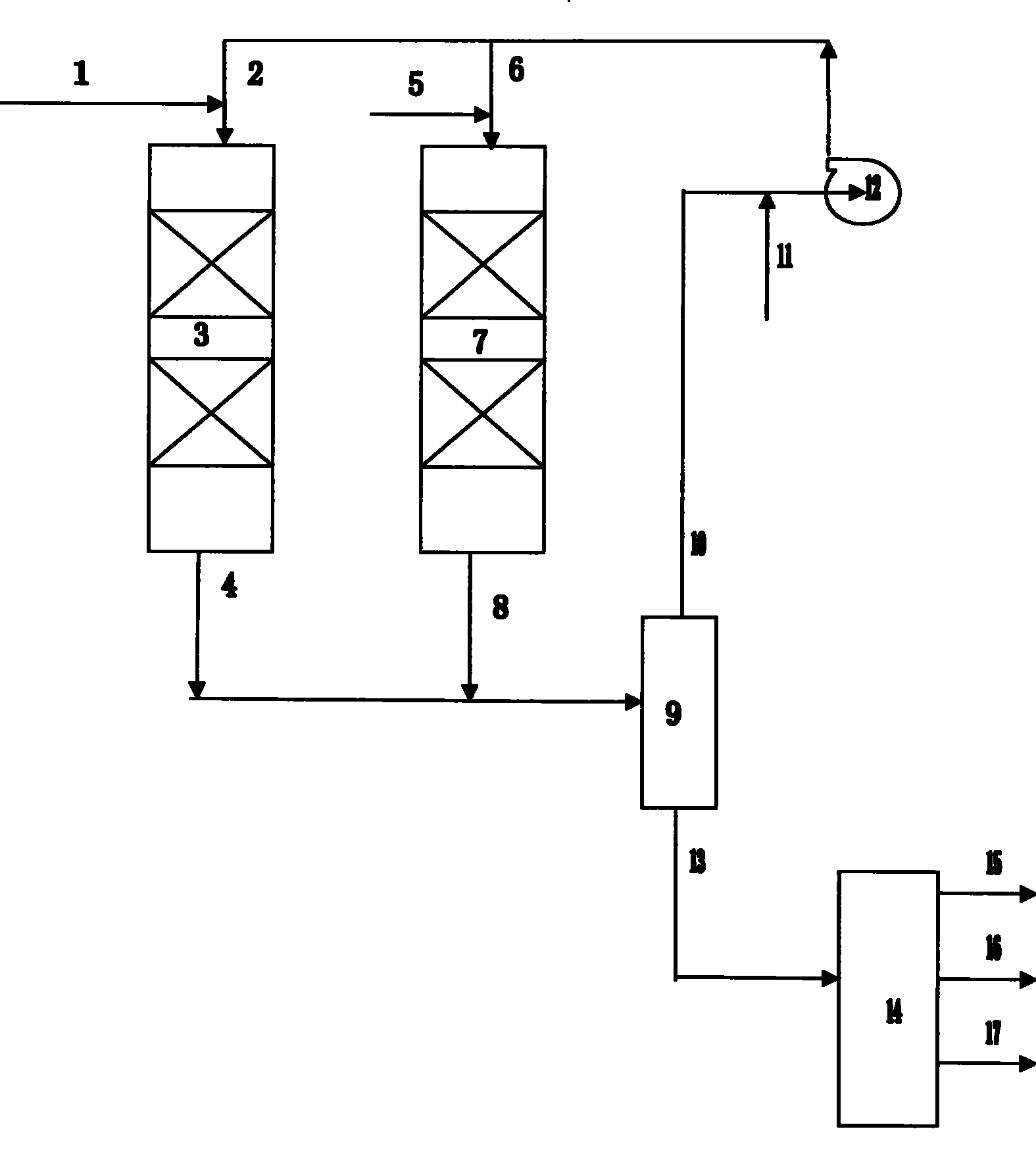

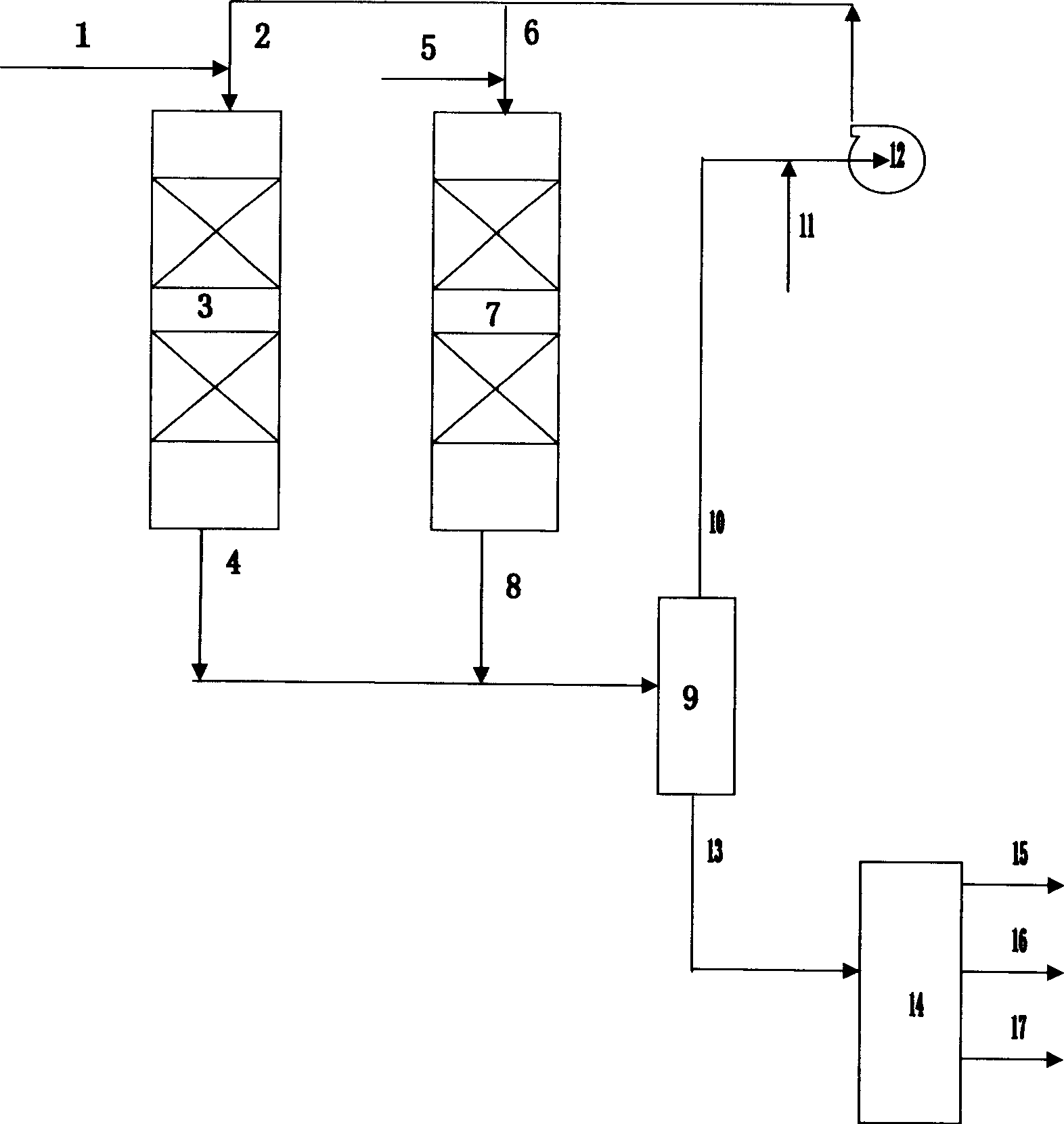

Method used

Image

Examples

preparation example Construction

[0037] According to the preparation process of the HT-A catalyst, according to the component content ratio of the catalyst HT-B in Table 1, add aluminum chloride, nickel chloride, sodium tungstate in the reaction tank, then add 16% ammonia water to form a gel, until The pH value is 9, the gelling temperature is 80°C, aging for 3 hours after gelling, and then filtering, the filter cake is washed twice with 500mL clean water, added clean water and molybdenum trioxide, beaten and stirred evenly, filtered, the filter cake is at 70 Dry at ℃ for 7 hours, then extrude, wash with clean water twice, dry at 100℃ for 8 hours, and calcined at 550℃ for 3 hours to obtain the final catalyst HT-B. The composition and main properties are shown in Table 1.

[0038] Table 1 Composition and main properties of highly active hydrotreating catalysts

[0039] Catalyst number

[0040] The preparation process of the involved hydrogenation upgrading catalyst HC is as follows:

[0041] Take by...

Embodiment 5

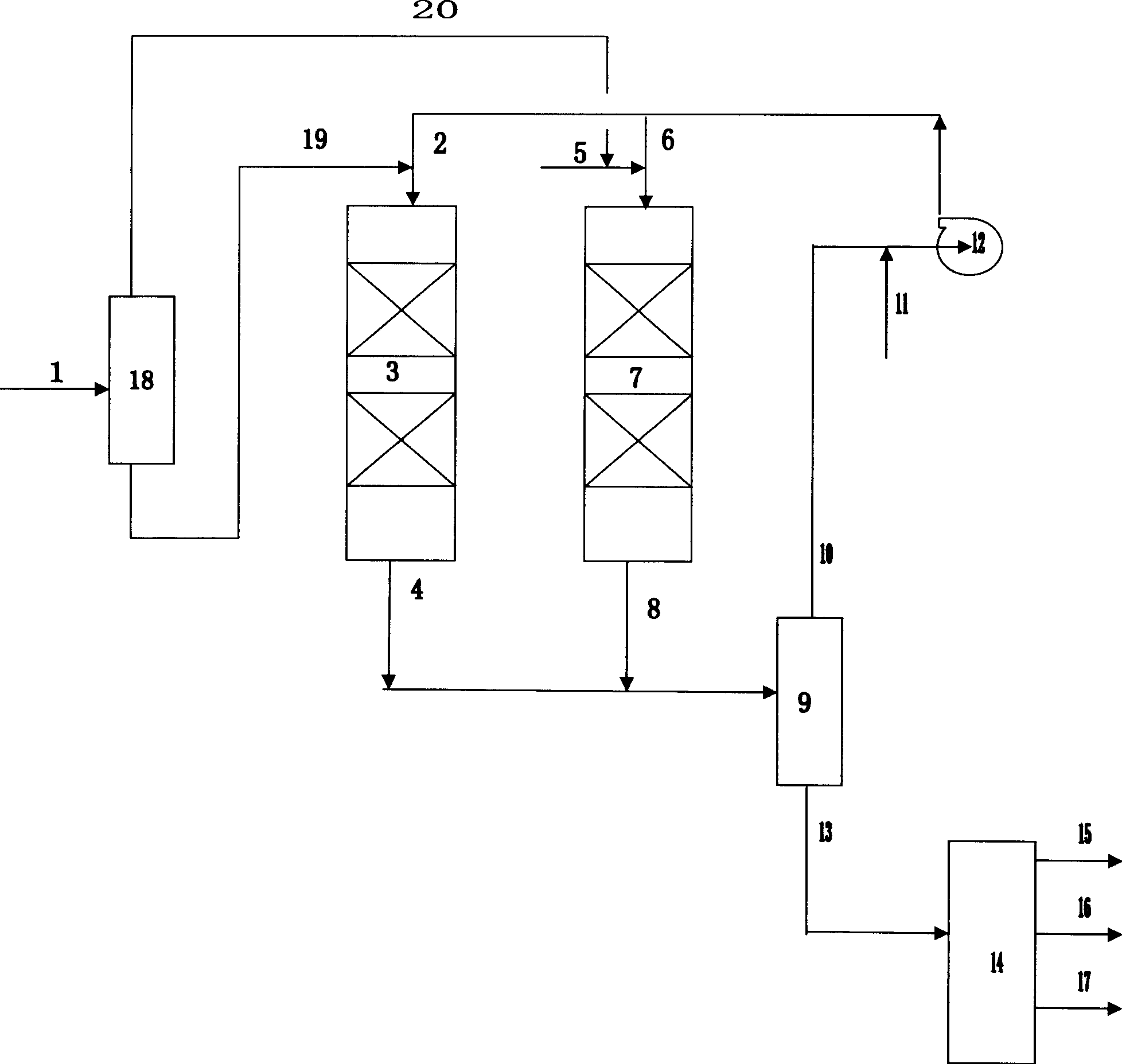

[0047]Example 5 Operate according to the flow chart in Figure 2, referring to the conditions described in Example 3, fractionate the catalytic cracking diesel oil feedstock at 210 ° C into heavy fractions and light fractions, the heavy fractions are hydrogenated and upgraded, and the light fractions are mixed with coking distillates. Hydrofining.

[0048] Table 3 Hydro-upgrading operating conditions and results

[0049] Numbering

[0050] Numbering

[0051] Table 4 Hydrofining operating conditions and results

[0052] Numbering

[0053] Table 5 embodiment gained product properties

[0054] Numbering

[0055] It can be seen from the above examples that the biggest feature of this combined process is that it rationally utilizes the respective characteristics of the hydroupgrading process and the hydrofining process, while maintaining a high yield of diesel fraction, it not only greatly reduces the The content of sulfur, nitrogen and othe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com