On-line pretreatment device for sample gas of ethylene cracking furnace and installing method thereof

A pretreatment device, ethylene cracking furnace technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of continuous and stable operation of online chromatography, pipeline blockage, chromatographic column pollution, etc., to ensure long-term effective operation, Easy to use and maintain, analyze the effect of accurate data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is further described below in conjunction with embodiment. The scope of the present invention is not limited by these Examples.

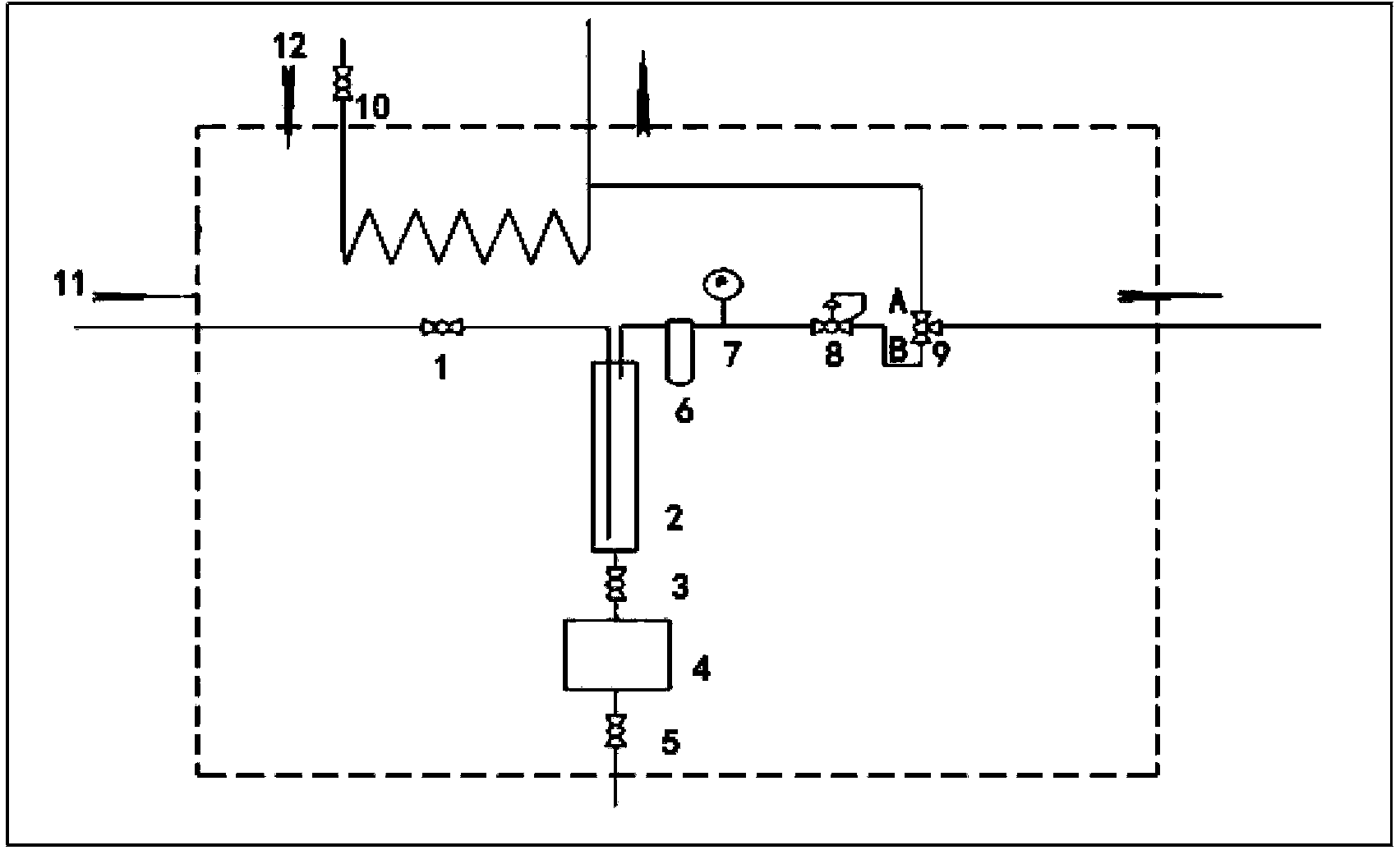

[0024] The schematic diagram of online pretreatment device for sample gas of ethylene cracking furnace of the present invention is shown in figure 1 , the way of use is: confirm that the vortex cooler of the cracking furnace is in the closed state. After the installation of the device is completed, all the on-off valves are in the off state. First, confirm that the three-way switching valve 9 is in the B position and then open the on-off valve 10, and the medium-pressure steam 12 enters the heating pipeline Heat the device, and after 10 minutes of stabilization, open the switch valve 1 and turn on the cracking furnace vortex cooler, the sample gas 11 enters the ethylene cracking furnace sample gas online pretreatment device and passes through the liquid accumulation tank 2, the gas filter 6, and the pressure gauge 7 in s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com