Production method of veterinary vaccine white oil adjuvant

A production method and vaccine technology, applied in hydrocarbon oil treatment products, petroleum industry, hydrocarbon oil treatment, etc., can solve the problems of slow application of domestic white oil, long application time, high cost, etc., and achieve convenient raw material sources and marginal active centers The effect of many bits and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

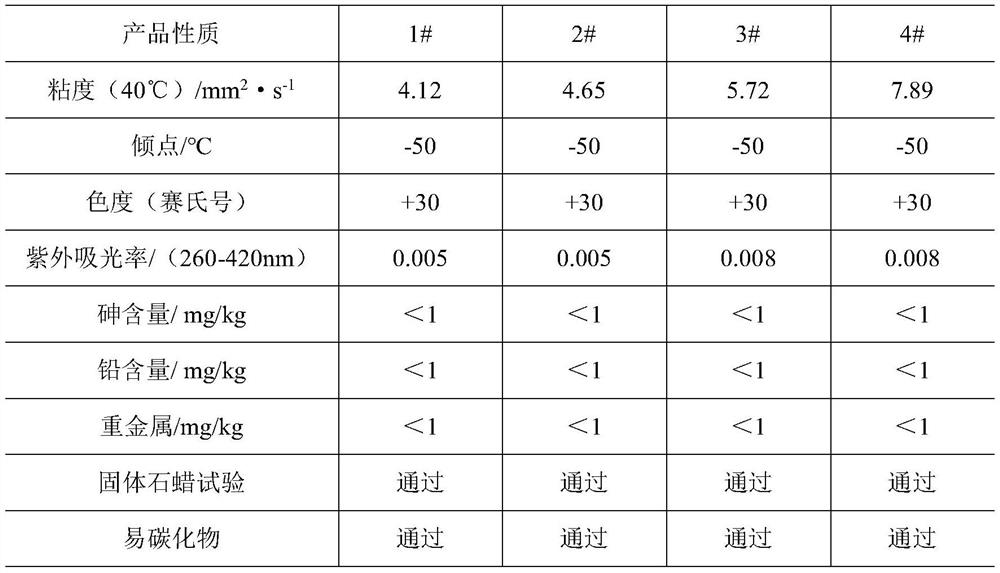

Embodiment 1

[0034] A kind of production method of veterinary vaccine white oil adjuvant, it comprises the following steps:

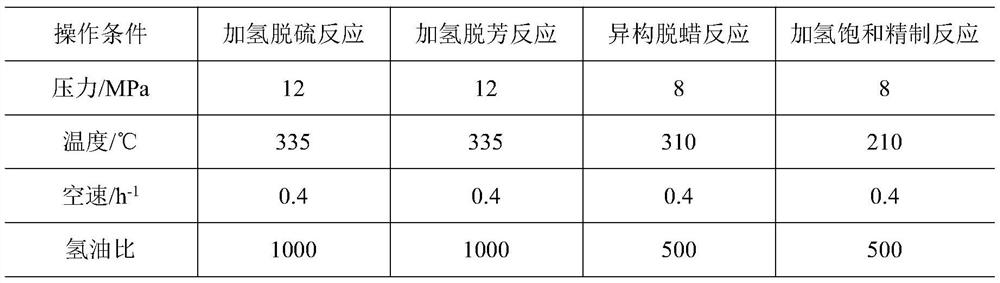

[0035] Step 1. Heat the raw oil to 310°C and mix it with hydrogen, introduce it into the first reactor loaded with hydrodesulfurization catalyst I to contact with the catalyst, carry out hydrodesulfurization and denitrogenation reactions under the action of the catalyst, and then react the product A Enter the second reactor loaded with hydrogenation dearomatization catalyst II to carry out hydrogenation dearomatization and hydrogenation saturation reaction with catalyst II, and remove aromatics and unsaturated hydrocarbons in the raw material. Catalyst I is a W-Mo-Ni hydrodesulfurization catalyst with a specific surface area of 200m 2 / g, the pore diameter is 25nm, the pore volume is 1.0ml / g, the water absorption rate is 120%, the bulk specific gravity is 0.50g / ml, the infrared acid content is 0.5mmol / g, the ratio of B acid / L acid is 1.8; Catalyst II It is a W-Ni...

Embodiment 2

[0058] A kind of production method of veterinary vaccine white oil adjuvant, it comprises the following steps:

[0059] Step 1. Heat the raw oil to 315°C and mix it with hydrogen, introduce it into the reactor loaded with hydrodesulfurization catalyst I to contact with the catalyst, and carry out hydrodesulfurization and denitrogenation reactions under the action of the catalyst, and the reaction product A enters the reactor loaded with hydrodesulfurization catalyst I. In the reactor of catalyst II, hydrogenation dearomatization and hydrogenation saturation reaction are carried out with hydrogenation dearomatization catalyst II to remove aromatics and unsaturated hydrocarbons in raw materials. Catalyst I is a W-Mo-Ni type hydrodesulfurization catalyst with a specific surface area of 180m 2 / g, the pore diameter is 30nm, the pore volume is 0.8ml / g, the water absorption rate is 130%, the bulk specific gravity is 0.60g / ml, the infrared acid content is 0.7mmol / g, the ratio of B ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Bulk specific gravity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com