Preheating flow of high-temperature oil slurry pump

A high-temperature oil and pump technology, applied in mechanical equipment, pipeline heating/cooling, pipes/pipe joints/pipe fittings, etc., can solve problems such as wear, easy spontaneous combustion, valve erosion, etc., to achieve simple preheating process and eliminate wear Hazardous, operationally reliable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

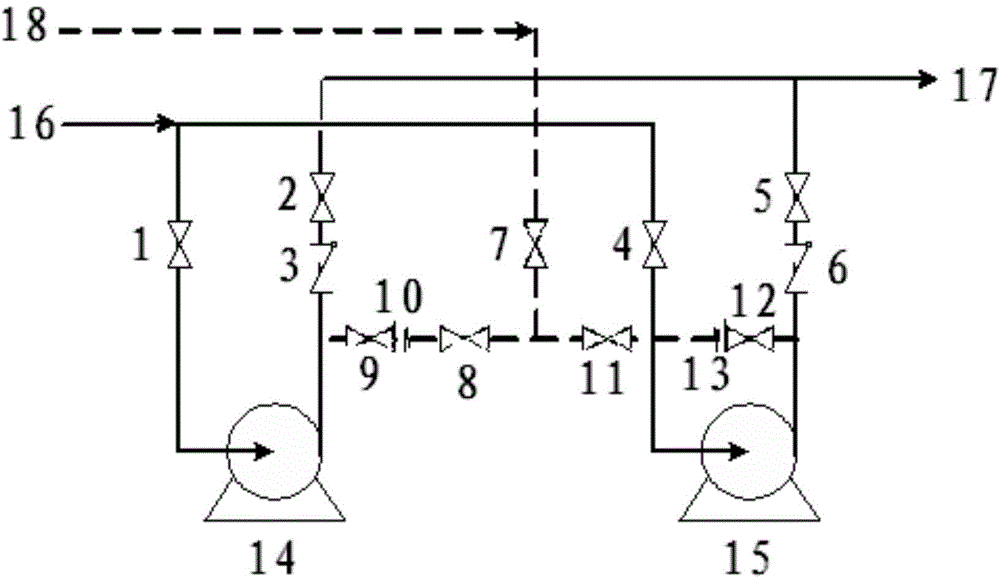

[0015] Such as figure 1 As shown, the re-refined oil at a temperature of 300°C is introduced from the preheating pipeline 18. After the main preheating valve 7, it can pass through the gate valve 8, the flow limiting orifice 10, the root cut-off valve 9 and the preheating pump 14, or pass through the gate valve 11, limiting Flow orifice 13, root cut-off valve 12 preheating pump 15; preheating main valve 7 can also be closed to communicate with gate valve 8, flow-limiting orifice 10, root cut-off valve 9 and gate valve 11, flow-limiting orifice 13, root cut-off valve 12 , realize the mutual preheating of the pump 14 and the pump 15. The medium velocity of the flow-limiting orifice 13 is about 5 m / s.

[0016] In case of an abnormal situation, the preheating line can be partially isolated by closing the main preheating valve 7, the root cut-off valve 9 and the root cut-off valve 12.

[0017] If it is found that the preheating line is not blocked smoothly, the medium reverse flo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com