A cable wrapping intermediate joint and a manufacturing process thereof

A technology for intermediate joints and cables, applied in cable joints, equipment for connecting/terminating cables, etc., can solve problems such as affecting the high-voltage shielding contact of the cable conductor core, thermal breakdown at the high-voltage shielding electrode, affecting the safety and stability of the cable, etc. , to achieve the effect of long-term safe operation, not easy to breakdown, and high waterproof sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0091] The utility model relates to a cable wrapping intermediate joint, which is used for the butt joint of two sections of cables.

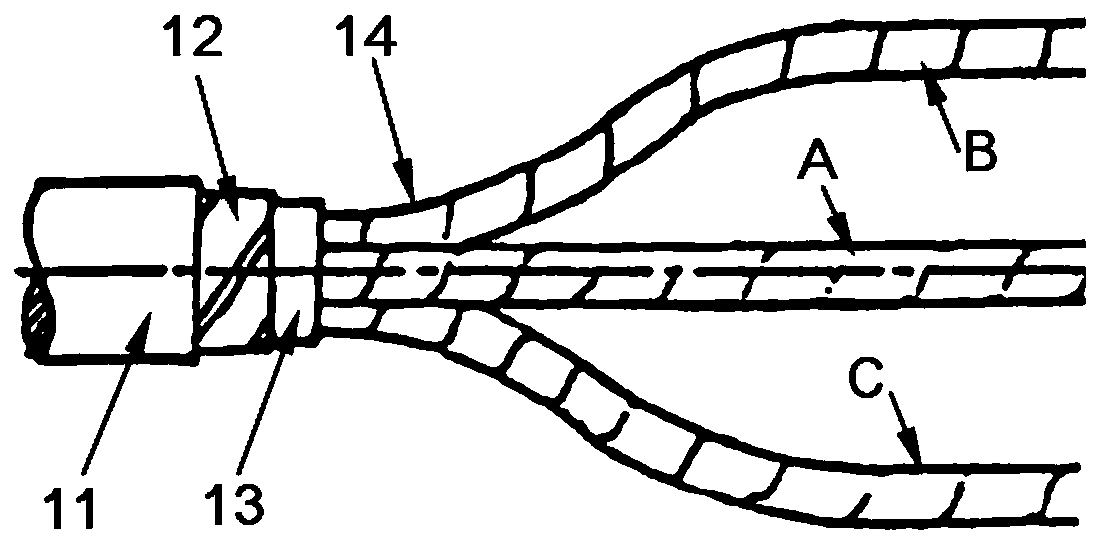

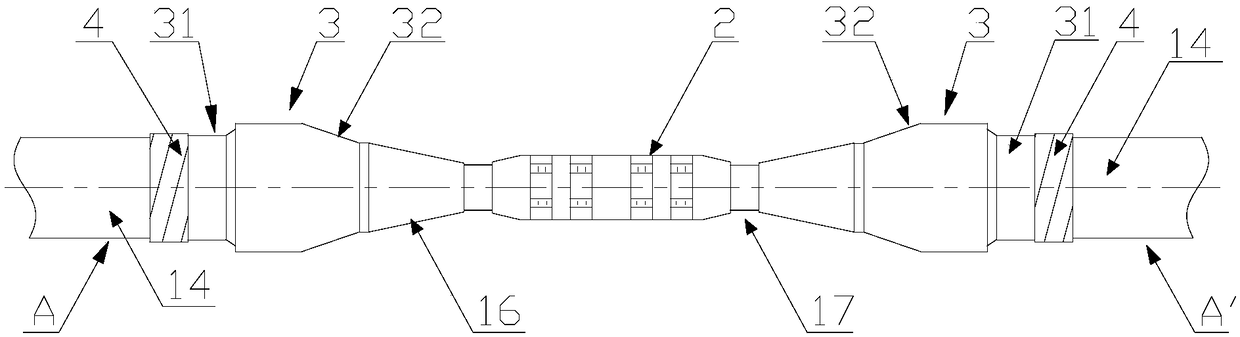

[0092] Such as figure 1 Schematic diagram of the three-core cable structure in the prior art, figure 2 The connection diagram of two same-phase single-phase cables is as follows:

[0093] The three-core cable in the prior art includes a sheath 11, armor 12, liner 13 from the outside to the inside, and the liner 13 includes three strands of single-phase cables, such as figure 1 Three strands of single-phase cables A, B, and C shown in ; each single-phase cable includes a metal shielding layer 14, an insulating shielding layer 15, a main insulating layer 16, an inner shielding layer (not shown in the figure) and a conductor from outside to inside Core 17.

[0094] Wrapped intermediate joints include joint wraps connecting the same-phase single-phase cables, and protective wraps outside the same-phase single-phase cable joint wraps.

[0095] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com