Preparation method for amination polyphenyl ether

A technology of polyphenylene ether and amination, applied in the direction of plastic/resin/wax insulators, organic insulators, etc., can solve the problems of increasing industrialization and environmental protection, achieve excellent mechanical properties, excellent heat resistance and electrical properties, and improve electrical properties. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

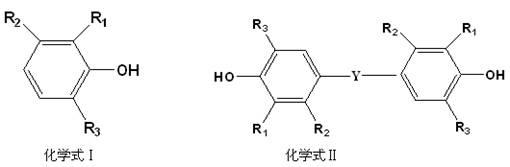

Method used

Image

Examples

Embodiment 1

[0054] In a reactor equipped with a reflux condenser, stirring, and a thermocouple, 1.35 g (0.0061 mol) of copper bromide, 6.34 g (0.0491 mol) of dibutylamine, and 1180 g of methanol were added successively, and complexed at room temperature for 10 min. Add 116g (0.409mol) 3,3,5,5-tetramethylbisphenol A and 200g (1.637mol) 2,6-dimethylphenol, (the molar ratio of the two monomers is 1:4,) to maintain the temperature At 25°C, under the condition of vigorous stirring, air was introduced at a speed of 1.637 NL / min, and the reaction was carried out for 2 hours. Terminate the reaction with 1 mL of acetic acid with a concentration of 1 mol / L, filter, then wash with deionized water, methanol, and dry to obtain 230 g of white powder, which is PPO-2OH, with a yield of 73%. Mn=1507g / mol, Mw=2828g / mol, D=1.87 measured by GPC (gel permeation chromatography).

Embodiment 2

[0056] In a reactor equipped with a reflux condenser, stirring, and a thermocouple, 2.024g (0.009mol) of copper bromide, 4.43g (0.09822mol) of dimethylamine, and 3681g of ethanol were added successively, and complexed at room temperature for 10min. Add 209.4g (0.818mol) 3,3,5,5-tetramethylbisphenol F and 200g (1.637mol) 2,6-dimethylphenol, (the molar ratio of the two monomers is 1:2,) keep The temperature was 60°C, under the condition of vigorous stirring, air was introduced at a speed of 0.2 NL / min, and the reaction was carried out for 2.5 hours. Terminate the reaction with 1 mL of oxalic acid with a concentration of 1 mol / L, filter, then wash with deionized water, methanol, and dry to obtain 227.6 g of white powder, which is PPO-2OH, with a yield of 55.5%. Mn=1031 g / mol, Mw=1912 g / mol, D=1.85 were measured by GPC.

Embodiment 3

[0058] In a reactor equipped with a reflux condenser, stirring and thermocouple, add 0.5485g (0.0025mol) of copper bromide, 1.8g (0.0246mol) of diethylamine, 782g of 40% methanol and 60% ethanol in sequence mixed solvent, complexed at room temperature for 10min, added 34.8g (0.1227mol) 3,3,5,5-tetramethylbisphenol A and 300g (2.456mol) 2,6-dimethylphenol, (two mono The volume molar ratio is 1:20,) keeping the temperature at 10°C, under the condition of vigorous stirring, the air was passed in at a speed of 0.082NL / min, and the reaction was carried out for 10h. Terminate the reaction with 1 mL of hydrochloric acid with a concentration of 1 mol / L, filter, wash with deionized water, methanol, and dry to obtain 286 g of white powder, which is PPO-2OH, with a yield of 85.4%. Mn=2631 g / mol, Mw=5098 g / mol, D=1.94 were measured by GPC.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com