Flexographic printing equipment with high fitting degree and printing method

A technology of fit and flexo printing, applied in printing, printing machines, printing processes, etc., can solve the problems that the ink cannot be completely pressed on the surface of the material, the low fit of the embossing cylinder, and the influence of ink transfer, etc., to meet the long-term requirements The effect of time running work, improvement of printing quality, and improvement of utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

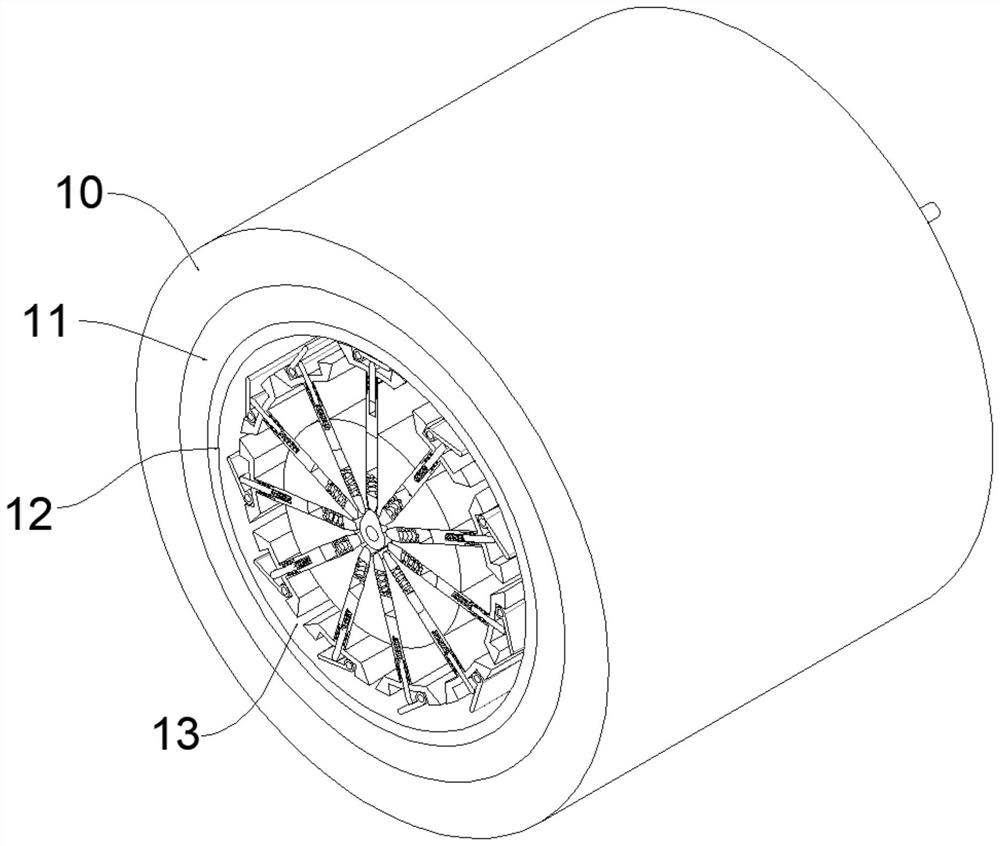

[0022] see Figure 4 and Figure 5 , the impact part includes a pneumatic sliding plate 40, an impacting plate 41 and a drive assembly, the pneumatic sliding plate 40 is fixedly connected with the impacting plate 41, and the end of the pneumatic sliding plate 40 away from the impacting plate 41 is inserted into the roller core 14 and is slidably connected with the roller core 14, The end face of the impact plate 41 away from the pneumatic sliding plate 40 is a curved surface; the pneumatic sliding plate 40 slides in the roller core 14 to generate the air pressure cavity 32, and the driving component is arranged at the connection between the axis of the roller core 14 and the air pressure cavity 32, and the driving component generates The pneumatic pressure drives the pneumatic sliding plate 40 to move away from the axis of the roller core 14 .

[0023] see Figure 4 , the drive assembly includes a fixed cam 22, a sealing sliding block 30, a fixed baffle 31, an elastic spring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com