Method for producing high quality light white oil from base oil

A base oil, high-quality technology, applied in hydrocarbon oil treatment products, petroleum industry, hydrocarbon oil treatment, etc., can solve environmental pollution, restricted development, low white oil yield and other problems, achieve significant economic benefits, wide application range, The effect of large pore volume and specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

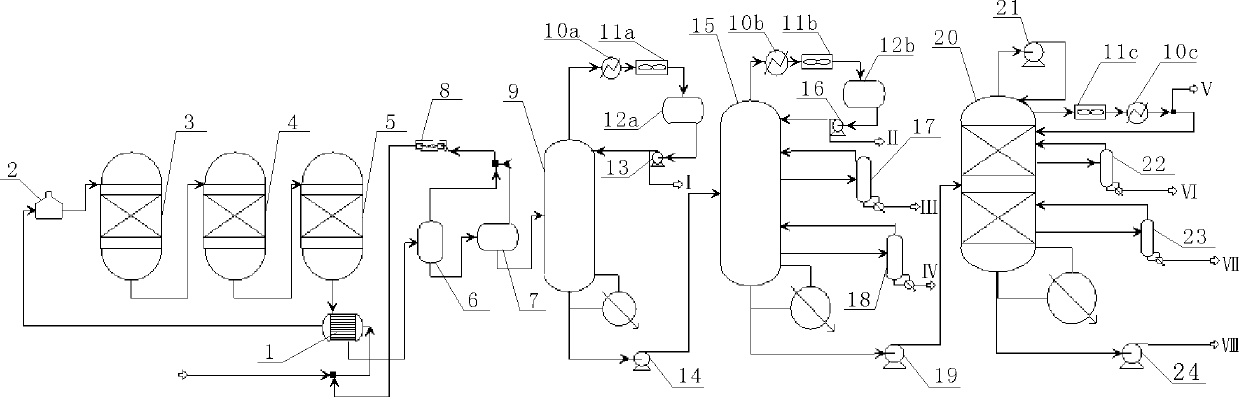

Method used

Image

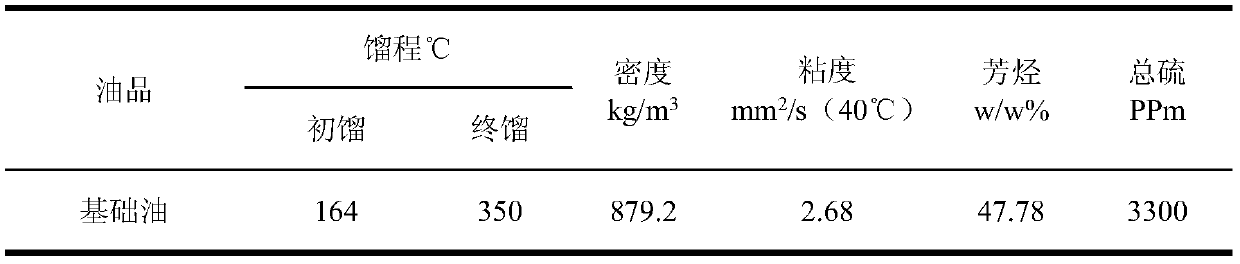

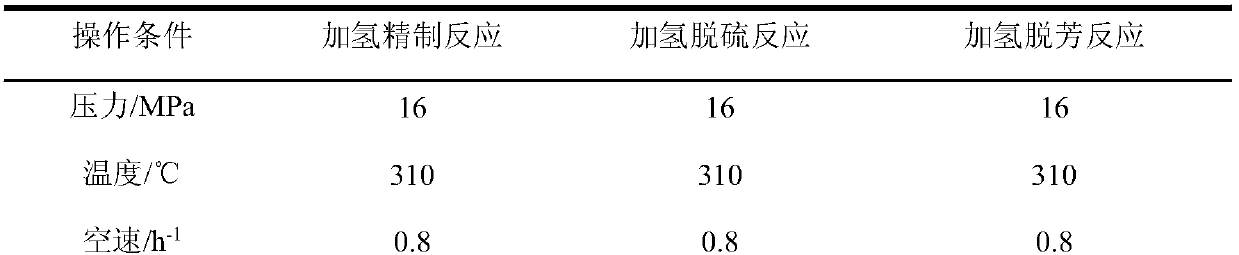

Examples

preparation example Construction

[0039] One, the preparation steps of catalyst carrier are:

[0040] 1. Raw materials are pre-mixed, and pseudo-boehmite, solid aluminum sol, and activated α-alumina powder are mixed according to the net weight ratio of 70-90:30-5:0-10, and 1-20% of the weight of the bond is added Put the agent and 1%~30% pore expander into the mixer, dry mix for 10~60 minutes, take out the powder and pass it through the 20~60 mesh screen to remove the coarse particles;

[0041] 2. Preparation of mud-making solution: based on the total weight of the powder in step 1, weigh 0.5-10% of phosphoric acid and acetic acid by weight and dissolve them in deionized water with 60-150% of the total weight of the powder;

[0042] 3. Put the powder into the mud-making machine, add the mud-making solution obtained in step 2, and seal the mixture for 5 to 30 minutes to make the powder into mud;

[0043] 4. Send the mud material obtained in step 3 into the mud refining machine, and train the mud material into ...

Embodiment 1

[0052] a. Put 5.9kg of pseudo-boehmite, 3.6kg of solid alumina sol, 0.5kg of activated α-alumina powder, 0.2kg of safflower gum, and 2kg of starch into the conical mixer, take it out and put it into the mixer after 15 minutes of mixing inside the clay machine;

[0053] b. Then dissolve 0.5kg of citric acid monohydrate, 0.32kg of phosphoric acid, and 0.2kg of acetic acid in 8.8kg of deionized water, and finally add the aqueous solution into the mud making machine by spraying, and make mud for 8 minutes. After the mud becomes a block take out;

[0054] c. Load metal on the catalyst carrier obtained in step b: Dissolve 40 grams of metal salts ammonium metatungstate, ammonium heptamolybdate, cobalt nitrate hexahydrate, nickel nitrate hexahydrate and phosphoric acid in 105 grams of water, without precipitation and with After a long period of stability, the catalyst carrier is fully impregnated in the metal solution and then dried and roasted. The conditions for drying and roasting...

Embodiment 2

[0058] a. Put 6.7kg of pseudo-boehmite, 2.8kg of solid aluminum sol, 0.5kg of active α-alumina powder, 0.2kg of safflower gum, and 2kg of starch into the conical mixer, take it out and put it into the conical mixer after 15 minutes of mixing inside the clay machine;

[0059] b. Then dissolve 0.5kg of citric acid monohydrate, 0.5kg of phosphoric acid, and 0.35kg of acetic acid in 8.8kg of deionized water, and finally add the aqueous solution into the mud making machine by spraying, and make mud for 8 minutes. After the mud becomes a block take out;

[0060] c. Load metal on the carrier obtained in step b: Dissolve 40 grams of metal salt and phosphoric acid in 105 grams of water. After no precipitation and long-term stability, the carrier is fully immersed in the metal solution and then dried and The conditions of roasting, drying and roasting are as follows: drying in an oven at 55°C for 13 hours, and roasting in an oxidizing atmosphere at a temperature of 750°C for 7 hours; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com