Efficient operation PCS long-term cooling water tank

A high-efficiency operation and cooling water tank technology, applied in the direction of cooling devices, greenhouse gas reduction, climate sustainability, etc., can solve the problems of unfavorable system circulation flow and increased air flow resistance, so as to improve heat exchange efficiency and increase heat exchange Effect of heat and reduction of volatilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

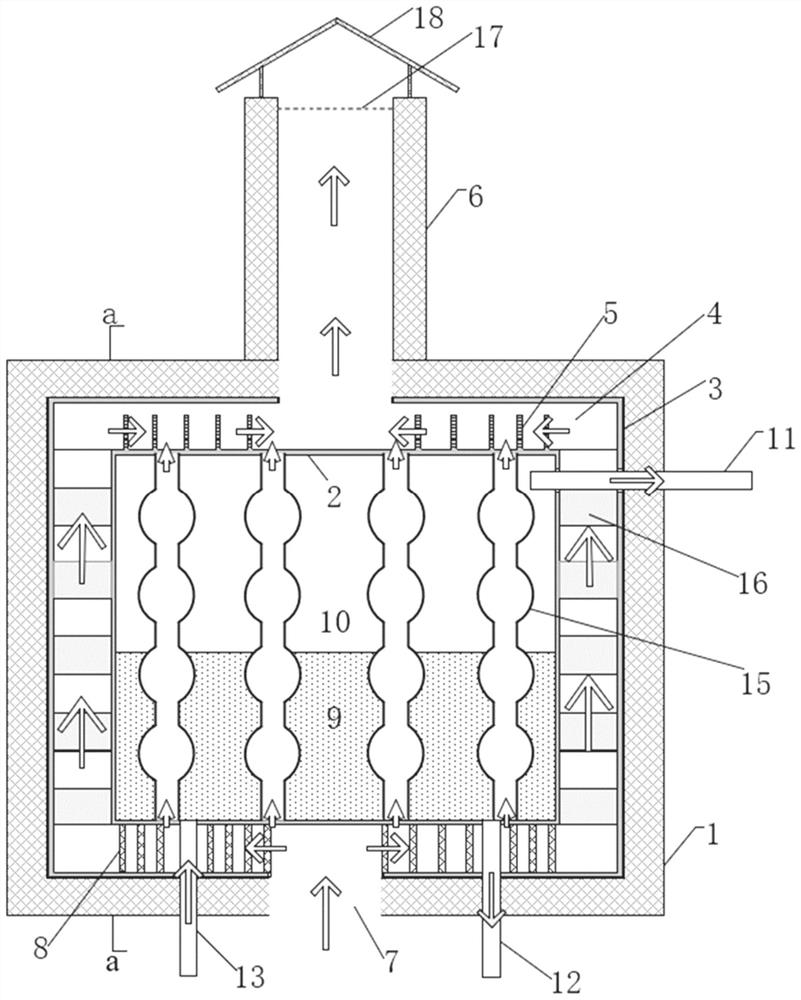

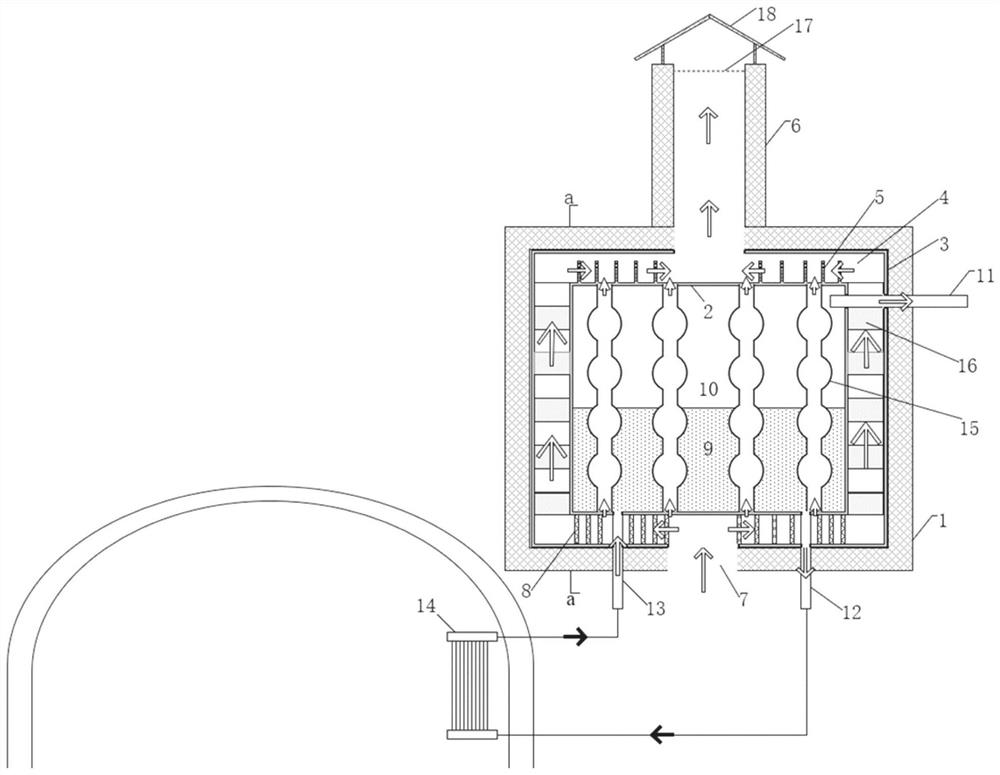

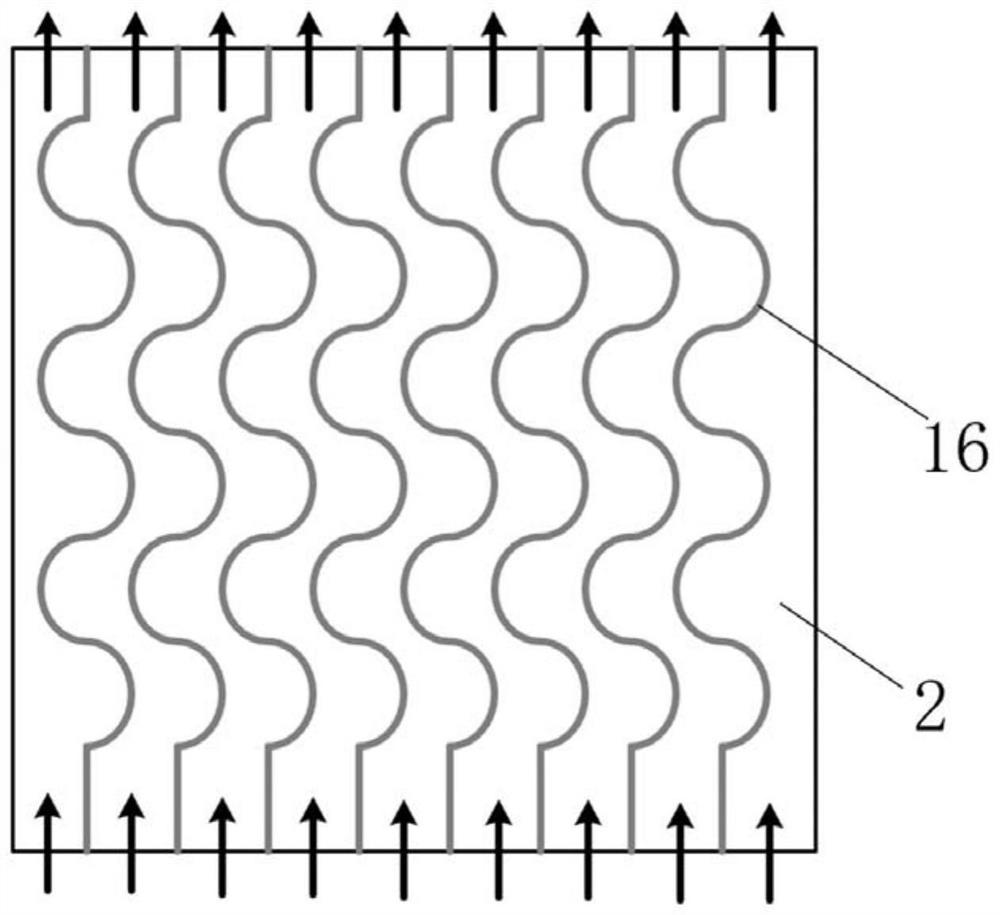

[0023] combine Figure 1 to Figure 7 , a PCS long-term water exchange tank based on the natural circulation of air in the parallel flow channel and the principle of enhanced heat transfer of the present invention, including a reinforced concrete shell, a steel water tank body, the distance between the body and the shell, and an S-shaped vertical folding plate Parallel air channels formed by splitting, enhanced heat exchange tubes running through the water tank. Specifically, the main structure includes a reinforced concrete shell, a steel water tank body, a parallel air passage between the water tank body and the concrete shell, an S-shaped vertical flap installed on the outer surface of the water tank body, and a large-diameter wave node running through the inside of the water tank. The internal air space of the water tank communica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com